Patents

Literature

41results about How to "Fully smelted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

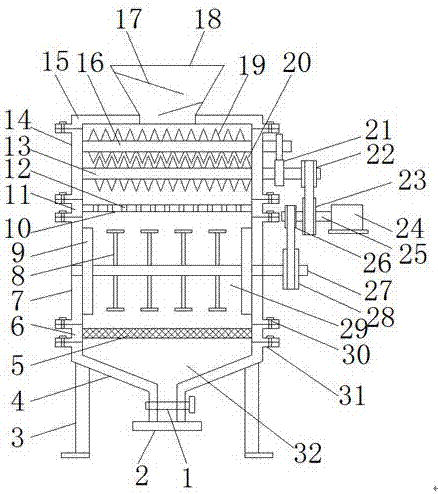

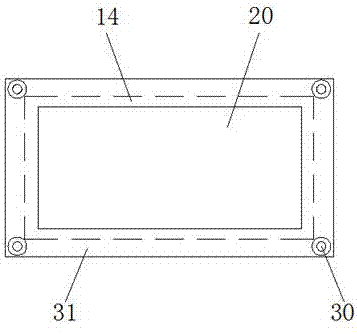

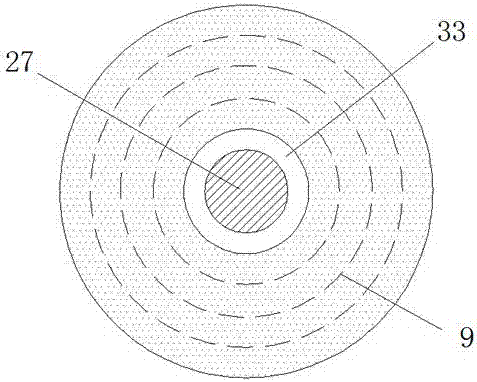

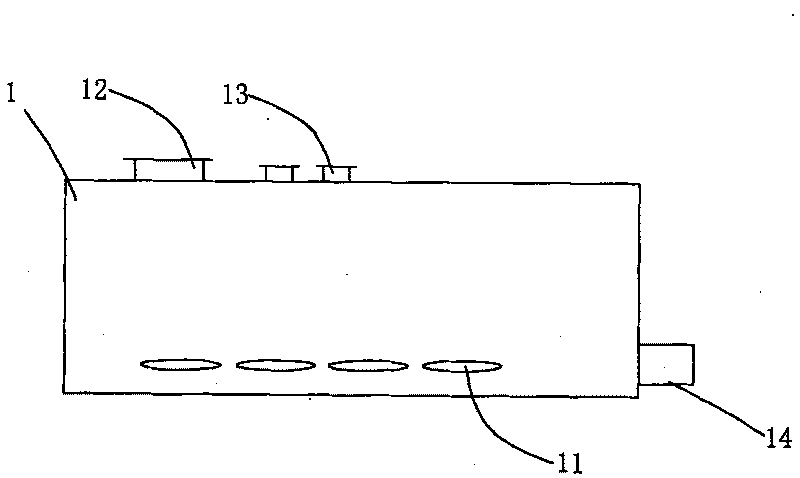

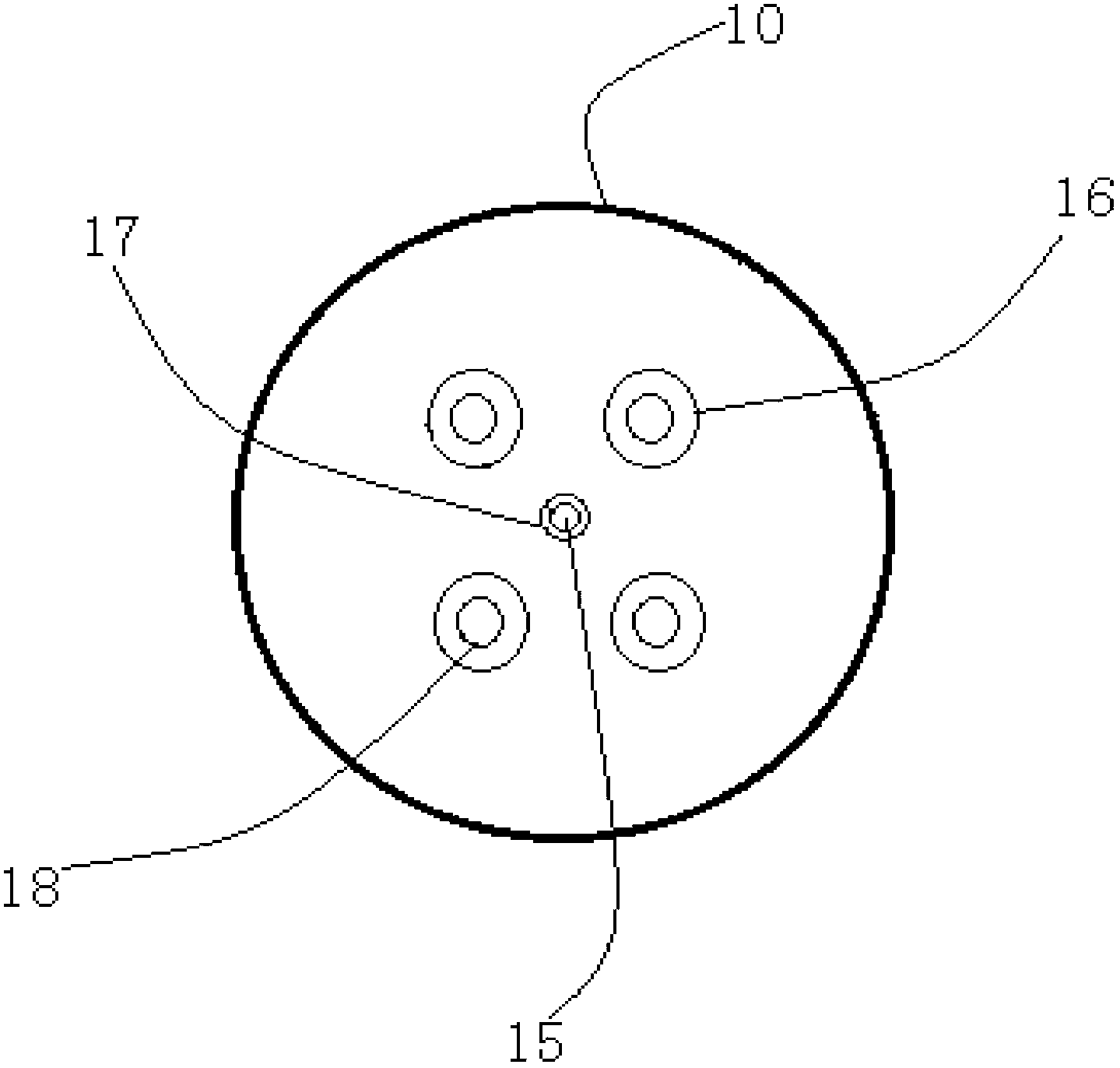

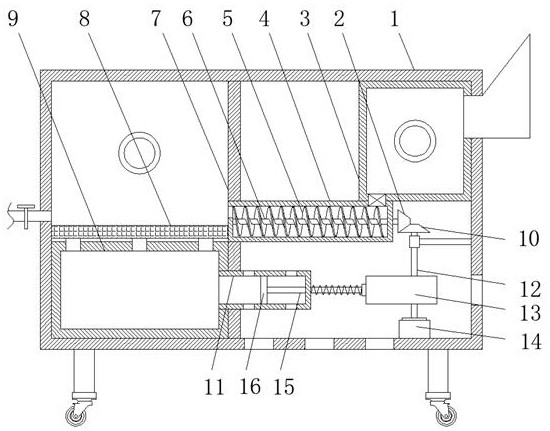

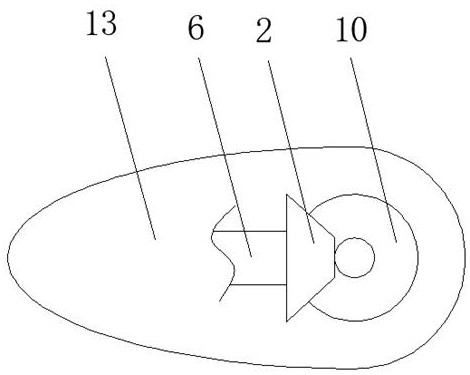

Chemical fiber raw material grinding and melting device

ActiveCN106914306ACompact structureEasy to assemble and disassembleFilament forming substance formingTransportation and packagingFiberEngineering

The invention discloses a chemical fiber raw material grinding and melting device. The device comprises a feed liquor collecting box, a stirring box, a grinding box, and a feed hopper. A discharge pipe is welded on the bottom of the feed liquor collecting box. The upper end of the feed liquor collecting box is connected to a melt filtering box. A filter screen is arranged in the melt filtering box. The upper end of the melt filtering box is connected to the stirring box. A melting and stirring chamber is arranged in the stirring box. A heating disc is arranged on the internal wall of the stirring box. The heating disc is in an annular disc shape. A shaft hole is arranged in the middle of the heating disc. A stirring shaft is arranged in the shaft hole. Multiple stirring rods are vertically welded on the stirring shaft. The provided chemical fiber raw material grinding and melting device has the advantages that the structure is compact, the assembly and disassembly are convenient, the raw materials can be easily added, the grinding is convenient and fast, the screening effect is good, the heating is carried out during stirring process, the raw material melting efficiency is improved, the melt is filtered so as to improve the quality of chemical fiber products, and the raw materials can be fully melted.

Owner:温岭市旗亮鞋业有限公司

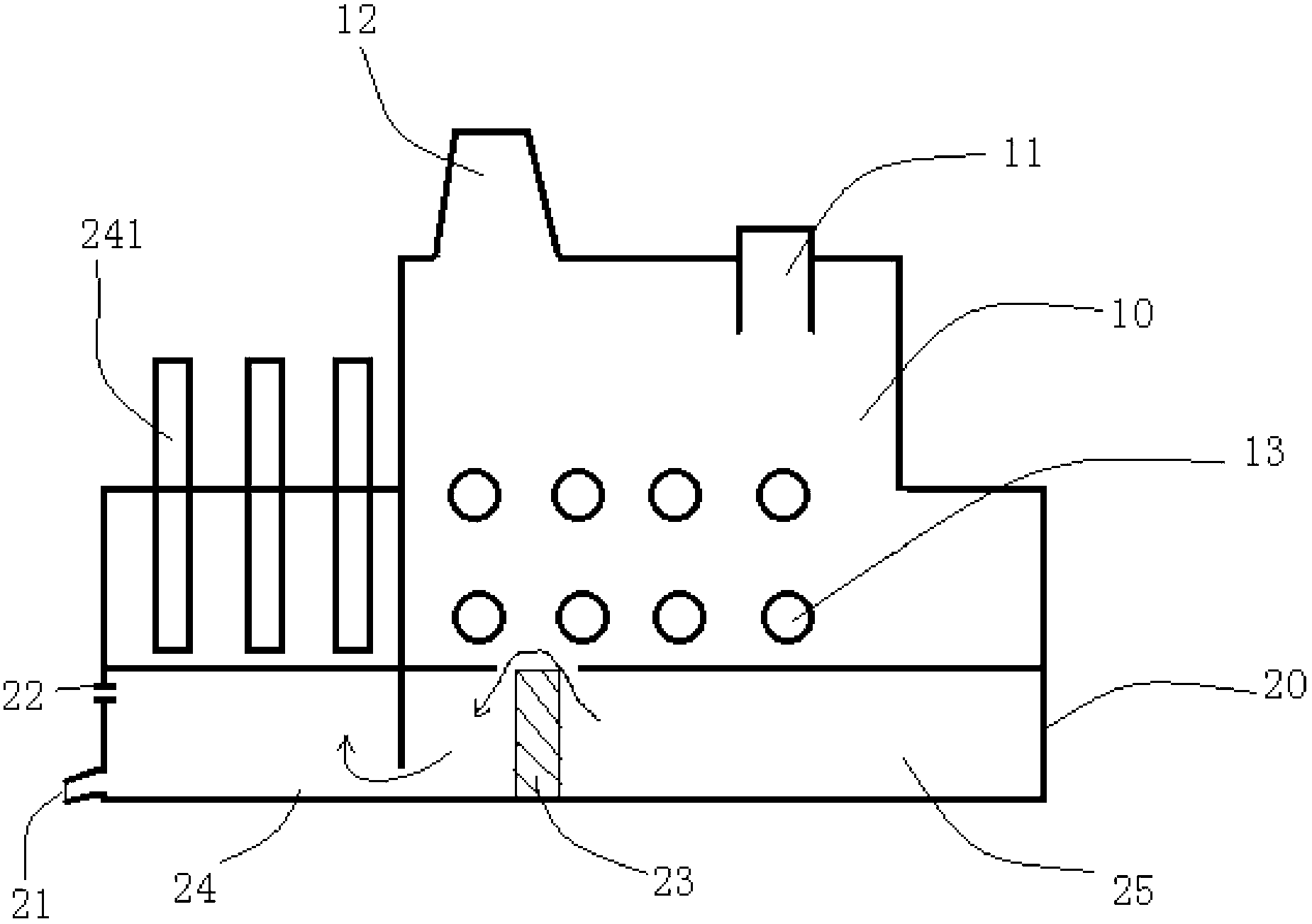

Non-ferrous metal smelting furnace

InactiveCN107764063AImprove smelting effectImprove efficiencyRemovable covers for furnacesCharge manipulationDrive shaftNon-ferrous extractive metallurgy

The invention discloses a non-ferrous metal smelting furnace, which comprises a furnace body, a feeding port, a smelting chamber and a bracket. At the lower end of the furnace body, an exhaust fan is arranged on one side of the furnace body, an exhaust pipe is connected to the upper end of the exhaust fan, and the exhaust fan is connected to the smelting chamber through the exhaust pipe, and a motor is installed on the other side of the furnace body. , one end of the motor is connected with a transmission shaft. In the present invention, an exhaust fan is arranged on one side of the furnace body to extract dust and toxic and harmful gases, thereby improving the smelting effect of non-ferrous metals. By setting a crushing shaft under the feeding port, the volume of the solid metal is more uniform after crushing. It is convenient for smelting operation. By setting a mesh screen at the lower end of the crushing shaft and connecting a vibrating spring at the lower end of the mesh screen, the mesh screen can be used to select different standards of screening, so that the non-ferrous metal smelting is more sufficient.

Owner:WUXI SANZHONG MOLD CO LTD

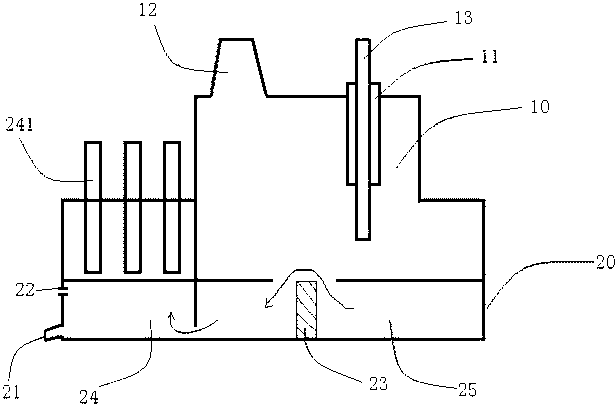

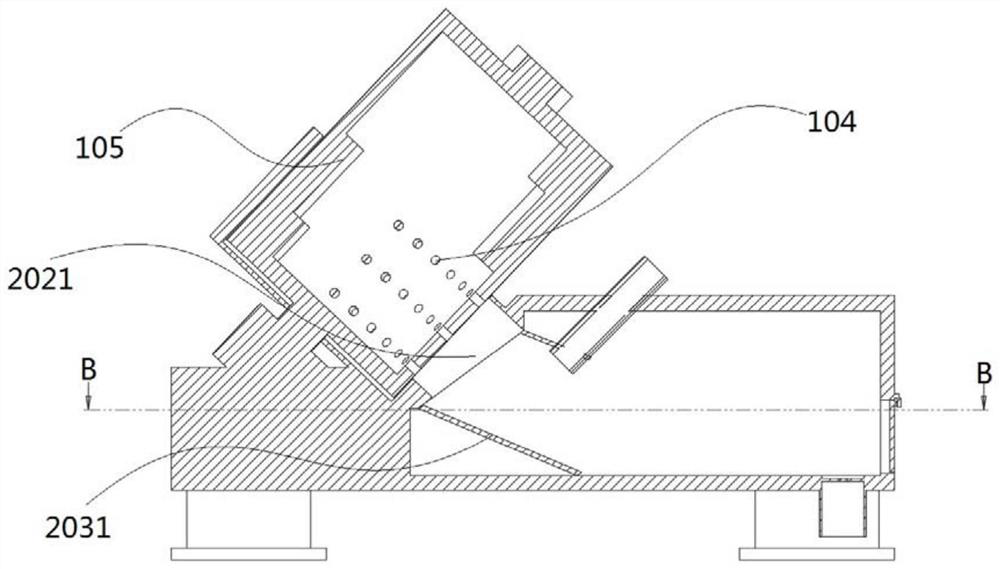

Side-blown smelting equipment

InactiveCN102703732AWell mixedImprove reaction efficiencyLighting and heating apparatusPulp and paper industryEnergy consumption

The invention discloses side-blown smelting equipment, which includes a furnace body and a base, wherein a material inlet and an air outlet are arranged at the top of the furnace body; the base is mounted at the bottom end of the furnace body; a waste residue outlet and a product outlet are arranged on the base; a vent hole for ventilating the interior of the furnace body is arranged at the side part of the furnace body; and the base accommodates the material to be reacted and discharges the reaction product and waste residue. According to the side-blown smelting equipment of the invention embodiment, by adopting the vent hole at the side part of the furnace body for ventilating the interior of the furnace body, the material entering the material inlet can be sufficiently blended and mixed, thereby saving the process of otherwise blending, improving the reaction efficiency of the smelting reaction, and reducing the energy consumption.

Owner:CHINA ENFI ENGINEERING CORPORATION

Bath smelting method for waste

ActiveCN107363072AImprove pyrolysis combustion effectFully smeltedSolid waste disposalTransportation and packagingMelting tankLiquid waste

The invention provides a bath smelting method for waste. The bath smelting method comprises the steps that solid-liquid separation is conducted on the waste, and a solid waste part and a liquid waste part are obtained; the solid waste part is smelted in a bath smelting device, and a metal phase and smelting slag are obtained; the liquid waste part is atomized, the atomized liquid waste part is subjected to pyrolysis and combustion in the bath smelting device, then pyrolysis gas is obtained, and the atomized liquid waste part can replace at least part of smelting fuel. In the smelting method, the solid waste part and the liquid waste part are treated separately and can be more sufficiently smelted and burned by combining a liquid atomization mode. Meanwhile, the technical process of the method is short, and the advantages of low energy consumption and low cost are achieved. In addition, after the waste is treated according to the method, a product is free of secondary pollution and can be applied to other purposes, and thus the economic benefits can be increased.

