Patents

Literature

338results about How to "Big market demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling temperature in the production process of seaweed polysaccharide plant empty capsules

The invention discloses a temperature control technology and temperature control parameters for all production processes which have significant influences on the production quality of enterprises engaged in the production of hardshell empty capsules, in particular to a method for controlling the temperature in the production process of seaweed polysaccharide plant empty capsules. The method adopts cellulose hydroxypropyl methyl ether as film forming agent, seaweed polysaccharide as film assisting agent, hydrolyzed starch as thermal reversible colloid and calcium citrate as coagulant aid; the dissolution temperature of all raw materials in capsule material is controlled at 70-90 DEG C; the balanced reaction time of solution is within 2-4 hours, and the reaction temperature is 70-80 DEG C; the adhesive film-forming temperature is 45-55 DEG C; the adhesive time is controlled at 3-7 seconds; the humidity of a film forming workshop is controlled to be 30-45 percent, and the temperature in the film forming workshop is 30-36 DEG C; the temperature of a drying channel is controlled at 30-40 DEG C, and the humidity of the drying channel is controlled to be 30-45 percent; and the temperature of a plastic plate is controlled at 32-37 DEG C.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Polyethenoxyamines used as main agent of gasoline detergent and preparation method thereof

InactiveCN101225332AUnique chemical structureEasy to cleanOrganic chemistryLiquid carbonaceous fuelsCombustion chamberHydrogen

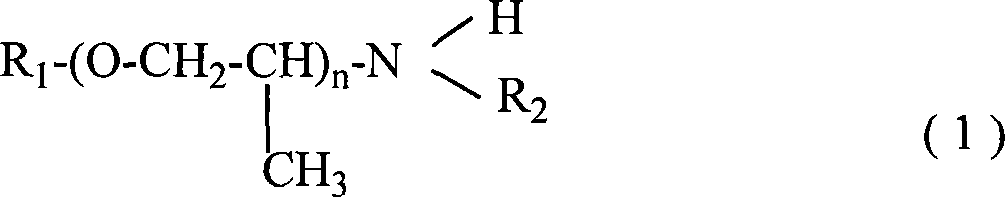

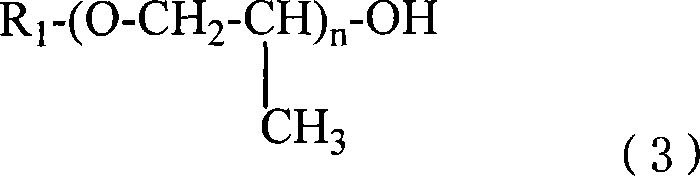

The invention relates to a polyetheramine used as the major component of gasoline detergent and the preparation method, which can be indicated by a general formula (1), in the formula (1), n is the repeated unit of the polyether segmer and the value is between 9 to 34; R1 is any one of the alkyl (C4 to C20), nonyl phenyl, octyl phenyl, dodecyl phenyl, pentadecyl phenyl, dinonyl phenyl and 2,6-di-tert-butyl-p-methylphenyl; R2 is any one of the hydrogen, methyl, ethyl, isopropyl or butyl. The preparation method comprises two steps: the preparation of polyether and the preparation of polyetheramine by the polyether with hydro-ammonification in a batch tank reactor. The polyetheramine used as the major component of gasoline detergent can be used as the major component of gasoline detergent and has the advantages of inhibiting carbon accumulation in the intake system and the combustion chamber of gasoline engine.

Owner:金浦新材料股份有限公司

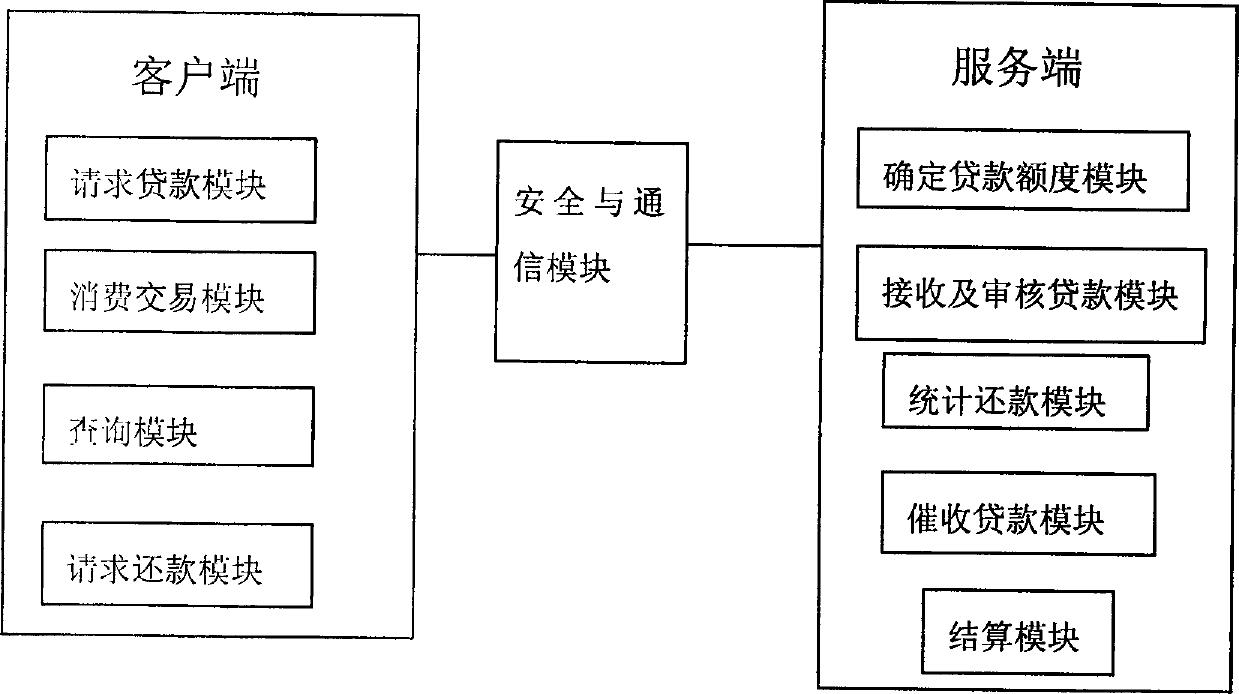

Online virtual currency third-party credit method and data processing system thereof

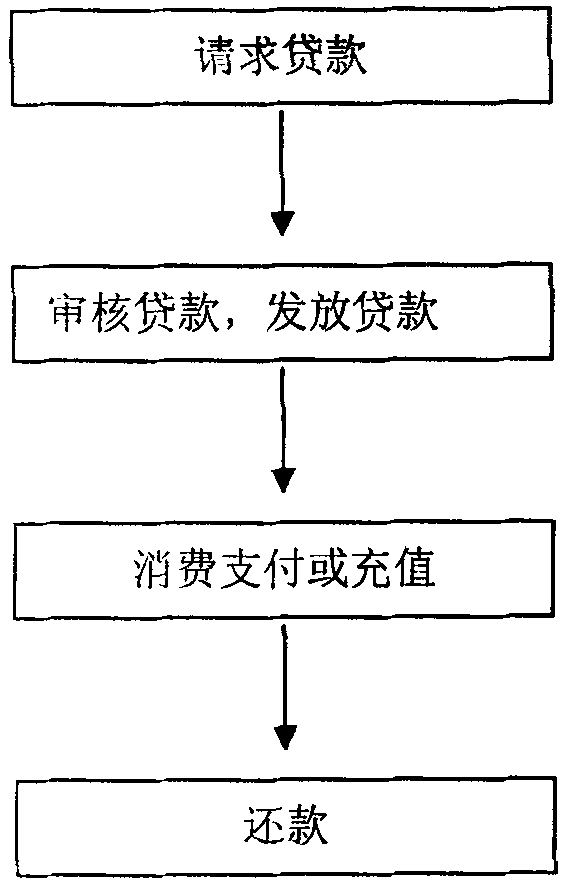

The invention provides an online virtual currency third-party credit method and a data processing system thereof. The online virtual currency third-party credit method includes steps of determining user credit line, user loan application, third-party credit supplier assessment and lending, user recharging or trading by loan, user repayment and payment requesting, settlement of a third-party credit supplier and a platform supplier and the like. The data processing system comprises a client and a server, the client realizes users' various service requests and the server processes the users' service requests. By the aid of the online virtual currency third-party credit method and the data processing system, value of personal online digital assets is explored, trade is promoted by means of load leverage and simple consumption payment ways, trade scale is enlarged, and the platform supplier is assisted in exploring and keeping high-quality users, and user experience is improved.

Owner:孔庆发 +1

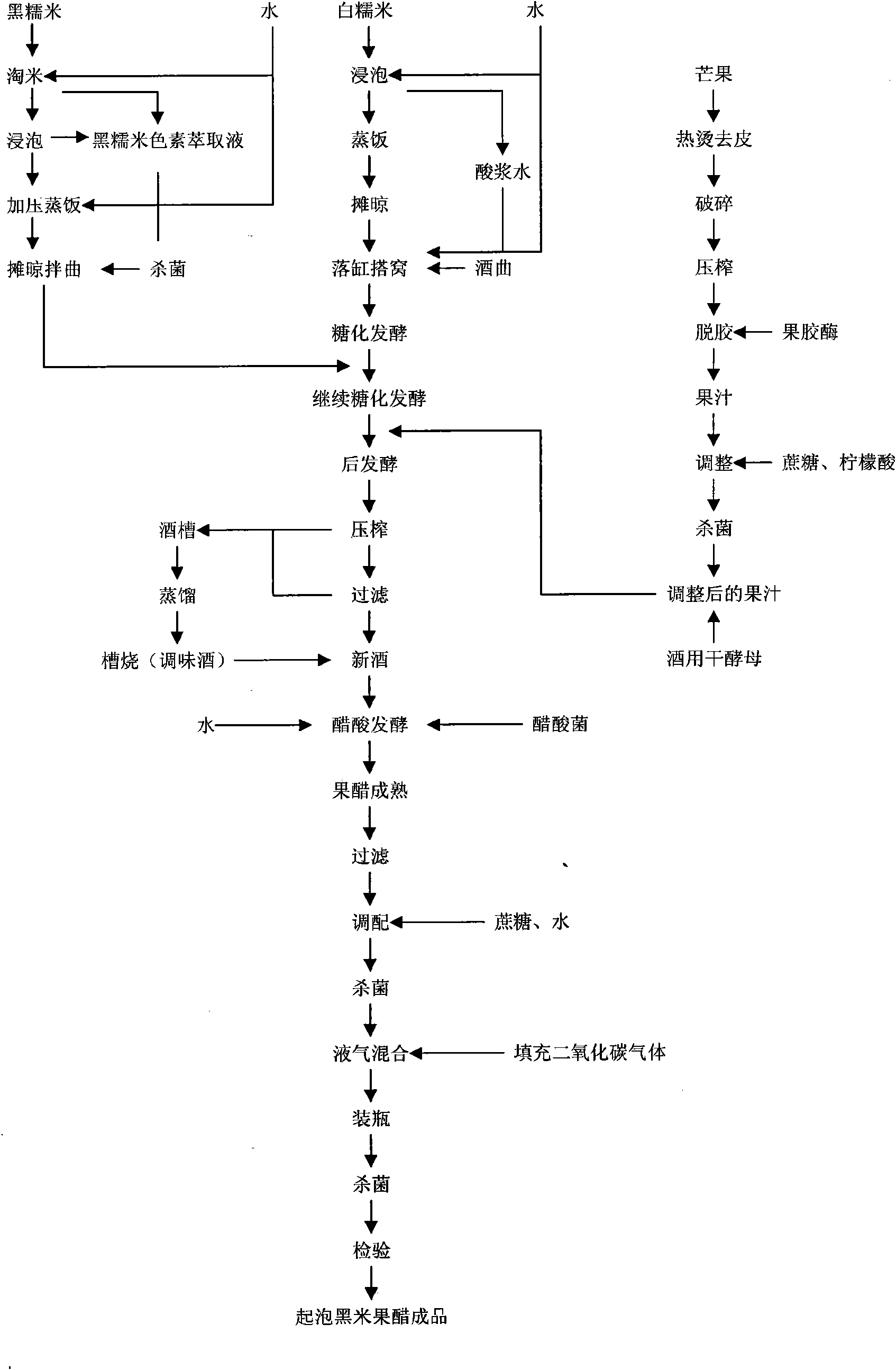

Foaming black-rice fruit vinegar and preparation method thereof

InactiveCN101647594AFruityBrake taste is strongMicroorganism based processesVinegar preparationFermentationOrganoleptic

The invention discloses a foaming black-rice fruit vinegar and a preparation method thereof. Aiming at the problems of little dry extractive, homogenization, single mouth feel, insufficient function and the like of the fruit vinegar drinks, the method has the technical proposal that: on the basis that tonic characteristics of natural materials such as fruits, black rice, black glutinous rice and the like are utilized and the compound technique of fermentation, vinegar making and the like is comprehensively used, the method emphasizes the nutrient value and the added value of the foaming black-rice fruit vinegar product as well as the health-care functions for beautifying the face and moisturizing the skin, and combines the air-entrapping foaming technique to present the visual and sensingeffects and the advantages in color, fragrance and taste of the foaming black-rice fruit vinegar. The fruit vinegar has the effects for moisturizing the skin, beautifying the face and preserving the health.

Owner:刘名汉

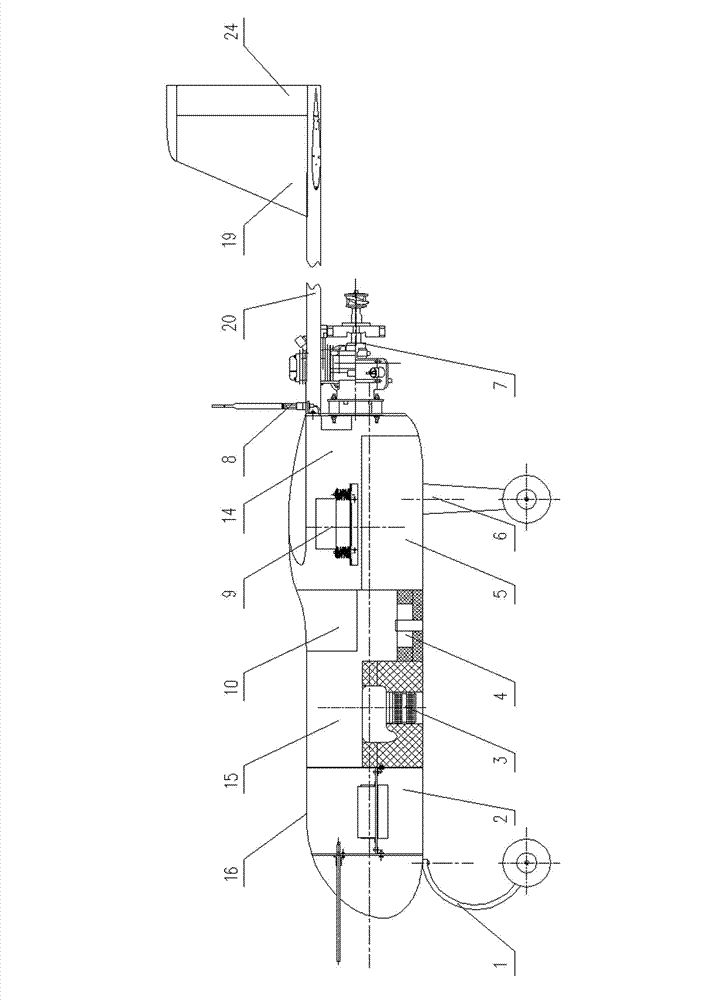

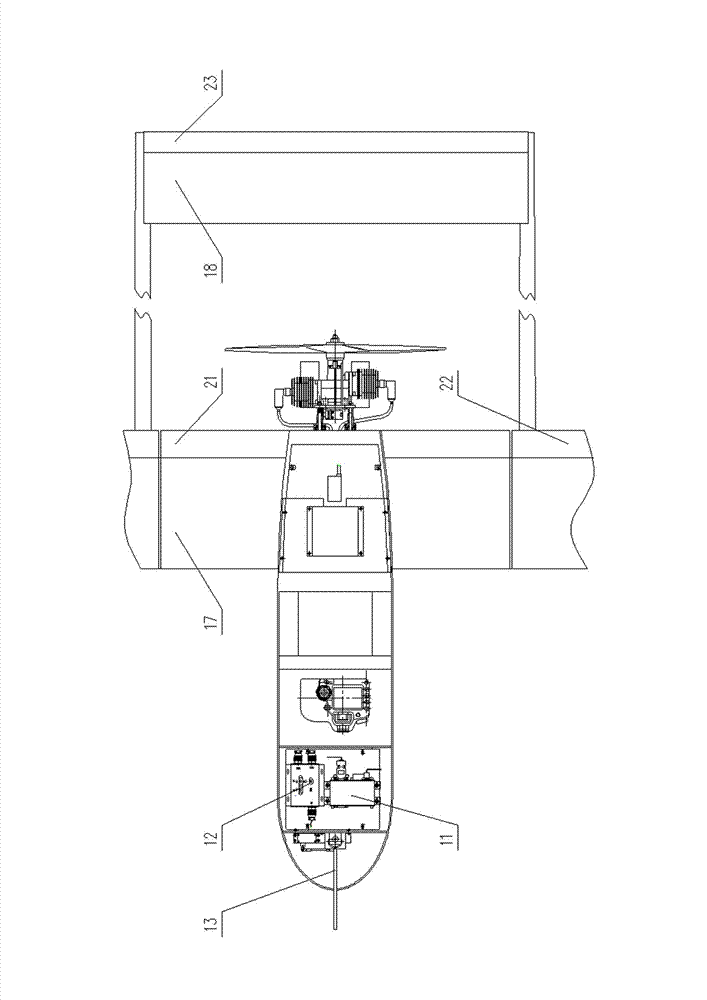

Portable mapping unmanned aerial plane

InactiveCN102806990AEasy to carryEasy to use and maintainActuated automaticallyWingsEmergency rescueFuel tank

The invention relates to a portable mapping unmanned plane. A mapping task is executed by the unmanned plane instead of a manned plane, and visible image data and video data can be acquired. The unmanned plane comprises a main body, wherein the main body is configured aerodynamically and provided with an H-shaped fixed wing and comprises a body, a wing, a horizontal tail wing, a vertical tail wing and a tail boom which are connected with one another through inserted pins; the main body is a lifting body main body, and the interior of the main body is sequentially divided into four cabins, namely an equipment cabin, a loading cabin, a parachute cabin and a power cabin from front to back according to functions; an airborne data transmission radio station and a loading part are respectively arranged in the equipment cabin and the loading cabin; an engine and a propeller are arranged at the back end of the power cabin, and an autopilot is arranged on the upper part of an oil tank in the power cabin; and a flap, an auxiliary wing, and steering engines of an elevating rudder and a yaw rudder are arranged in the tail boom. The unmanned plane has the characteristics that the unmanned plane is convenient to carry, easy to maintain and use, low in cost, reusable and the like, has great advantages in the aspect of emergency rescues and broad market demands and is easy to popularize and apply.

