Bath smelting method for waste

A technology for molten pool smelting and waste, which is applied in the removal of solid waste, chemical instruments and methods, and improvement of process efficiency, etc., can solve the problems of secondary pollution treatment scale, etc. Reducing the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] raw material:

[0060] Solid organic hazardous waste (HW12, dye and paint waste), calorific value 3400Kcal / kg, waste mineral oil (HW08, calorific value 9000kcal / kg), rotary kiln incineration slag (HW18).

[0061] Slagging agent: limestone, steel slag.

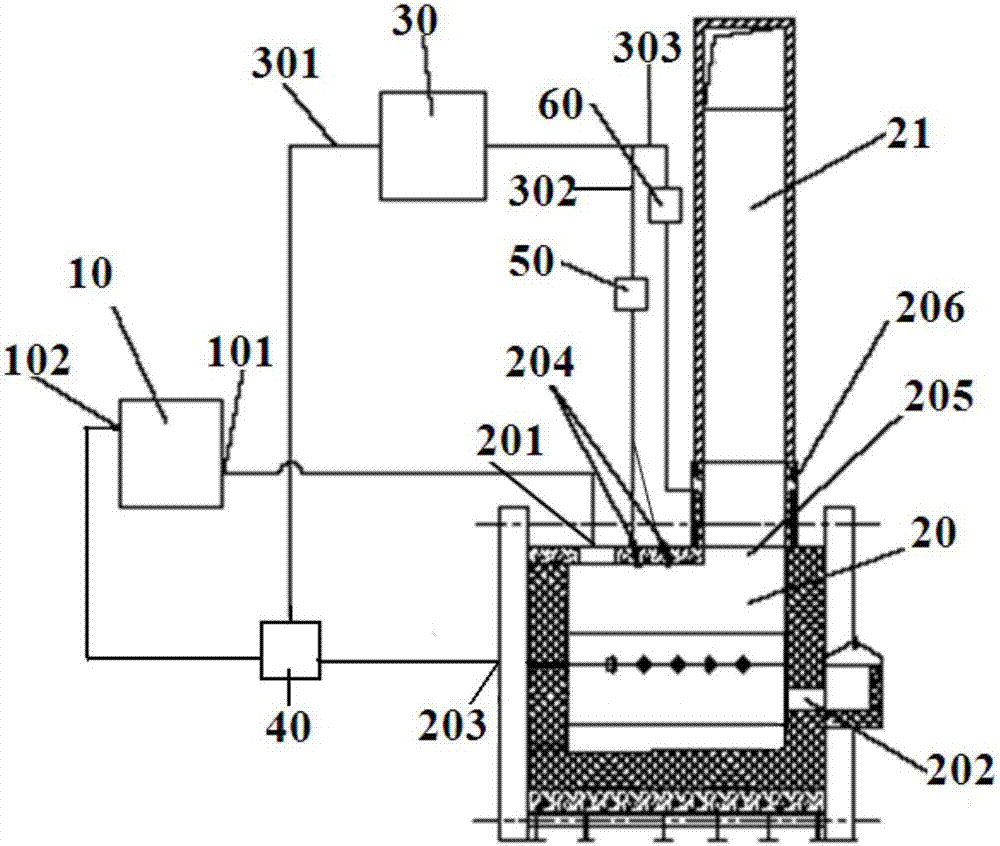

[0062] Solid organic hazardous waste, rotary kiln slag, slagging agent and waste mineral oil are sprayed into the figure 1 Treatment is carried out in the waste treatment system shown, the slag is removed and water quenched. The melting parameters are shown in Table 1.

[0063] The industrial composition of organic hazardous waste is shown in Table 2.