Owner:CHINA ENFI ENGINEERING CORPORATION

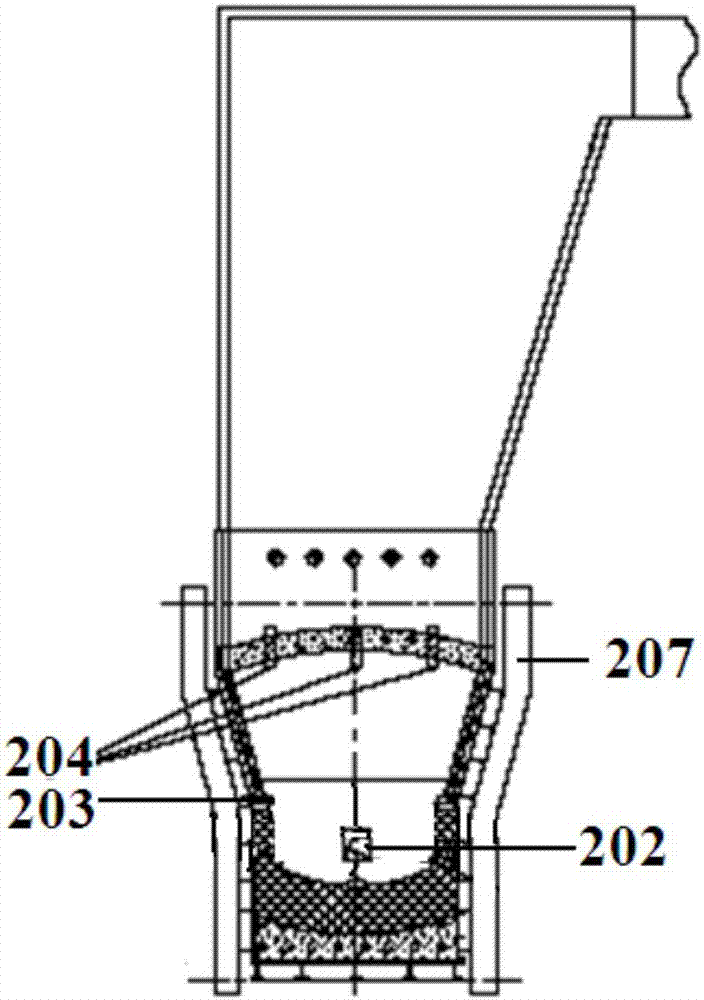

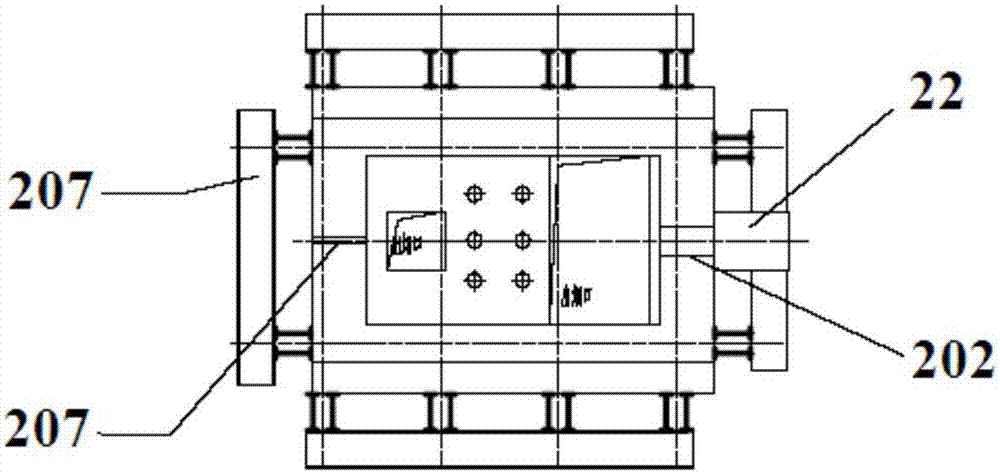

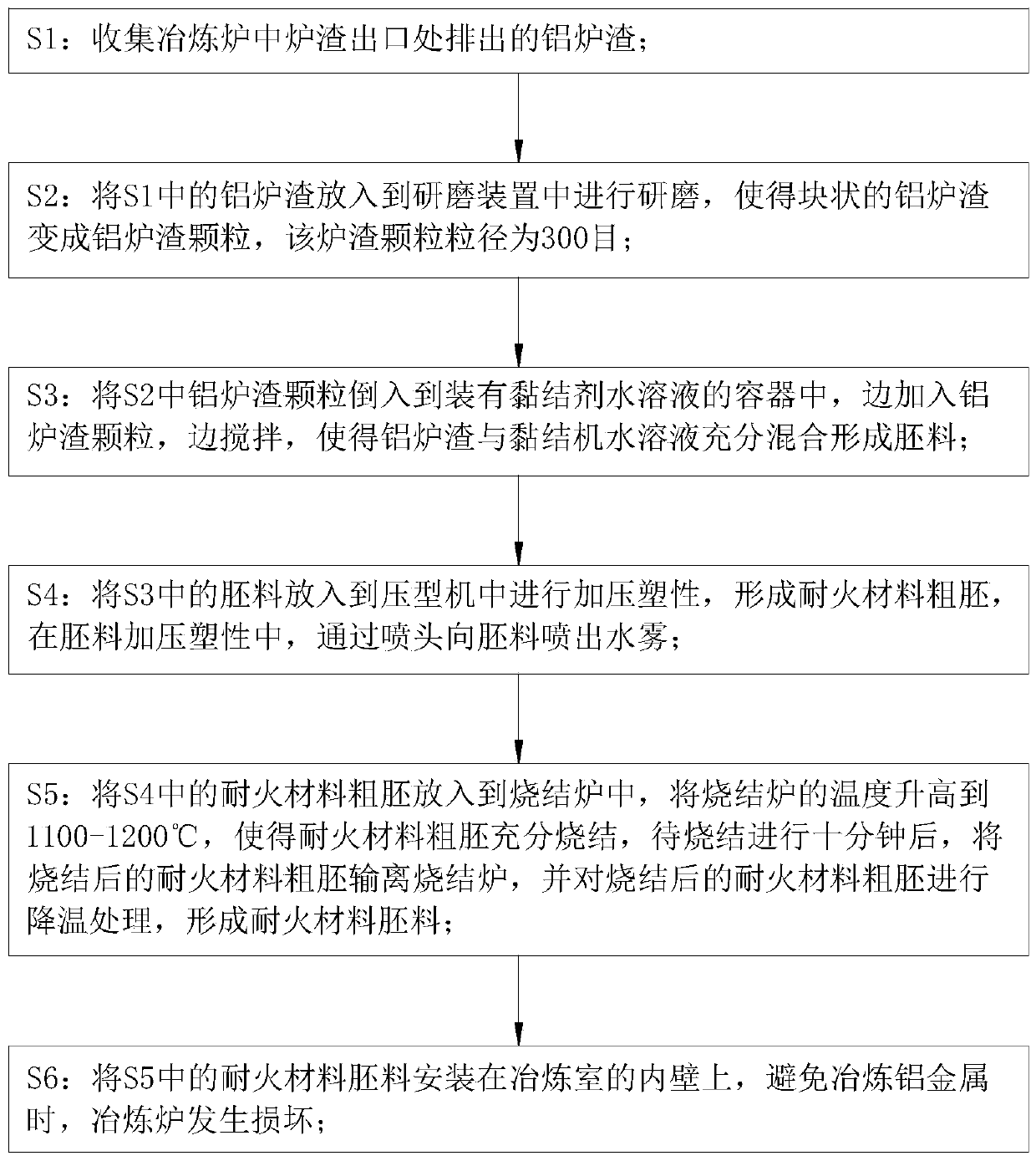

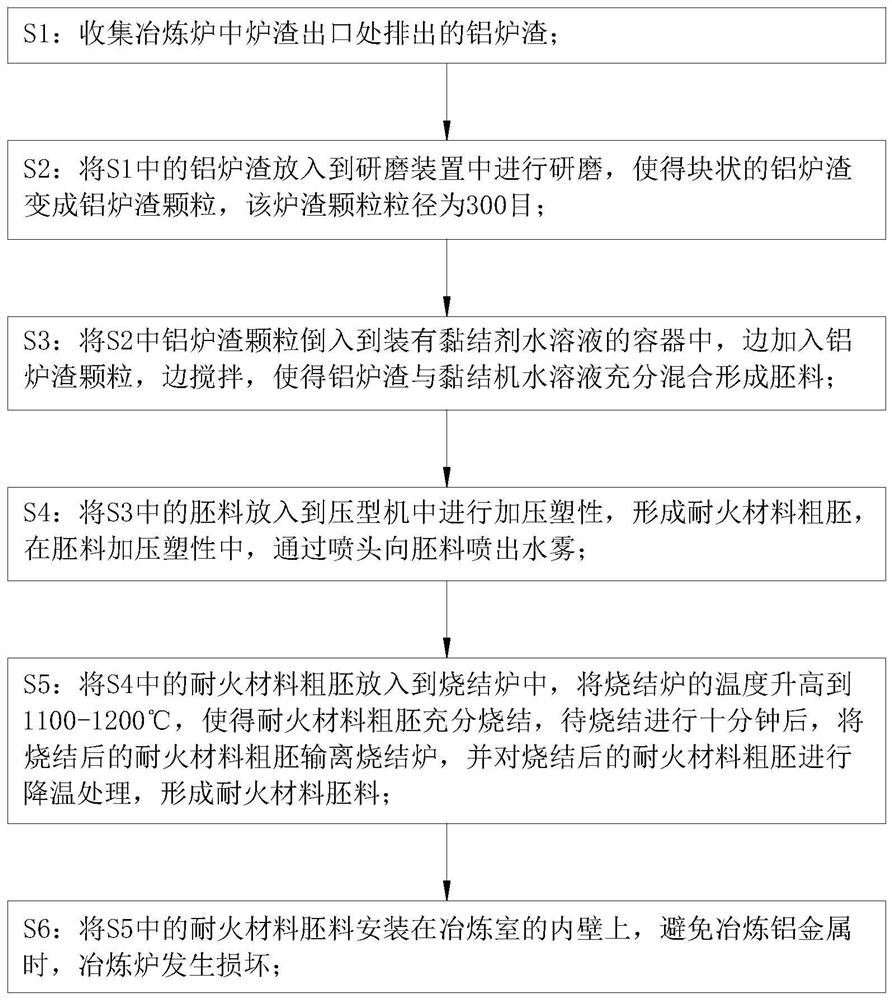

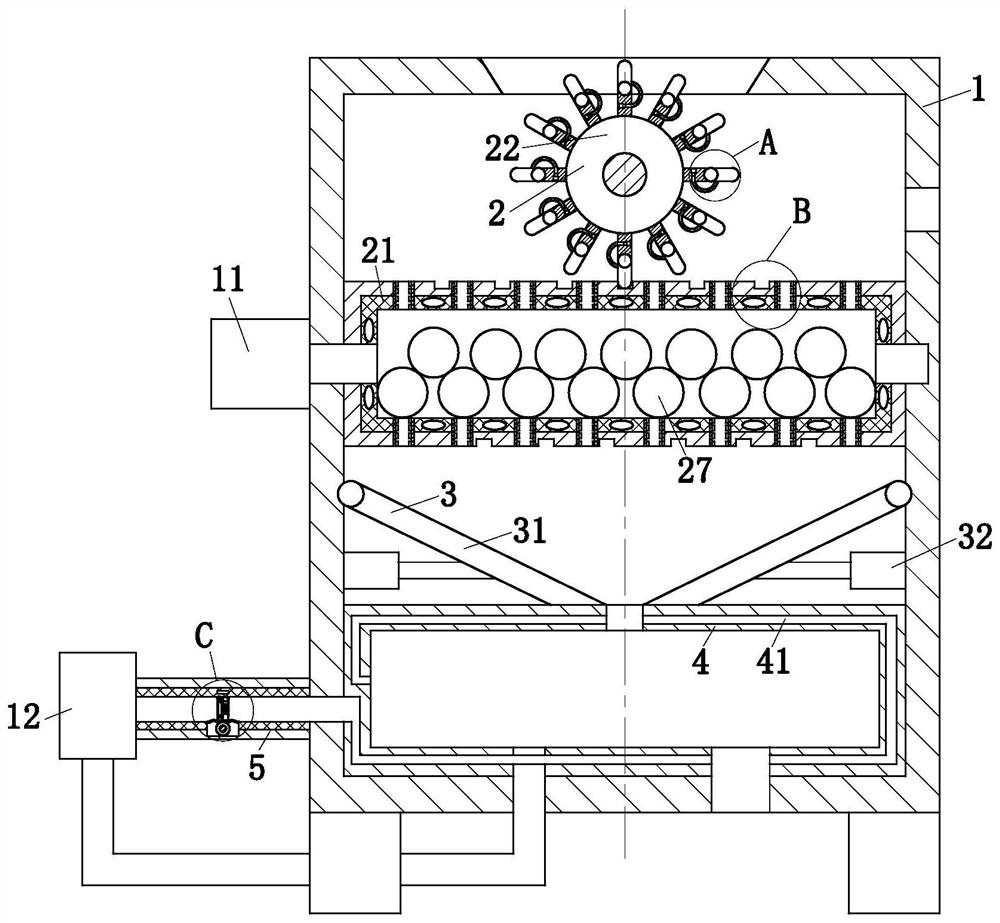

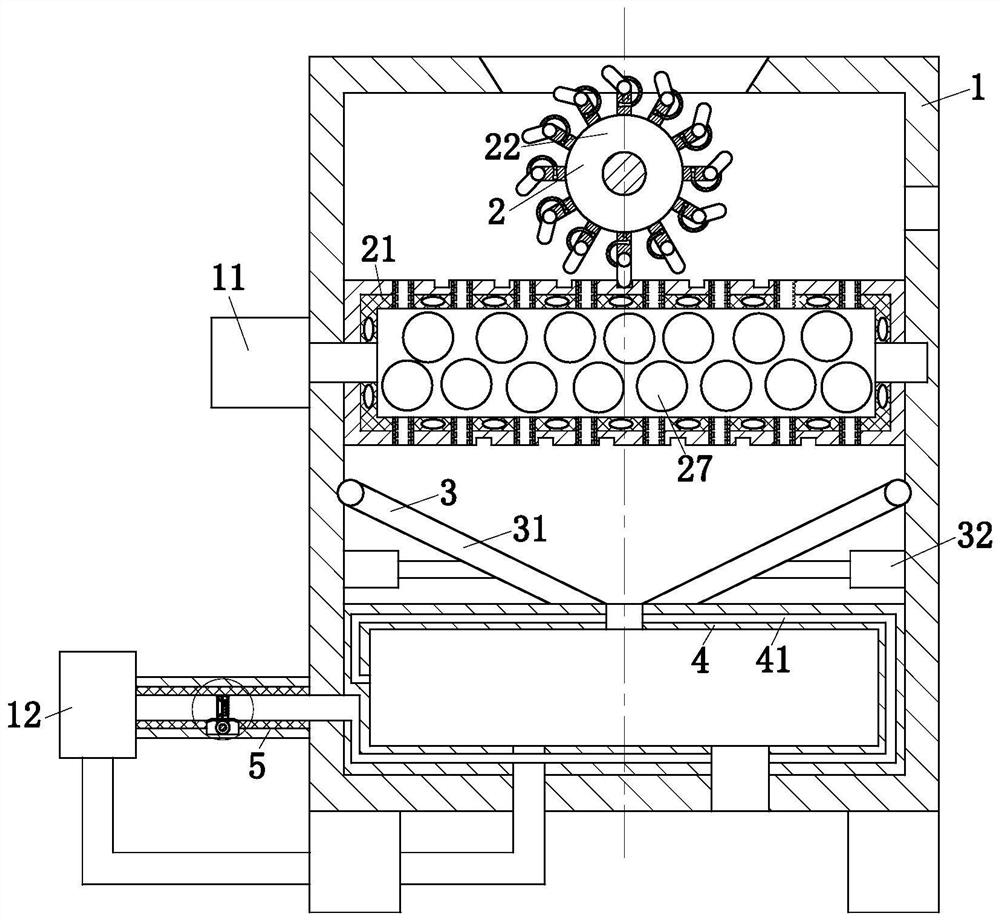

Process for reusing slag of aluminum smelting furnace

ActiveCN109719114AImprove qualityExtended service lifeSolid waste disposalIncreasing energy efficiencySlagSpray nozzle

The invention belongs to the technical field of slag reutilization and particularly relates to a process for reusing slag of an aluminum smelting furnace. The process adopts the smelting furnace. Thesmelting furnace comprises a box body and further comprises a crushing unit, material guide units, a smelting chamber, a motor, a collecting box, a first pipe, a purifying unit and a controller. By the adoption of the process, on the one hand, in the process of mixing the aluminum slag and an aqueous solution of a sintering machine, the aluminum slag and the aqueous solution of the sintering machine are fully mixed to form blanks while being added and stirred; meanwhile, spray nozzles are used to spray water mist to the blanks during the pressurization and plasticity of the blanks, so that theblanks are tightly attached, no fracture occurs between the blanks during sintering in the sintering furnace, and thus the quality of a refractory blank is improved; and on the other hand, the formedrefractory blank is installed on the inner wall of the smelting chamber to prevent the smelting furnace from being damaged when aluminum metal is smelted, so that the service life of the smelting chamber is prolonged.

Owner:绥化春达矿渣高细制造有限公司

Mother alloy for iron-based nanocrystalline alloy, smelting technology for mother alloy and cast steel groove used in smelting technology

ActiveCN107385325AUniform compositionLow manufacturing costMolten metal conveying equipmentsSmeltingNanocrystalline alloy

The invention discloses a mother alloy for an iron-based nanocrystalline alloy. The mother alloy is composed of, by weight percentage, 8.8-9.2% of Si, 1.5-1.7% of B, 1.2-1.3% of Cu, 5.5-5.8% of Nb, less than 0.03% of P, less than 0.02% of S, less than 0.05% of C, less than 0.07% of Cr, less than 0.05% of Mn, less than 0.03% of Ti and the balance Fe and impurities. The invention further relates to a smelting method for the mother alloy for the iron-based nanocrystalline alloy and a cast steel groove used in the smelting method. The mother alloy for the iron-based nanocrystalline alloy is uniform in composition and low in manufacturing cost; and qualified iron-based nanocrystalline alloy strips can be produced by taking the mother alloy as raw materials, the strips have the characteristics of high saturation magnetic induction intensity, high magnetic conductivity, low loss and the like, the comprehensive soft magnetic performance is very excellent, the energy-saving and environment-friendly requirements of the development in the new century can be met, and the mother alloy is an environment-friendly and energy-saving material.

Owner:中能建华南电力装备有限公司

Zinc metallurgy apparatus and process

Owner:CHINA ENFI ENGINEERING CORPORATION

Bottom-blowing smelting equipment

ActiveCN102706146AFull melting reactionReduce reaction energy consumptionCharge manipulationCrucible furnacesSlagFlue gas

The invention discloses bottom-blowing smelting equipment, which comprises a furnace body. A material inlet and a flue gas outlet are arranged at the upper part of the furnace body. A product outlet and a slag outlet are arranged on the side part of the furnace body. A vulcanizing agent steam passage and a reaction gas passage are arranged at the bottom of the furnace body to respectively feed vulcanizing agent and reaction gas into the furnace body. The bottom-blowing smelting equipment provided by the embodiment of the invention has the advantages that since the reaction materials are added into the furnace body from the top of the furnace body and the reaction gas and the vulcanizing agent are fed into the furnace body from the bottom of the furnace body, the reaction materials can be agitated, the smelting reaction is enabled to be more full and the consumption of energy for reaction is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Automatic secondary aluminum smelting aluminum and iron separation device

ActiveCN111763829APurificationFully smeltedProcess efficiency improvementElectrolytic agentElectric machine

The invention discloses an automatic secondary aluminum smelting aluminum and iron separation device and relates to the technical field of secondary aluminum smelting. The automatic secondary aluminumsmelting aluminum and iron separation device comprises a smelting separation furnace and a separation device, wherein a stirring motor is mounted on the surface of the smelting separation furnace andan electric heating block is mounted in the smelting separation furnace. By arranging the smelting separation furnace and the separation device which communicate to each other, in a process of smelting aluminum waste to separate iron impurities, secondary aluminum is purified favorably by means of two-stage separation, so that the separation efficiency is improved. By arranging a stirring motor,aluminum waste can be fully and completely smelted by the smelting separation furnace under the stirring action. Meanwhile, by forming a filter hole, it is convenient to separate fully smelted moltenaluminum from the iron impurities and the molten aluminum flows into an auxiliary separation box along a separation channel for further separation treatment. By arranging the auxiliary separation box,the molten aluminum is cooled and condensed to a solid quickly by a method of injecting a cooling liquid and an electrolyte into the box, and micro impurities on the surface of the molten aluminum are separated out by the electrolyte for separation.

Owner:重庆顺博铝合金股份有限公司

White copper alloy and preparation technique thereof

InactiveCN105803251AImprove performanceThe tensile strength corrosion degree meetsCupronickelDeoxygenation

The invention discloses white copper alloy. The white copper alloy comprises, by weight, 15%-20% of Ni, 5%-10% of Zn, 2%-5% OF Sn, and the balance copper. A preparation method of the white copper alloy includes the steps that 1% of manganese dioxide is added as an oxidizing agent firstly, and then the 15%-20% of Ni and 65%-78% of Cu are added, so that a mixture A is formed; the mixture A is heated for 2-4 hours till the temperature rises to 1300-1330 DEG C for melting, so that a mixed solution B is formed; the 5%-10% of Zn and 2%-5% of Sn are added to the mixed solution B, and the mixture is heated for 20-70 minutes till the temperature rises to 1330-1360 DEG C, so that a mixed solution C is formed; a deoxidizing agent is added to the mixed solution C for deoxygenation, so that a mixed solution D is formed, wherein phosphor copper alloy serves as the deoxidizing agent; and the mixed solution D is cooled at the rate of 10-20 DEG C per minute, oxide impurities on the surface are removed with a tool after cooling is completed, and finally the molten white copper alloy is formed. The white copper alloy can meet the requirement for crafts and has no harm to people, the manufacturing technique is simpler, and less cost is required.