Owner:HIWING AVIATION GENERAL EQUIP

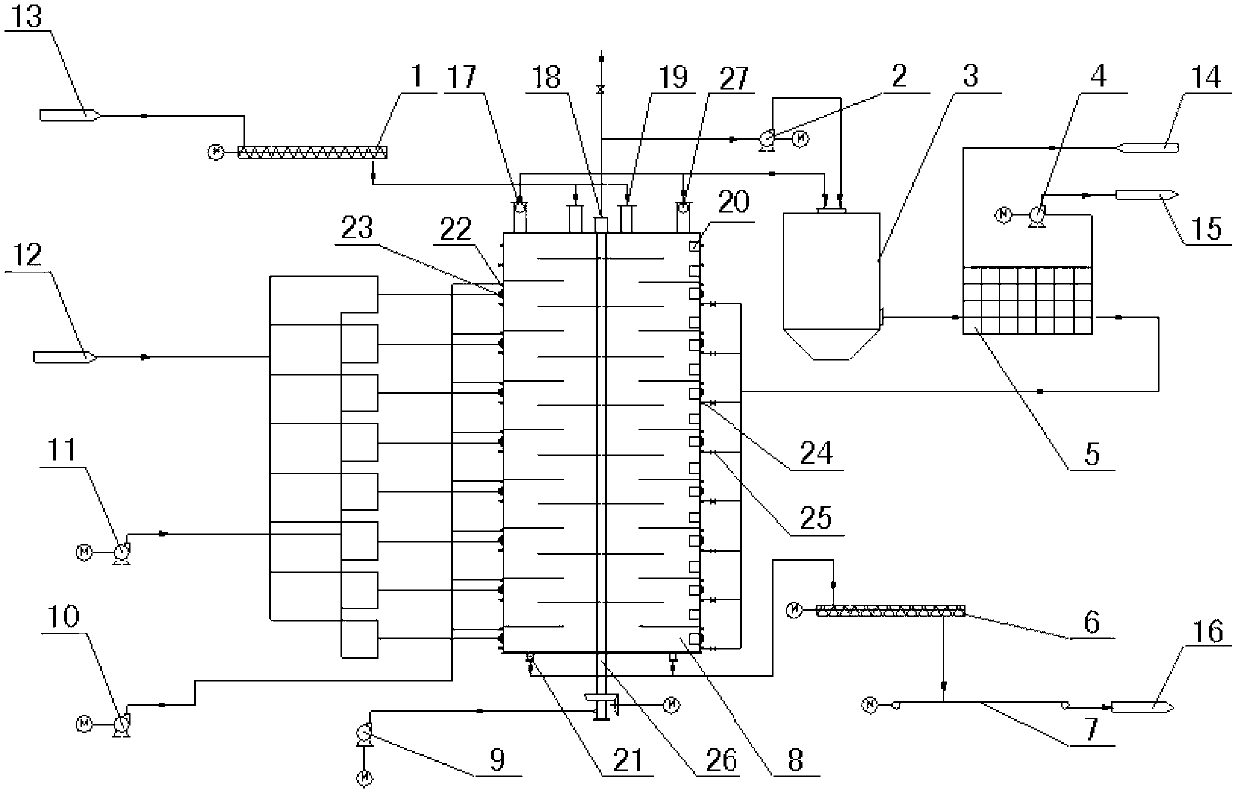

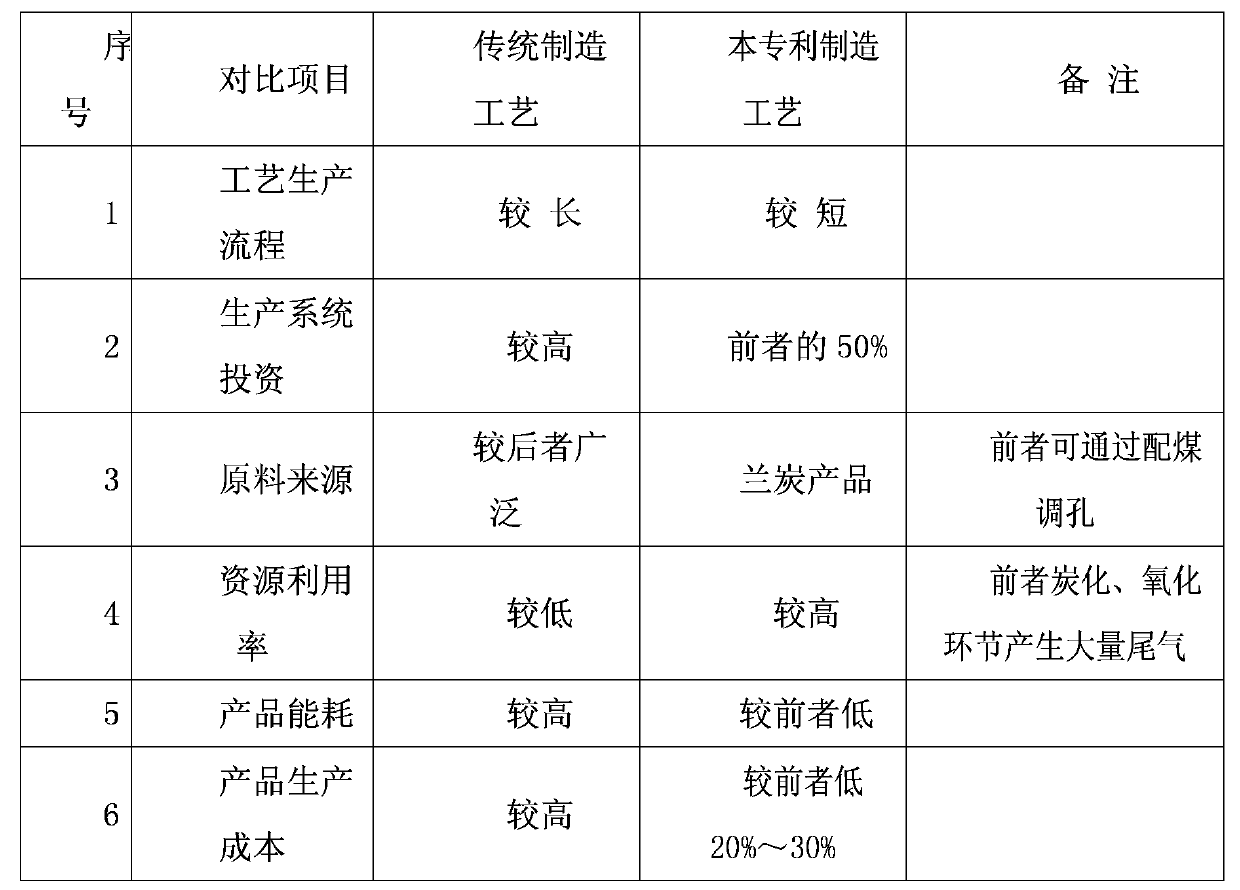

Method for preparing activated carbon from semi-coke and device used in same

ActiveCN103130222ABig market demandTo satisfy the market's needsCarbon compoundsActivated carbonCoke

The invention discloses a method for preparing activated carbon from semi-coke and a device used in the method. The method comprises the following steps of: taking semi-coke of which the volatile matter is greater than 5% and the thermal stability is greater than 70%, screening and feeding the semi-coke of which the granularity is 5-20mm into a rake-type activating furnace (8) to be subjected to activation treatment to generate the activated carbon; discharging the activated carbon from the rake-type activating furnace (8), cooling at a helix cooling machine (6) and conveying through a belt conveyer (7); and finally entering an activated carbon packaging period to be selected and packaged. According to the method, the structural characteristics of organic matter components and micro-pores of a semi-coke product are sufficiently utilized, and with the combination of the operation control principle of the domestic activation furnace, a novel process control method is innovated, and the activation process of the rake-type furnace is applied to the production process of the semi-coke-made activated carbon, so that the activation process control precision of a product is greatly improved, activated carbon products of higher quality are produced, the additional value of a semi-coke product is greatly increased, the application space of the semi-coke is widened, and the market requirements of the activated carbon are met.

