Sludge environment-friendly renewable coal and preparation method thereof

A sludge and environmental protection technology, applied in the field of sludge environmental protection and recycled coal and its preparation, can solve environmental pollution and other problems, and achieve the effects of broad market prospects, good combustion effect, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

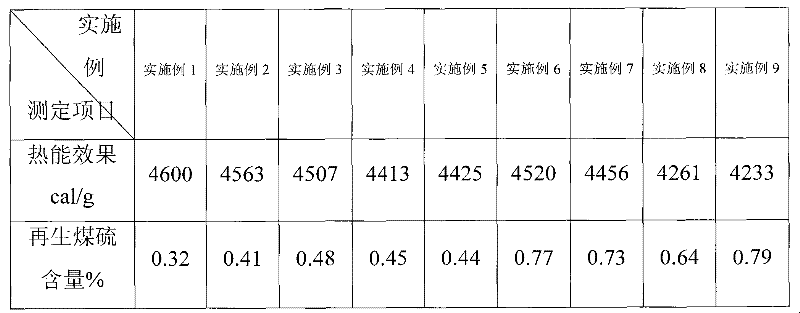

Examples

Embodiment 1

[0026] Dry and dehydrate the sludge to a moisture content of 20%, place it for 24 hours, and send it to a pulverizer to pulverize it into powder.

[0027] Send calcium oxide, calcium carbonate, calcium hydroxide, sodium carbonate, kaolin, sodium nitrate, and potassium permanganate into the mixer according to the ratio of 1:1:1:1:0.5:0.5:0.5 and mix evenly to obtain the ready-to-use product I .

[0028] Send the sawdust into a pulverizer and pulverize it into a powder, and mix it with the waste oil of the repair shop in a ratio of 8:3 to obtain the ready-to-use product II.

[0029] The materials to be used I, materials to be used II and powdered sludge are mixed in a ratio of 4:36:60 and sent to a mixer for uniform mixing, and then taken out and pressurized to form a formed massive sludge environmentally friendly recycled coal.

Embodiment 2

[0031] The sludge is dried and dehydrated to a moisture content of 25%, and after standing for 24 hours, it is sent into a pulverizer to be pulverized into powder.

[0032] Send calcium oxide, calcium carbonate, calcium hydroxide, sodium carbonate, kaolin, sodium nitrate, and potassium permanganate into the mixer according to the ratio of 1:1:1:1:0.5:0.5:0.5 and mix evenly to obtain the ready-to-use product I .

[0033] Put aluminum waste into a pulverizer and pulverize it into powder, and mix it with leather treatment waste oil at a ratio of 8:3 to obtain the ready-to-use product II.

[0034] The materials to be used I, materials to be used II and powdered sludge are mixed in a ratio of 3:27:70 and sent to a mixer for uniform mixing, and then taken out and pressurized to form a formed massive sludge environmentally friendly recycled coal.

Embodiment 3

[0036] The sludge is dried and dehydrated to a moisture content of 26%, and after standing for 24 hours, it is sent to a pulverizer to be pulverized into powder.

[0037] Send calcium oxide, calcium carbonate, calcium hydroxide, sodium carbonate, Guanyin soil, sodium nitrate, and potassium permanganate into the mixer according to the ratio of 1:1:1:1:0.5:0.5:0.5 and mix evenly to obtain the ready-to-use product I.

[0038] Send the solid cycloalkane into a pulverizer to pulverize it into a powder, and mix it with edible waste oil at a ratio of 10:3 to obtain the ready-to-use product II.

[0039]Mix the materials to be used I, materials to be used II, and powdered sludge in a ratio of 5:25:70 and send them into a blender to mix evenly, then take them out and press them to form, so as to obtain the molded massive sludge environmentally friendly recycled coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com