Owner:NANJING CHENGUANG ART ENG CO LTD

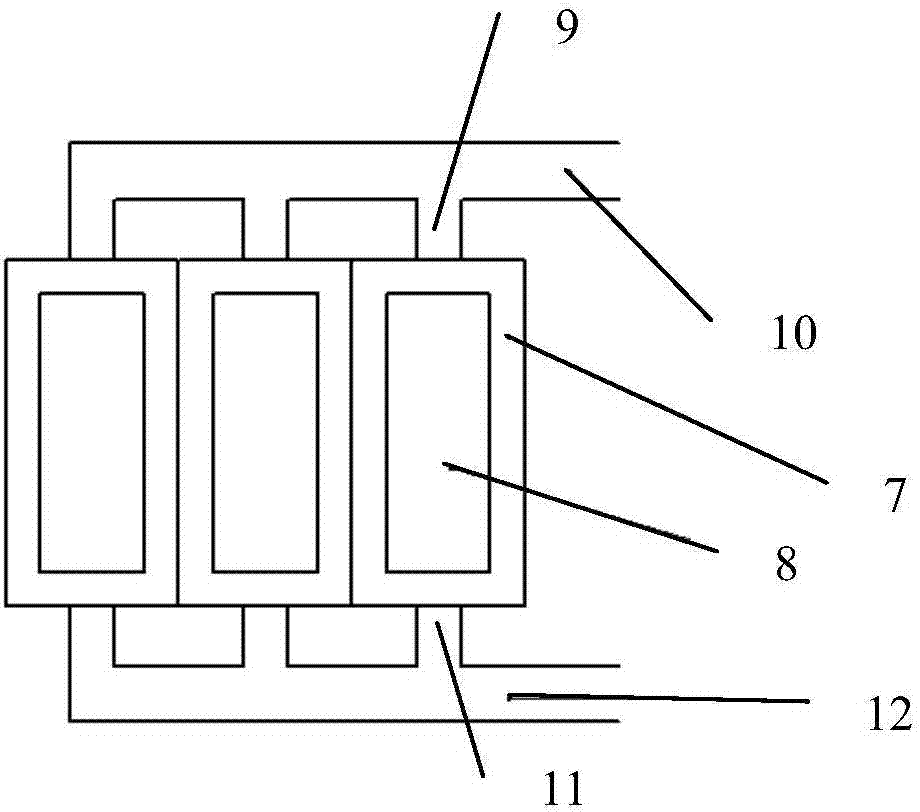

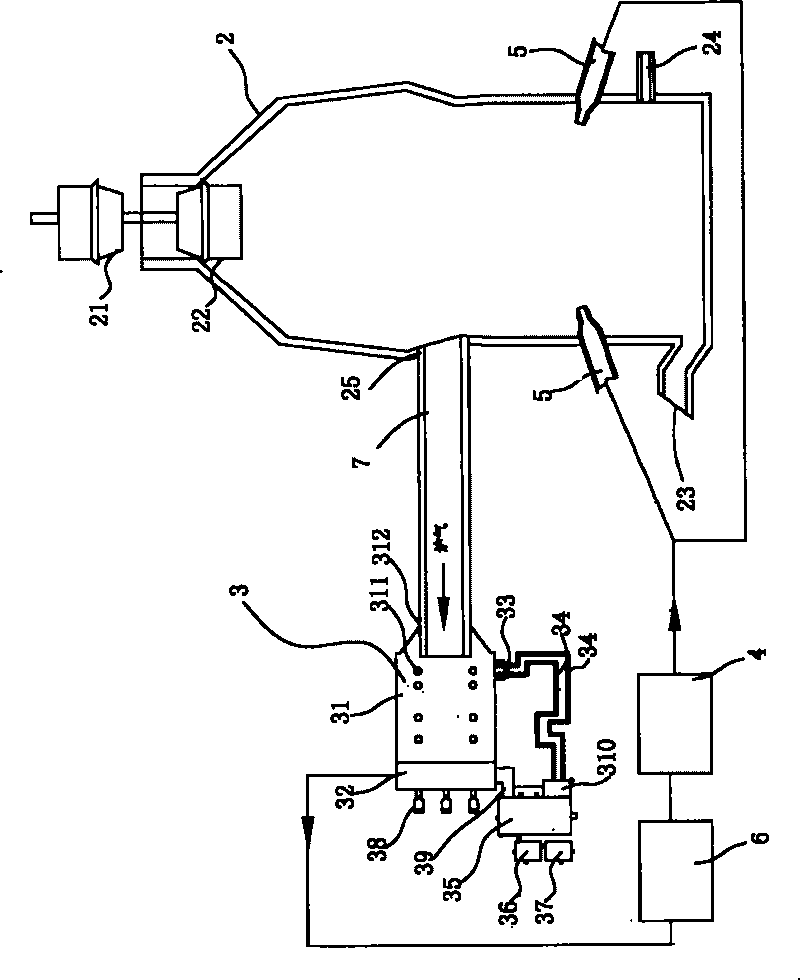

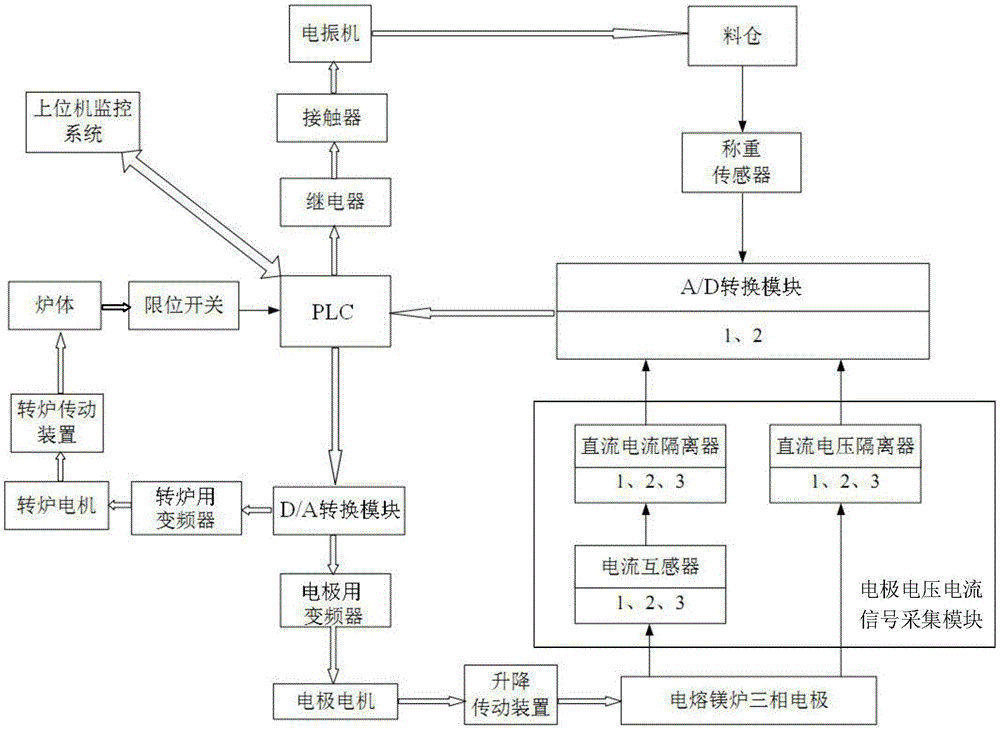

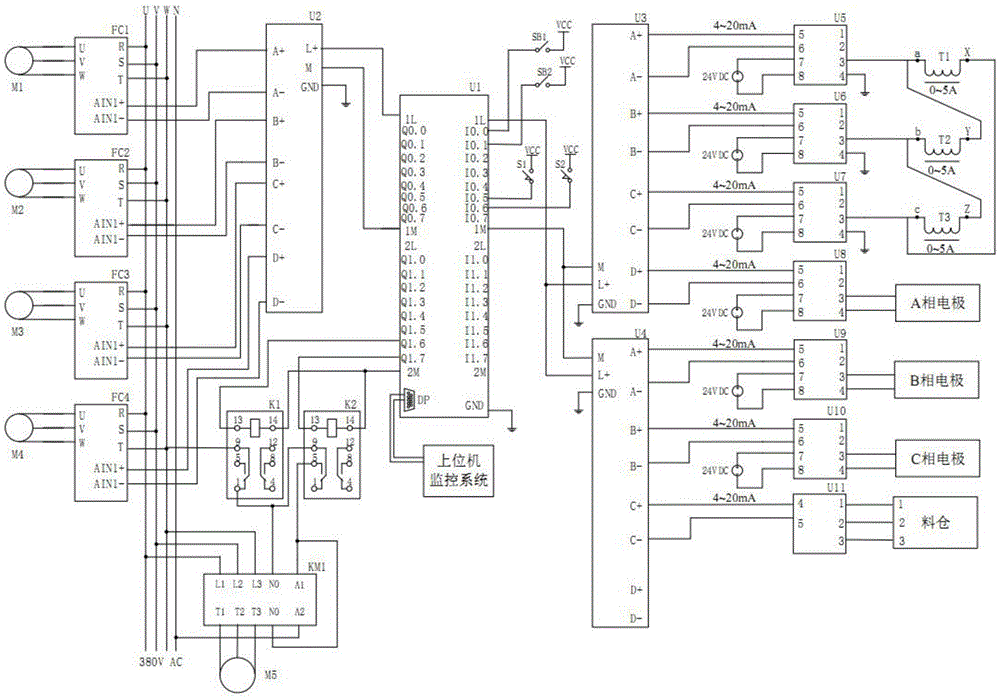

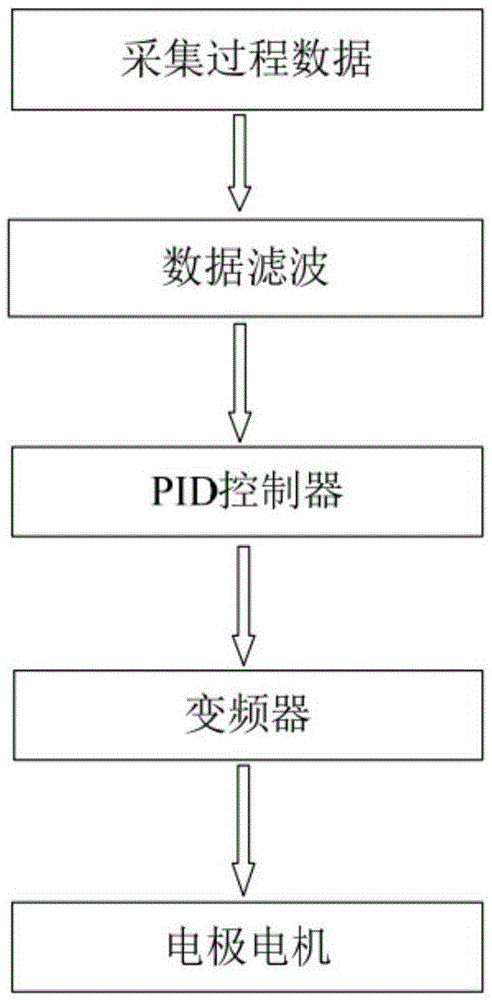

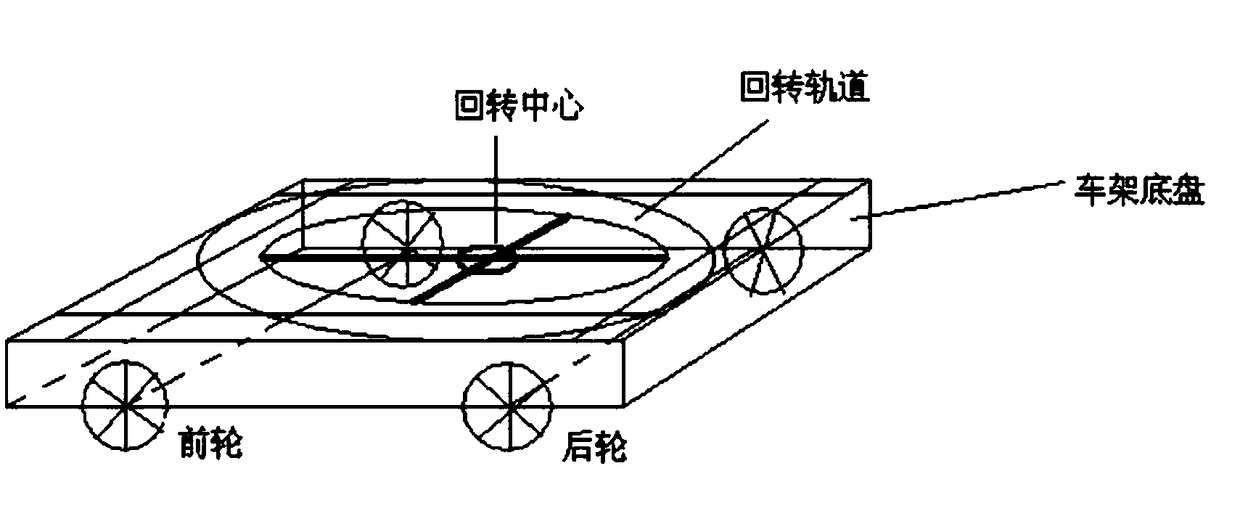

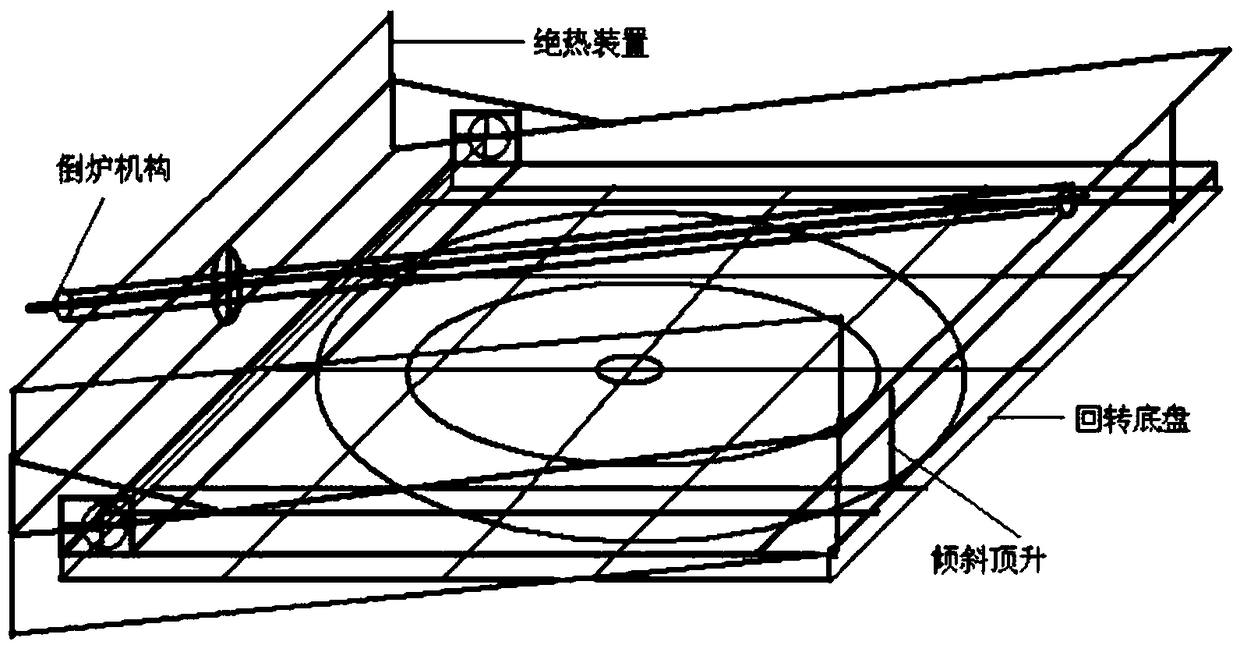

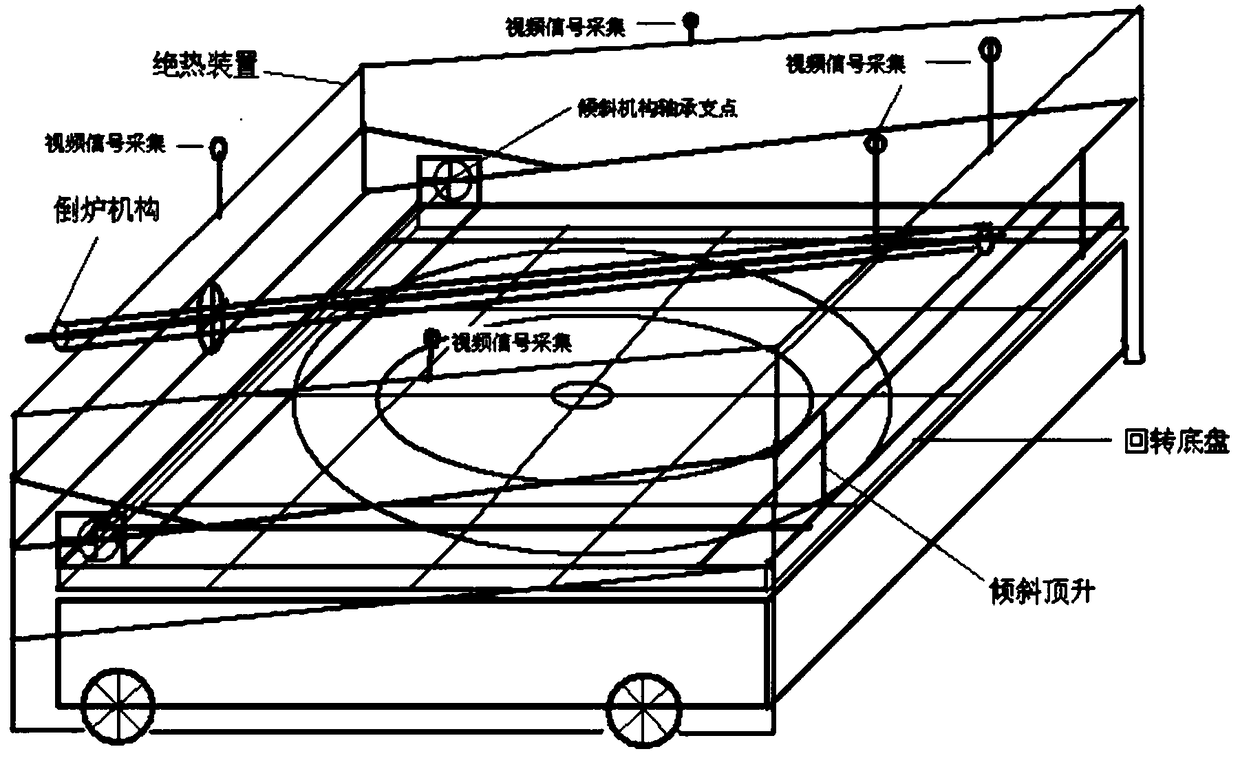

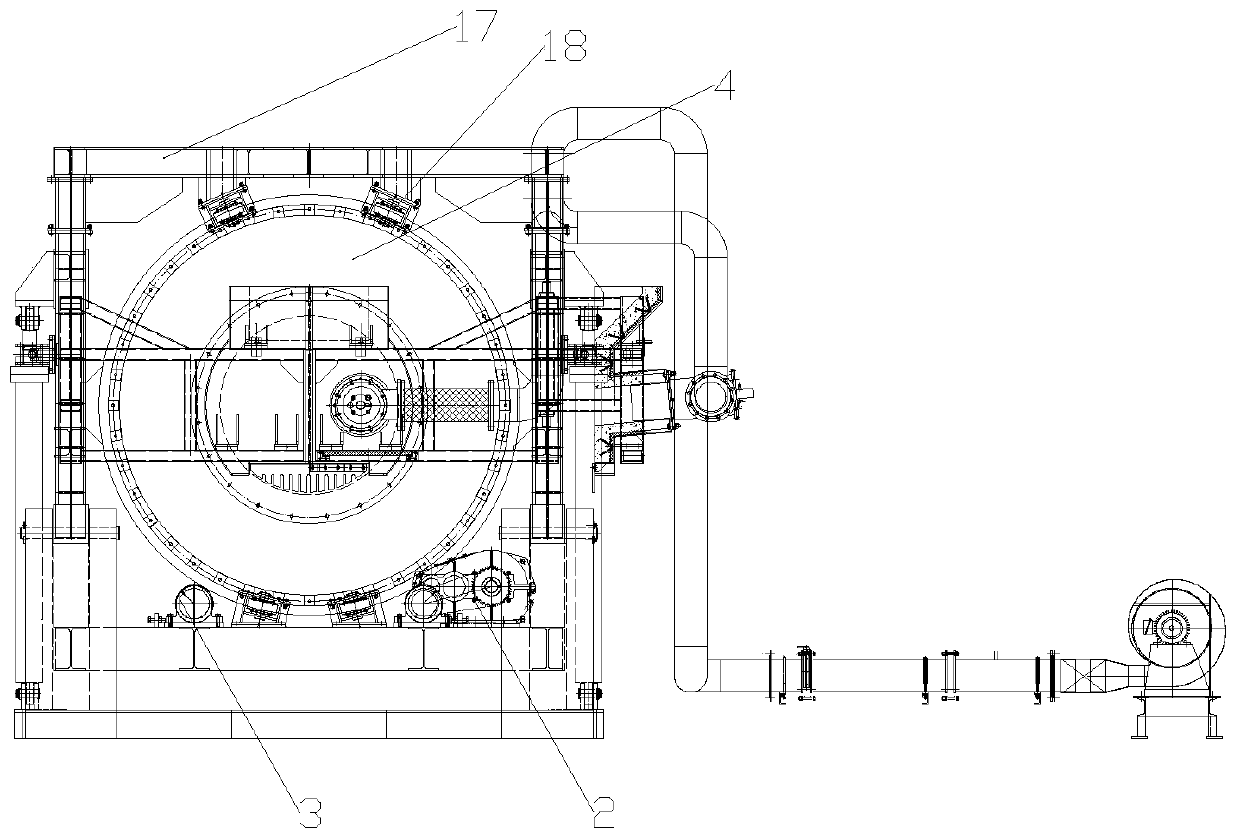

Automatic control device of rotation type electric smelting magnesium furnace and electrode current control method

ActiveCN105571340ARealize the rotation functionReduce work intensityControl devices for furnacesFrequency changerAutomatic control

The invention discloses an automatic control device of a rotation type electric smelting magnesium furnace and an electrode current control method, and belongs to the technical field of electric smelting magnesium furnace process control. The device comprises a PLC (Programmable Logic Controller), an electric vibrator, a converter motor, a converter rotating and positioning limiting switch, a converter frequency changer, an electrode motor, an electrode frequency changer, a D / A conversion module, a weighing sensor, an electrode voltage and current signal collecting module an A / D conversion module and an upper computer monitoring system. The method comprises the steps that the three-phase current and the three-phase voltage flowing through a three-phase electrode of the electric smelting magnesium furnace are collected and converted into standard analog quantity current signals; the standard analog quantity current signals are converted into corresponding digital signals to be output to the PLC; and the current control over the electrode of the rotation type electric smelting magnesium furnace is finished in the PLC. According to the method, the functions of current collecting, controlling and the like of the three-phase electrode of the rotation type electric smelting magnesium furnace can be achieved, the error between the current of the three-phase electrode and the current set value is stabilized within the allowable error range, and electric energy consumption is reduced while the product quality is guaranteed.