Owner:HUADIAN HEAVY IND CO LTD

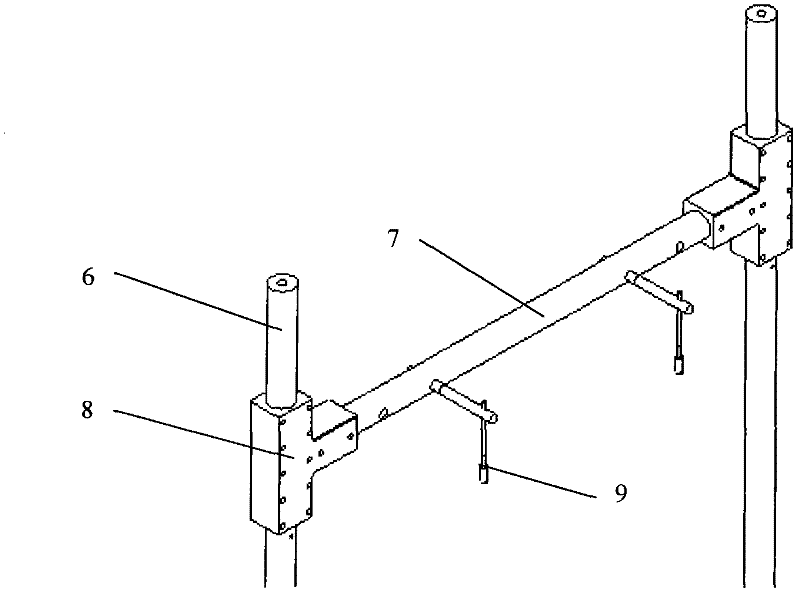

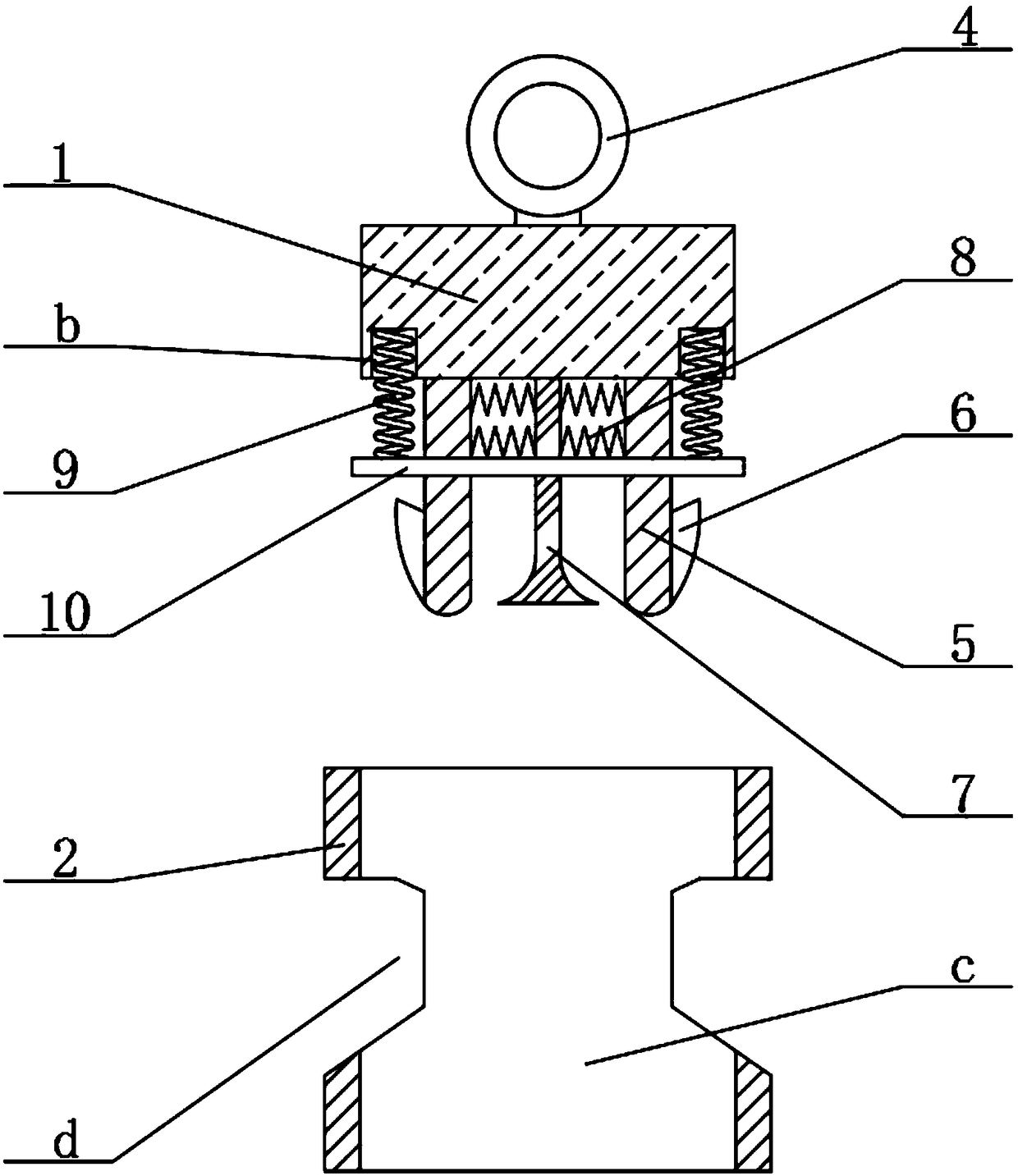

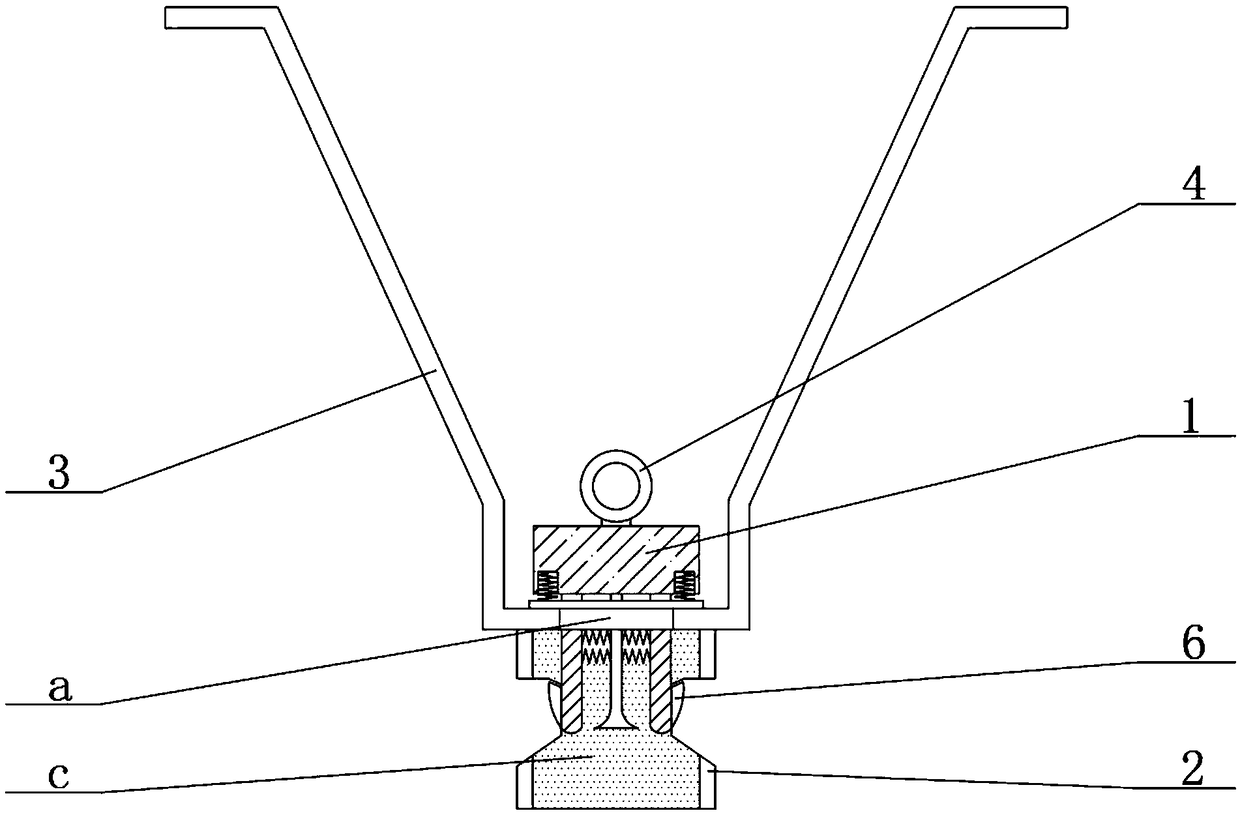

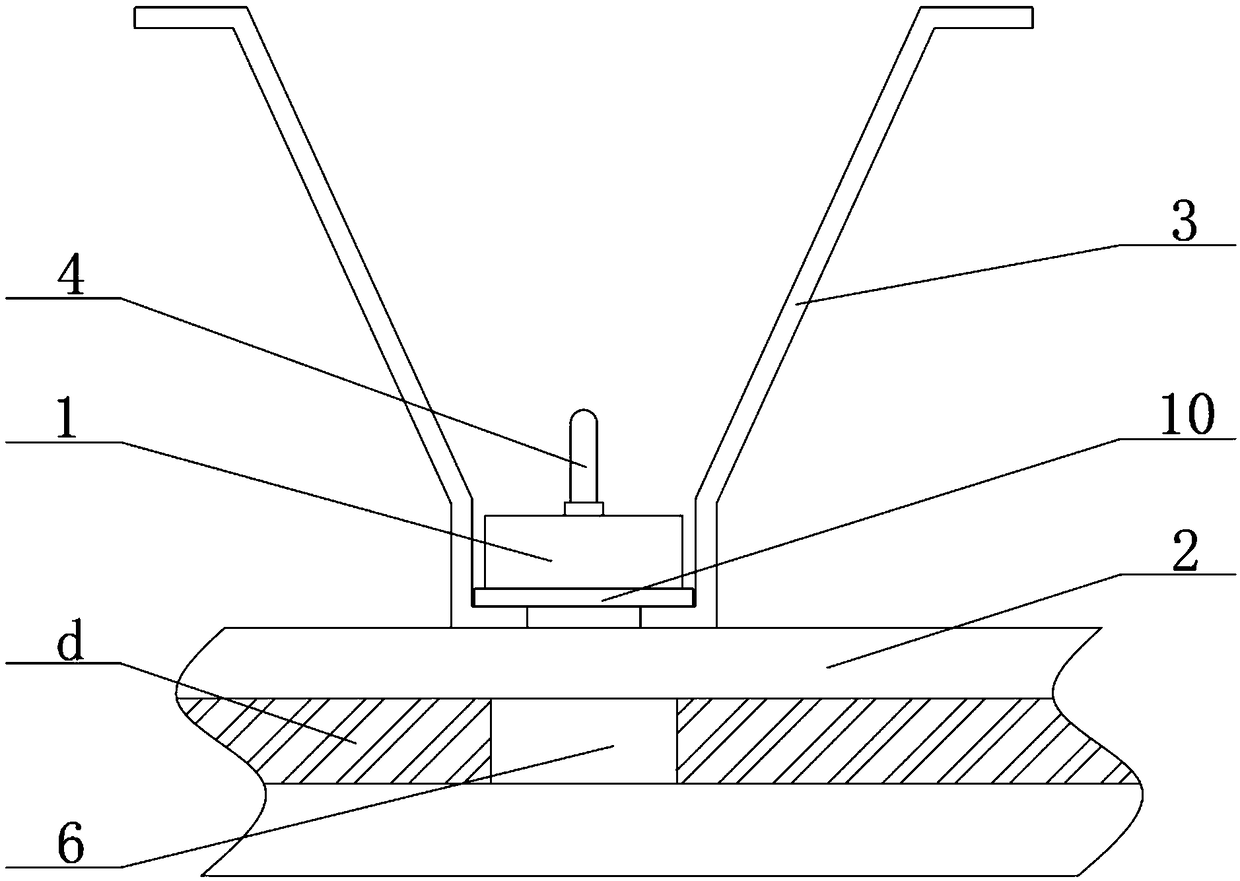

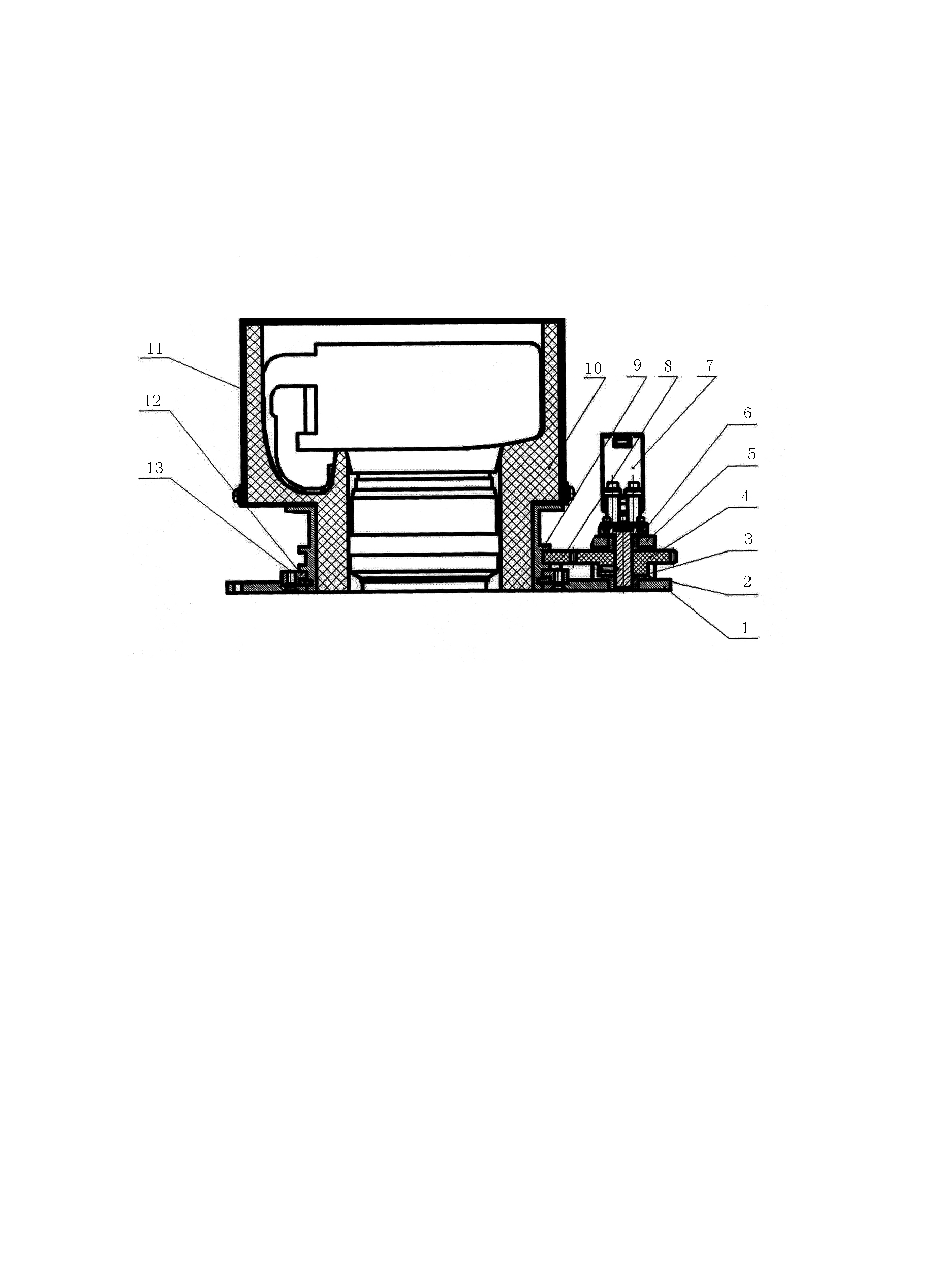

Decoupling-type free vibration suspending structure of bridge segment model

InactiveCN102175418AAdapt to initial position requirementsEasy to transportAerodynamic testingSet screwThree degrees of freedom

The invention relates to a decoupling-type free vibration suspending structure of a bridge segment model, which comprises a base, a body support rack, a pull rod, a bottom plate, a vertical guide post, a vertical sliding block, a spring connecting rod, a horizontal guide post, a horizontal sliding block, a rotating shaft, a force bearing disc and a connecting plate, wherein the spring connecting rod is respectively in threaded connection with upper and lower connecting shafts of the body support rack and two ends of the vertical sliding block; the bottom plate is fixed on two connecting shafts in the middle of the body support rack through threads, the vertical guide post is fixed on a support base of the bottom plate via a fastening screw, the vertical sliding block is inserted on the vertical guide post in a penetrating manner, the horizontal guide post is fixed at two ends of the vertical sliding block, the horizontal sliding block is inserted on the horizontal guide post in a penetrating manner, the force bearing disc is fixed on the rotating shaft via a flat key, and one end of the rotating shaft is inserted into the horizontal sliding block while the other end thereof is fixed with the connecting plate via a set screw. Three degrees of freedom in the structure of the invention can be locked independently, measurement can be carried out based on the desired degree of freedom, and with the spring tensioning forces in various directions being adjustable, the structure is suitable for the demands of various initial positions.

Owner:HARBIN INST OF TECH

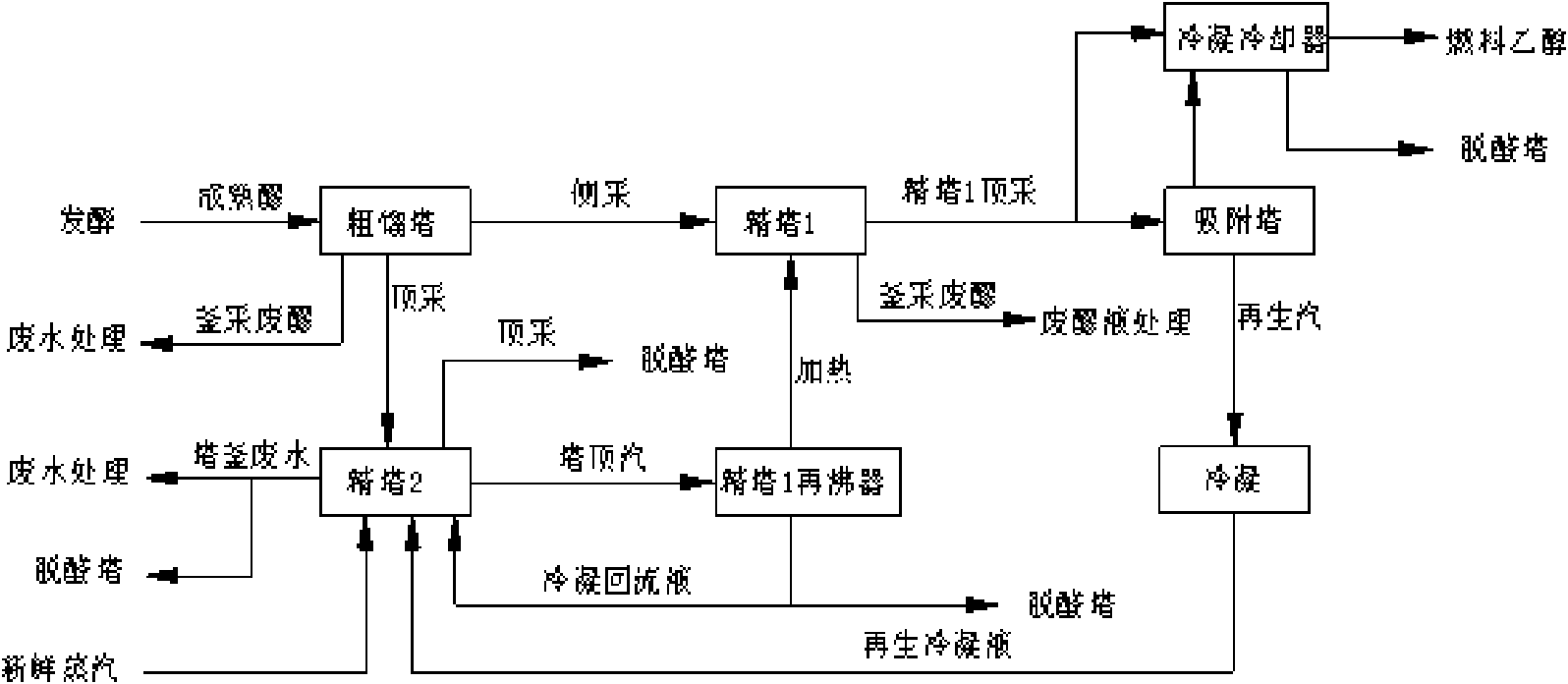

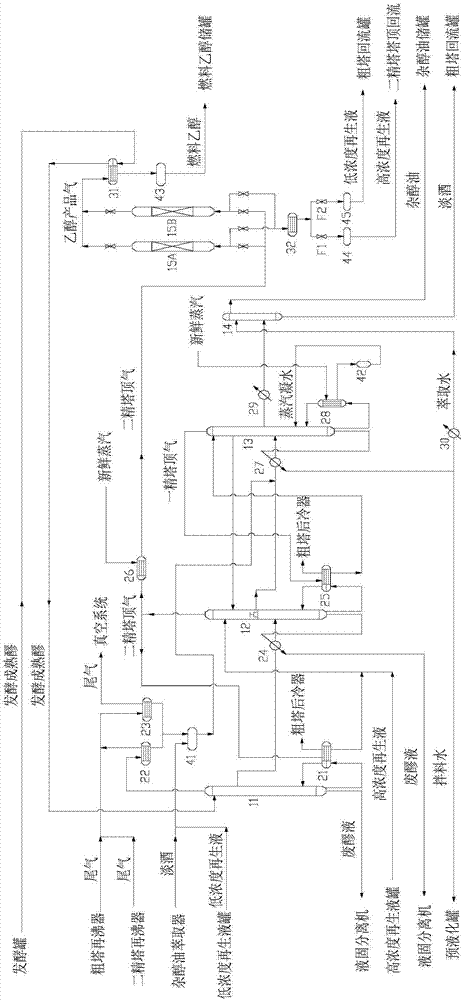

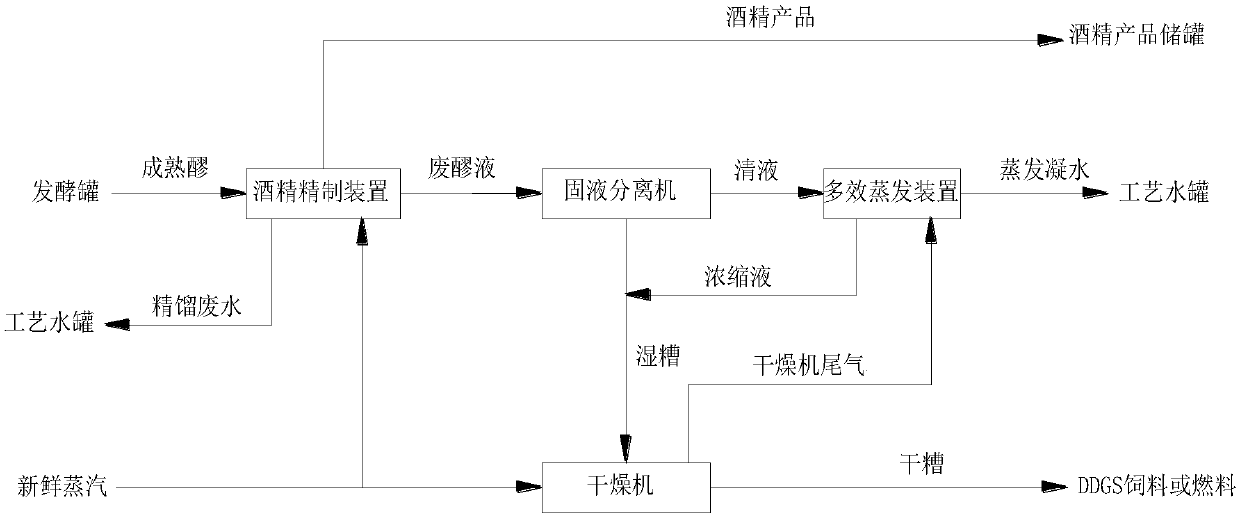

Composite process of fuel alcohol and edible alcohol

ActiveCN101648847AReduce material consumptionReduce energy consumptionOrganic compound preparationBiofuelsMolecular sieveDistillation

The invention relates to a composite process of fuel alcohol and edible alcohol. In the production process of alcohol products, fermented mash mature in a self-fermentation unit enters a rough distillation column, crude alcohol distilled from the top of the rough distillation column is fed into a rectification column (2), liquid alcohol distilled from the side of the rough distillation column column is fed into a feed inlet of a rectification column (1), vapor phase objects distilled from the top of the rectification column (1) are fed into a molecular sieve absorption column, and thus, fuel alcohol is obtained. In the production process of edible alcohol products, objects distilled from the top of the rough distillation column and the top of the rectification column (1) and partial objects distilled from the boiler of the rectification column (2) are all fed into an aldehyde disengagement column, liquid alcohol distilled from the boiler of the aldehyde disengagement column is fed into the rectification column, and then, the liquid alcohol is distilled from the top of the column and fed into a reclaiming column as feed; the liquid alcohol is distilled from the side of the upper part of the rectification column (2) and fed into the feed inlet of a rectification column (3) , and qualified edible alcohol is distilled from the boiler of the rectification column (3). The invention realizes multiple varieties of alcohol products on the same device, effectively decreases consumption in materials and energy in the production process of fuel alcohol and edible alcohol, reduces the investment on device, and improves the market competitiveness of the fuel alcohol and the edible alcohol.

Owner:TIANJIN UNIV

Heavy type gas turbine compressor exhaust cylinder casting process

ActiveCN104907499AReduce the chance of deformationQuality improvementFoundry mouldsFoundry coresEngineeringCylinder block

The present invention discloses a heavy type gas turbine compressor exhaust cylinder casting process, in order to fully feed the casting solidification process, a cylinder body is vertically poured, an annular open riser is placed on the upper part of the cylinder body, a plurality of annular blind risers are placed on a sector, a chiller and a patch are simultaneously assembled for feeding the casting; a wood-type skin sample is used for shaping to ensure a precision casting size; an alkaline phenolic resin sand is used as back sand, chrome ore sand is used as a surface sand, and the air permeability and deformability of the sand mold surface can be increased; an open-type water nozzle is used for pouring, the chance of casting distortion can be reduced, and the casting quality is improved. Compared with the prior art, the beneficial effects are that: the technical problems of the defects of being complex in structure, large in volume, uneven in partial casting wall thickness, difficult to feed, easy to deform, easy to loosen, crack and deform, and the like of a heavy type gas turbine compressor exhaust cylinder steel casting part can be effectively solved.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

Fixing device for spraying clamp

InactiveCN108612716AQuick releaseQuick installationSpraying apparatusFriction grip releasable fasteningsEngineeringGasket

Owner:繁昌县众运机械制造有限公司

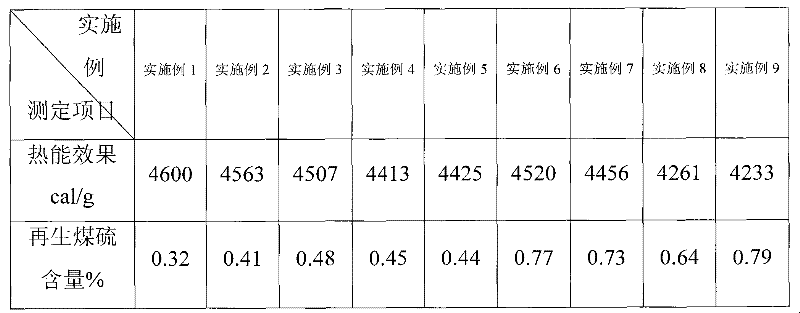

Sludge environment-friendly renewable coal and preparation method thereof

InactiveCN101747974AHighlight substantive featuresSignificant progressBiofuelsSolid fuelsCombustionSludge

The invention relates to a sludge environment-friendly renewable coal and a preparation method thereof. The sludge environment-friendly renewable coal adopts the following formula: 45 to 70 percent of sludge, 25 to 50 percent of combustion improver, 1 to 5 percent of ignition substance, 1 to 5 percent of oxidant, 0 to 5 percent of sulfur fixing agent and 0 to 5 percent of forming agent; and adopts the following preparation technology: 1) the sludge is dried and dehydrated and is sent into a crusher to be crushed into powder after 24 hours; 2) the sulfur fixing agent, the oxidant and the forming agent are sent into a mixing machine to be uniformly blended to obtain a mixture; 3) the combustion improver is sent into the crusher to be crushed into powder which is uniformly mixed with the ignition substance to obtain the mixture; 4) the powder sludge which is obtained in step 1), the mixture which is obtained in step 2) and the mixture which is obtained in step 3) are sent into the mixing machine to be uniformly blended to obtain a mixture, and then the mixture is taken out to be pressed and formed to obtain the formed sludge environment-friendly renewable coal. The preparation technology is simple, the raw materials can be obtained easily, the technical problem of the sludge treatment is solved through a method with the lowest cost, and a renewable energy which can satisfy the market requirement is produced.

Owner:SUZHOU INDAL PARK RUIDE ENVIRONMENTAL SCI TECH

Pomelo beverage containing pomelo fruit granule

InactiveCN101011172ASolve the problem of strippingSolve the taste problemNervous disorderAntipyreticThroatPreparing skin

The invention relates to a pomelo drink, which uses the pomelo as main material, separates skin and caro, prepares skin into liquid, adds fragrant solomonseal rhizome and licorice extractives, mixes and filters. The inventive drink has suspended pomelo caro, with throat-moistening functions, while it can be used on the patients with diabetic, high blood pressure or the like.

Owner:刘思强

Method for producing one-dimensional nanometer flake zinc powder by directly electrolyzing strong alkaline solution

InactiveCN102181886AImprove current efficiencyIncrease current densityNanotechnologyElectrolysisHigh energy

The invention provides a method for producing one-dimensional nanometer flake zinc powder by directly electrolyzing strong alkaline solution, relating to the production technology of flake zinc powder. The method is characterized by firstly preparing zinc-containing strong alkaline solution, wherein the solution contains 1-100g / L of Zn, 10-200g / L of OH<->, 5-70mg / L of additive A and 10-110mg / L ofadditive B; secondly taking a stainless steel plate as an anode and a magnesium plate as a cathode to electrolyze the solution for 1-180min under the following conditions: the distance between the two plates is 0.5-5cm; the current density is 100-2500A / m2; and the solution temperature is 10-100 DEG C, then stopping electrolysis, rapidly taking out the electrodeposit and washing the electrodepositwith water until the pH value of the water is lower than 8; and finally, rapidly vacuum-drying the washed electrodeposit, thus obtaining the one-dimensional nanometer flake zinc powder, wherein the electrolysis waste liquor is returned to be used for preparing the zinc-containing strong alkaline solution. The method has the following advantages and effects: the produced zinc powder has high activity, is flaky and is 10-100nm thick; the method is low in production cost and energy consumption, is simple to operate and is convenient for mass production; and the defects of high cost, high energy consumption, low capacity, difficulty in controlling quality and the like in the traditional production methods are thoroughly overcome.

