Method for preparing activated carbon from semi-coke and device used in same

A technology of activated carbon and blue carbon, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of inaccurate control of activation process, uneven pore structure of products, and no more successful applications, and achieves an increase in industrial Application methods, increase product added value, and meet market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

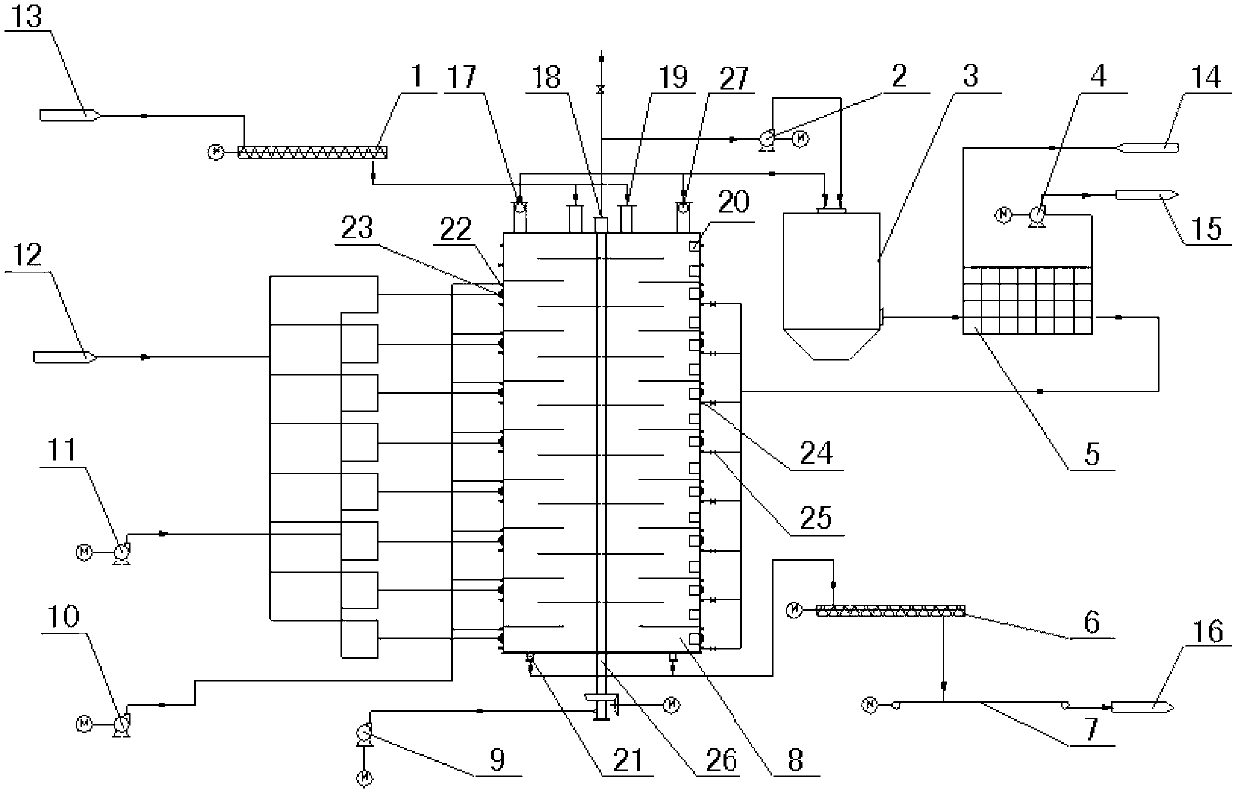

[0043] Embodiment 1 of the present invention: as figure 1 As shown, a method of preparing activated carbon from blue charcoal, taking blue charcoal with a volatile content greater than 5% and a thermal stability greater than 70%, after screening, the blue charcoal with a particle size of 5 mm to 20 mm is sent to the rake activation furnace 8 for activation After the activated carbon is discharged from the rake activation furnace 8, it is cooled by the spiral cooler 6 and transported by the belt conveyor 7, and finally enters the activated carbon packaging section for screening and packaging. The semi-coke is fed from the top of the rake activation furnace 8 close to the feed port 19 of the central axis 26 of the activation furnace, and falls into the first layer of hearth. The blue charcoal on the first layer of hearth is turned from inside to outside under the turning of the rake teeth. , that is, the outer rake, and then fall into the second layer of hearth from the blanking...

Embodiment 2

[0056] Embodiment 2 of the present invention: as figure 1 As shown, a method for preparing activated carbon from blue charcoal, taking blue charcoal with a volatile content greater than 10% and a thermal stability greater than 70%, after screening, sending the blue charcoal with a particle size of 5mm to 20mm into the rake activation furnace 8 for activation After the activated carbon is discharged from the rake activation furnace 8, it is cooled by the spiral cooler 6 and transported by the belt conveyor 7, and finally enters the activated carbon packaging section for screening and packaging. The semi-coke is fed from the top of the rake activation furnace 8 close to the feed port 19 of the central axis 26 of the activation furnace, and falls into the first layer of hearth. The blue charcoal on the first layer of hearth is turned from inside to outside under the turning of the rake teeth. , that is, the outer rake, and then fall into the second layer of hearth from the blanki...

Embodiment 3

[0073] Embodiment 3 of the present invention: as figure 1 As shown, take the semi-coke with a volatile content greater than 10% and a thermal stability greater than 70%, and after screening, send the semi-coke with a particle size of 5mm to 20mm into the rake activation furnace 8 for activation treatment to generate activated carbon. After the activation furnace 8 is discharged, it is cooled by the spiral cooler 6 and transported by the belt conveyor 7, and finally enters the activated carbon packaging section for screening and packaging. The semi-coke is fed from the top of the rake activation furnace 8 close to the feed port 19 of the central axis 26 of the activation furnace, and falls into the first layer of hearth. The blue charcoal on the first layer of hearth is turned from inside to outside under the turning of the rake teeth. , that is, the outer rake, and then fall into the second layer of hearth from the blanking hole on the outside of the hearth. The central blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com