Method for smelting aluminum ore by carbon thermal reduction and non-ferrous metal smelting furnace therefor

A smelting furnace and aluminum ore technology, applied in the field of non-ferrous metal smelting furnaces, can solve the problems of wasting resources, polluting the environment, and high cost, and achieve the effects of saving resources, maintaining the environment, and uniform smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

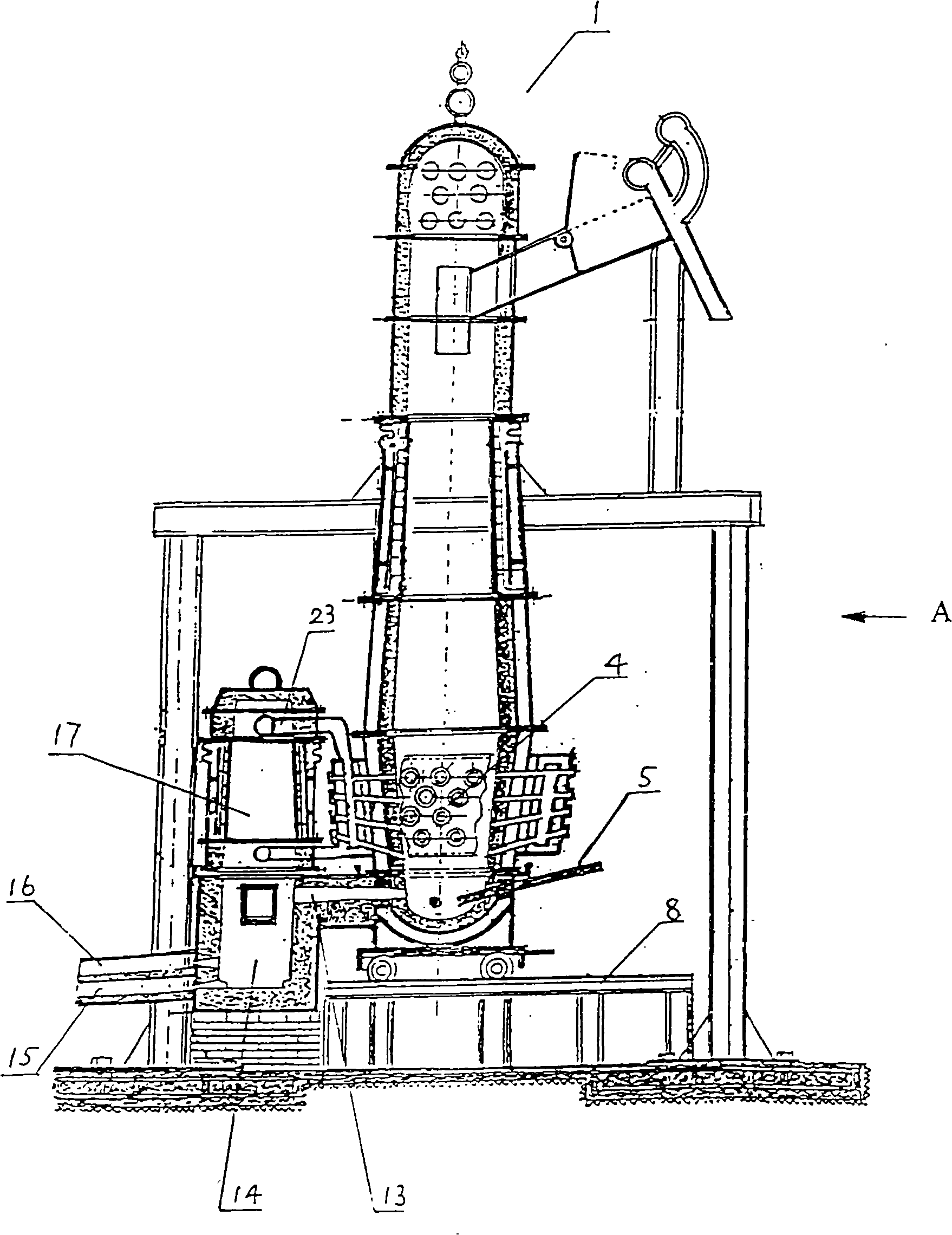

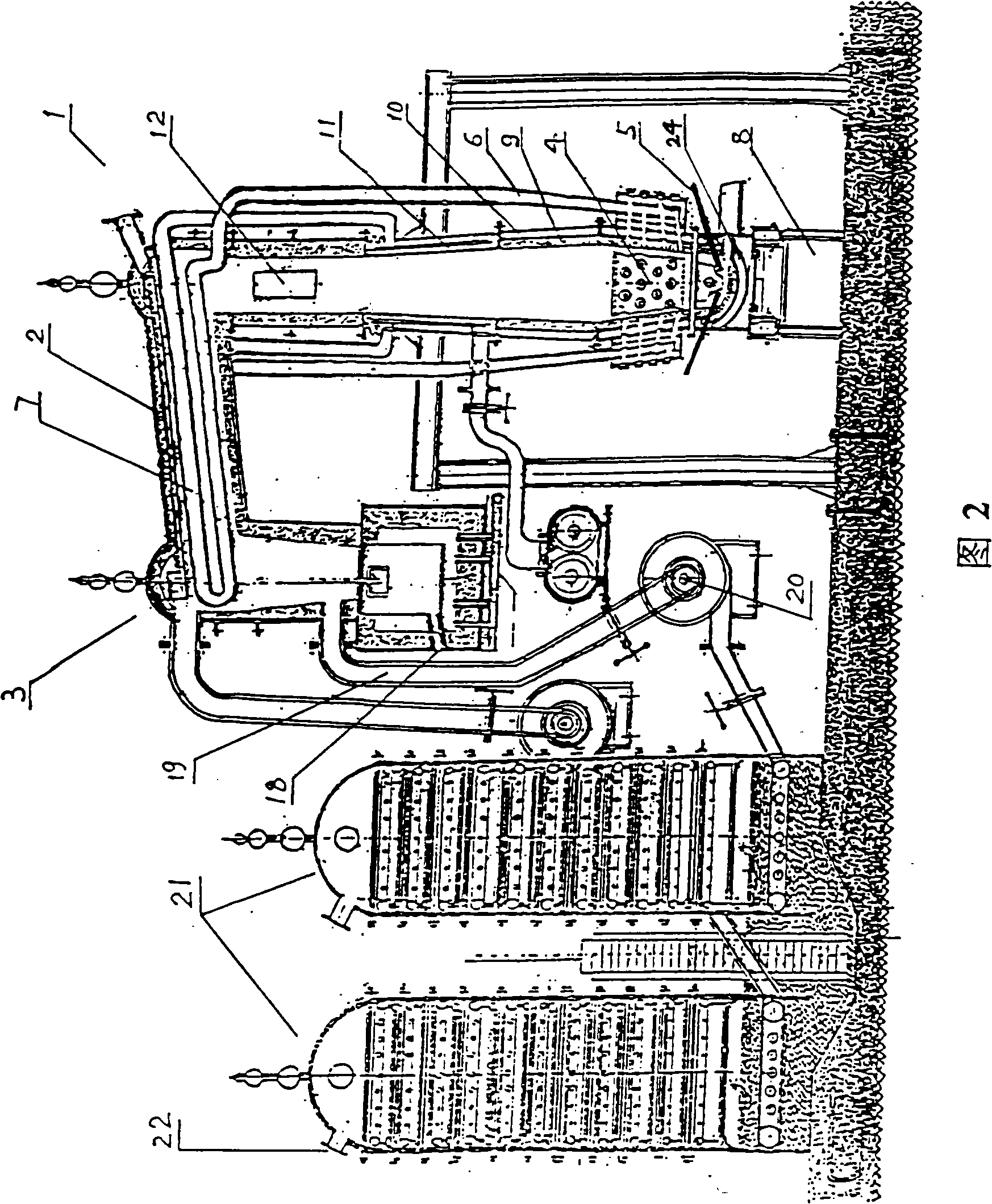

[0029] The present invention will be further described now in conjunction with accompanying drawing

[0030] A method for smelting aluminum ore by carbothermal reduction, the operation is completed according to the following technological process:

[0031] 1) Preparation of pellets

[0032] ①Crush and grind coal gangue and bauxite,

[0033] ②Crush and grind waste fibers,

[0034] ③ Preparation of binder,

[0035] ④ Evenly mix powdery or small granular coal gangue, bauxite and fiber particles in a fixed proportion as required to form a mixture;

[0036] ⑤ Mixing 5% to 6% of the binder with the rest as a mixture to make a mixed pellet;

[0037] ⑥ Dry or dry the mixed pellets for later use;

[0038] 2) Furnace smelting process:

[0039] ① Put one layer of mixed pellets and one layer of coke, one layer of mixed pellets and one layer of coke, and put the mixed pellets and coke interlayer into the non-ferrous metal smelting furnace,

[0040] ②The rising waste hot gas in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com