Owner:TONGJI UNIV

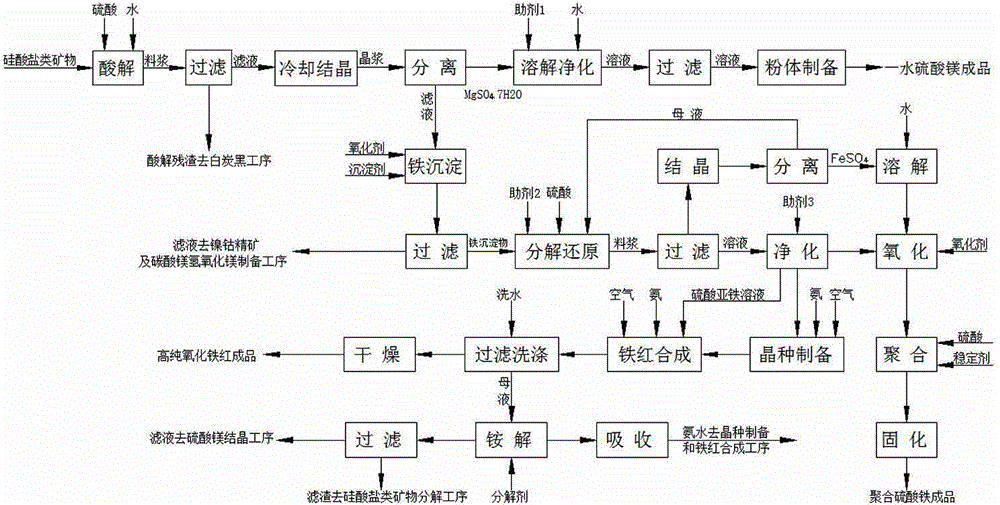

Comprehensive utilization method of silicate minerals

ActiveCN104891537ABig market demandGood market demandMagnesium sulfatesFerric oxidesFerric hydroxideHigh energy

The invention discloses a comprehensive utilization method of silicate minerals. The method comprises the following steps: firstly decomposing silicate minerals by using sulfuric acid as a decomposing agent, and carrying out acid leaching of residues for preparation of white carbon black; sending an acidolysis solution into a magnesium sulfate heptahydrate crystallizer to prepare a magnesium sulfate heptahydrate product and an acidolysis solution obtained after separation of magnesium sulfate; mixing magnesium sulfate heptahydrate and water, adding an oxidizing agent, a pH regulator and an adsorbent to convert iron in the solution to a ferric hydroxide precipitate, filtering to obtain a pure magnesium sulfate solution, sending the magnesium sulfate solution into a magnesium sulfate monohydrate powder dedicated preparation system to prepare a feed-grade magnesium sulfate monohydrate product; separating an iron precipitate from the acidolysis solution by an oxidation-precipitation process, carrying out oxidation, carrying out a polymerization reaction, and solidifying to prepare a solid polymeric ferric sulfate product; and sending the acidolysis solution after separation of the iron precipitate to a follow-up process to prepare a magnesium compound. According to the invention, insufficiencies such as high energy consumption during present technical process of production, low product purity and the like are overcome; and there is no emission of ''three wastes (waste gas, waste water and industrial residue) '' during the production process, so as to minimize the influence on the environment.

Owner:河南省睿博环境工程技术有限公司

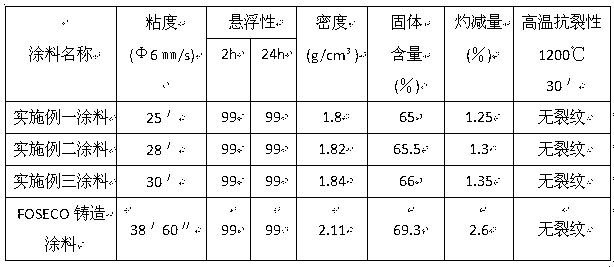

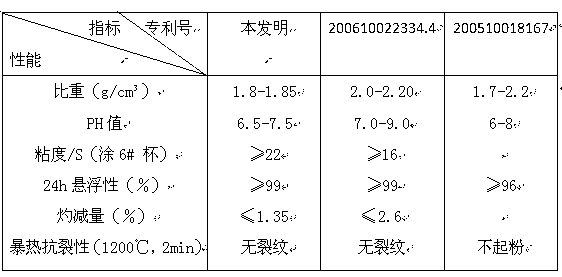

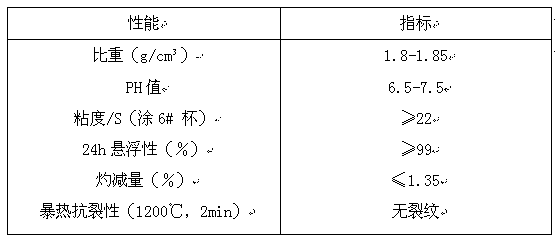

Simple alcohol-based casting coating and preparation method thereof

InactiveCN103008528AShorten production timeIncrease productivityFoundry mouldsFoundry coresAlcoholPolyvinyl alcohol

The invention discloses a simple alcohol-based casting coating and a preparation method thereof and belongs to the field of casting coatings. The coating comprises the following components in parts by weight: 65-75 parts of zircon power, 1.5-4 parts of lithium-based bentonite, 1-2.5 parts of clay, 0.8-3.5 parts of resin, 5-10 parts of silica sol, 0.1-0.3 part of polyvinyl butyral and 45-55 parts of industrial alcohol. The coating preparation method sequentially comprises the following steps of: 1, weighing and grinding the zircon power, adding and grinding lithium-based bentonite, adding and grinding clay and silica sol, adding and grinding resin, wherein the powder is uniformly ground; and adding an additive polyvinyl butyral into the powder, and fully grinding to prepare dry powder; and 2, slowly adding alcohol into the dry powder, stirring to a proper concentration, and preparation the coating. The defects in the prior art are overcome, the coating has good effects on aspects of suspension, brushing property, high-temperature cracking resistance and burnt-on sand resistance, and the produced casting piece is excellent in surface quality; and moreover, the coating is simple and rapid in process, short in production cycle, high in production efficiency, low in cost and good in market prospect.

Owner:LANZHOU LANSHI CASTING

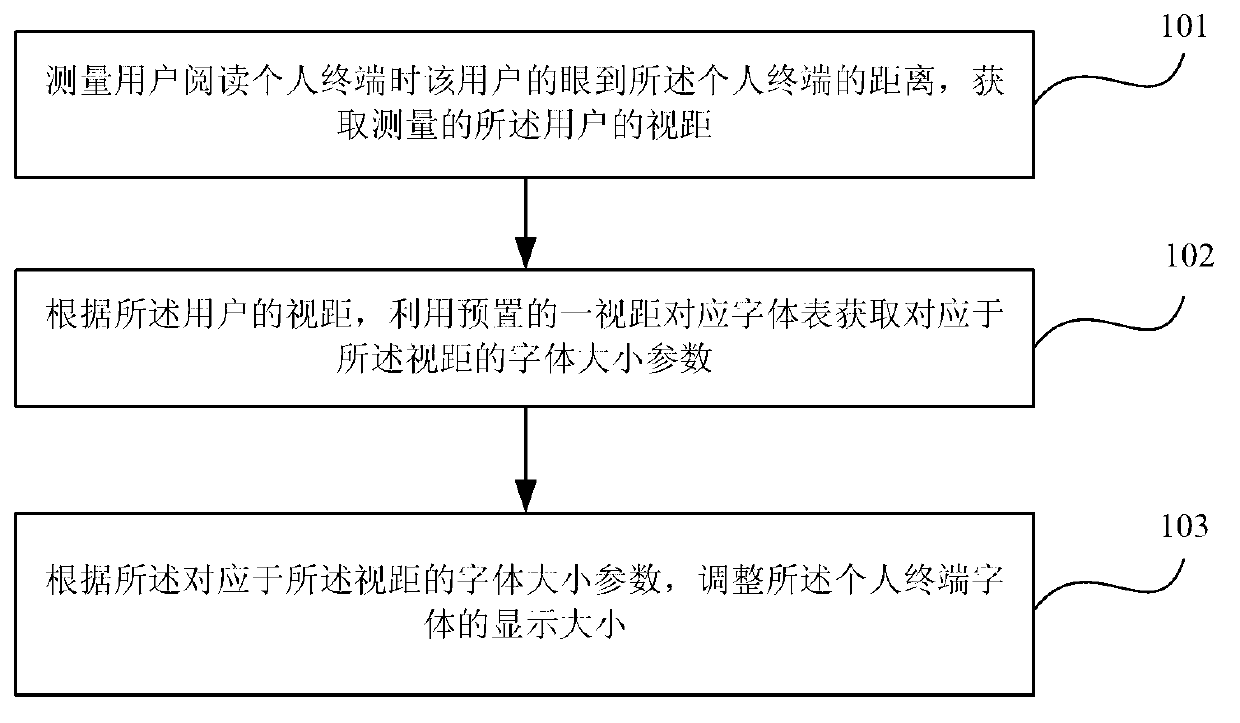

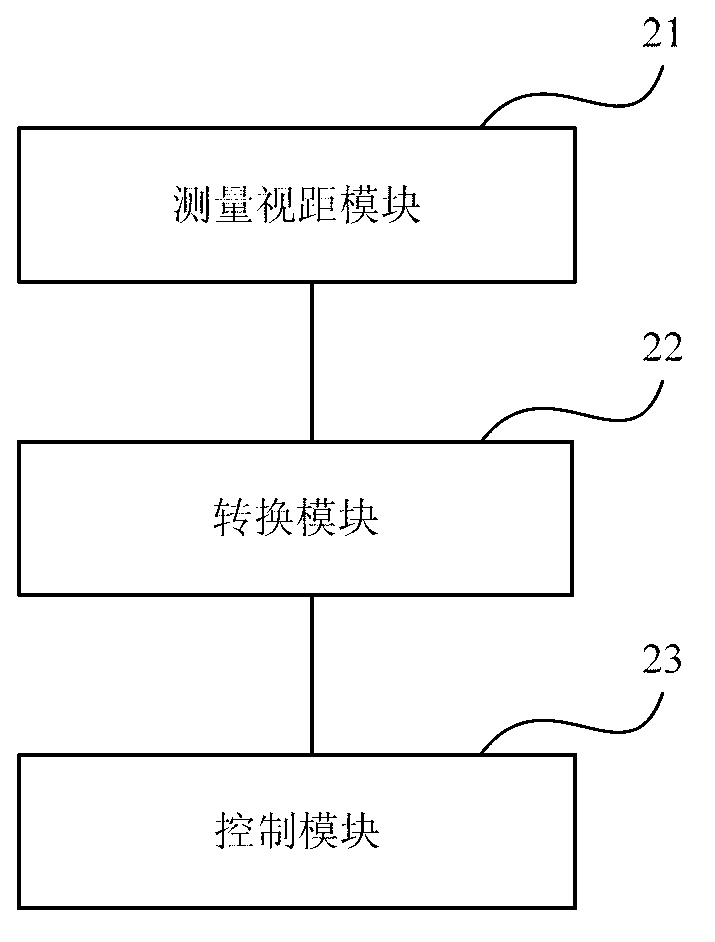

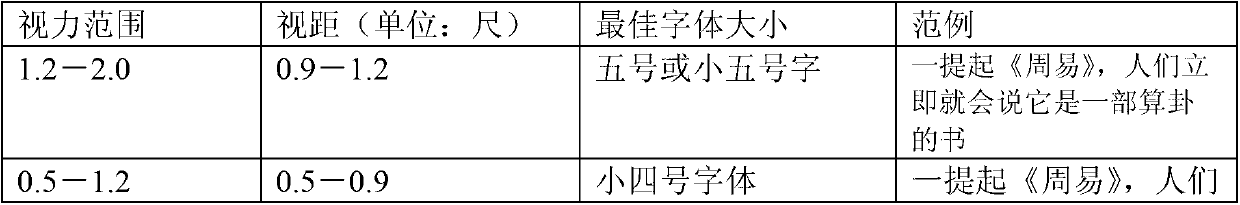

Automatic adaptive terminal font size method and device according to human eyesight

InactiveCN103220386ABig market demandEasy to adjustTelephone sets with user guidance/featuresComputer visionArtificial intelligence

The invention provides an automatic adaptive terminal font size method and device according to the human eyesight. The method comprises measuring the distance between eyes of a user to a personal terminal when the user reads the personal terminal to acquire the sight distance of the user; utilizing the preset sight distance corresponding to a font table to acquire the font size parameters corresponding to the sight distance according to the sight distance of the user; and adjusting font display size of the personal terminal according to the font size parameters corresponding to the sight distance. The automatic adaptive terminal font size method and device according to the human eyesight has the following advantages being capable of automatically adjusting the font display size of the terminal according to strength and change of the human eyesight to greatly protect the human eyesight through the humanized design; enabling people older than 40 years to fully use the personal terminal; and expanding market requirements. Furthermore, a manual adjusting key for font display size of the personal terminal is installed on the surface of a casing of the personal terminal so as to be convenient to adjust.

Owner:高正峰

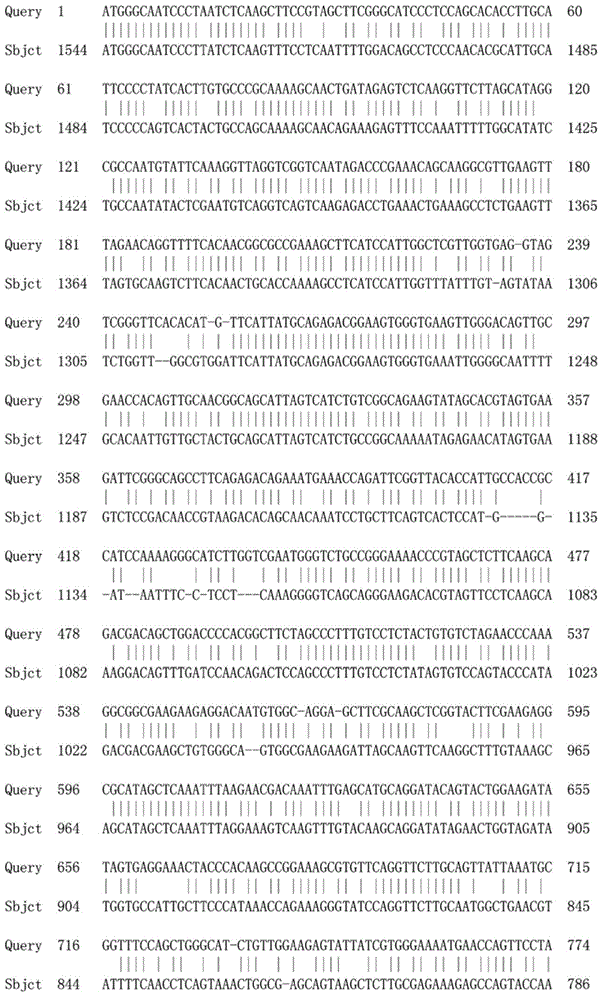

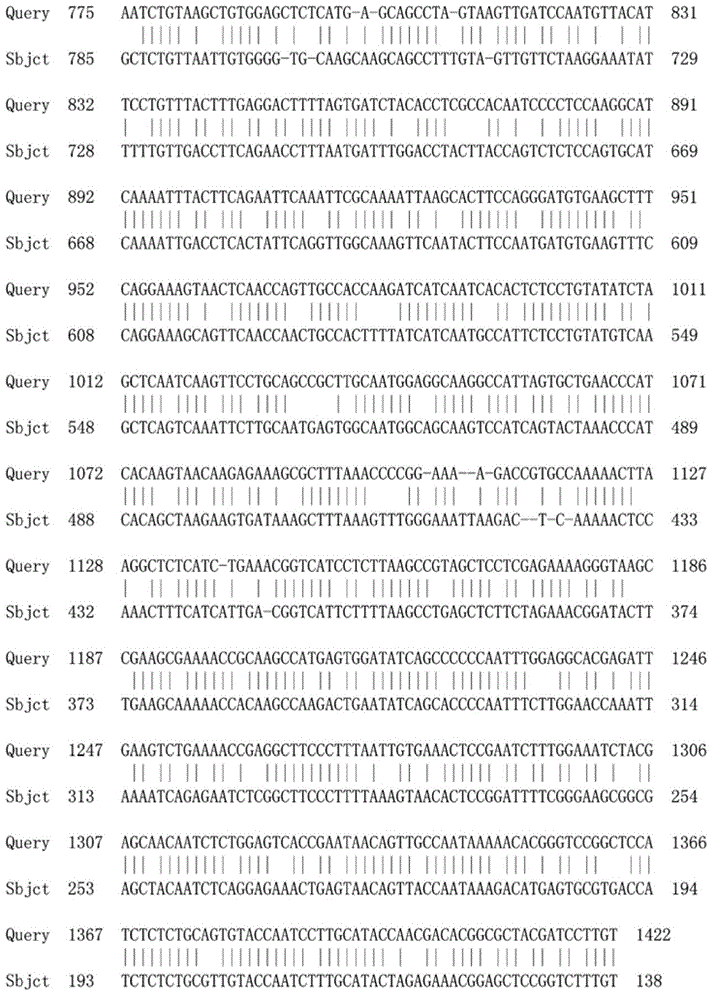

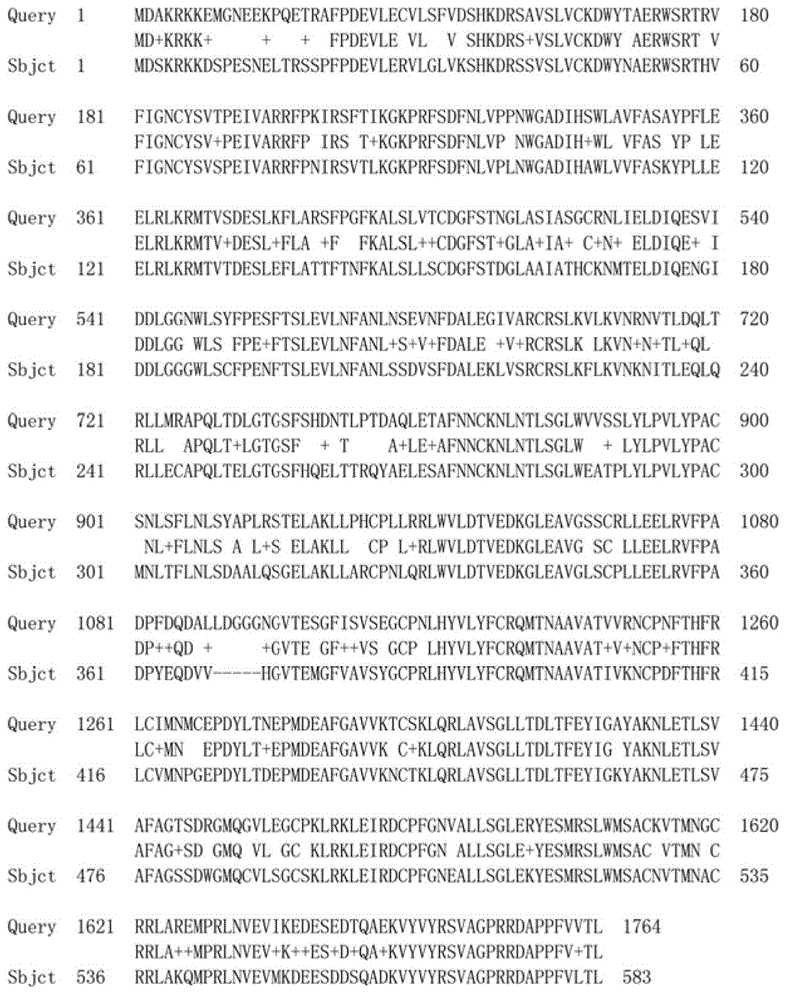

Agapanthus praecox auxin receptor protein TIR1 and coding gene and probe thereof

InactiveCN103333233AImprove viewing valueReduce the incidence rateMicrobiological testing/measurementPlant peptidesAuxin receptorProtein activity

The invention relates to an agapanthus praecox auxin receptor protein TIR1 and a coding gene and probe thereof. The protein is: (a) a protein consisting of the amino acid sequence shown in SEQ ID No.4; or (b) a protein obtained by substituting, losing or adding one or multiple amino acids of the amino acid sequence shown in SEQ ID No.4, having agapanthus praecox auxin receptor protein activity and derived from (a). The invention also provides a nucleotide sequence for coding the protein and a probe for detecting the nucleotide sequence. According to the agapanthus praecox auxin receptor protein TIR1 and the coding gene and probe thereof provided by the invention, the agapanthus praecox auxin signal transduction pathway is regulated by the genetic engineering technology to reach an aim of controlling the growth development and organ morphogenesis, thereby providing a theoretical basis for molecular breeding and creating great application value.

