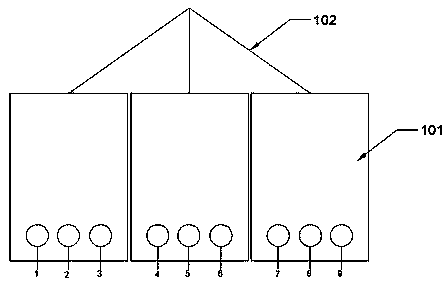

Reduction and volatilization smelting method of a composite fuel fuming furnace

A fuming furnace and composite technology, applied in the field of reduction and volatilization smelting of composite fuel fuming furnace, can solve the problems of difficulty in fine control of coal supply, impact on the safety of the dust collection system, and unstable smelting process, etc., and achieve long-term cleanliness Periodic continuous production operation, prevention of difficulty in slag release, full effect of smelting process and molten pool reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

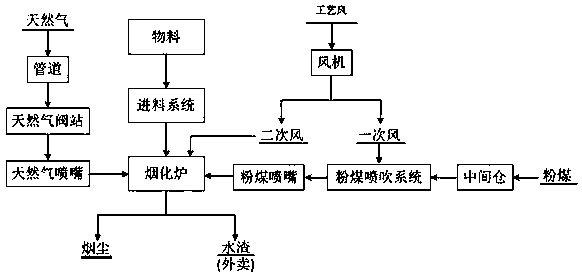

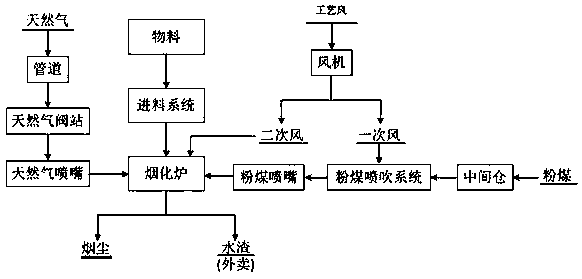

Embodiment 1

[0025] The smelting material zinc wet leaching slag is added into the sooting furnace according to the standard of 25t / h, and at the same time, pulverized coal, natural gas and secondary air are introduced into the sooting furnace for smelting. The pulverized coal is in Clyde powder The coal injection system is mixed with the primary air, the air pressure of the primary air is 60kPa, and the flow rate is 11500Nm 3 / h, and then sprayed into the smoker through the pulverized coal nozzle; the natural gas is sprayed into the smoker through the natural gas nozzle, the pressure of the natural gas is 0.4 MPa, and the natural gas nozzle and the pulverized coal nozzle in the smoker The secondary air pressure is 60kPa. The smelting process includes three stages: feeding, fuming and volatilization, and slag discharge. The operation mode of intermittent feeding and discharging slag is adopted. During the smelting process, the temperature of the molten pool is controlled at 1050~1250°C, enric...

Embodiment 2

[0032] The smelting material zinc wet leaching slag is added into the sooting furnace according to the standard of 22t / h. At the same time, pulverized coal, natural gas and secondary air are passed into the sooting furnace for smelting. The pulverized coal is in Clyde powder The coal injection system is mixed with the primary air, the air pressure of the primary air is 50kPa, and the flow rate is 6500Nm 3 / h, and then sprayed into the sooting furnace through the pulverized coal nozzle; the natural gas is sprayed into the sooting furnace through the natural gas nozzle, the pressure of the natural gas is 0.2 MPa, and the natural gas nozzle and the pulverized coal nozzle in the sooting furnace are arranged at intervals, two The secondary air pressure is 30kPa, and the smelting process includes three stages: feeding, fume and volatilization, and slag discharge. The operation mode of intermittent feeding and discharging slag is adopted. During the smelting process, the temperature of ...

Embodiment 3

[0039] The hot slag of the smelting material reduction furnace is added into the sooting furnace at a rate of 38t / h, and at the same time, pulverized coal, natural gas and secondary air are passed into the sooting furnace for smelting. The pulverized coal is injected into the Clyde pulverized coal The system is mixed with the primary air, the pressure of the primary air is 55kPa, and the flow is 9500Nm 3 / h, and then sprayed into the sooting furnace through the pulverized coal nozzle; the natural gas is sprayed into the sooting furnace through the natural gas nozzle, the pressure of the natural gas is 0.3MPa, and the natural gas nozzle and the pulverized coal nozzle in the sooting furnace are arranged at intervals, two The secondary air pressure is 40kPa. The smelting process includes three stages: feeding, fuming and volatilization, and slag discharge. The operation mode of intermittent feeding and discharging slag is adopted. During the smelting process, the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com