Owner:NORTHEASTERN UNIV LIAONING +1

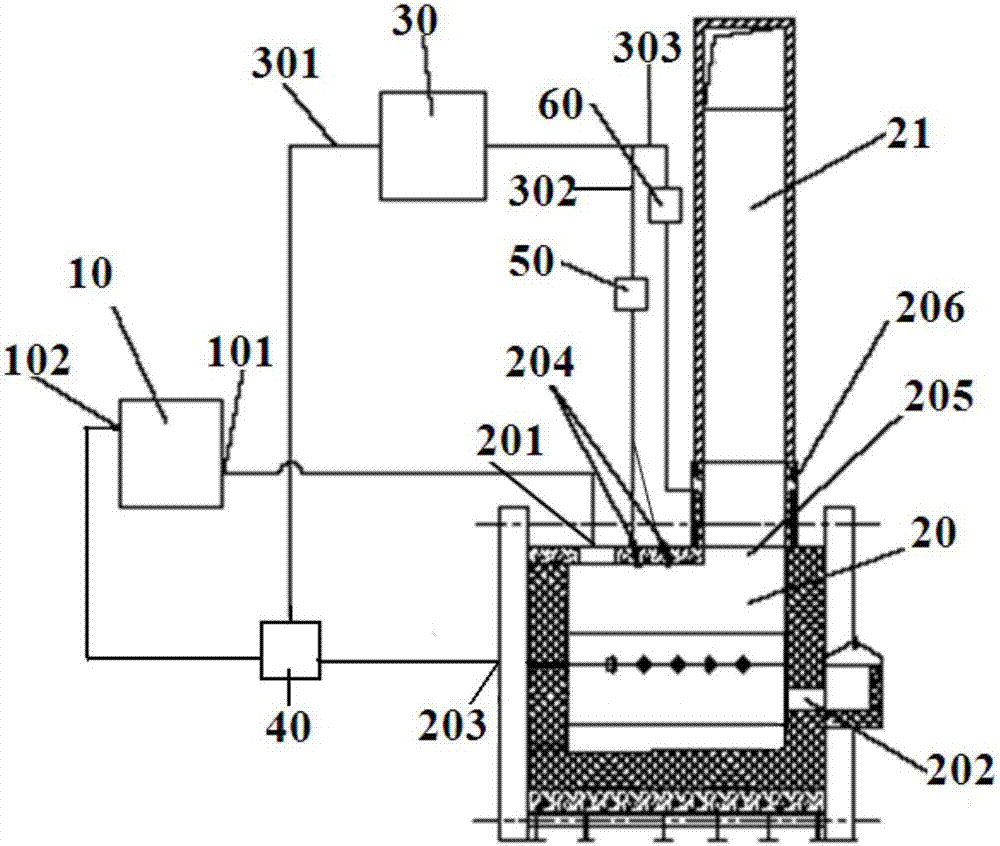

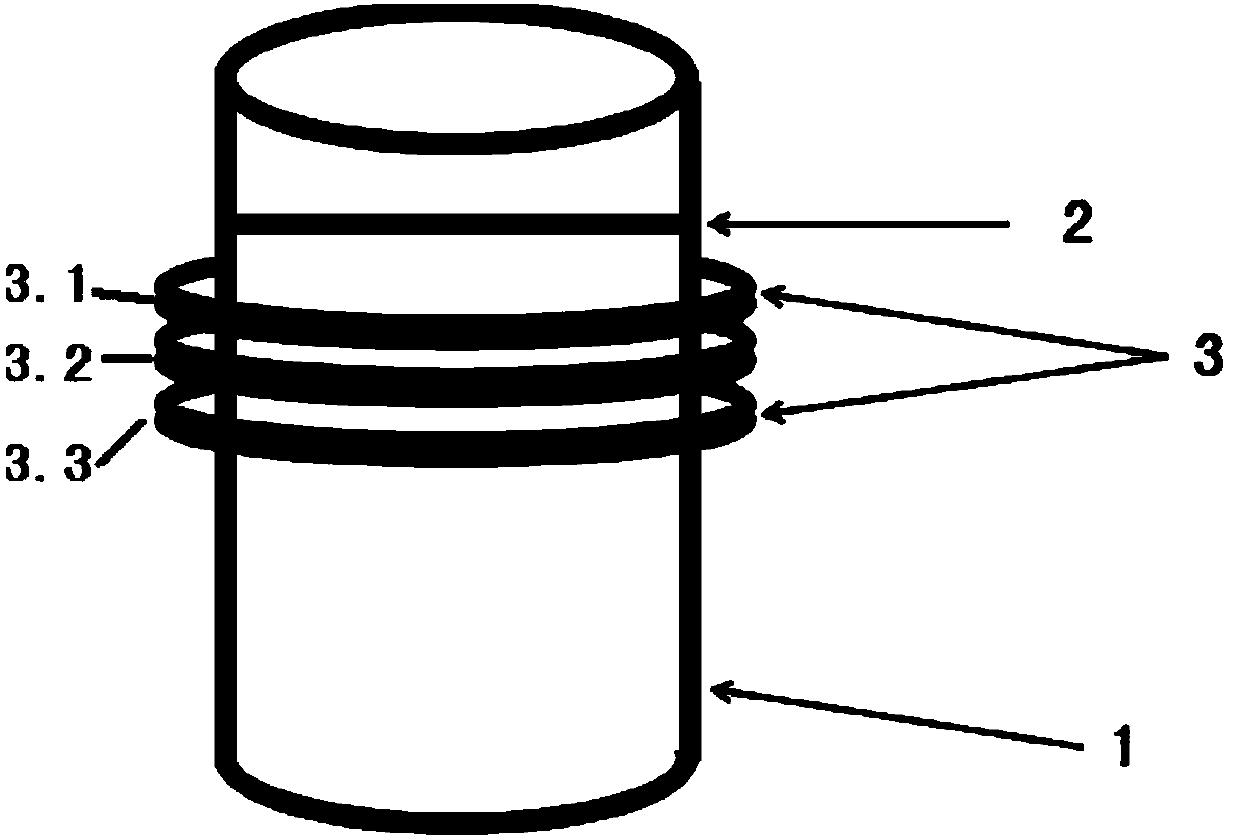

Preparation method of large-size Al2O3 polycrystal

InactiveCN107747127ADoes not affect puritySufficient ignition timePolycrystalline material growthSingle crystal growth detailsTemperature controlCrucible

The invention relates to a preparation method of a large-size Al2O3 polycrystal, in particular to a process flow for forming a high-purity and high-volume-density Al2O3 polycrystal in a process of preparing a large-size Al2O3 polycrystal in a cylindrical cold crucible with an inner diameter of phi 150-230mm, a height of more than 500mm and a thickness of 15-30 mm. The process flow comprises the following steps of: preparing a crucible, adding raw materials and adding and placing a kindling in the early stage of smelting; and controlling ignition of the kindling and melting of the raw materialsin the initial stage of smelting. A relative position between a melting liquid surface and a heating induction coil is controlled in the middle and later stages of smelting. The invention provides apreparation method of an Al2O3 polycrystal, which is simple and safe to control and operate, through in-depth analysis of factors such as selection of a starting kindling, laying of the starting kindling, ignition, heating, temperature control and material adding, and the prepared Al2O3 polycrystal is high in purity, high in density and large in size.

Owner:鄂尔多斯市达瑞祥光电科技有限公司

Top-blown smelting equipment

InactiveCN102703734ASimple structureFully smeltedLighting and heating apparatusEngineeringProduct gas

The invention discloses top-blown smelting equipment, which includes a furnace body and a base, wherein a material feeding channel and an air outlet are arranged at the top of the furnace body; the base is mounted at the bottom end of the furnace body; a waste residue outlet and a product outlet are arranged on the base; a vent duct for ventilating the interior of the furnace body is arranged in the material feeding channel; and the base accommodates the material to be reacted and discharges the reaction product and waste residue. According to the top-blown smelting equipment of the invention embodiment, by ventilating the interior of the furnace body through the material feeding channel, the process for further forming a gas channel on the furnace body is omitted, the top-blown smelting equipment is simplified, and the ventilation can serve for blending the material when feeding the material through the material feeding channel, so as to accelerate the smelting reaction and enable the smelting reaction to be more sufficient.

Owner:CHINA ENFI ENGINEERING CORPORATION

Staged online monitoring method for steelmaking by refining furnace

InactiveCN110306008AImprove refining efficiencyFully smeltedSteel manufacturing process aspectsIncreasing energy efficiencySteelmakingFuzzy control system

The invention discloses a staged online monitoring method for steelmaking by a refining furnace. The method comprises the following steps: monitoring an argon blowing signal in an argon blowing stage,a first heating stage signal and a second heating stage signal of the refining furnace to obtain a plurality of monitoring signals; comparing and classifying the monitoring signals with a normal working signal to obtain an identifier which represents the operating state of the refining furnace; determining the operating condition of the refining furnace according to the identifier of the operating state of the refining furnace; and when the identifier of the monitoring state is not available, giving out an operating type of the monitored signals according to a neural network model, wherein the step of giving out the operating type of the monitored signals comprises the steps of constructing the neural network model by the monitoring signals obtained by monitoring and analyzing and outputting the monitored signals in a neural network; and inputting an output result to a fuzzy controller to obtain an output vector group which represents the adjusting type as an adjusting key output. Bymonitoring steelmaking processes in stages in the refining furnace, the refining process is carried out smoothly.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