Owner:SHANGHAI JIAO TONG UNIV

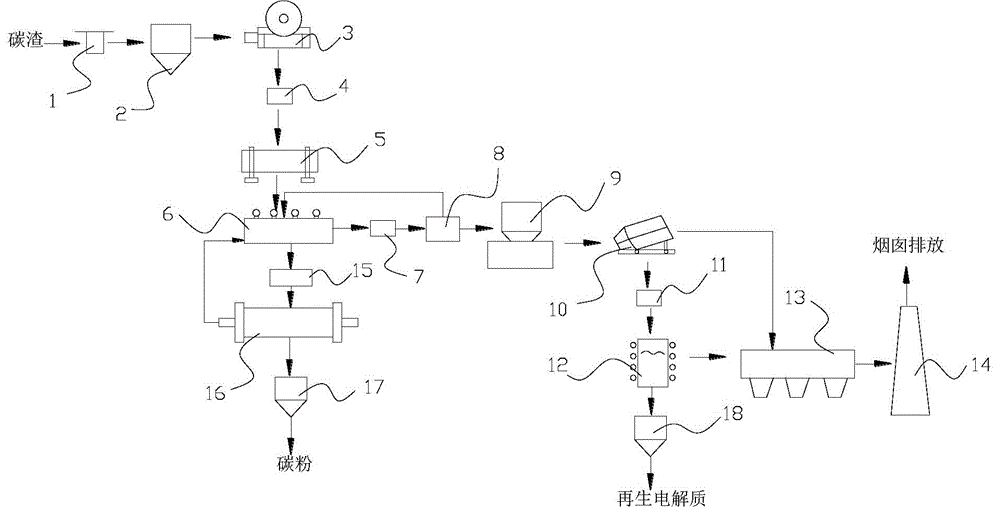

Device and method for producing regenerative electrolyte from aluminum-electrolysis carbon residues

InactiveCN103949460ANo dischargeSimple processSolid waste disposalIntermediate frequencyProcessing cost

The invention relates to a device and a method for producing regenerative electrolyte from aluminum-electrolysis carbon residues. The device comprises a sorting platform, a carbon residue stock bin, a crushing device, a first magnetic separation device, a ball milling device, a flotation tank, a second magnetic separation device, a sedimentation basin, a feeding device, a drying device, a third magnetic separation device, an intermediate frequency furnace, a dust-removal device and a chimney, which are sequentially connected with one another, wherein a carbon powder tank, a filter-press device and a carbon powder bin are further sequentially connected to the flotation tank, and a regenerative electrolyte bin is connected to the intermediate frequency furnace. The method comprises the following steps: (a) raw material sorting, (b) carbon residue crushing, (c) ball-milling, (d) flotation, (e) drying, (f) regenerative electrolyte refining, and (g) tail gas treatment. The method has the beneficial effects that the carbon residues are sorted to be a utilizable value resource, and basically no industrial waste residue is generated; the process is simple, the processing cost is low, the industrialized application is easily realized, the production water supply is completely recycled in the whole process, no polluted gas is discharged, and the method is a brand new method for processing and comprehensively utilizing the carbon residues and has a high promotional value.

Owner:JIANSHUI DEFU RENEWABLE RESOURCES

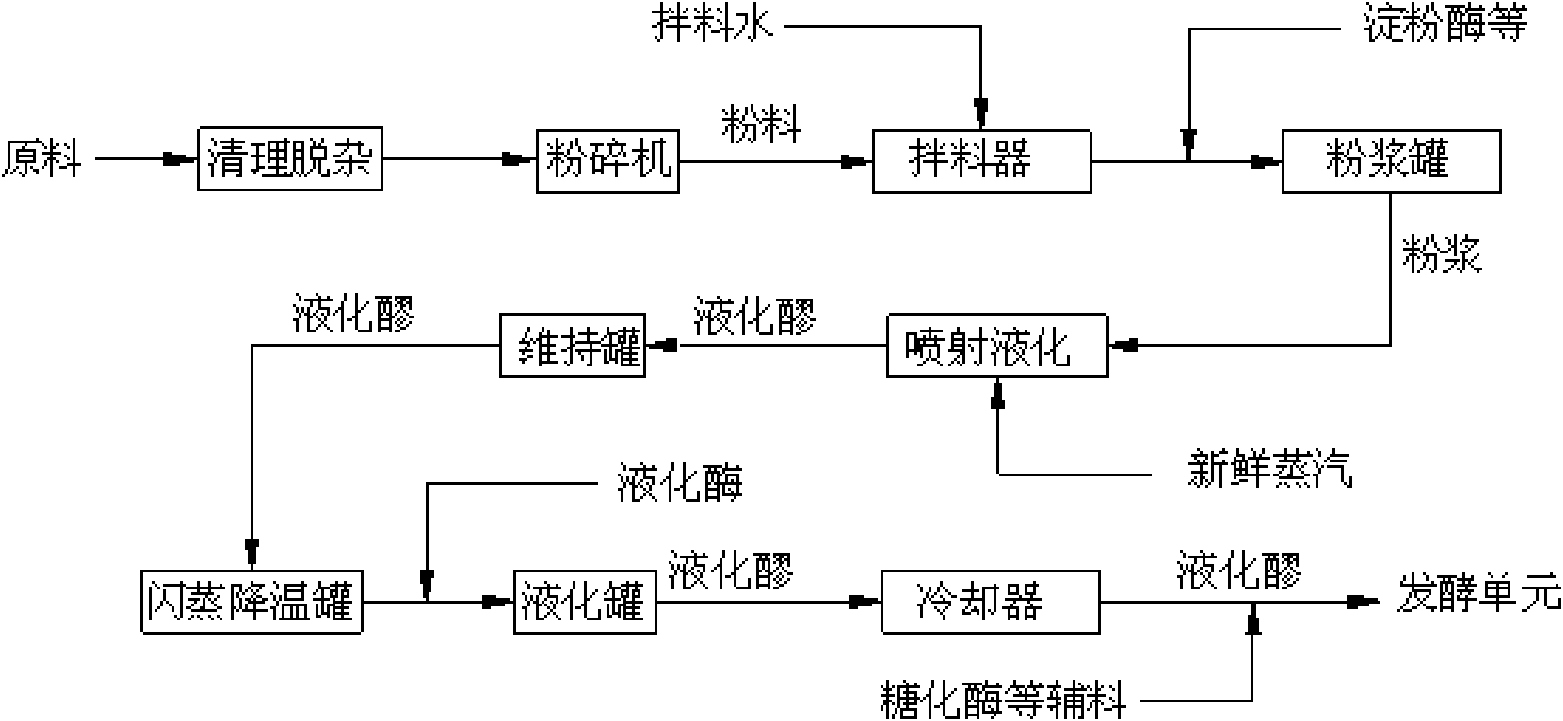

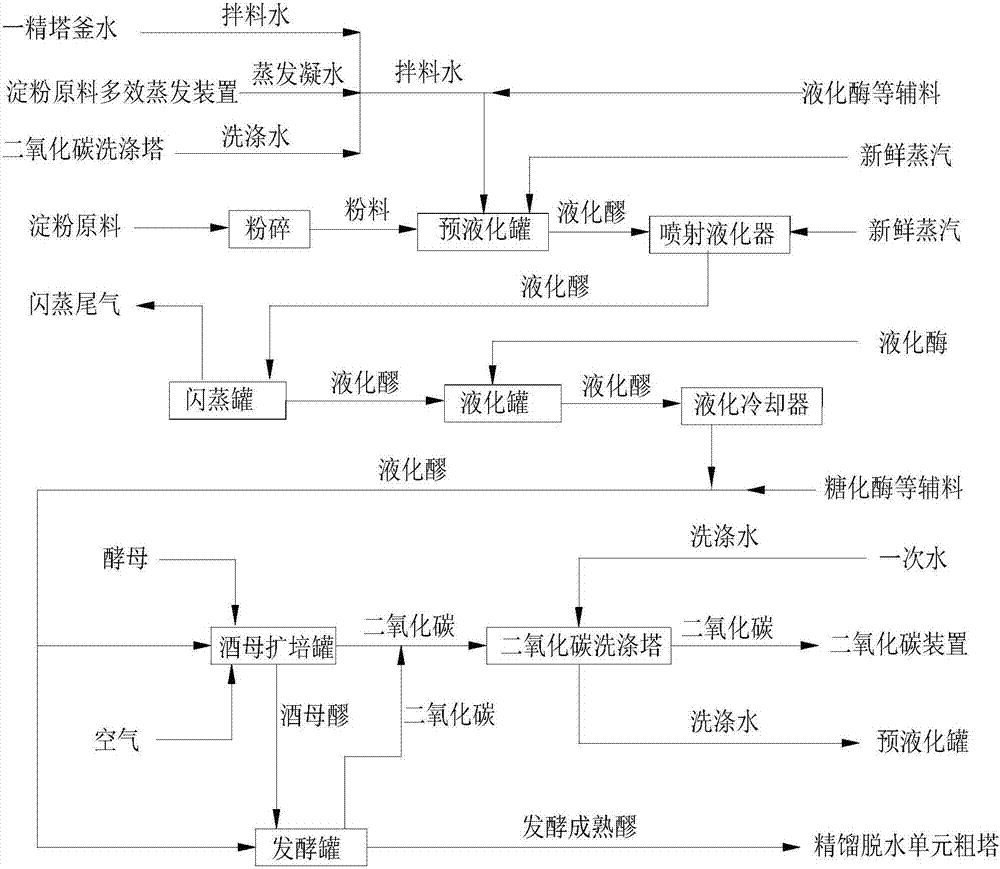

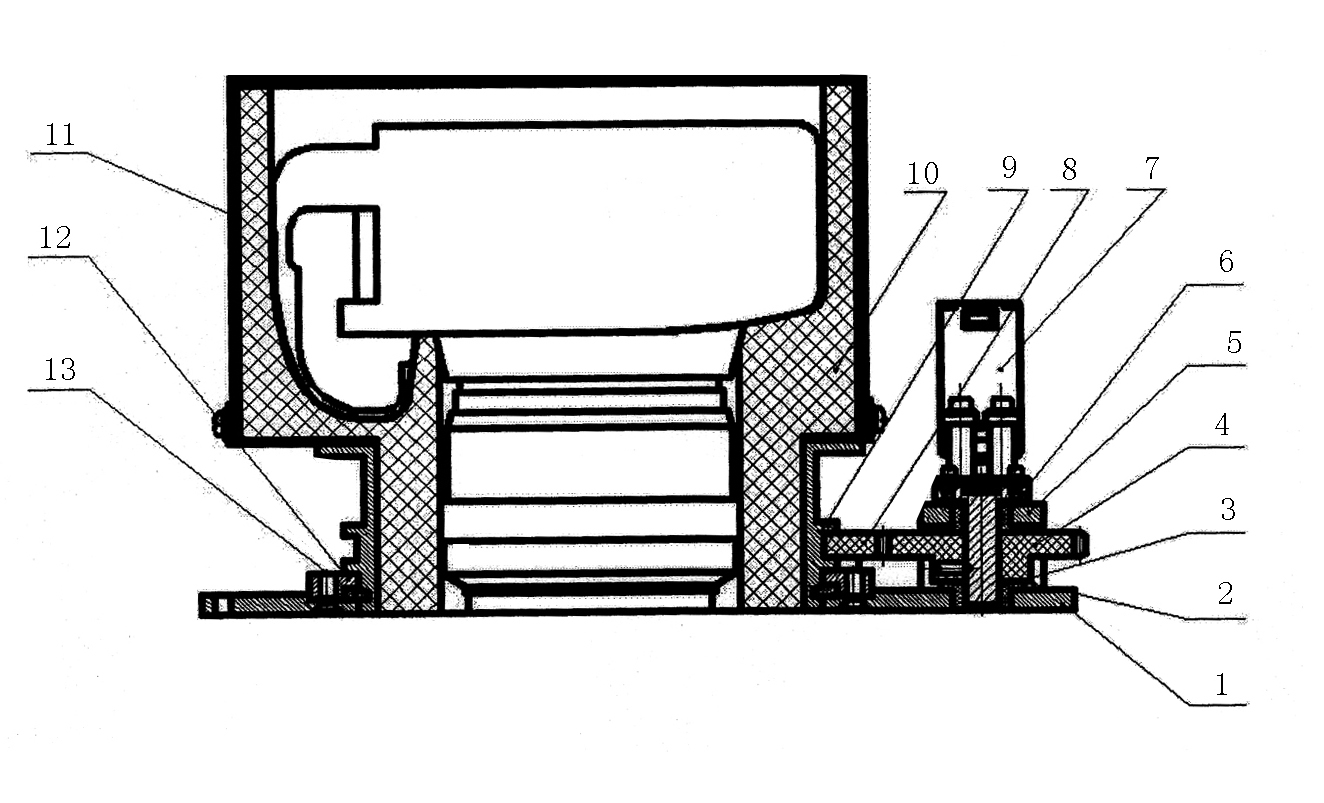

Energy-saving and clean fuel ethanol production method

ActiveCN107418979AReduce consumptionRealize green energy savingChemical industryBiofuelsReboilerDesorption

The invention discloses an energy-saving and clean fuel ethanol production method. According to the energy-saving and clean fuel ethanol production method, a production process comprises a mash preparation unit, a distillation and dehydration unit and a mash waste processing unit; heating steam of a first distillation tower reboiler of the distillation and dehydration unit is fresh steam, and exhausted steam condensate is collected and conveyed to a first distillation tower column to directly heat tower bottoms. By means of the techniques of multi-stage multi-effect utilization of steam, side-draw impurity removal, two-stage desorption and regeneration, tail gas impurity removal via liquefaction and flashing, process wastewater recycling and the like, steam consumed for producing 1 ton of fuel ethanol products is less than or equal to 1.3 tons, and the acidity index of the fuel ethanol products is less than or equal to 40 mg / L, so that energy and material consumption during fuel ethanol production can be effectively reduced, clean production with zero emission of industrial wastewater can be achieved, the industrial problem that the acidity index of fuel ethanol products is instable and fails to meet the of GB18350-2013 denatured fuel ethanol standard requirements, and the marketing competitiveness of biofuel ethanol can be improved. The energy-saving and clean fuel ethanol production method belongs to the technical field of renewable clean energy technology.

