Brewing alcohol production method

A production method and alcohol technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of complex decontamination purification process, unstable product quality, and high energy and material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

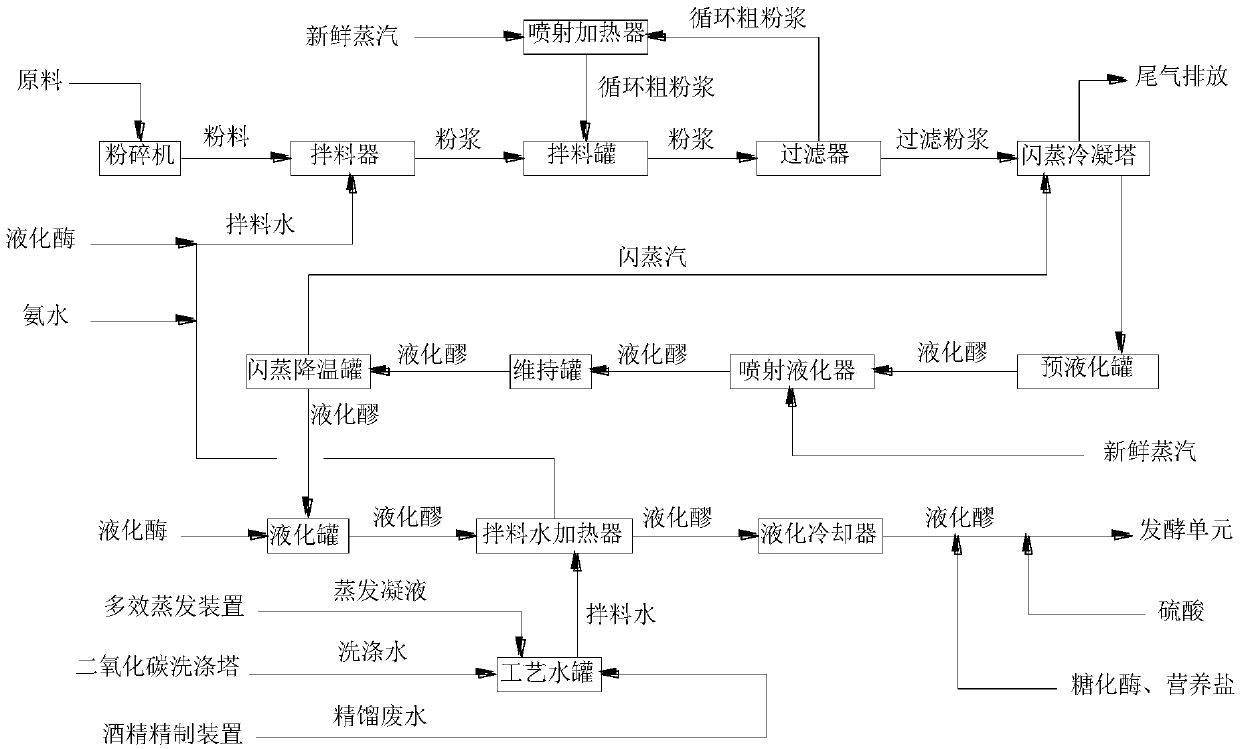

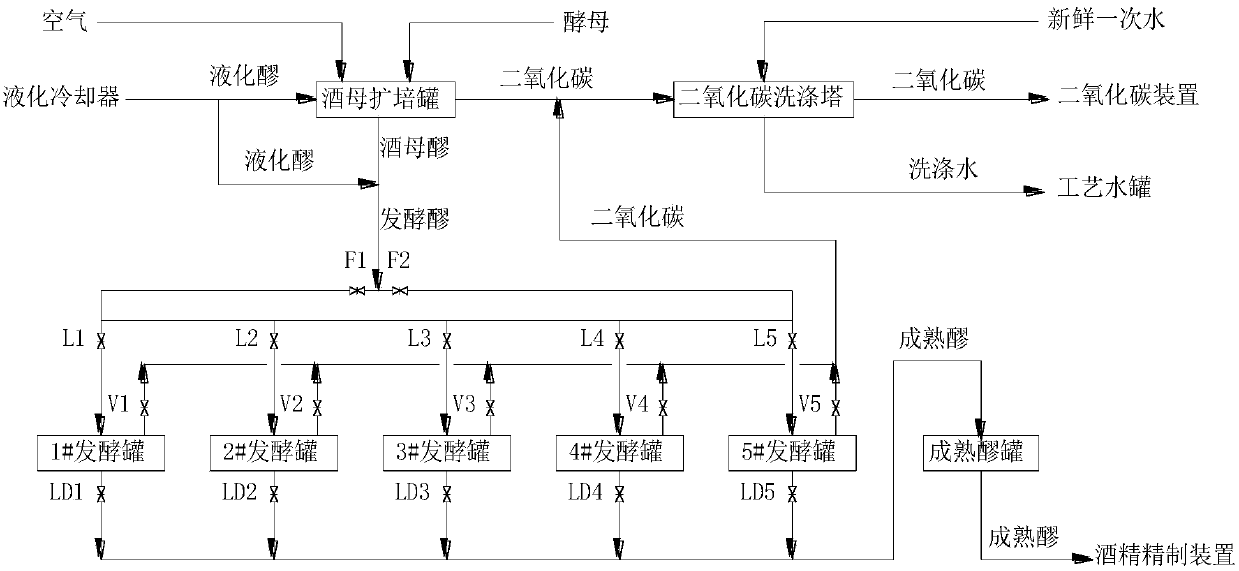

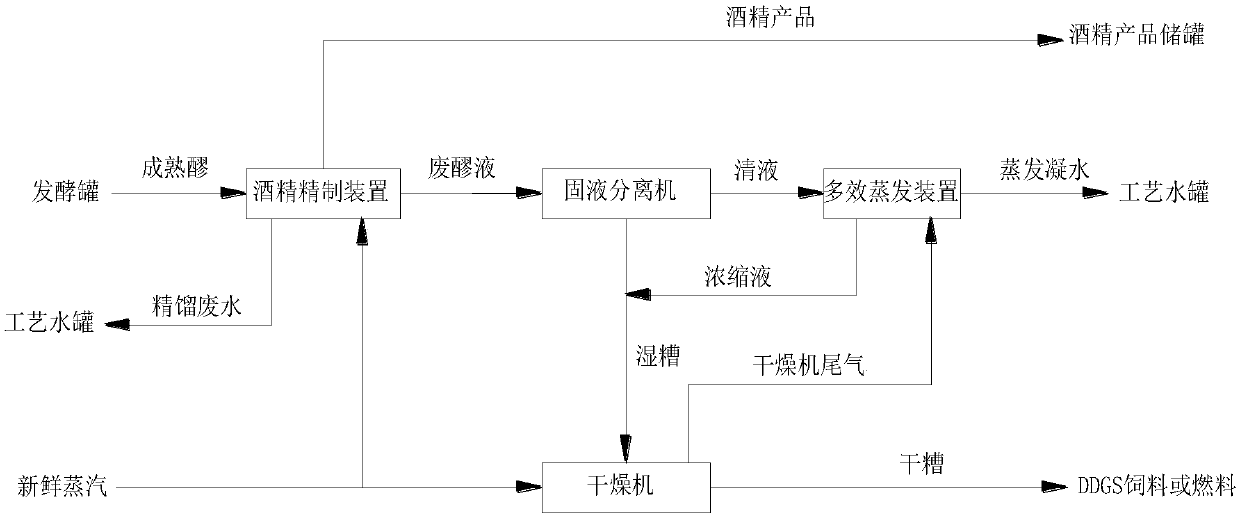

[0088] Using cassava as raw material to produce super edible brewing alcohol products that meet GB 18350-2013, the production process mainly includes liquefaction unit, fermentation unit, rectification and waste liquid treatment unit, see for example figure 1 , figure 2 , image 3 , Figure 4 . Specific steps are as follows:

[0089] 1. Liquefaction unit

[0090] First, the cassava raw material is sent to a pulverizer for crushing, and the pulverized powder is sent to a mixer, and the mixer simultaneously adds mixing water. The mixing water in the process water tank is heated by the mixing water heater and then sent to the mixing device, and auxiliary materials such as liquefied enzyme and ammonia water are added. The hot side material of the mixing water heater is liquefied mash, which is obtained by the mixing device The powder slurry is sent into the mixing tank, and the temperature of the mixing material is greater than 72°C.

Embodiment 2

[0110] Using corn as raw material to produce special-grade edible brewing alcohol products that meet GB 18350-2013, the production process mainly includes liquefaction unit, fermentation unit, rectification and waste liquid treatment unit, see for example figure 1 , figure 2 , image 3 , Figure 4 . Specific steps are as follows:

[0111] 1. Liquefaction unit

[0112] Firstly, the corn raw material is sent to the grinder for crushing, and the crushed powder is sent to the mixer, and the mixer is added with mixing water at the same time. The mixing water in the process water tank is heated by the mixing water heater and then sent to the mixing device, and auxiliary materials such as liquefied enzyme and ammonia water are added. The hot side material of the mixing water heater is liquefied mash, which is obtained by the mixing device The powder slurry is sent into the mixing tank, and the temperature of the mixing material is 85°C.

[0113] The powder slurry obtained from...

Embodiment 3

[0132] Using corn as raw material to produce special-grade edible brewing alcohol products that meet GB 18350-2013, the production process mainly includes liquefaction unit, fermentation unit, rectification and waste liquid treatment unit, see for example figure 1 , figure 2 , image 3 , Figure 4 The body steps are as follows:

[0133] 1. Liquefaction unit

[0134] First, raw materials such as corn, wheat, sorghum, rice, cassava and sweet potato are sent to the grinder for crushing, and the crushed powder is sent to the mixer, and the mixer is added with mixing water at the same time, and the mixing water comes from the process water tank. The process water tank includes the evaporation condensate from the multi-effect evaporation unit, the washing water from the carbon dioxide scrubber, and the rectification wastewater from the alcohol refining unit.

[0135] The mixing water in the process water tank is heated by the mixing water heater and then sent to the mixing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com