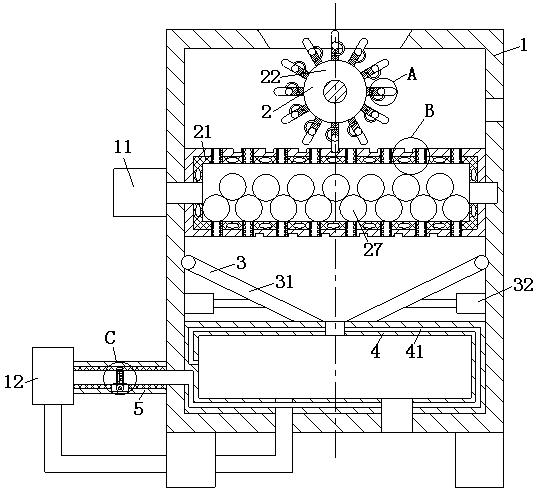

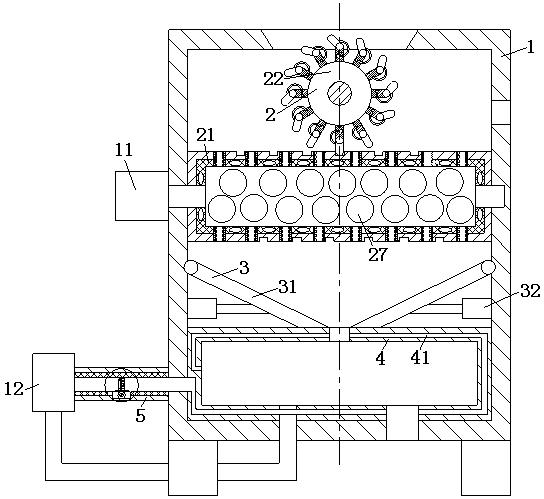

a metal smelting furnace

A metal smelting and metal technology, applied in the field of metal smelting, can solve the problems of exhaust gas pollution, insufficient metal crushing, etc., achieve huge economic benefits, improve the efficiency of metal smelting, and be easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

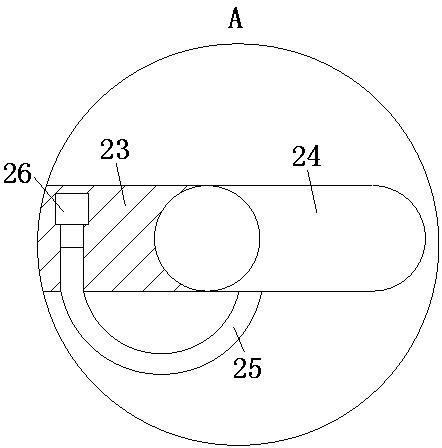

[0027] As an embodiment of the present invention, the No. 1 hole 211 is provided with a grinding unit 7; the grinding unit 7 is used for grinding metal, and the grinding unit 7 includes a dust-staining plate 71 and a grinding block 72; The gray plate 71 is clamped on the side wall of the No. 1 hole 211 ; the grinding blocks 72 are discontinuously arranged on the dust staining plate 71 , and the grinding blocks 72 are fixedly connected to the dust staining plate 71 . A lot of dust is generated during the crushing of metals, and the dust falling into the smelting chamber 4 will affect the metal smelting, thereby reducing the effect of metal smelting; the present invention sets the grinding unit 7, on the one hand, the dust-stained plate 71 is clipped together On the side wall of the number hole 211, the dust produced in the metal crushing is adhered by the ash-staining plate 71, so as to avoid affecting the metal smelting due to the dust, thereby improving the metal smelting effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com