Owner:TIANJIN UNIV

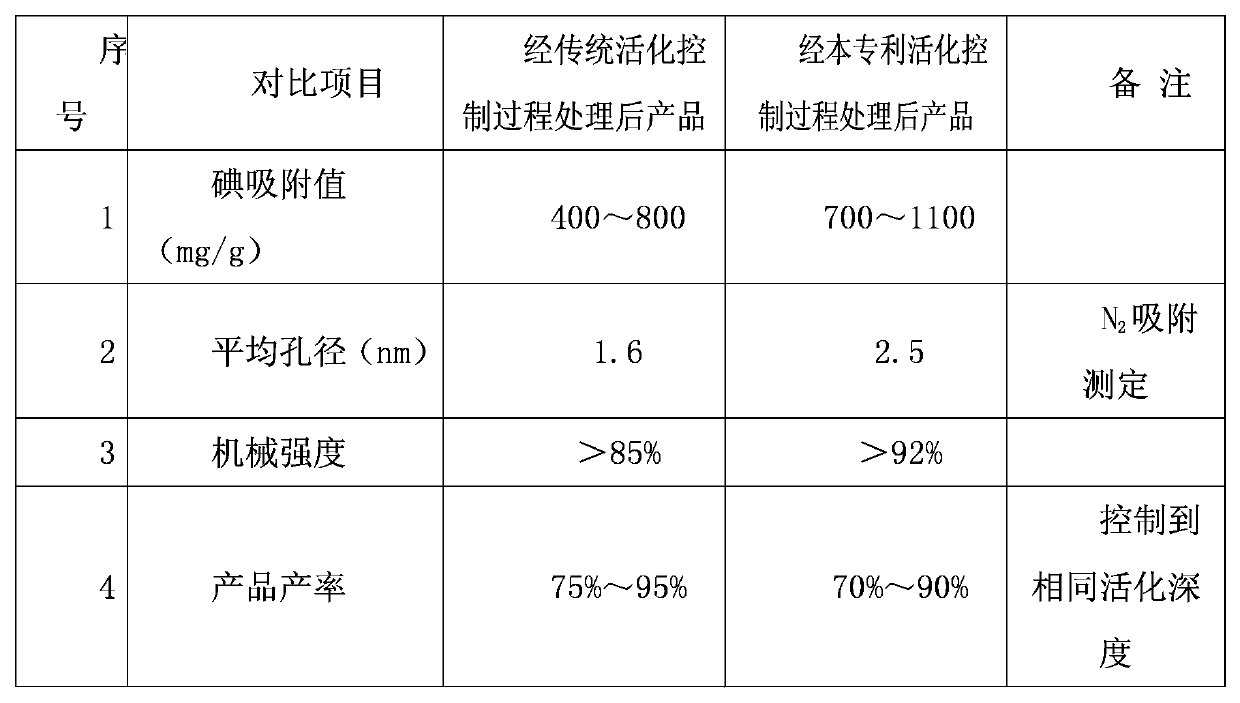

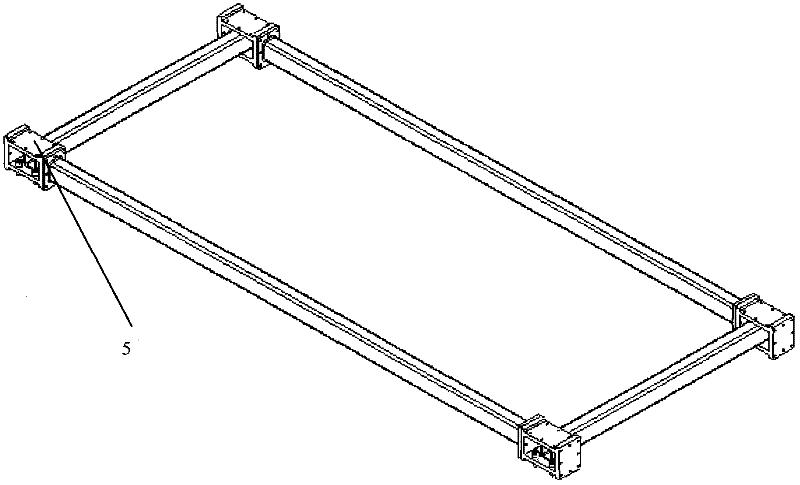

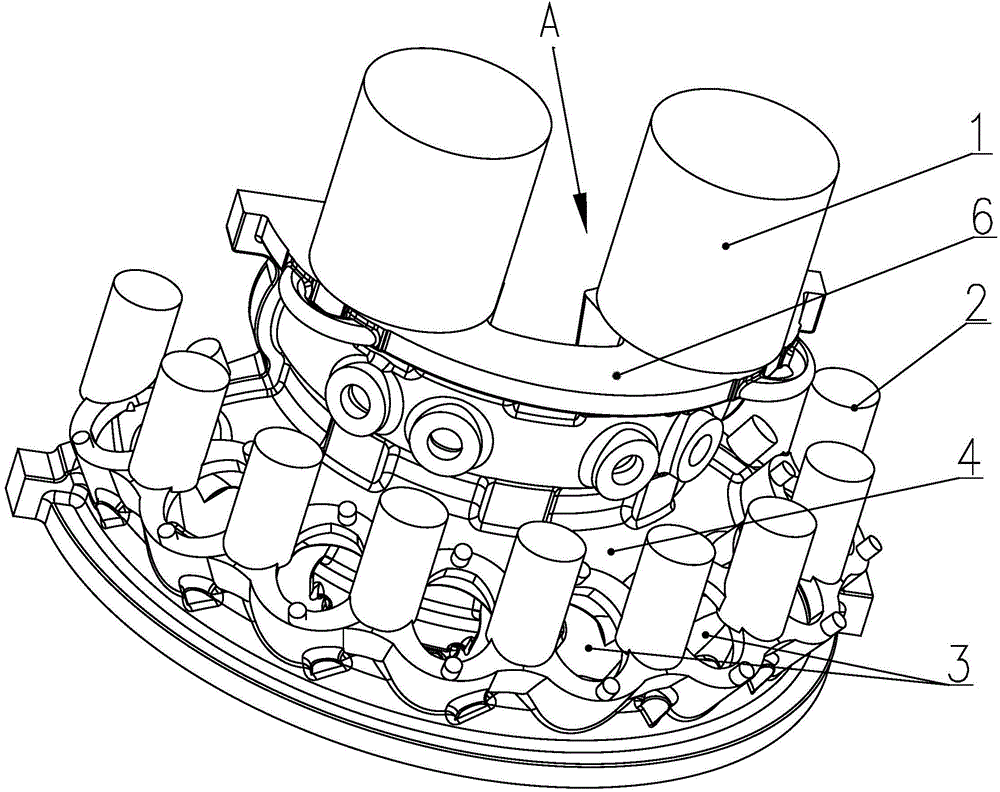

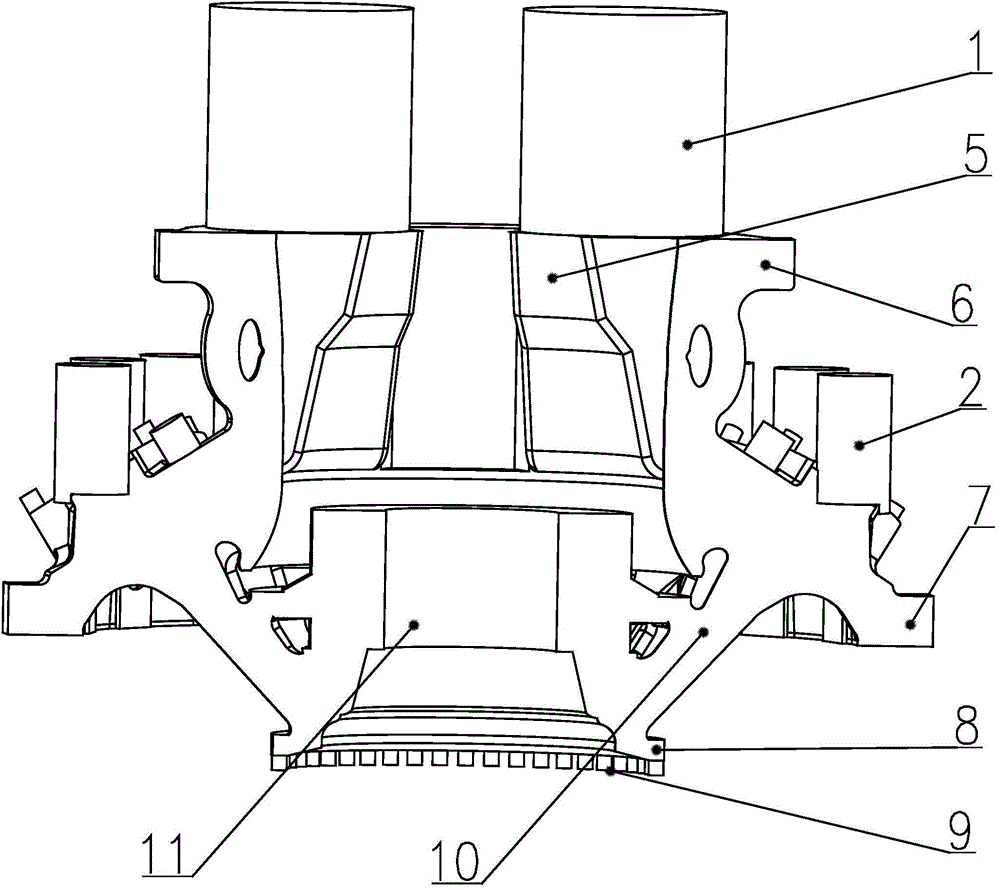

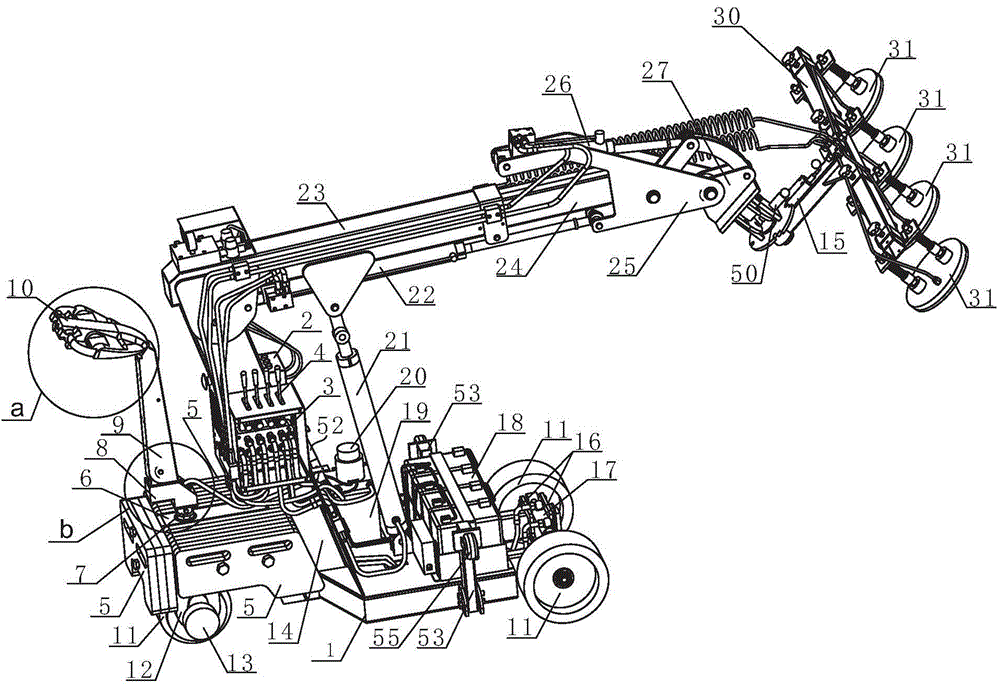

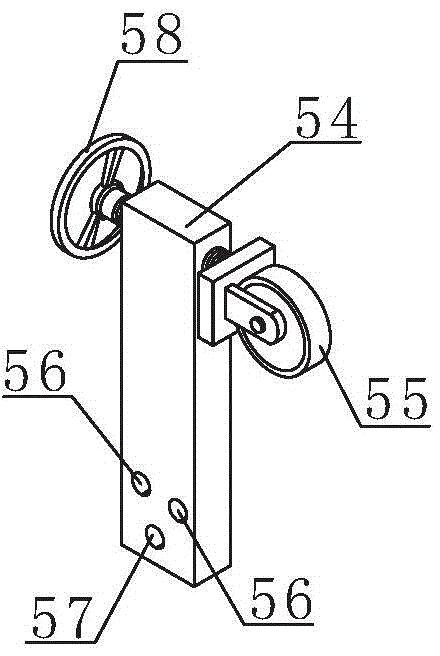

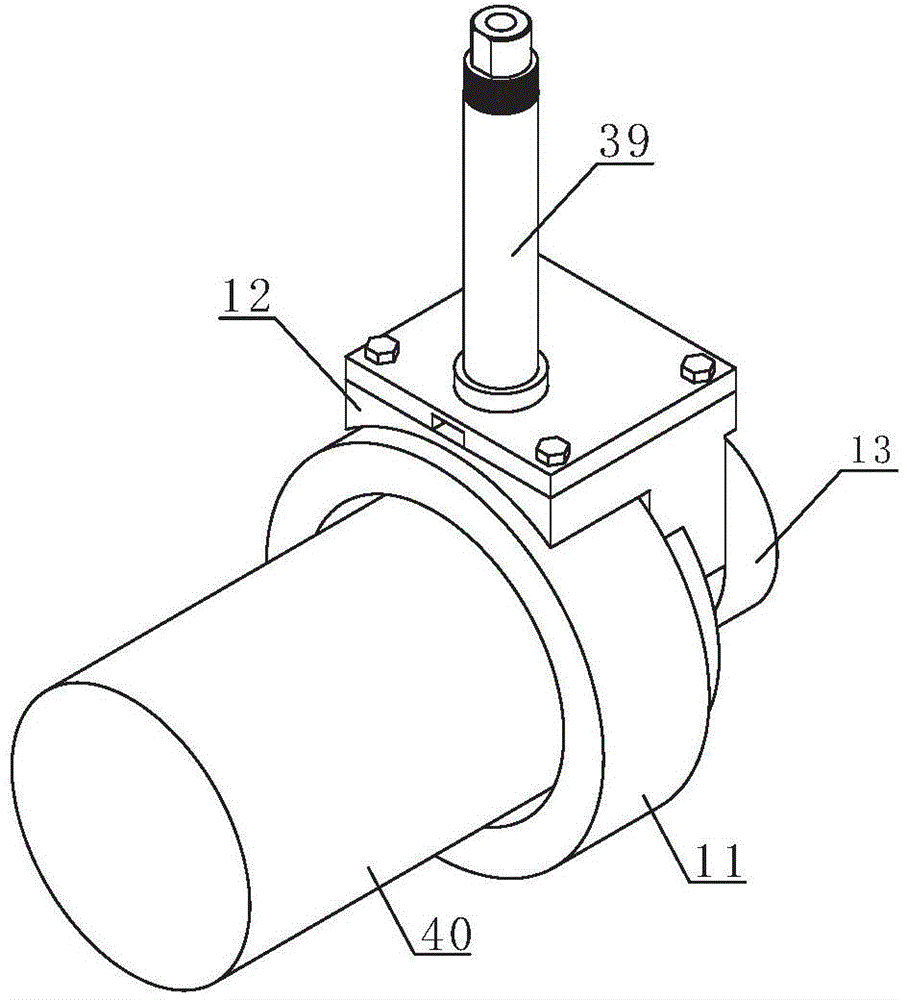

Wall building robot

ActiveCN104878945ABig market demandEconomicalBuilding material handlingManipulatorVehicle frameEngineering

A wall building robot comprises a framework, wheels, a steering wheel, a telescopic arm, a power device, a power source, an oil circuit system, a gas circuit system and an electronic control system, the telescopic arm is composed of a movable arm and a fixed arm which is connected with the framework and a first oil cylinder, the free end of the movable arm is connected with a second oil cylinder and a positioning part, and the positioning part is further connected with a third oil cylinder; a steering shaft device installed on a tail beam of the framework is connected with a rear wheel shaft and a direction control device, the positioning part is connected with a T-shaped frame provided with multiple sucking disc devices, a front wheel shaft is fixed on a frame through a linear bearing, and plug pins penetrating through the middle of the front wheel shaft are connected with z-shaped plates which are connected with a fourth oil cylinder. A sucking disc vehicle can not only move materials with large areas or weight materials with large areas, but also conduct multi-angle adjustment on lifted objects in the spatial position, and the wall building robot is suitable for being used in the occasions of conducting construction on objects such as various kinds of sheet materials with larger areas, fabricated parts, glass or unconventional bricks and stones.

Owner:GUANGXI FENGGE GREEN HOUSE CONSTRUCT TECH

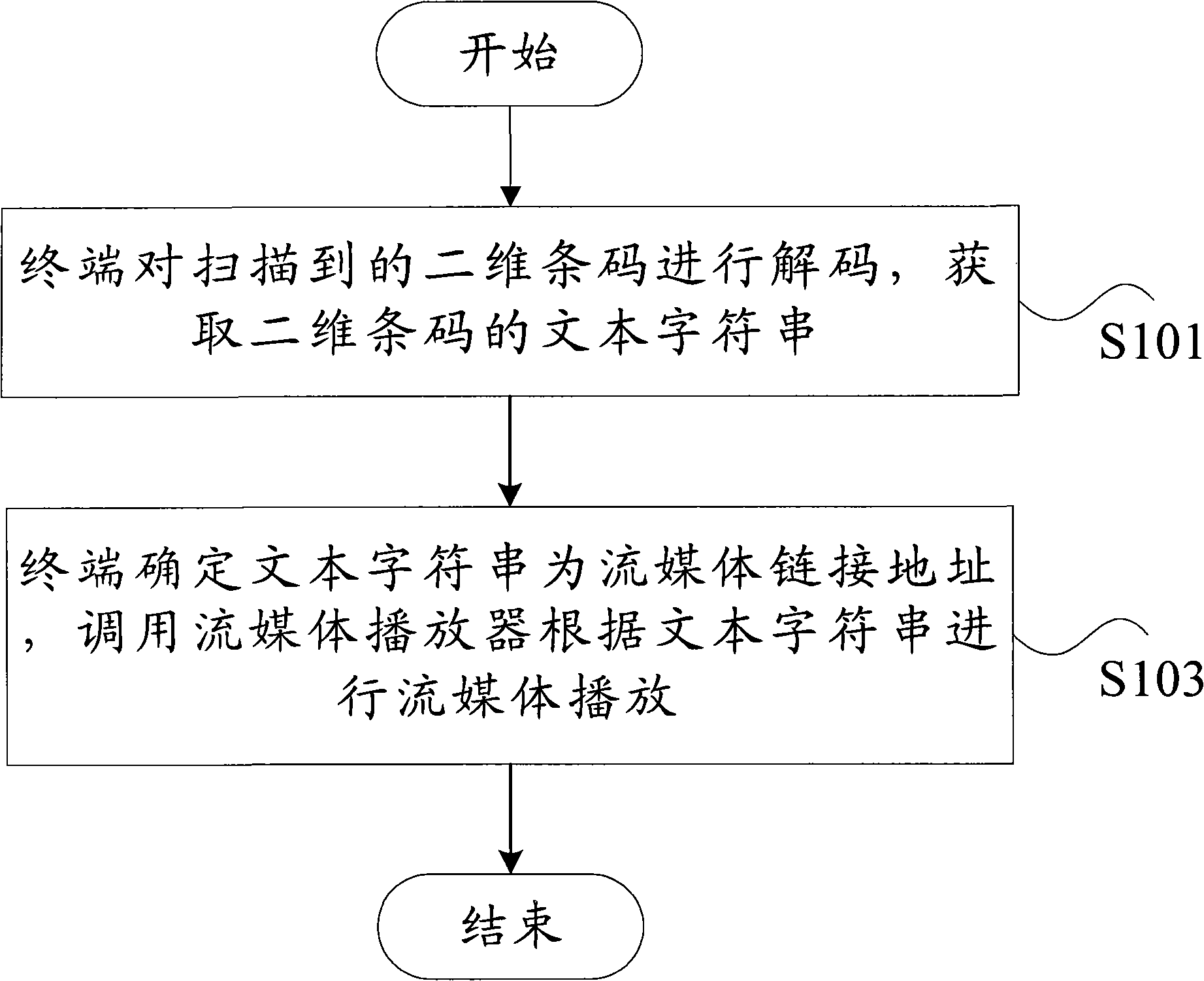

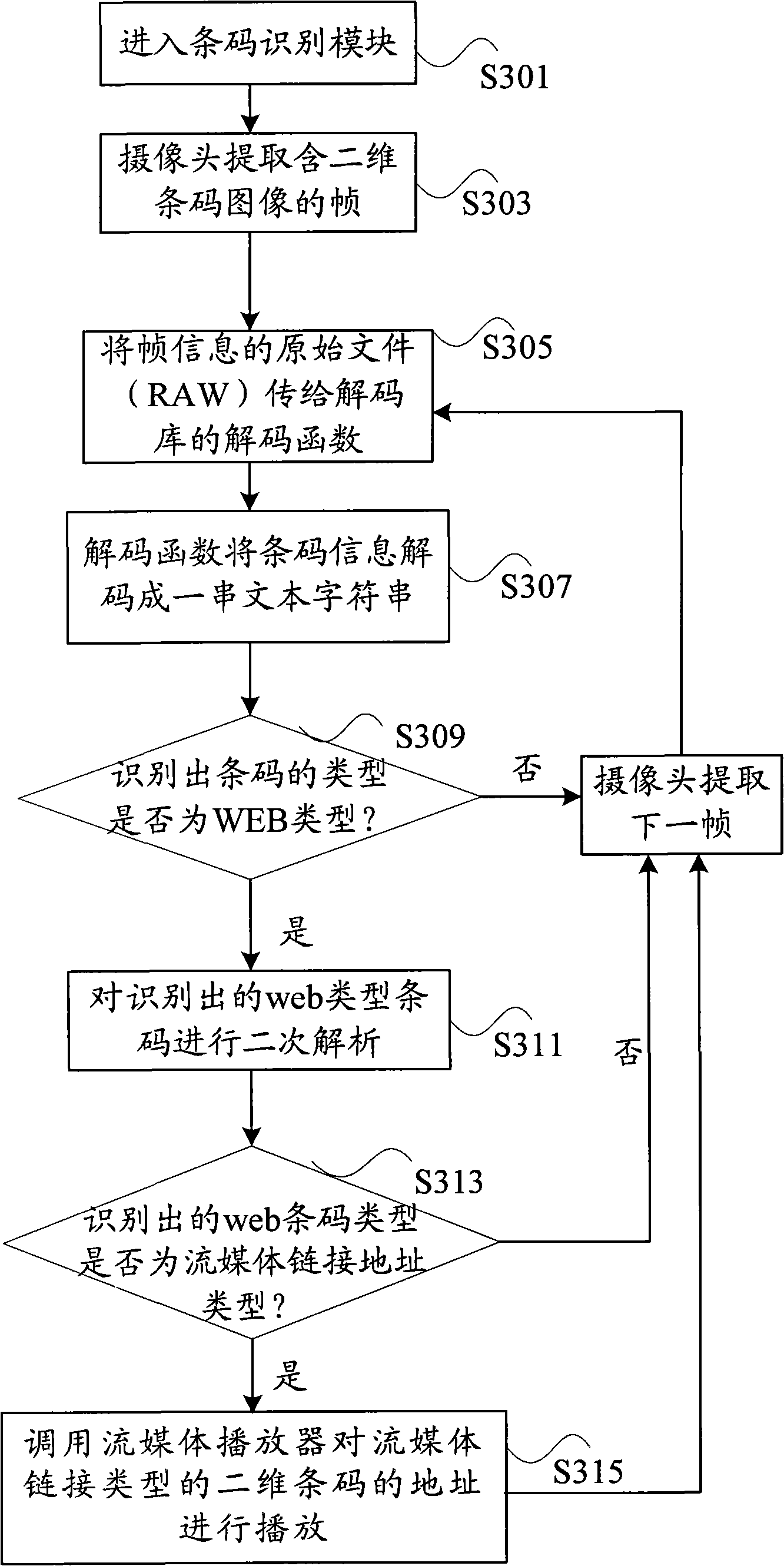

Streaming media playing method and terminal thereof

InactiveCN101556618AImprove experienceBig market demandDigital data information retrievalSpecial data processing applicationsComputer networkText string

The invention discloses a streaming media playing method and a terminal thereof, wherein, the streaming media playing method comprises the following steps of: decoding a two-dimensional bar code scanned by the terminal and obtaining text string of the two-dimensional bar code; and determining that the text string is a link address of the stream media, and calling a stream media player to play according to the text string by the terminal. The streaming media playing method and the terminal thereof can effectively integrate the two-dimensional bar code identification technology of the terminal with the stream media playing technology, thus meeting more requirements of users and improving the user experience.