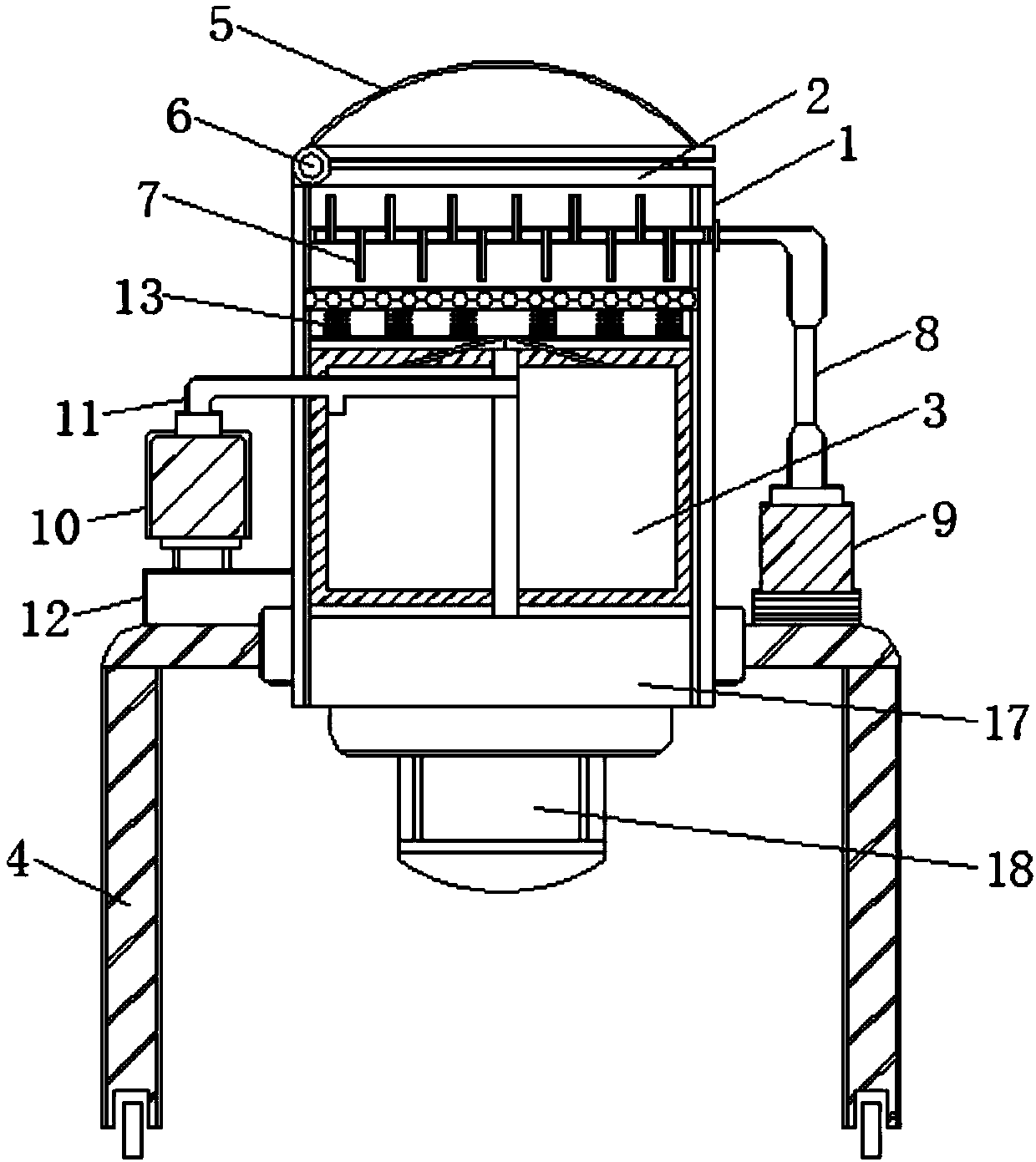

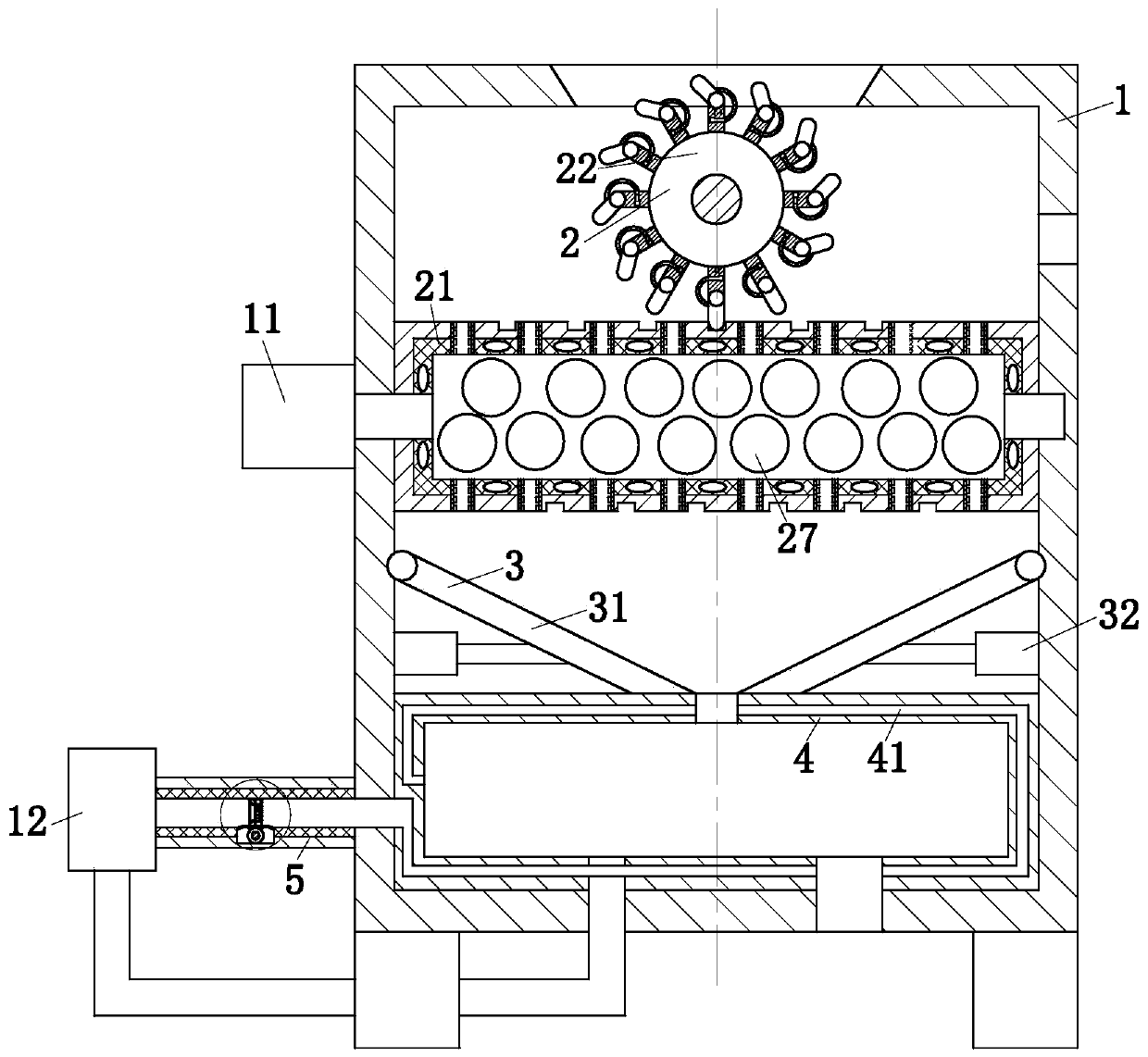

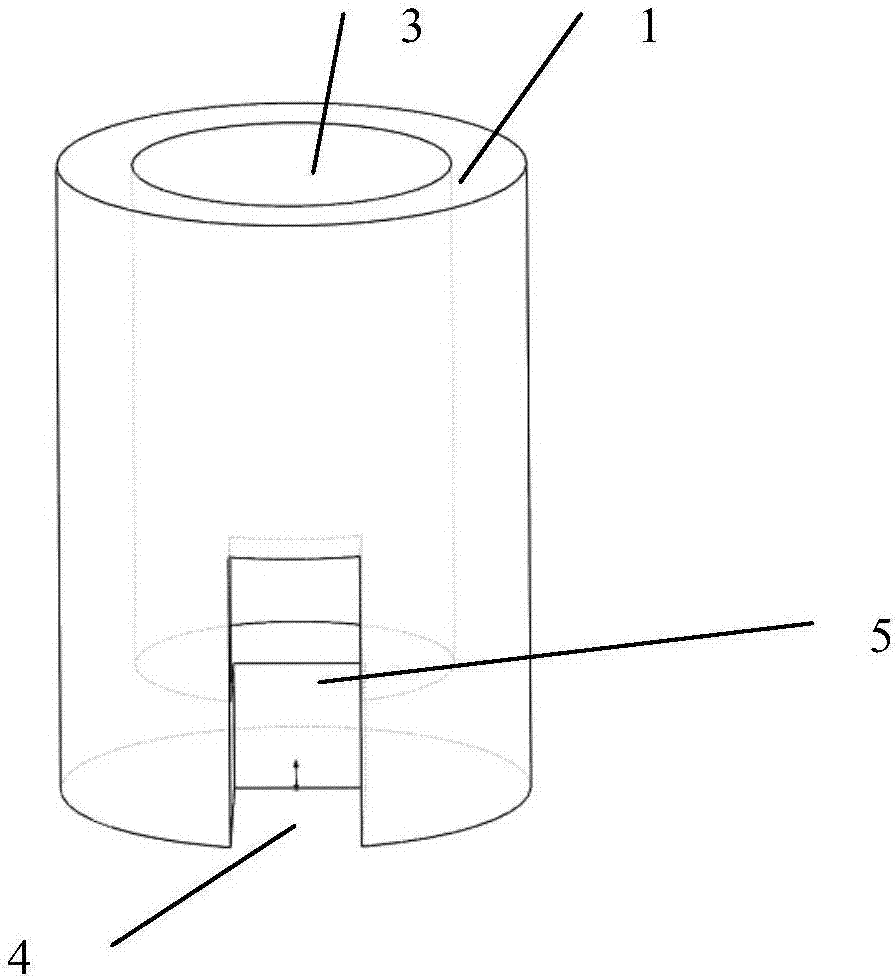

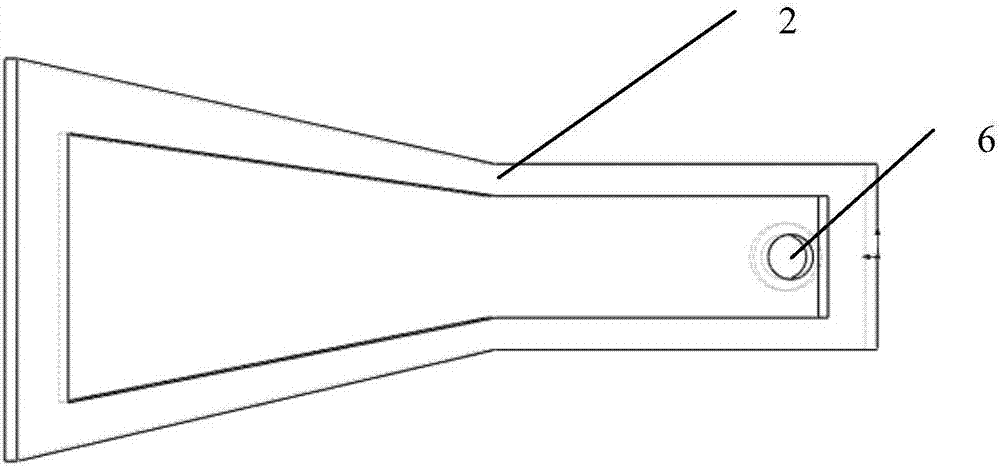

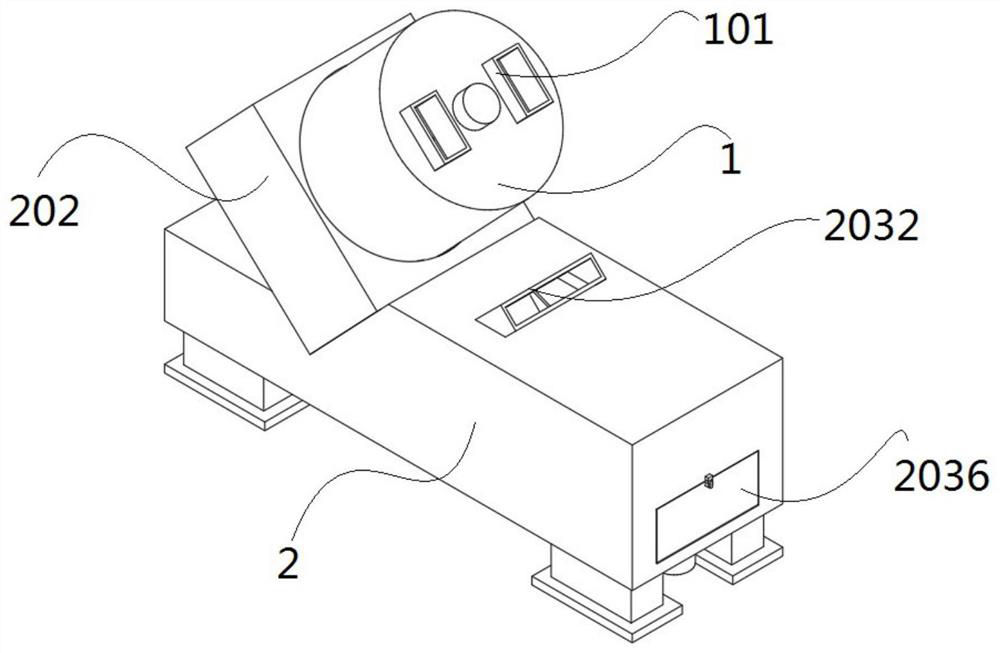

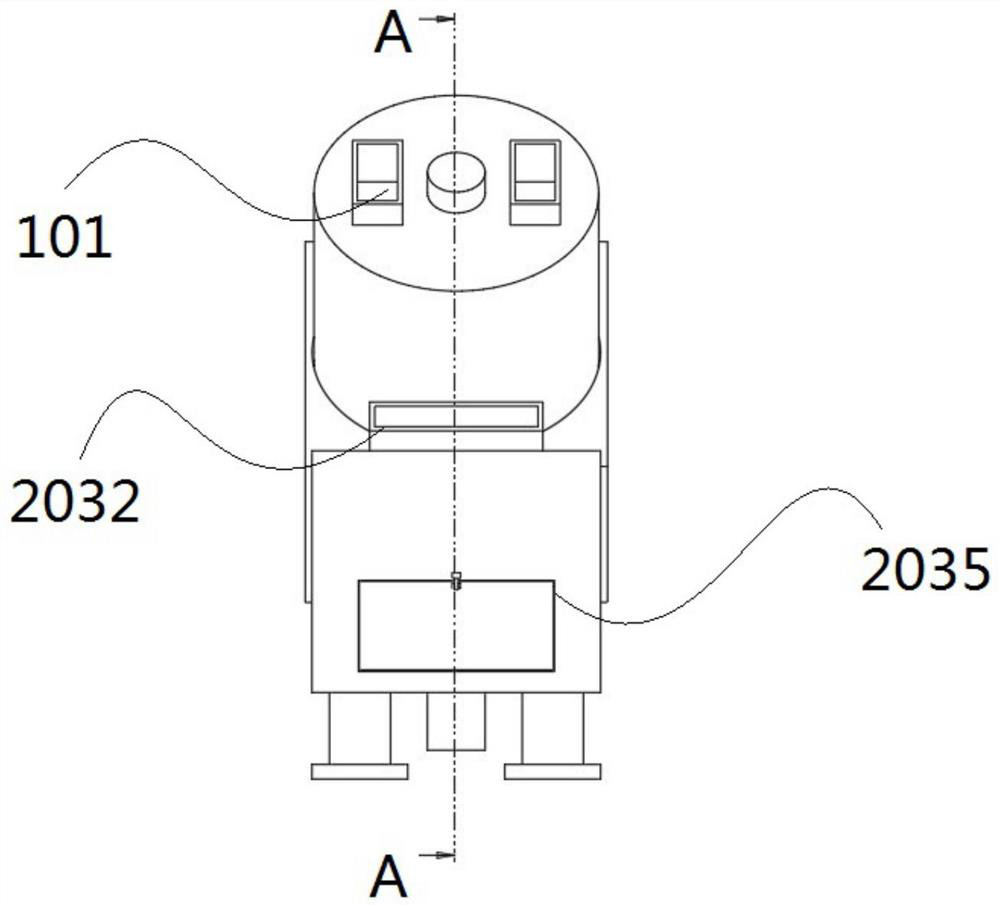

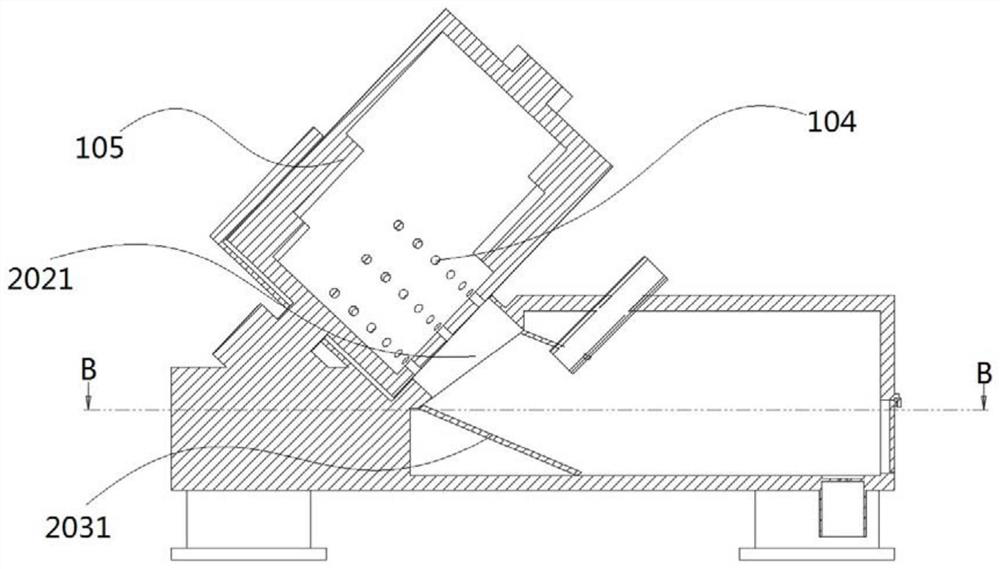

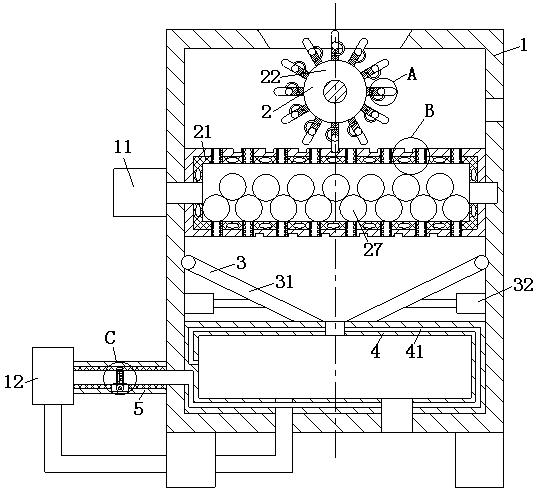

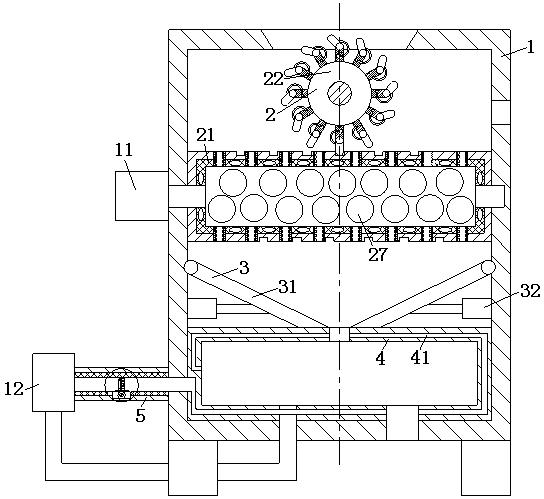

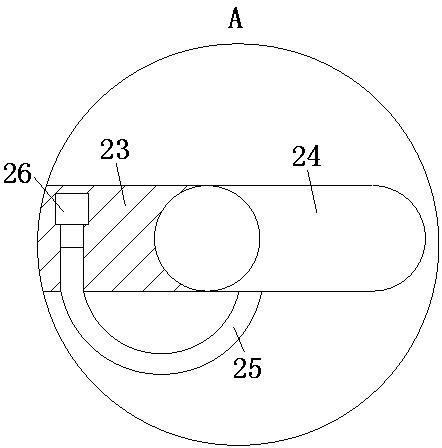

High-performance nodular cast iron spheroidizing agent and manufacturing equipment thereof

ActiveCN113718080AImprove processing efficiencyImprove packaging efficiencySievingScreeningDuctile ironSmelting

The invention relates to the technical field of spheroidizing agent processing, in particular to a high-performance nodular cast iron spheroidizing agent. The high-performance nodular cast iron spheroidizing agent comprises 35-45 parts of Si, 7-9 parts of Mg, 3-4 parts of Re, 1-2 parts of Ca, 30-50 parts of Fe and 1-5 parts of Ce. The invention further provides the high-performance nodular cast iron spheroidizing agent and manufacturing equipment thereof. The manufacturing equipment of the high-performance nodular cast iron spheroidizing agent comprises a smelting part, a casting part, a crushing part, a screening part and a mixing part; the mixing part is arranged on one side of the smelting part; the casting part is arranged at the bottom of the smelting part; the casting part is in sliding connection with the bottom of the smelting part; the crushing part is arranged at the bottom of the casting part; and the screening part is arranged at the bottom of the crushing part. The problems that the spheroidizing agent in the prior art is high in cost, the processing equipment is low in automation degree, manual loading and unloading are mostly adopted, and the production efficiency is low are solved. The invention further discloses a using method of the high-performance nodular cast iron spheroidizing agent manufacturing equipment.

Owner:镇江东丰特殊合金有限公司

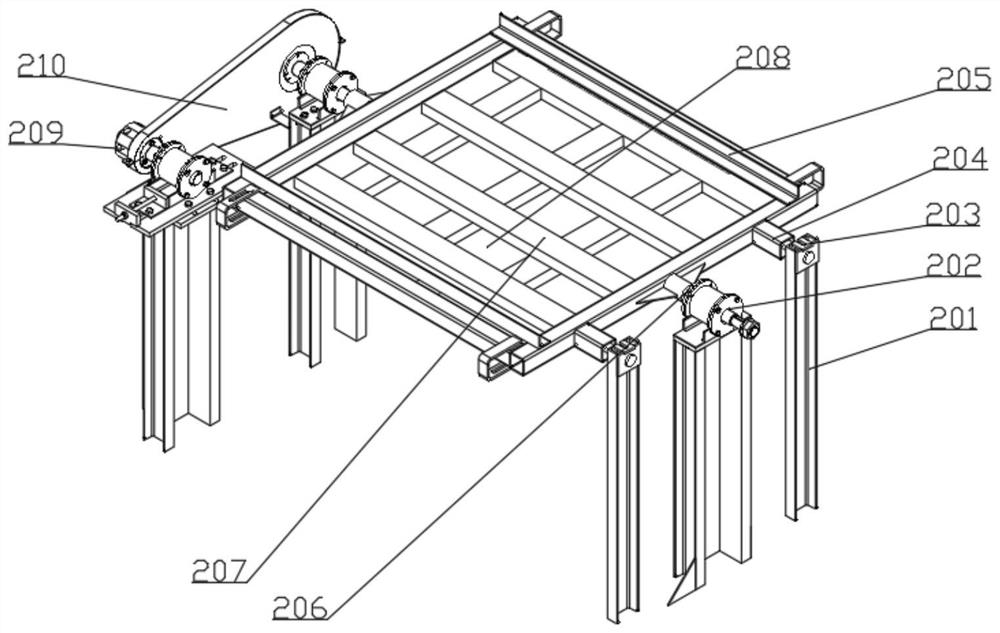

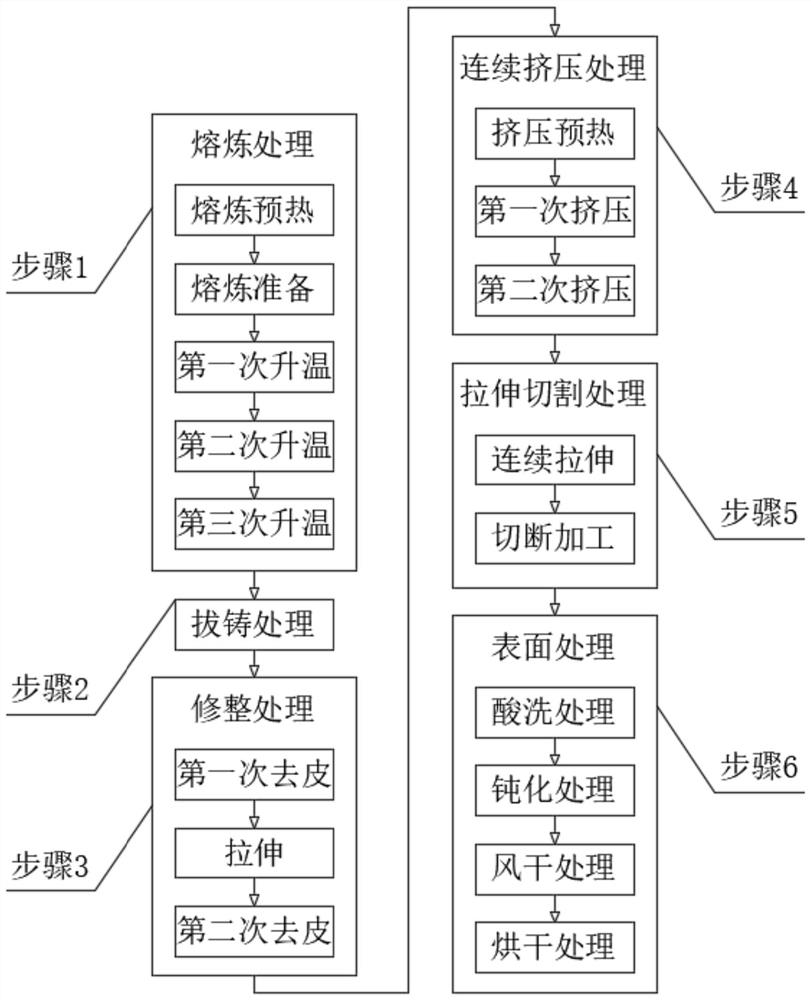

Processing method of conductive copper bus

The invention relates to a processing method of a conductive copper bus. The method is characterized by comprising the following steps of first, smelting, wherein the first step specifically comprisesthe following steps of smelting and preheating, smelting preparation, temperature rise for the first time, temperature rise for the second time, and temperature rise for the third time; second, casting treatment, wherein molten copper is crystalized into a copper billet through a continuous casting machine, and the copper billet is pulled into a take-up stand by the continuous casting machine; third, finishing treatment, wherein the third step specifically comprises the following steps of peeling for the first time, stretching, and peeling for the second time; fourth, continuous extrusion treatment, wherein the fourth step specifically comprises the steps of extrusion and preheating, extrusion for the first time, and extrusion for the second time; fifth, stretching and cutting treatment,wherein the fifth step specifically comprises the steps of continuous stretching, and cutting and processing; sixth, surface treatment, wherein the sixth step specifically comprises the steps of acidpickling treatment, passivation treatment, air drying treatment, and drying treatment; and obtaining of a finished product. With the processing method of the conductive copper bus, the problems that according to casting in the prior art, because the internal structure of a finished product is uneven, the hardness of the finished product is poor, and because of continuous extrusion forming, the surface quality of the finished product is poor are solved.

Owner:WUXI TONGWEI ELECTRIC POWER EQUIP

Aluminum-vanadium-tin-chromium intermediate alloy and preparation method thereof

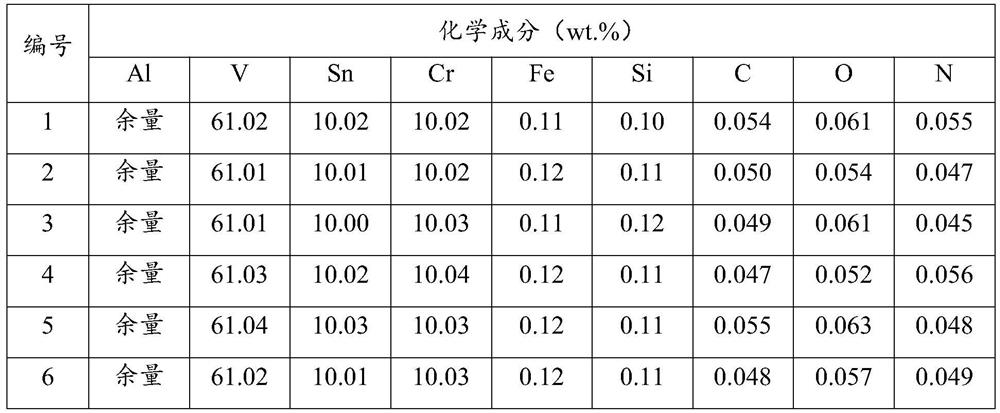

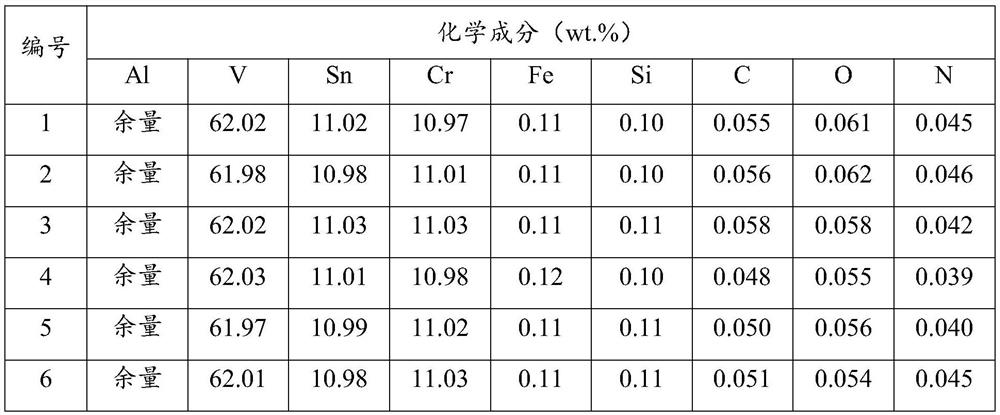

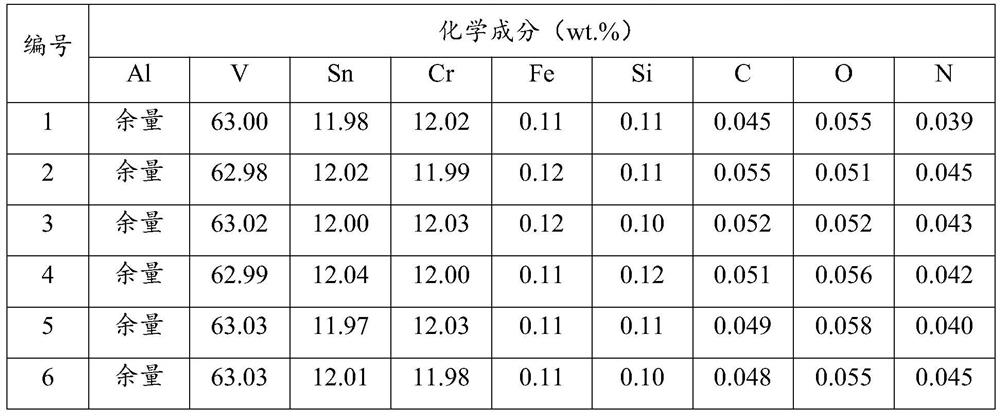

The invention provides an aluminum-vanadium-tin-chromium intermediate alloy and a preparation method thereof, and relates to the technical field of metal materials. The invention provides an aluminum-vanadium-tin-chromium intermediate alloy. The alloy comprises the following components in percentage by mass: 61.0 to 65.0 percent of V, 10.0 to 14.0 percent of Sn, 10.0 to 14.0 percent of Cr, less than or equal to 0.15 percent of Fe, less than or equal to 0.15 percent of Si, less than or equal to 0.06 percent of C, less than or equal to 0.08 percent of O, less than or equal to 0.08 percent of N and the balance being Al. According to the invention, by controlling element composition and content, content of impurities in the aluminum-vanadium-tin-chromium intermediate alloy is low, components are uniform, segregation is small, homogenization of components of a titanium alloy is facilitated when the titanium alloy is smelted, and metallurgical defects of component segregation and inclusion are prevented.