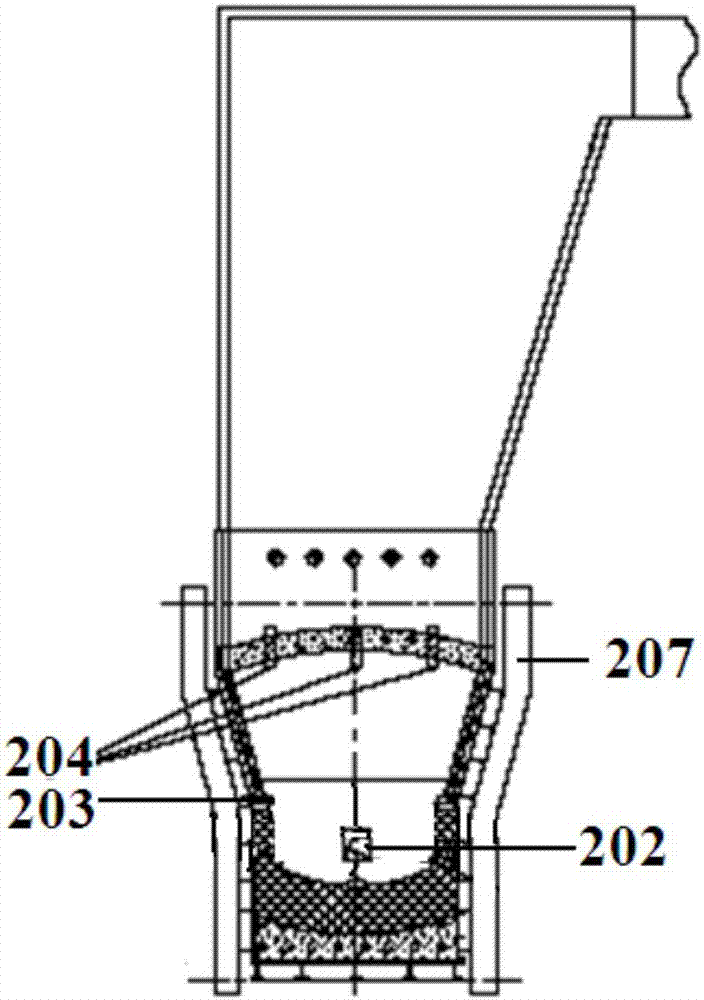

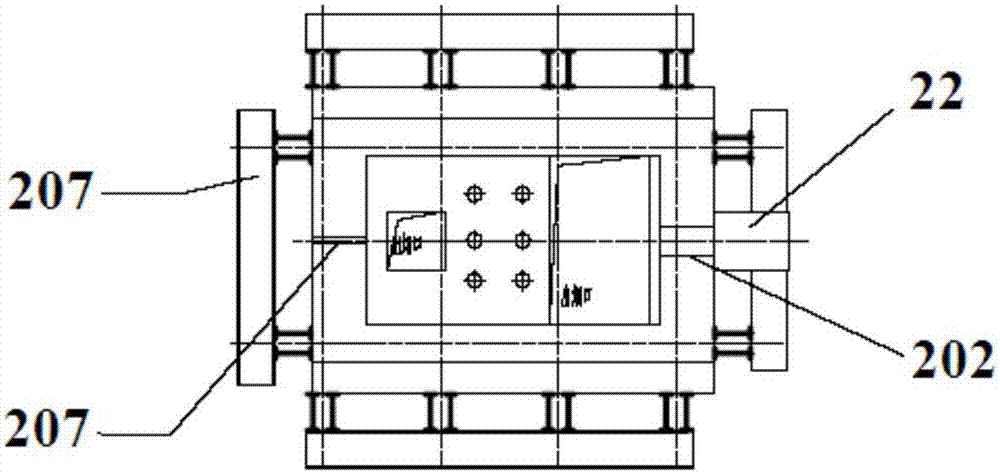

[0064] The waste treatment unit is a side-blowing smelting furnace, and its material balance is shown in Table 3.

[0065] Discharge the main pollutants in the flue gas, Table 4.

[0066] See Table 5 for the results of the leaching toxicity analysis of the discharged slag.

[0067] The melting point of the slag is 1220°C, the viscosity value at 1300°C is 0.23Pa·s, a...

Embodiment 2

[0069] The difference from Example 1 is that the melting temperature is 1100°C. As a result, the molten slag was not completely melted, and the viscosity value was 3.3 Pa·s at the smelting temperature, which was difficult to discharge slag compared with Example 1.

Embodiment 3

[0071] The difference from Example 1 is that the weight content of CaO in the slag is increased to 35%, and the weight content of FeO is correspondingly reduced to 18%. As a result, the melting point of the slag rises above 1300° C., the slag is not completely melted at the melting temperature, and the viscosity value at the melting temperature is 2.8 Pa·s, which is difficult to discharge slag compared with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com