Owner:ZTE CORP

Method for preparing greenhouse culture sprout stoup with water hyacinth

InactiveCN101427640ARich in Essential NutrientsSimple processCultivating equipmentsSodium bicarbonateGreenhouse

The invention discloses a planter culture method in greenhouse using waterhyacinth, comprising: dissolving starch in water; adding hydrogen peroxide and sodium bicarbonate into the uniform mixing liquid of starch and water; adding sodium hydroxide solution into uniformly stirred mixing liquid; obtaining starch glue after stirring and dissolving; guiding starch glue into a bowl module; compacting by extrusion and drying after flange trimming. The bowl culture method can effectively solve the waterhyacinth resource problem and replace the plastic bowl widely used in the prior greenhouse culture and solve the waterhyachinth utilization path and eliminate the pollution of traditional bowl greenhouse culture and resource waste, with wide market development foreground and economic benefit.

Owner:ZHEJIANG UNIV

A method for preparing release paper based on inorganic powder materials and polymers

InactiveCN102277791AWaterproofMoisture-proofNon-fibrous pulp additionSpecial paperPolymer scienceFoaming agent

The invention belongs to the field of papermaking, and relates to a preparation method of release paper based on inorganic powder materials and high molecular polymers. It is characterized in that: the formula is 60-85 parts by weight of inorganic powder material; 10-40 parts by weight of high molecular polymer; 0.3-3 parts by weight of lubricant; 0.1-2 parts by weight of foaming agent; 0.1-3 parts by weight of active agent . During preparation, in a high-speed mixer, first add inorganic powder materials and active agents to stir; then add high molecular polymers, lubricants, and foaming agents to obtain a mixture, and send the mixture to a paper film forming machine to make base paper ; Apply silicone oil evenly on the base paper; finally, dry and cool in sections to obtain release paper. By adopting the method of the invention, no trees are felled, the cost is low, and the production process does not require coating; and it has the characteristics of waterproof, moisture-proof and high strength, meets the requirements of environmental protection and energy saving, and has great development potential and market demand.

Owner:HUNAN FUTAI DIGITAL MATERIAL TECH

Method for preparing health nutrition instant fish head and fish gelly

InactiveCN1943434AImprove resource utilizationNutritional diversityFood preparationPlant ingredientsFisheryFish head

The invention provides preparation for health care medicated fish head and jelly comprised of fish head and ripen fish meat as materials, prepared by adding healthy auxiliary materials and condiment according to different season , health effect and people, adding small fish head, after boiling in light fire removing fish head and soup materials into earthenware pot to be boiled for 100-150 minutes in said fire, thereafter dredging up all residue and cover oil and adding pepper seeds of 6-10g, to be boiled again for 10-30 minutes, dredging up residue and cover oil and adding said auxiliary and condiment to be mixed and filtering through sifter, adding ripen fish piece 50-100g to be mixed up, and the temperature falls naturally to 20-40deg.C, pouring into bunker of fruit jelly machine, to be bottled and sealed up to obtain said fish head and jelly.

Owner:乐子华

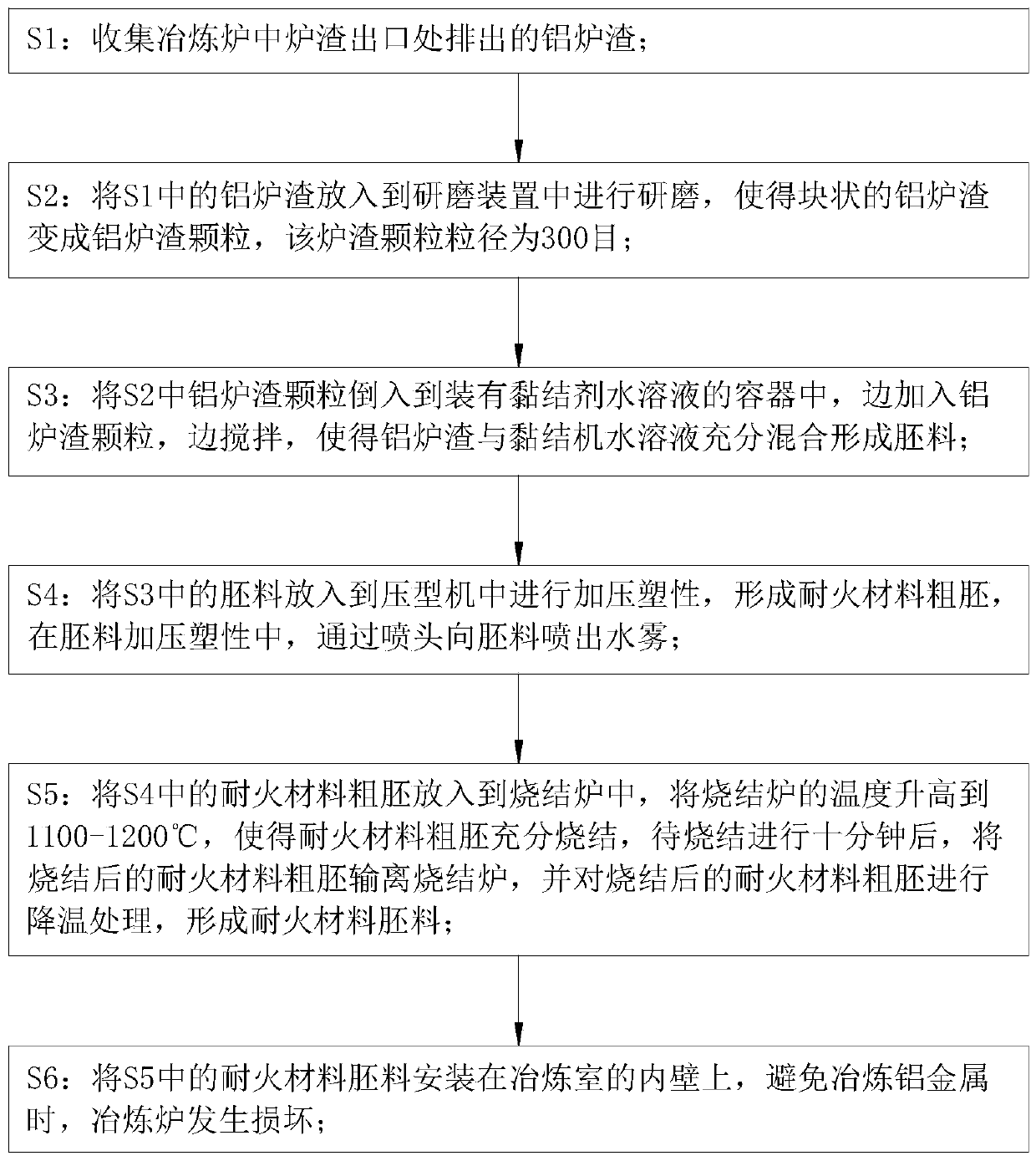

Process for reusing slag of aluminum smelting furnace

ActiveCN109719114AImprove qualityExtended service lifeSolid waste disposalIncreasing energy efficiencySlagSpray nozzle

The invention belongs to the technical field of slag reutilization and particularly relates to a process for reusing slag of an aluminum smelting furnace. The process adopts the smelting furnace. Thesmelting furnace comprises a box body and further comprises a crushing unit, material guide units, a smelting chamber, a motor, a collecting box, a first pipe, a purifying unit and a controller. By the adoption of the process, on the one hand, in the process of mixing the aluminum slag and an aqueous solution of a sintering machine, the aluminum slag and the aqueous solution of the sintering machine are fully mixed to form blanks while being added and stirred; meanwhile, spray nozzles are used to spray water mist to the blanks during the pressurization and plasticity of the blanks, so that theblanks are tightly attached, no fracture occurs between the blanks during sintering in the sintering furnace, and thus the quality of a refractory blank is improved; and on the other hand, the formedrefractory blank is installed on the inner wall of the smelting chamber to prevent the smelting furnace from being damaged when aluminum metal is smelted, so that the service life of the smelting chamber is prolonged.