Owner:CHENGDE TIANDA VANADIUM IND

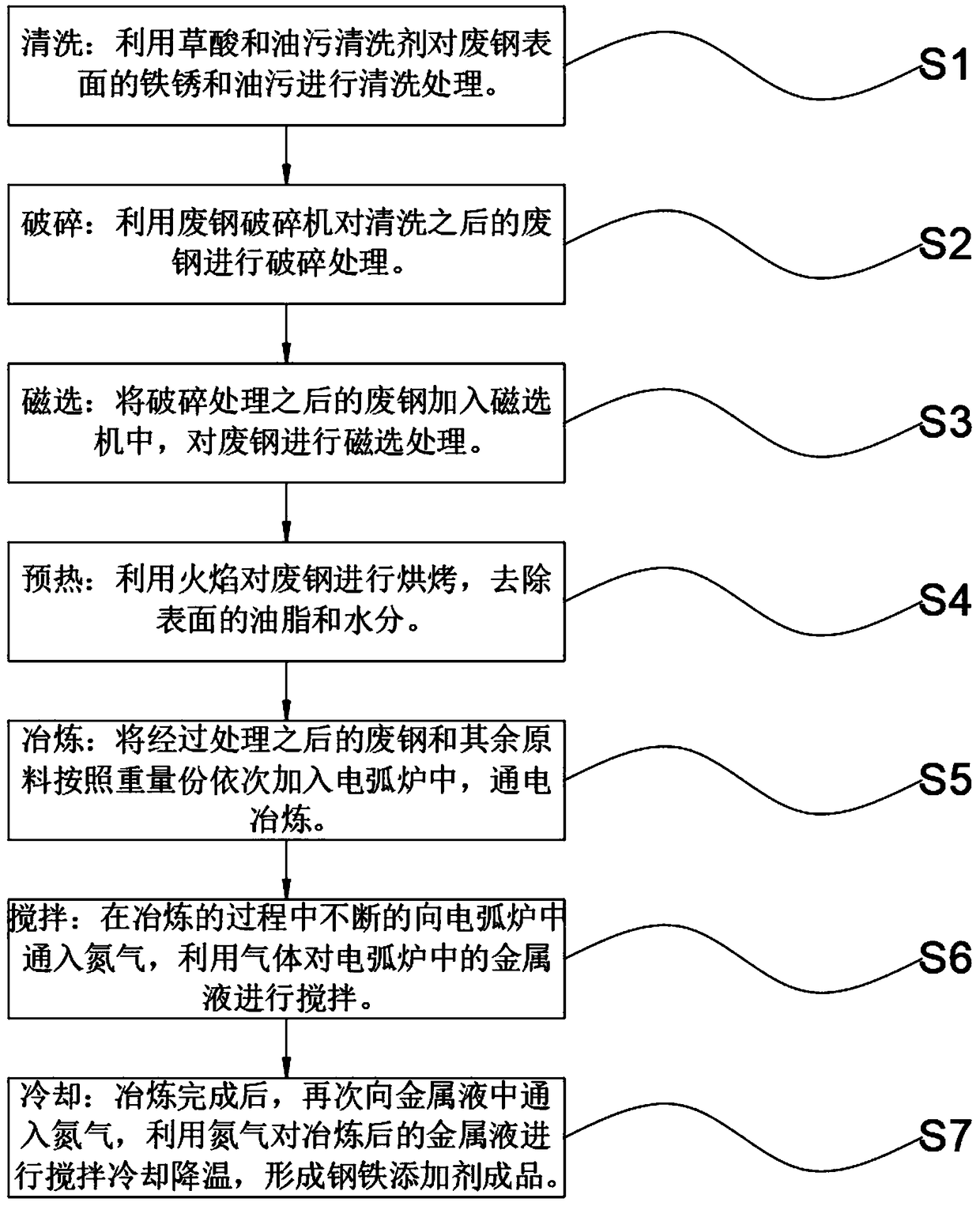

Method for preparing steel additive by taking waste steel as raw material

The invention discloses a method for preparing a steel additive by taking waste steel as a raw material. The steel additive is prepared from the following raw materials in parts by weight, 95 parts ofwaste steel, 15 parts of iron ore, 17 parts of metal aluminum, 12 parts of graphite, 13 parts of ferrosilicon powder, 25 parts of aluminum oxide, 7 parts of manganese silicide, 3 parts of bismuth and5 parts of antimony trioxide. The method has the advantages of being scientific and reasonable, the use is safe and convenient, the steel additive is prepared from the waste steel, the waste of steelresources can be effectively reduced, and the steel utilization rate is improved; the iron ores are added into the steel additives, so that the fierce effect of the decarbonization reaction is effectively promoted, the steel smelting is more sufficient, the impurity content in the steel is greatly reduced, and the performance of the steel is effectively improved; and the metal aluminum is added into the steel additive, so that the steel which needs to be smelted is subjected to sufficient deoxidation treatment, the oxygen content in the steel can be reduced, and the strength, the hardness andthe elasticity of the steel can be improved.

Owner:LIAONING INST OF SCI & TECH

A kind of aluminum smelting furnace slag recycling process

ActiveCN109719114BAvoid damageExtended service lifeSolid waste disposalIncreasing energy efficiencySlagElectric machine

The invention belongs to the technical field of slag reutilization and particularly relates to a process for reusing slag of an aluminum smelting furnace. The process adopts the smelting furnace. Thesmelting furnace comprises a box body and further comprises a crushing unit, material guide units, a smelting chamber, a motor, a collecting box, a first pipe, a purifying unit and a controller. By the adoption of the process, on the one hand, in the process of mixing the aluminum slag and an aqueous solution of a sintering machine, the aluminum slag and the aqueous solution of the sintering machine are fully mixed to form blanks while being added and stirred; meanwhile, spray nozzles are used to spray water mist to the blanks during the pressurization and plasticity of the blanks, so that theblanks are tightly attached, no fracture occurs between the blanks during sintering in the sintering furnace, and thus the quality of a refractory blank is improved; and on the other hand, the formedrefractory blank is installed on the inner wall of the smelting chamber to prevent the smelting furnace from being damaged when aluminum metal is smelted, so that the service life of the smelting chamber is prolonged.

Owner:绥化春达矿渣高细制造有限公司

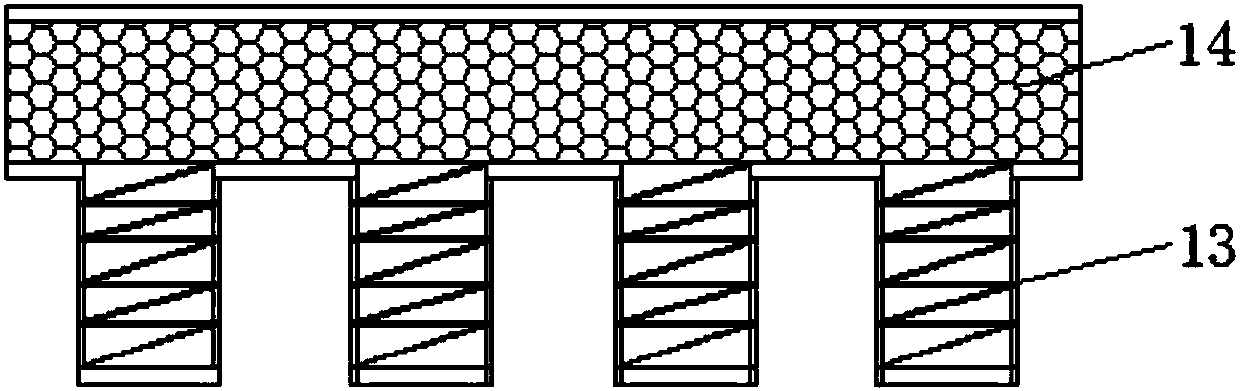

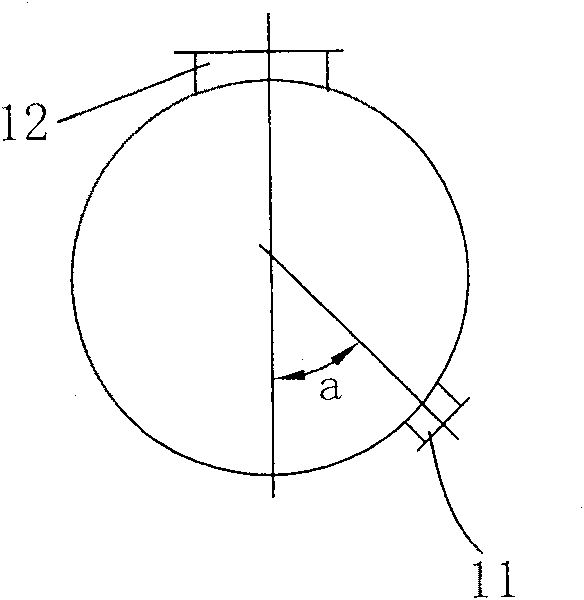

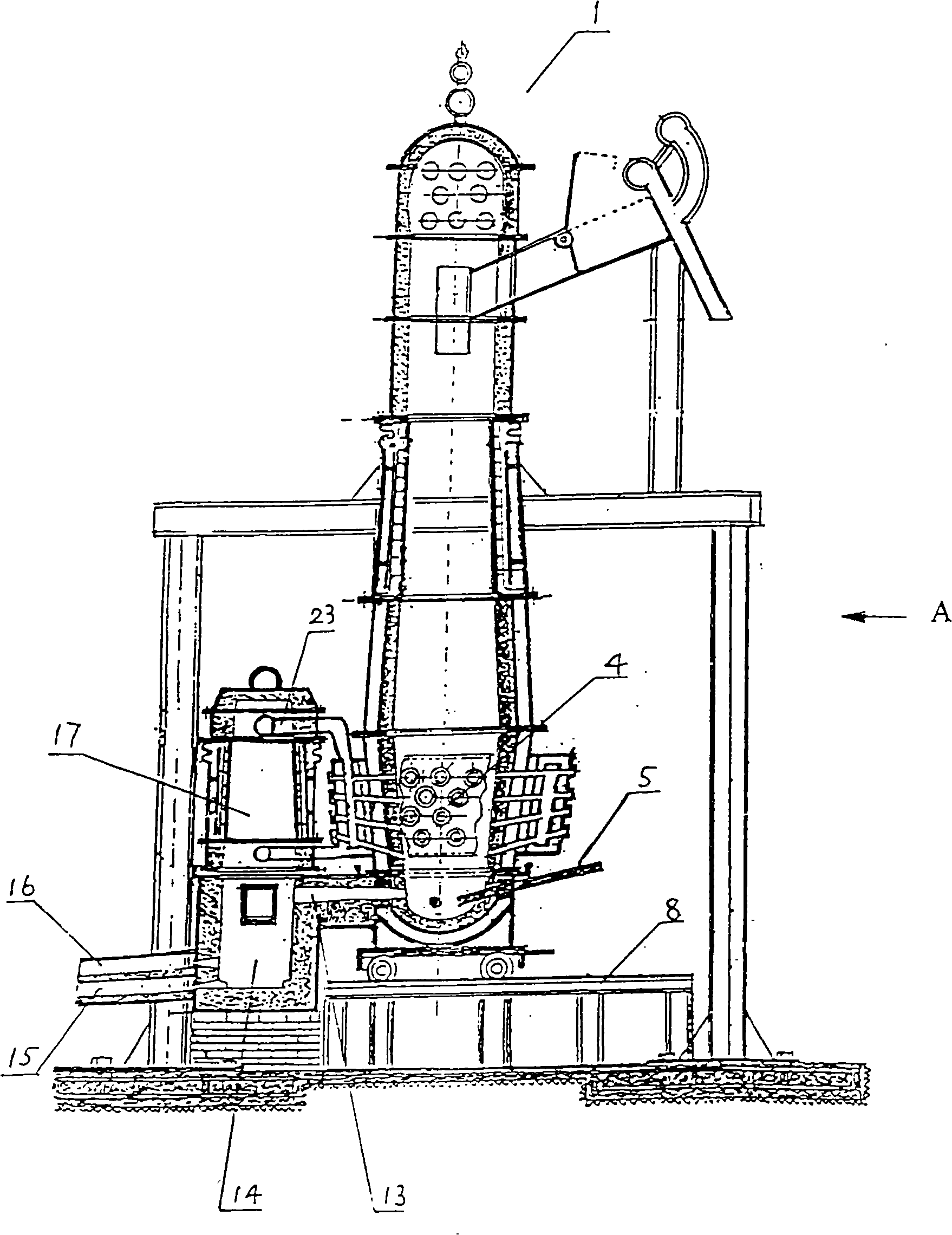

Method for smelting aluminum ore by carbon thermal reduction and non-ferrous metal smelting furnace therefor

InactiveCN101280367AReduce radiationSpeed up meltingFurnace typesProcess efficiency improvementFiberSlag

The invention relates to a method for reducing and smelting aluminum ore by using carbon heat and the nonferrous metal smelting furnace of the smelting aluminum ore, which belongs to the technical field of the metal ore smelting. The method is characterized in that the pellet preparation comprises the steps that, coal gangue, bauxite and waste fiber are crushed and levigated; binding agent is prepared; the powder or the short grained coal gangue and the bauxite are mixed uniformly with the fiber micro-particle in proportion; the mixture is made into the pellet by the binding agent; the pellet and the coke are put into smelting furnace alternatively. The smelting furnace is composed of a multi-hole melting zone connected with an air inlet pipe, a high temperature resistant furnace lining, a cooling atomizing sleeve, a pair of heating electrodes inserted at both sides of the smelting furnace bottom towards the centre and a cracking water burning chamber. After the method is applied, the polluted environment with black soot all over the sky is changed, and the distressed scene that the metal bearing slag is thrown away everywhere and the resources are wasted can be stopped; thus the resources is saved and used fully, and the environment is protected.

Owner:俞益根

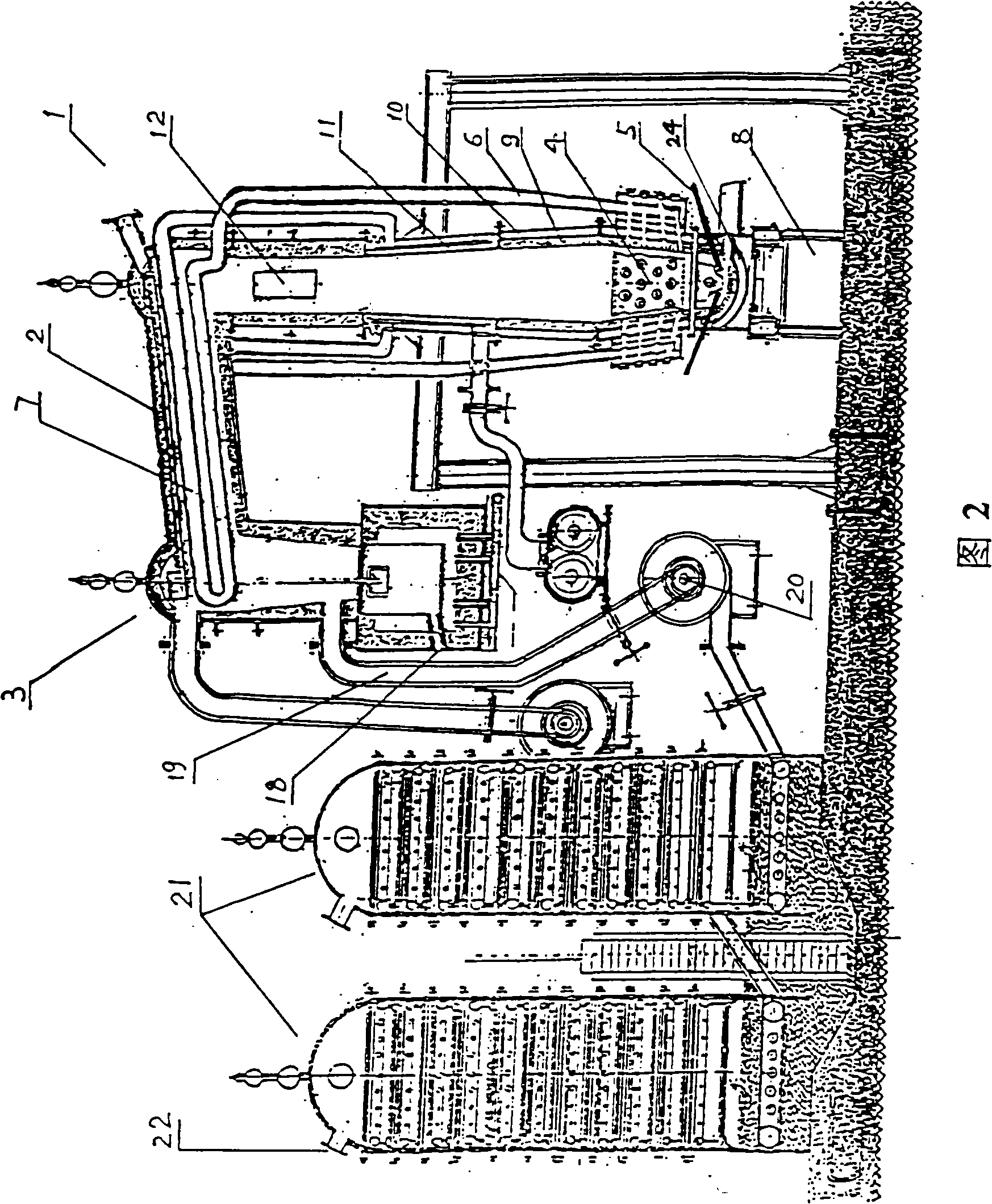

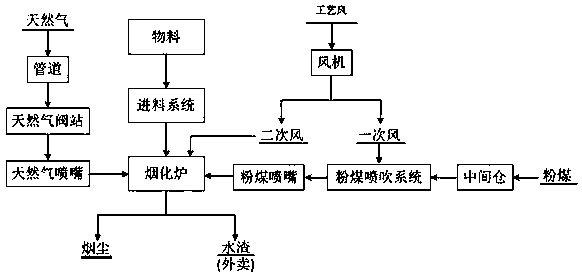

Reduction and volatilization smelting method of a composite fuel fuming furnace

ActiveCN107841625BFlexible operation and easy adjustmentHigh degree of automationProcess efficiency improvementSmelting processFuel supply

The invention relates to a composite fuel fuming furnace reduction and volatilization smelting method and belongs to the technical field of thermometallurgy. The method comprises the steps that pulverized coal and natural gas are adopted as a composite fuel of reduction and volatilization smelting of a fuming furnace, the natural gas is sprayed into the fuming furnace through natural gas spray nozzles, the pulverized coal and primary air are blended in a pulverized coal fuel supply system and then sprayed into the fuming furnace through pulverized coal spray nozzles; and in the reduction and volatilization smelting process, the pulverized coal spray amount and the natural gas spray amount are regulated according to the situation of cold and hot materials of the fuming furnace. By adoptingthe reduction and volatilization smelting method, the temperature rising speed is high, the fuming furnace is flexible to operate, regulation is easy and convenient, the automation degree is high, andthe problems that supply of the pulverized coal or the fuel gas is interrupted and consequentially slag discharging of the fuming furnace is difficult can be effectively prevented; clean and long-period continuous production and operation can be achieved, reduction and volatilization reaction of the fuming furnace is more thorough, and matching with an upstream and downstream operation system isfacilitated; and the production efficiency is high, production control is stable, and stable and refined production control can be achieved easily.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