Owner:绥化春达矿渣高细制造有限公司

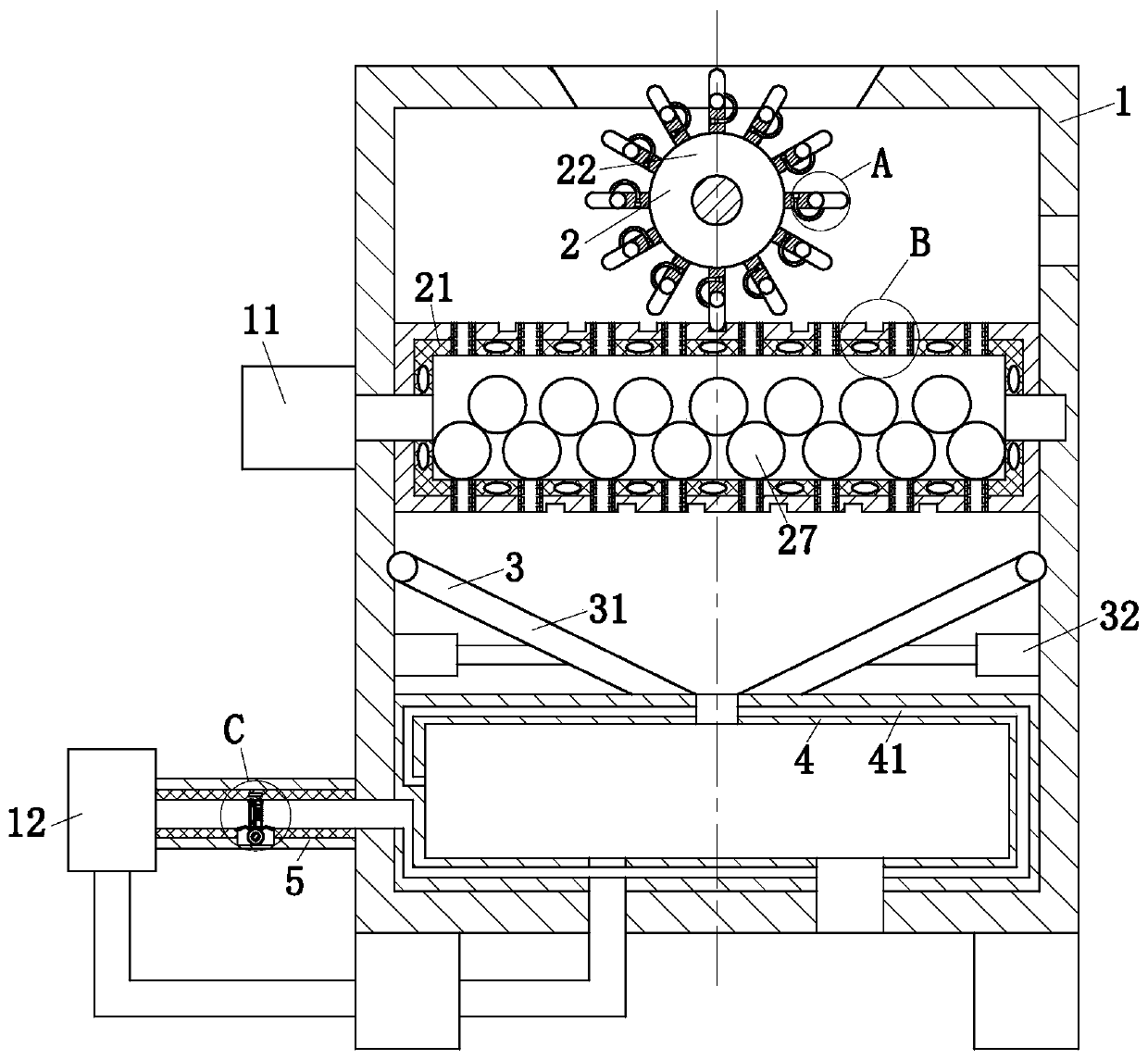

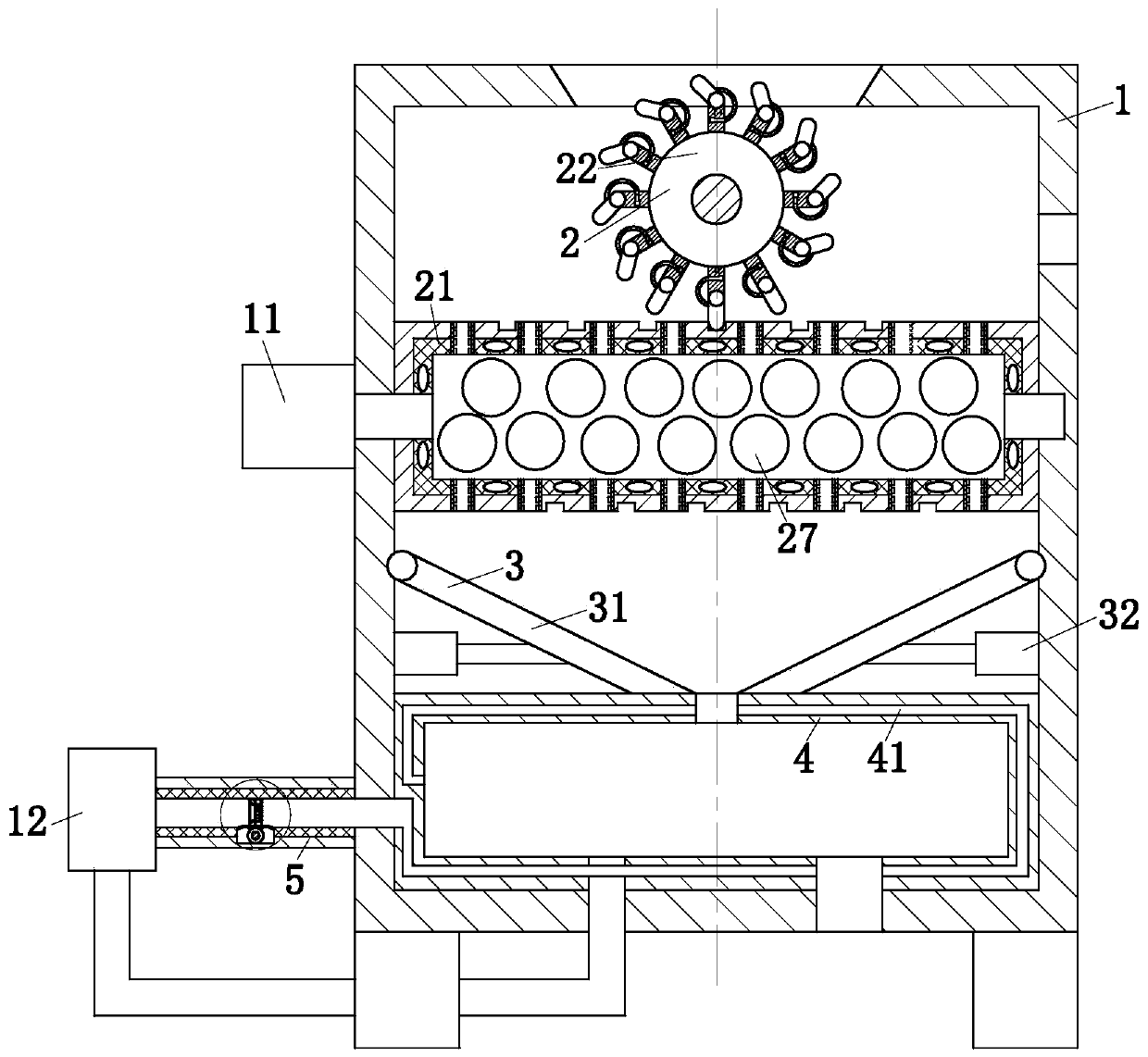

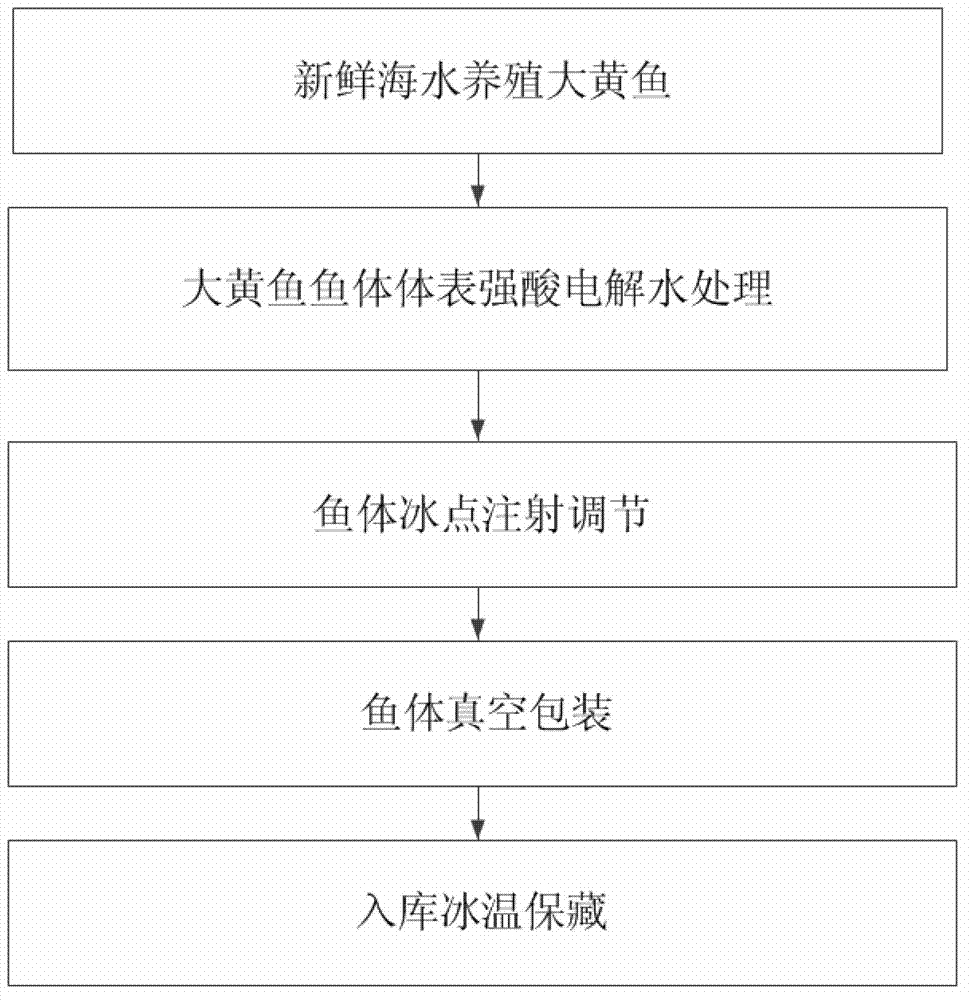

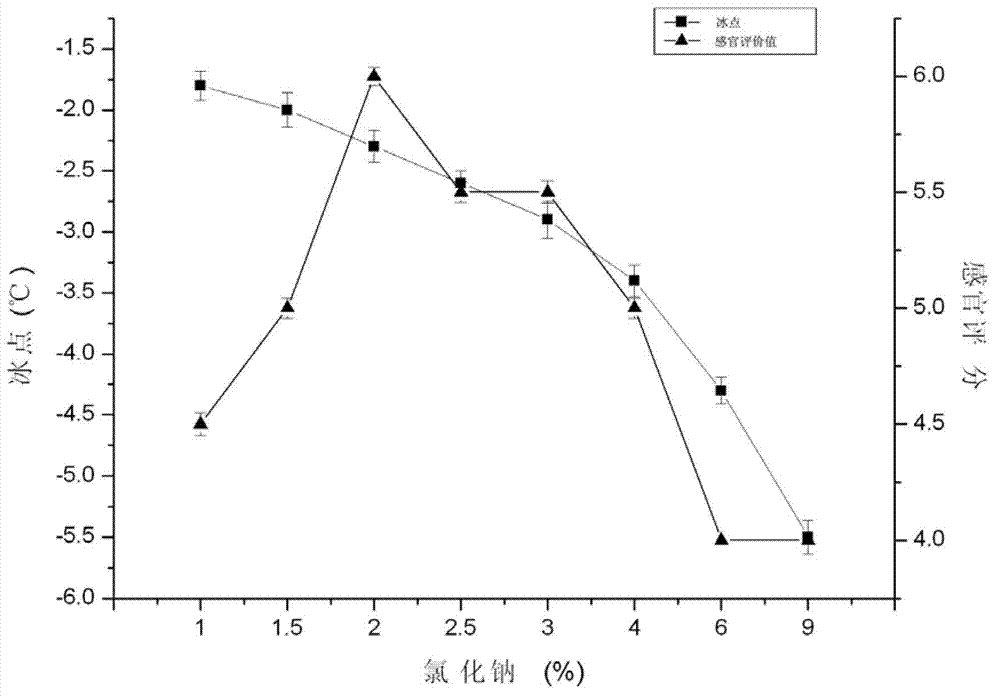

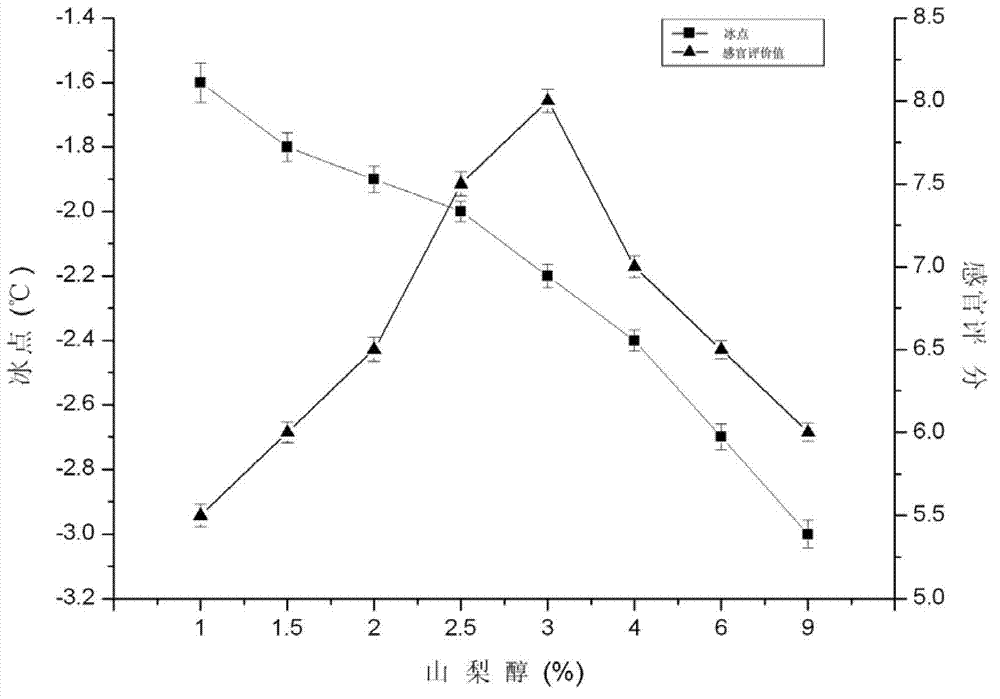

Fresh pseudosciaena crocea ice temperature fresh keeping method

InactiveCN102783516ABig market demandAdd flavorMeat/fish preservation by freezing/coolingCold chainThermodynamics

The invention relates to a fresh pseudosciaena crocea ice temperature fresh keeping method. According to the fresh pseudosciaena crocea ice temperature fresh keeping method provided by the invention, the water electrolysis sterilization technology is utilized for being combined with the ice point temperature regulating technology, the freshness, the flavor and the texture of the fresh pseudosciaena crocea are remained to the maximum degree while the ice point of the fresh pseudosciaena crocea is reduced, meanwhile, the work procedure time is short, in addition, the whole process of the work procedure conforms to the cold chain requirements, and the method has the industrialized large-scale production conditions.

Owner:ZHEJIANG OCEAN UNIV

Cross positioning navigation method combining satellite positioning and digital scene matching identification

InactiveCN104101351ASimplify computational workloadSimplify memcache pressureInstruments for road network navigationObfuscationScene matching

The invention discloses a novel positioning navigation method, and in particular relates to a cross positioning navigation method combining satellite positioning and digital scene matching identification. According to the method, digital characteristic function image recognition method is used for three steps of obfuscation, abstraction and digitization of an intersection scene filmed in real time, and a characteristic function is established for each intersection, then is bounded with a satellite positioning position and stored in a city geographic information database. When driving, the characteristic function of the intersection scene filmed in real time is matched with a corresponding intersection scene characteristic function prestored in the database by navigation equipment for comparison to achieve accurate intersection recognition, and an obtained position is compared with a current position generated by satellite positioning navigation, and if the obtained position does not agree with the current position generated by the satellite positioning navigation, a navigation deviation or a navigation error is occurred.

Owner:朱孝杨

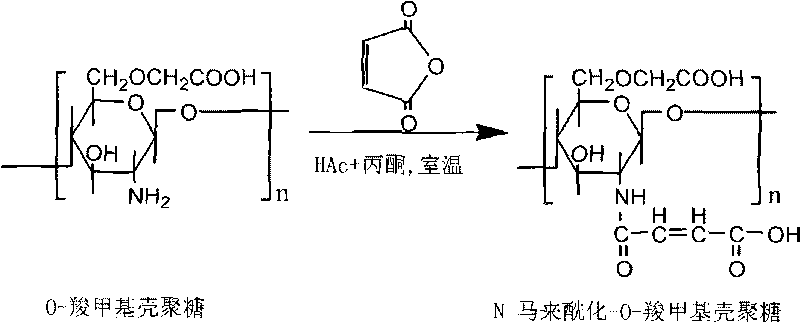

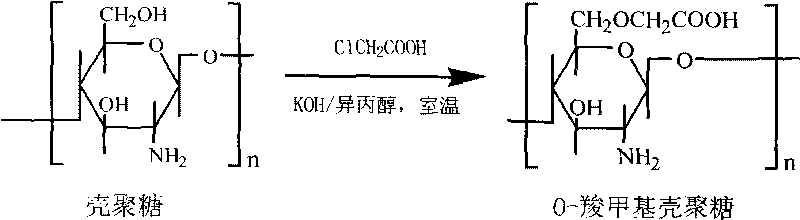

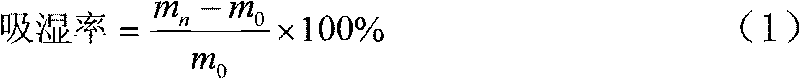

Method for preparing moisturizing agent N-maleylation-O-carboxymethyl chitosan

InactiveCN101696247AGood moisturizing effectImprove securityCosmetic preparationsToilet preparationsO carboxymethyl chitosanGram

The invention discloses a method for preparing a moisturizing agent N-maleylation-O-carboxymethyl chitosan, which is characterized by comprising the following steps: weighing 2 grams of O-carboxymethyl chitosan, putting the O-carboxymethyl chitosan in a reactor, adding 90 milliliters of acetic acid solution of which volume fraction is 3 percent into the reactor, stirring the mixture to dissolve for 1 hour till forming homogeneous phase solution, weighing maleic anhydride in a molar ratio of 1 to 1 with the O-carboxymethyl chitosan again, then dissolving the maleic anhydride in 5 milliliters of acetone, adding the solution into the reactor by stirring, and reacting the mixture for 15 hours at room temperature; and purifying the product by using the acetone, and drying the purified product in a vacuum constant temperature drying oven at the temperature of 50 DEG C to obtain N-maleylation-O-carboxymethyl chitosan. The method has the advantages that the moisturizing agent N-maleylation-O-carboxymethyl chitosan has better safety and bioactivity compared with other moisturizing agents and has broad market demands.

Owner:NANCHANG HANGKONG UNIVERSITY

Single-spindle cradle head device for aerial photography unmanned plane

InactiveCN102032426AHigh yieldScientific and reasonable structure designNon-rotating vibration suppressionStands/trestlesLow noiseAutomatic control

The invention relates to a single-spindle cradle head device for an aerial photography unmanned plane, which belongs to the technology of a single-spindle course deviation-rectifying mechanical cradle head which can be automatically controlled. The single-spindle cradle head has the structure that a barrel is installed on a motherboard, a gearwheel is fixed in the mounting groove of the barrel, and a box is fixed on the barrel; a pinion is connected to a coupling shaft after being meshed with the gearwheel, and a servo is installed on the shore and the coupling shaft of a bedplate. The single-spindle cradle head device ensures that the unmanned plane carries out real-time course deviation rectification and mechanical shock adsorption for cameras in the operation process, picture images are clear, and picture forming rate is high. Meanwhile, the invention has scientific and reasonable structural design, low cost, low noise and energy saving, is safe, efficient, small, portable, efficient and mobile, can be widely applied for monitoring and detecting in various fields of public security, national defense industry, the digital earth and the like, has wide market demands and is easy to popularize and apply.

Owner:HIWING AVIATION GENERAL EQUIP

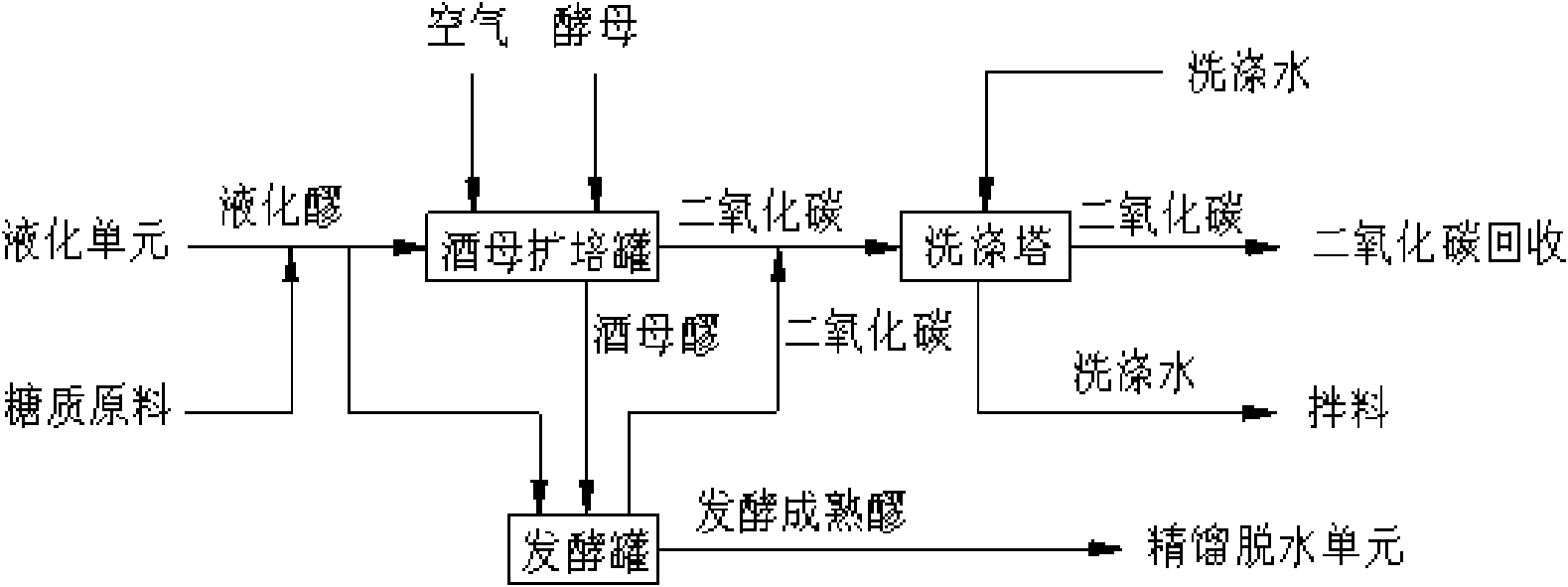

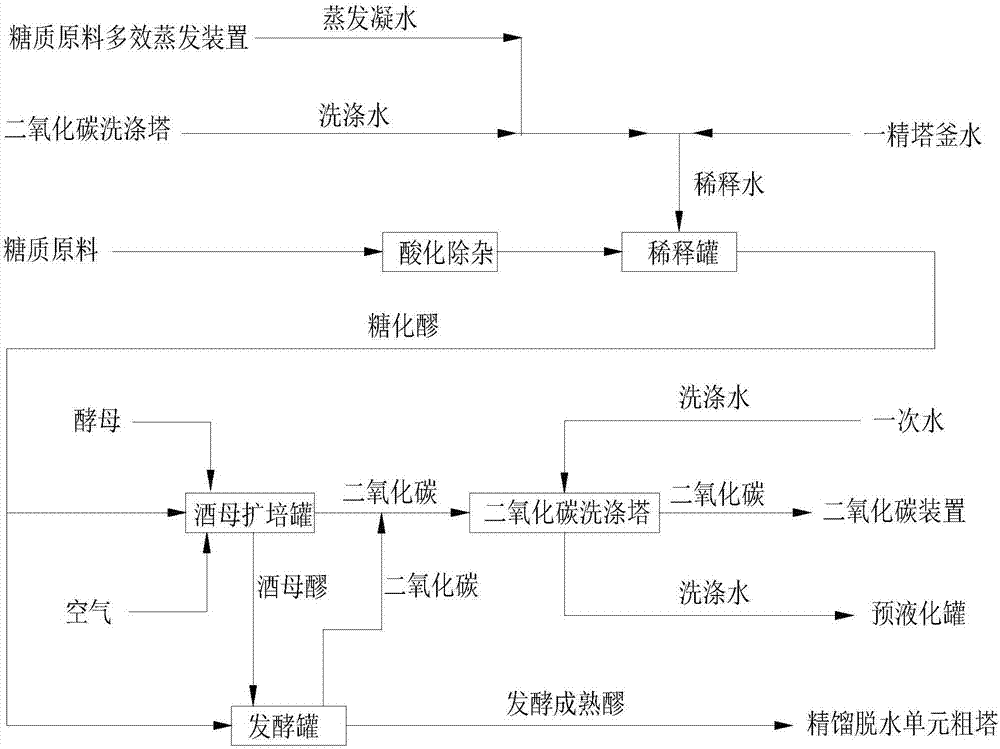

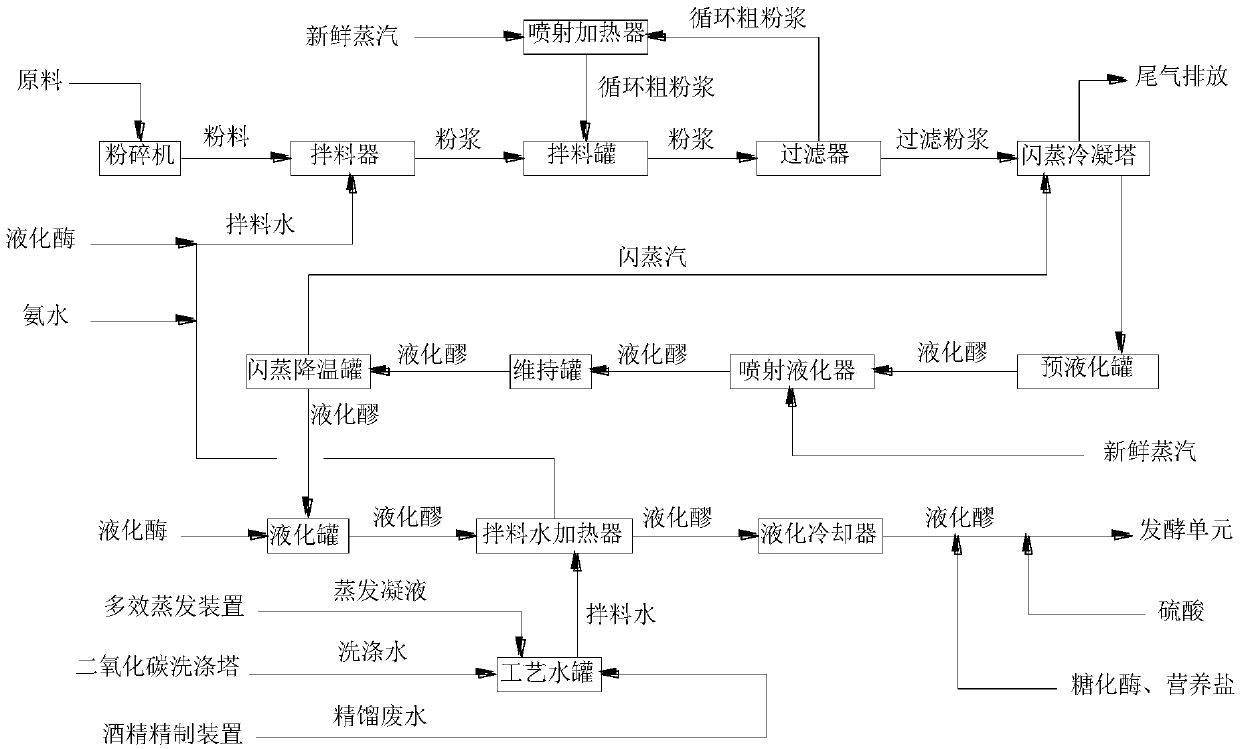

Brewing alcohol production method

InactiveCN107653135AReduce the difficulty of separationQuality improvementAlcoholic beverage preparationInstabilityEvaporation condensation

The invention discloses a brewing alcohol production method. The brewing alcohol production method mainly involves a liquefying unit, a fermenting unit and a rectifying and waste liquor treating unitand includes cross-gelatinization-point pulping, multiple-effect utilization of low-energy-level steam, non-condensable gas impurity removal of low-alcohol liquefied mash and recycling of process wastewater. An annular feeding pipe is used for a fermenting tank of the fermenting unit, bidirectional alternate feeding with sequential control is adopted, and the pipe is free from a fermented mash feeding lag deposit area, so that abnormal fermentation is inhibited. The brewing alcohol production method solves the industrial problems of alcohol product instability, high energy consumption, the requirement on redistillation and failure to reach the superfine edible alcohol standards of GB 18350-2013 in taste index of a mainstream brewing alcohol production technology, thereby meeting the development requirement of the liquid-base Baijiu industry. Brewing alcohol obtained by the brewing alcohol production method is 14-18% in alcohol content of mature mash, the alcohol yield of starch is notless than 92%, and zero wastewater discharge in a main production process is achieved through recycling of evaporation condensation water.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com