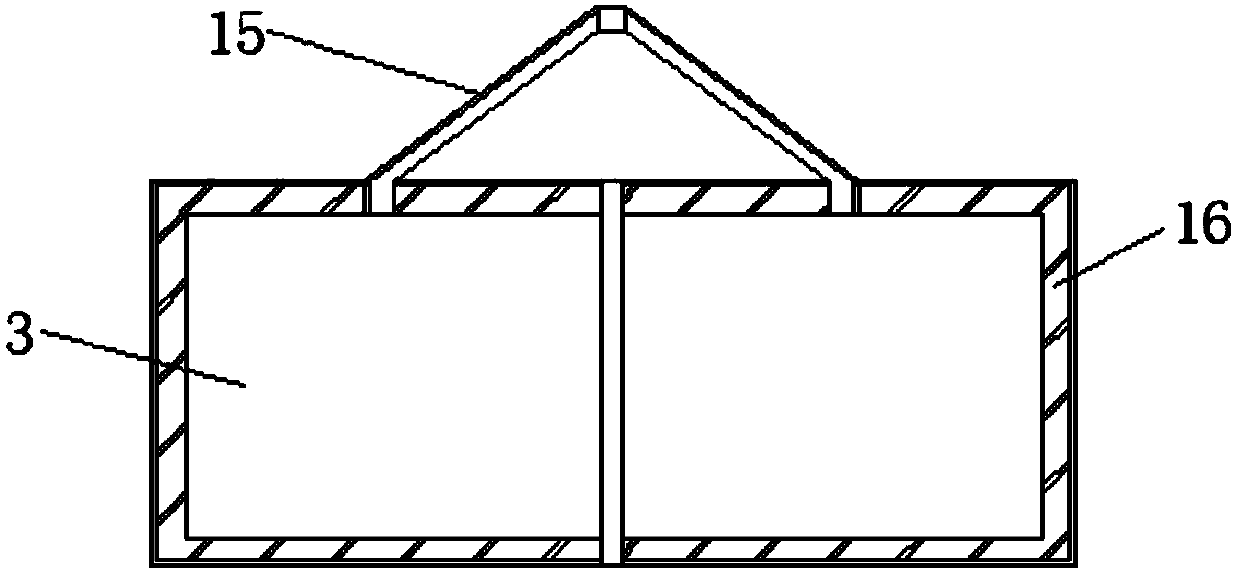

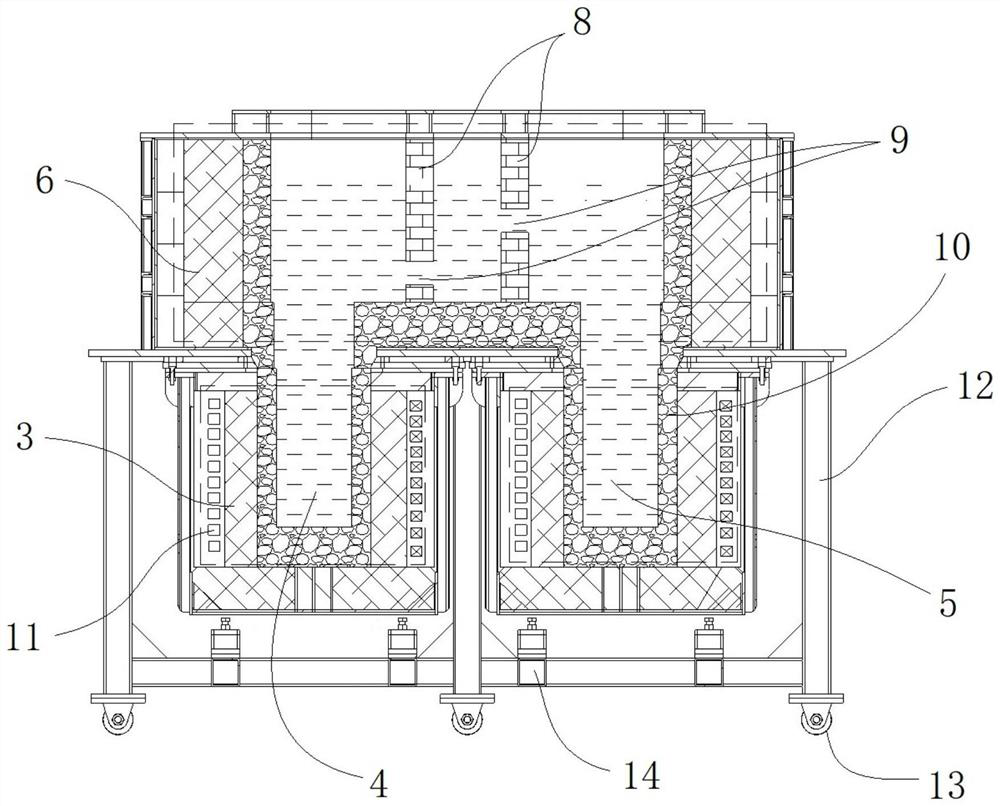

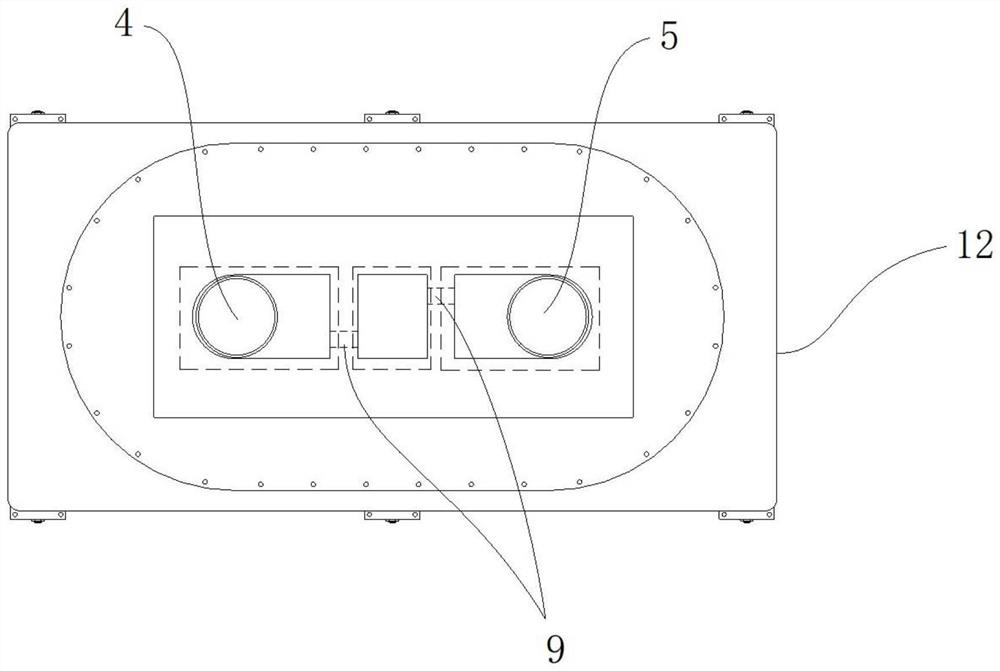

Double-chamber aluminum alloy smelting furnace

InactiveCN112229216AFully smeltedEasy to useCharge composition/stateCharge treatment typeDrive motorManufacturing engineering

The invention discloses a double-chamber aluminum alloy smelting furnace. The smelting furnace comprises a box body, a driving motor is fixedly connected to the right side of the inner wall of the bottom of the box body, a rotating shaft is welded to an output shaft of the driving motor, an eccentric wheel is welded to the outer ring of the rotating shaft, a second bevel gear is welded to the topend of the rotating shaft, a preheating box is welded to the right side of the inner wall of the top of the box body, a conveying box is welded to the left side of the bottom of the preheating box, arotating roller penetrating through and extending out of the conveying box is connected to the inner wall of the left side of the conveying box in a rotating mode, a conveying roller is welded to theouter ring, located in the conveying box, of the rotating roller, a first bevel gear is welded to the end, located outside the conveying box, of the rotating roller, and a partition plate is welded tothe left side of the conveying box. The smelting furnace has the advantages that the structure is simple, the design is novel, the combustion efficiency of fuel can be improved, the utilization rateof heat energy can be improved, aluminum alloy can be fully smelted, the use is easy, the practicability is high, and the smelting furnace is suitable for wide popularization.

Owner:CHANGDE HUAHAI HYDRAULIC MACHINERY MFG

Method for utilizing crystalline silicon cutting waste

The invention discloses a method for utilizing crystalline silicon cutting waste. The method comprises the following steps of smelting a ferromolybdenum alloy by using a pellet material containing the silicon cutting waste to obtain the ferromolybdenum alloy. The pellet material is prepared from, by mass, 100-150 parts of molybdenum calcine, 30-40 parts of the silicon cutting waste, 8-15 parts of aluminum particles, 30-38 parts of iron phosphorus, 30-42 parts of steel cuttings, 12-15 parts of quick lime, 2-5 parts of fluorite and 7-10 parts of saltpeter. The silicon cutting waste adopts monocrystalline silicon and / or polycrystalline silicon cutting waste, and the silicon cutting waste contains metal Si, SiC and polyethylene glycol. According to the method, the crystalline silicon cutting waste is used for ferromolybdenum smelting, ferrosilicon is replaced to serve as a reducing agent, the production cost in ferromolybdenum smelting is effectively reduced, and efficient and large-scale utilization of the crystalline silicon cutting waste is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Bottom-blowing smelting equipment

The invention discloses bottom-blowing smelting equipment, which comprises a furnace body. A material inlet and a flue gas outlet are arranged at the upper part of the furnace body. A product outlet and a slag outlet are arranged on the side part of the furnace body. A vulcanizing agent steam passage and a reaction gas passage are arranged at the bottom of the furnace body to respectively feed vulcanizing agent and reaction gas into the furnace body. The bottom-blowing smelting equipment provided by the embodiment of the invention has the advantages that since the reaction materials are added into the furnace body from the top of the furnace body and the reaction gas and the vulcanizing agent are fed into the furnace body from the bottom of the furnace body, the reaction materials can be agitated, the smelting reaction is enabled to be more full and the consumption of energy for reaction is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

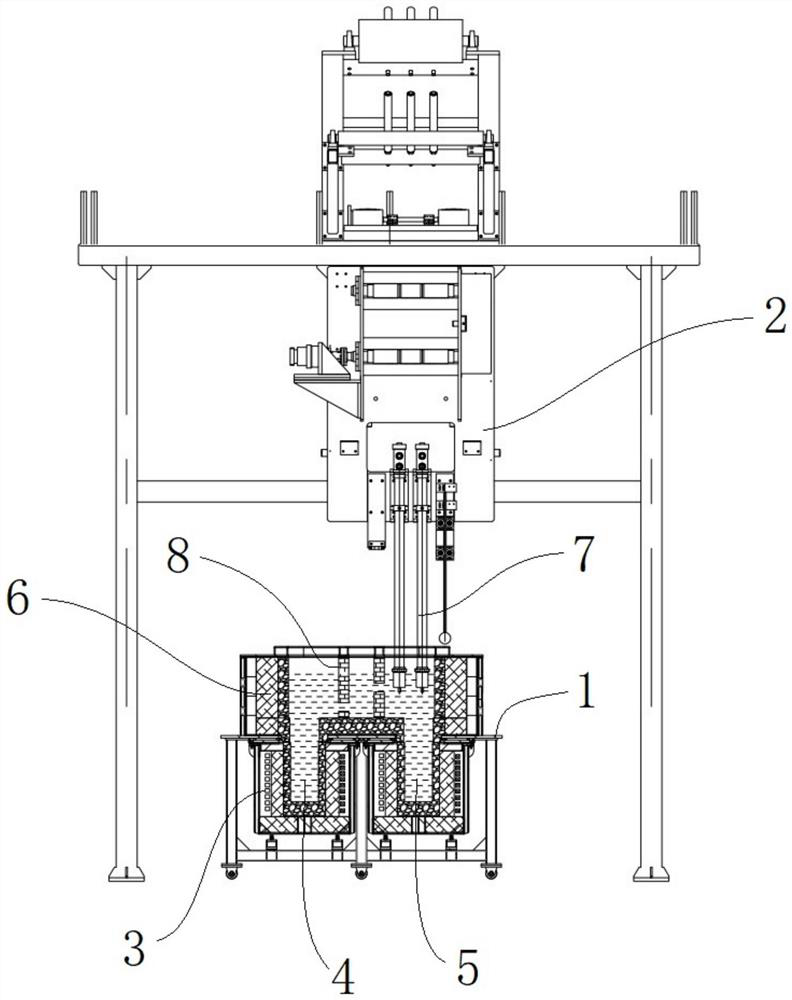

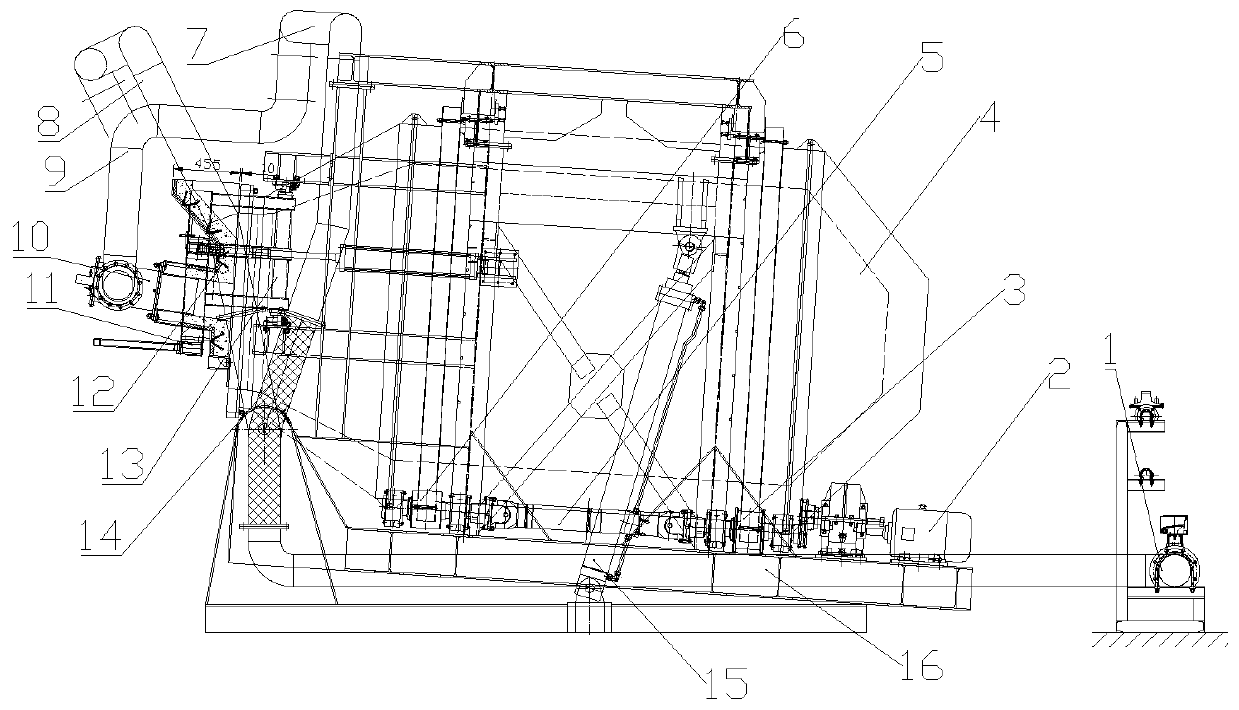

Automatic furnace overturning machine long-distance wireless control system

PendingCN108981399AFully smeltedCharge manipulationControl devices for furnacesWireless controlControl system

The invention discloses an automatic furnace overturning machine long-distance wireless control system. The system comprises a mechanical furnace overturning device and a wireless long-distance control system, and the mechanical furnace overturning device is formed by four main parts including a left-right swing mechanism, an advancing / retreating mechanism, an up-and-down inclining mechanism and afurnace overturning stretching mechanism. By means of the system, the wireless long-distance control system controls operation of the four main mechanisms of the mechanical furnace overturning device, and therefore silicon smelting raw materials are evenly distributed around a smelting electrode, and the raw materials can be sufficiently smelted.

Owner:杨金龙

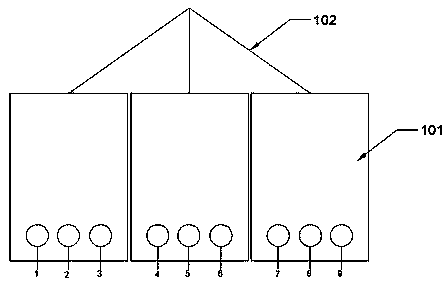

Continuous smelting furnace and ingot casting system with same

The invention provides a continuous smelting furnace and an ingot casting system with the continuous smelting furnace, and belongs to the technical field of smelting and casting equipment.The continuous smelting furnace comprises at least two coreless medium-frequency induction furnaces arranged side by side; the undercurrent heat preservation furnace is connected to the upper portions of the coreless medium-frequency induction furnaces which are arranged side by side, the bottom of the undercurrent heat preservation furnace communicates with the upper portion of each coreless medium-frequency induction furnace, and the undercurrent heat preservation furnace is provided with a blocking wall in the middle of the upper portion of every two adjacent coreless medium-frequency induction furnaces. A through hole suitable for molten liquid to pass through is formed in the blocking wall; according to the continuous smelting furnace, the multiple coreless medium-frequency induction furnaces are arranged in parallel, the upper ends of the multiple coreless medium-frequency induction furnaces are communicated through the undercurrent heat preservation furnace, and after materials are melted in one coreless medium-frequency induction furnace, the materials flow into the other coreless medium-frequency induction furnaces through the undercurrent heat preservation furnace to be subjected to heat preservation for casting; therefore, continuous smelting of the materials is achieved.

Owner:江西慧高导体科技有限公司

A recycling aluminum automatic melting aluminum iron separation device

ActiveCN111763829BPurificationFully smeltedProcess efficiency improvementElectrolytic agentElectric machine

The invention discloses an aluminum-iron separation device for automatic melting of recycled aluminum and relates to the technical field of recycled aluminum smelting. The invention includes a smelting and separating furnace and a separating device, wherein a stirring motor is installed on the surface of the smelting and separating furnace, and an electric heating block is installed inside. In the present invention, by setting a smelting separation furnace and a separation device, and connecting the two with each other, the waste aluminum material is automatically melted and separated from iron impurities, and through two-stage separation, it is beneficial to the purification of recycled aluminum and improves the separation efficiency; by setting a stirring motor , the smelting and separation furnace can fully smelt the waste aluminum by using the stirring effect; at the same time, by setting the filter hole, it is convenient to separate the completely smelted aluminum liquid from the iron impurities, and flow into the auxiliary separation box along the separation channel for the next step One-step separation process; by setting up an auxiliary separation box, using the method of injecting coolant and electrolyte into the box, the aluminum liquid is rapidly cooled and condensed into a solid, and then the electrolyte is used to separate trace impurities on the surface to complete the separation.

Owner:重庆顺博铝合金股份有限公司

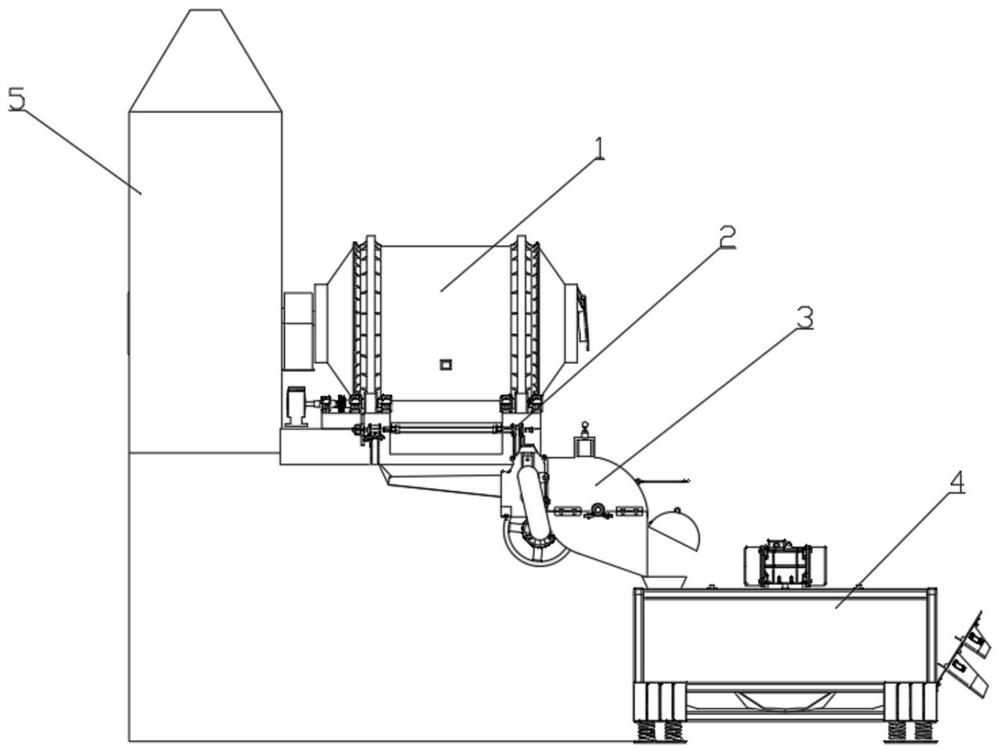

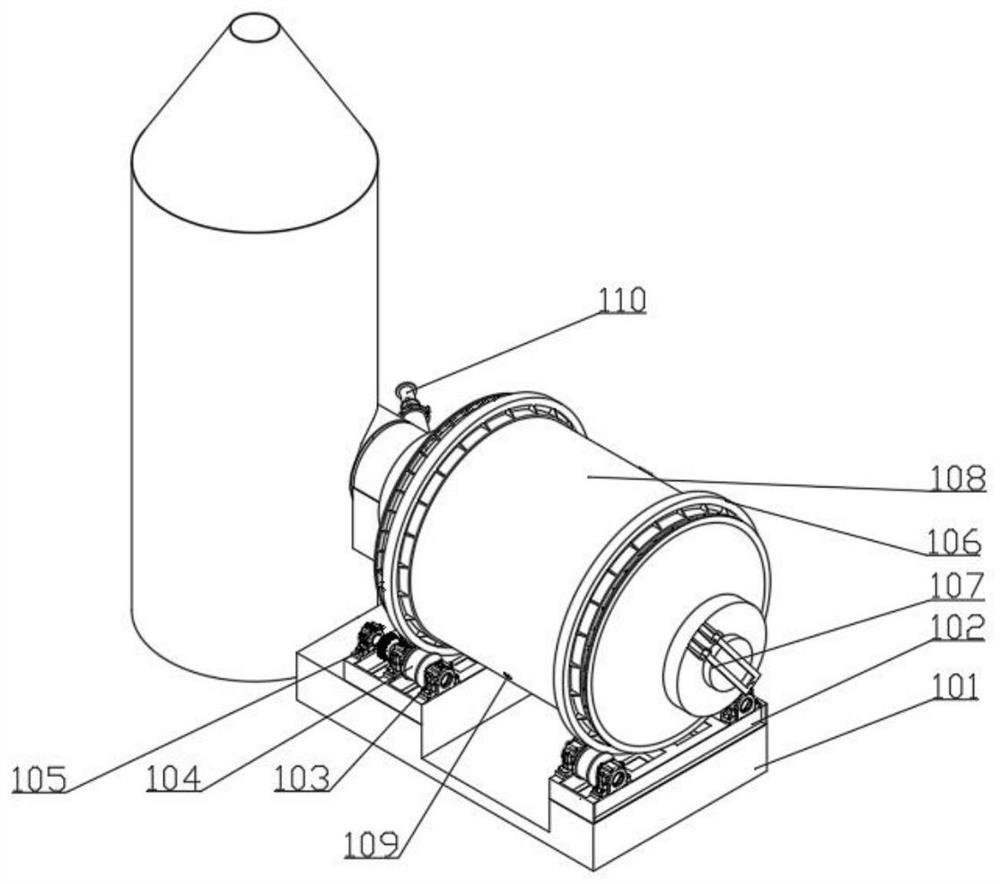

High-efficiency rotary furnace

InactiveCN111380356AImprove melting efficiencyFully smeltedRotary drum furnacesCombustion systemThermodynamics

The invention provides a high-efficiency rotary furnace. The high-efficiency rotary furnace comprises a rotary furnace body, a rotary power system, a circulating system, a combustion system and an airblowing system. The combustion system is arranged at one end of the rotary furnace body. The circulating system communicates with the combustion system. The air blowing system communicates with the circulating system and the combustion system. The rotary power system is arranged on the outer side of the rotary furnace body. The high-efficiency rotary furnace saves energy, is efficient and can fully smelt aluminum materials and reduce the aluminum oxidation burning loss rate.

Owner:SUZHOU XIAOBO TECH

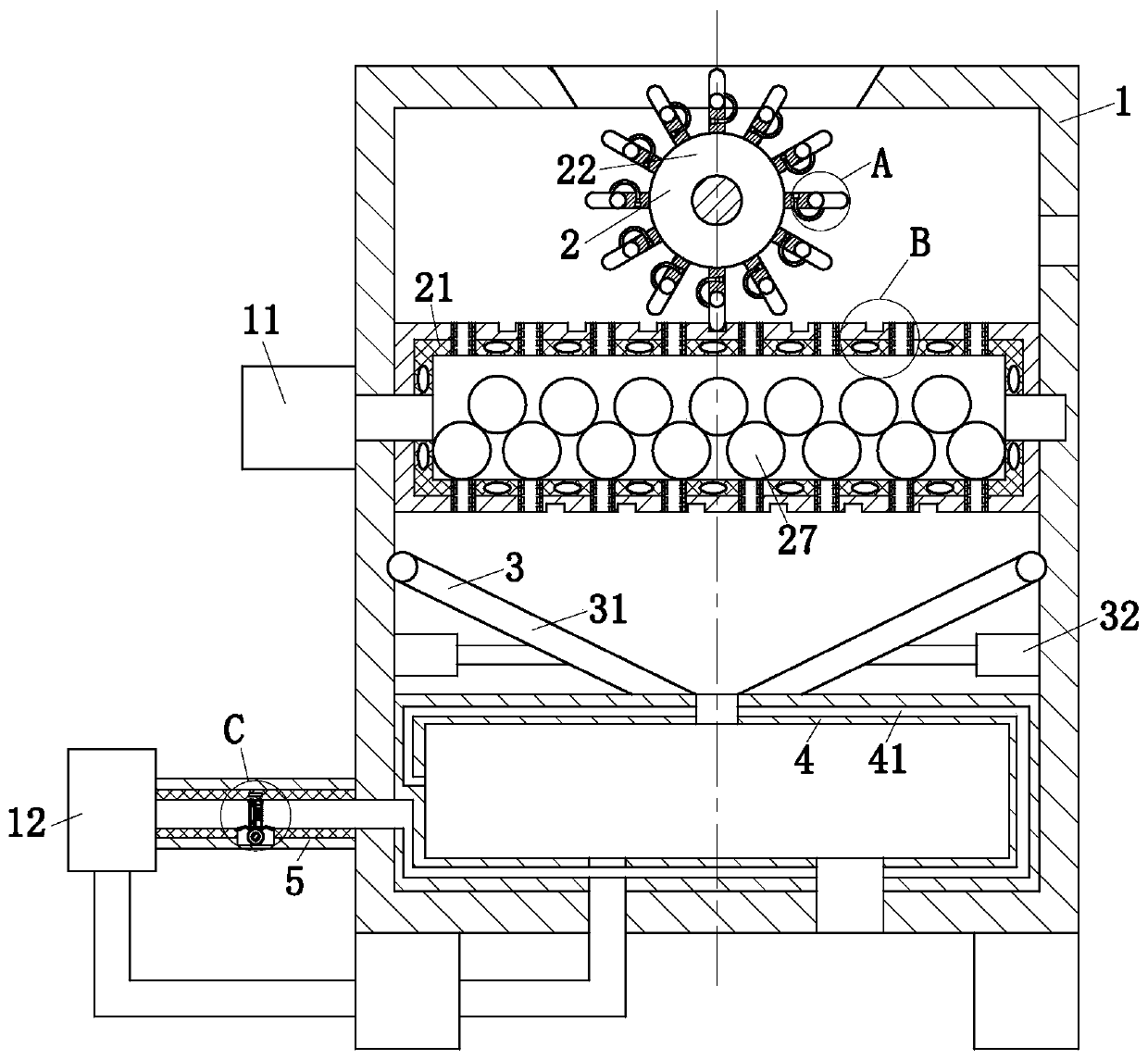

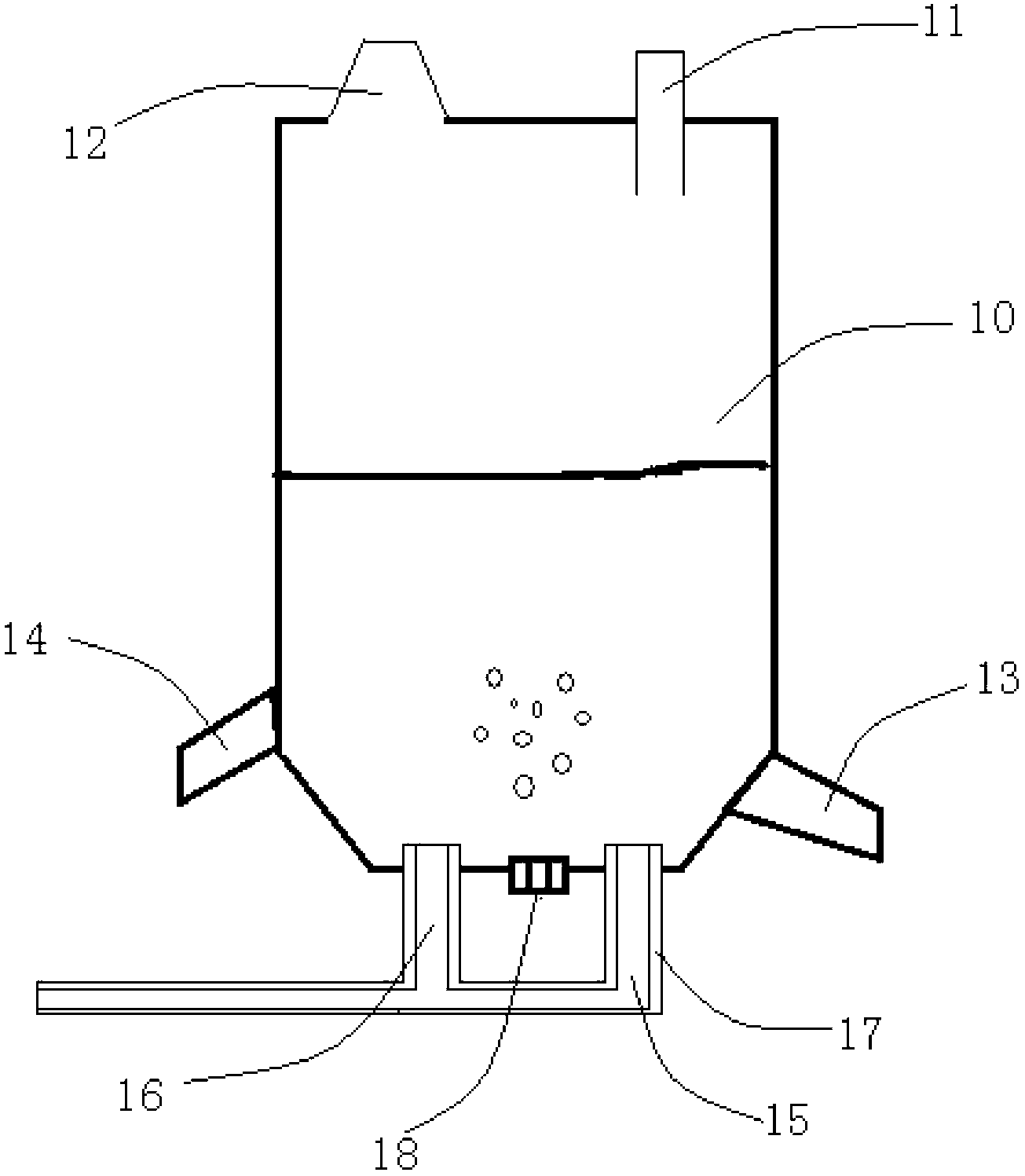

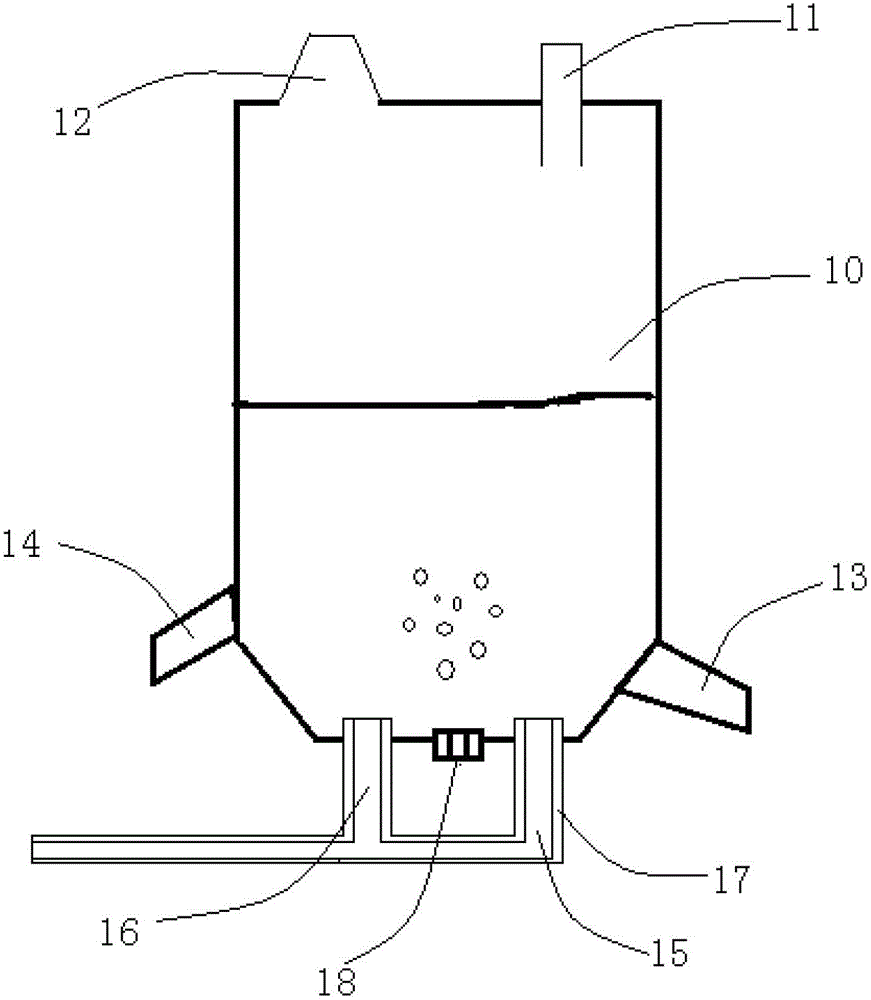

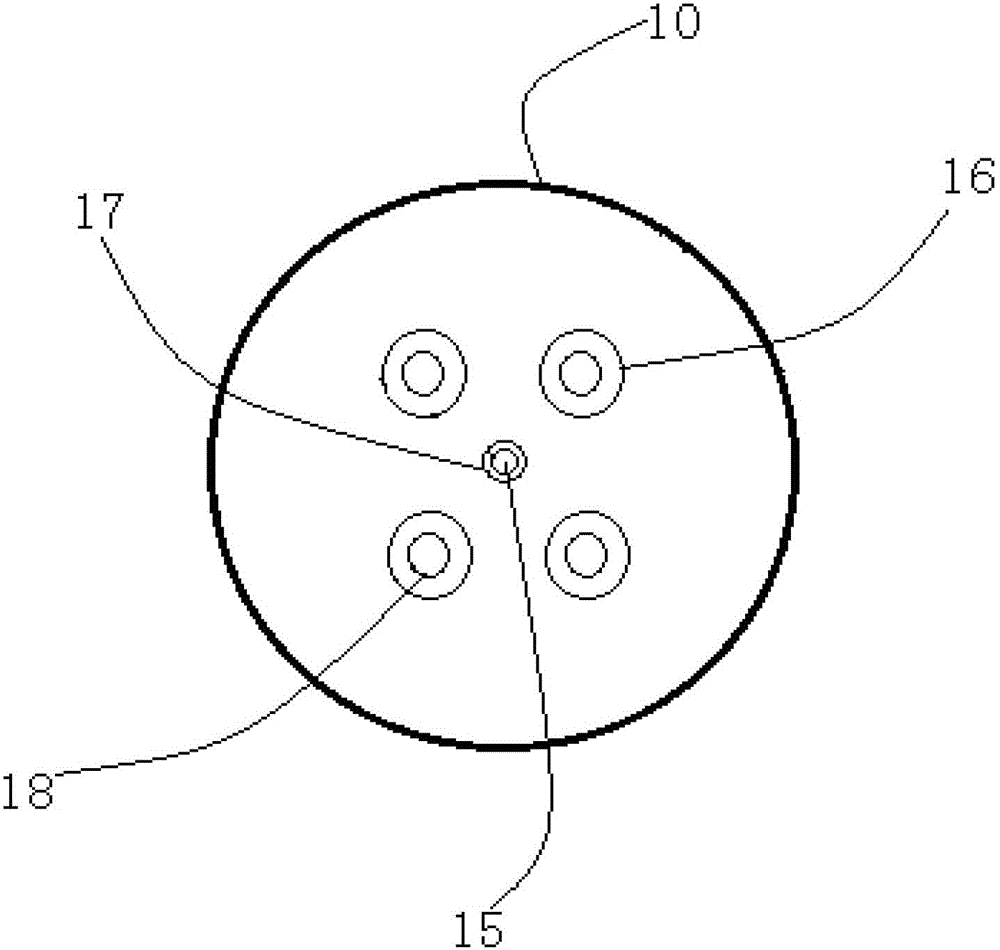

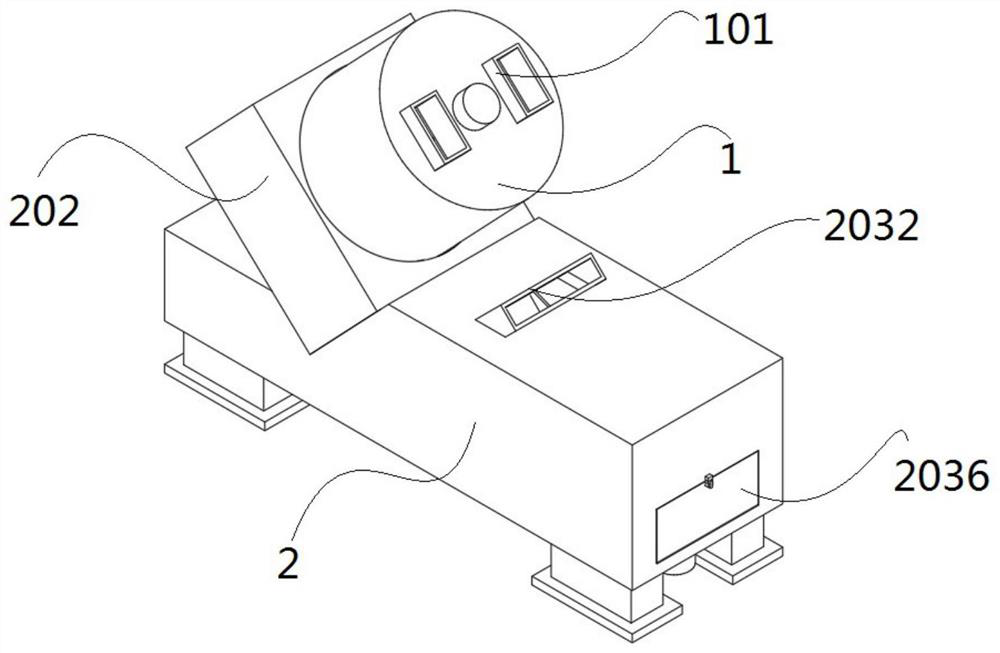

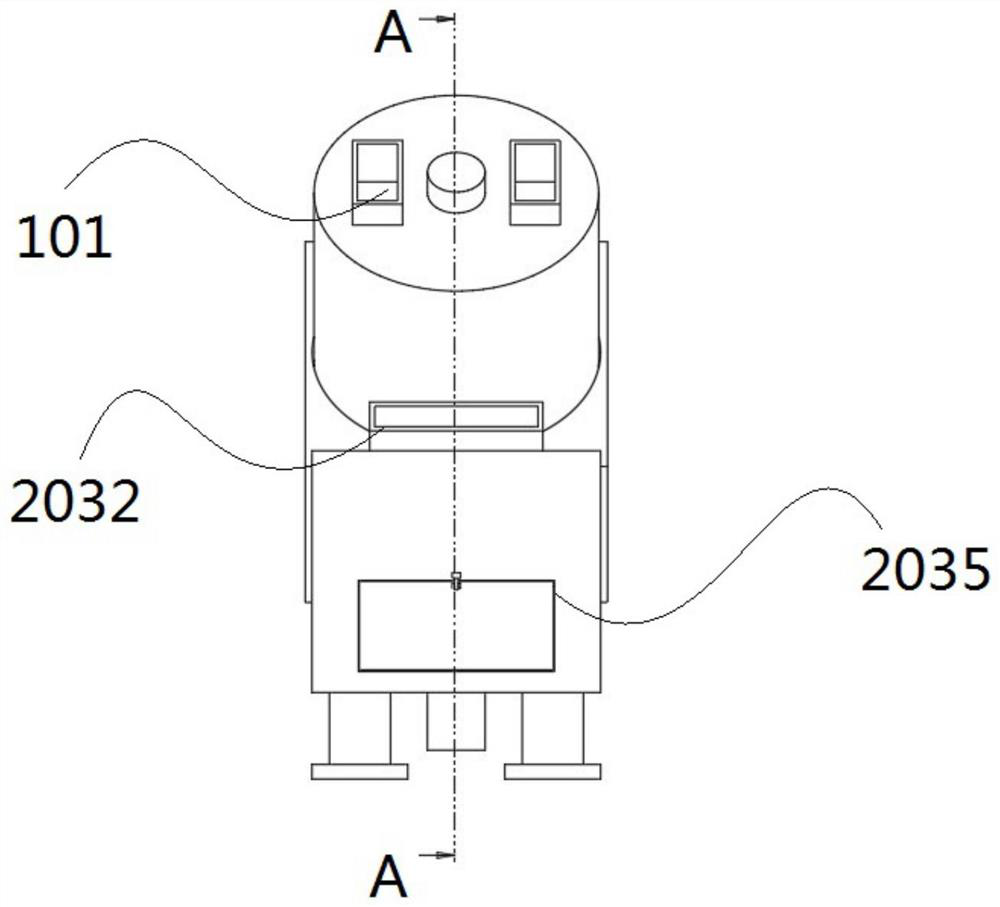

a metal smelting furnace

ActiveCN109737752BImprove smelting efficiencyScientific and reasonable structureCharge manipulationControl devices for furnacesElectric machineGas cylinder

The invention belongs to the technical field of metal smelting, and particularly relates to a metal smelting furnace. The metal smelting furnace comprises a box body, and further comprises a crushingunit, a material leading unit, a smelting chamber, a motor, a collecting box, a first pipe, a purification unit and a controller, wherein a crushing cylinder is driven by the motor to rotate, second crushing teeth are matched with spiral grooves to enable a rotating wheel to rotate, and the crushing cylinder and the second crushing teeth are matched to grind metal; and meanwhile, the collision among crushing balls is utilized to crush the metal, the gas generated by extruding an elliptical chamber is acted into a first gas cylinder, the second crushing teeth which are not meshed with the spiral grooves are rotated, first crushing teeth and the second crushing teeth are matched to crush the metal. The metal is crushed, smashed and crunched, the crushed metal can be fully smelted in a smelting chamber, and then the metal smelting effect is improved.

Owner:太和县奥能金属材料有限公司

Molten iron smelting additive and preparation method thereof

InactiveCN112176146AFully smeltedSpeed up smeltingGas emission reductionCarbide siliconSmelting process

The invention provides a molten iron smelting additive and a preparation method thereof, and relates to the technical field of molten iron smelting. The molten iron smelting additive comprises nano-silica, silicon carbide powder and aluminum sesquioxide powder, wherein the particle size distribution of nano-silica powder is 30-100 nanometers; the particle size of at least 20 percent by mass or more of the silicon carbide powder is smaller than or equal to 80 nanometers; the particle size of at least 15 percent by mass or more of the aluminum sesquioxide powder is smaller than or equal to 80 nanometers; and the mass ratio of the nano-silica to the silicon carbide powder to the aluminum sesquioxide powder is 5 to 0.12 to 0.03. According to the molten iron smelting additive and the preparation method thereof provided by the invention, the additive is directly added into a smelting furnace for use, is gradually fused with molten iron into a whole in the smelting process, and is simple in practical method, the technological process is easy to control, the molten iron smelting speed can be effectively increased, and molten iron smelting is more sufficient.

Owner:南京辉腾机械铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com