Method for recycling cyclohexanol from cyclohexanone device waste liquid

A technology of cyclohexanol and cyclohexanone, which is applied in the field of separation and recovery of cyclohexanol, can solve the problems of loss of useful components, environmental pollution, etc., and achieve the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

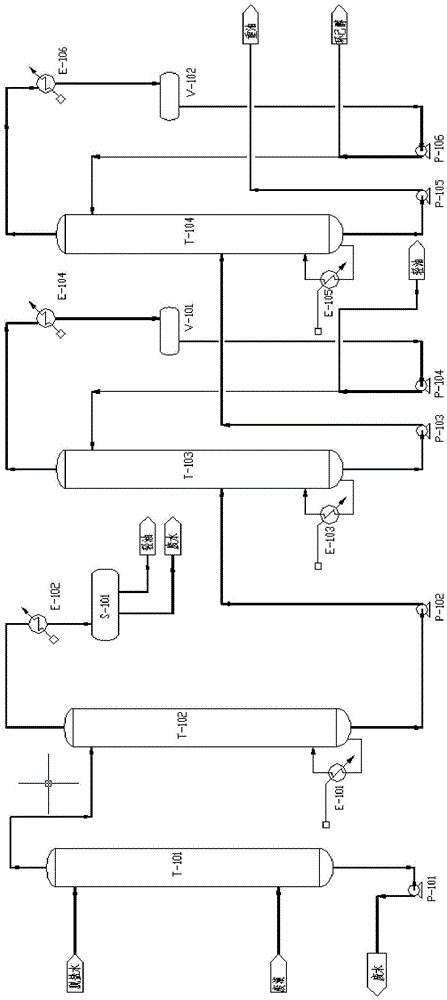

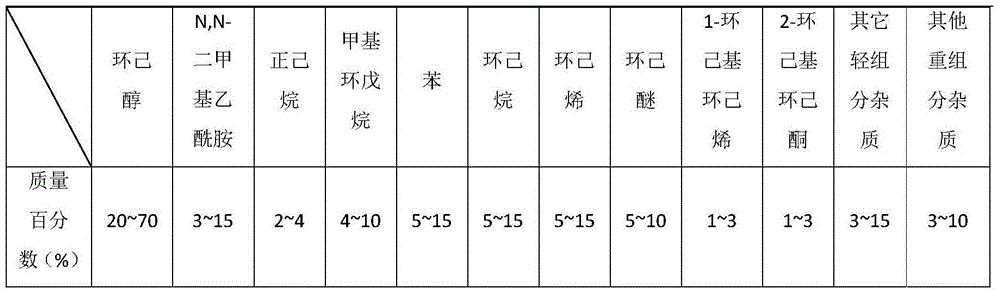

[0026] A kind of method technical process of reclaiming cyclohexanol from cyclohexanone plant waste liquid is as figure 1 Shown, the mass percent of each component of waste liquid is:

[0027]

[0028] Take the waste liquid and enter the extraction tower T-101. The theoretical plate number of the extraction tower T-101 is 20. The desalted water and waste liquid are fed from the top and bottom of the tower respectively, and the feed amount is 0.5m 3 / h, where the density of waste liquid is 967kg / m 3 ; The number of theoretical plates of the drying tower T-102 is 20, the feed at the top of the tower is operated under normal pressure, and the operating temperatures of the tower top and the bottom of the tower are 67 ° C and 90 ° C respectively; 50, feed material at the 20th theoretical plate, the operating pressure at the top of the tower is 50kPa, the control reflux ratio is 20, the temperature at the top of the tower and the bottom of the tower are 58°C and 142°C respective...

Embodiment 2

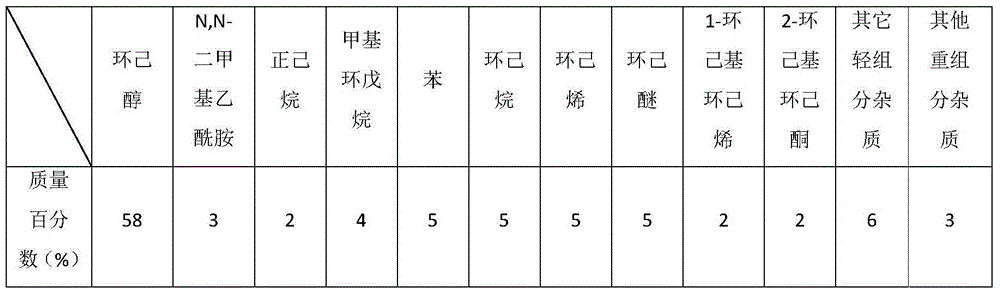

[0030] A kind of method technical process of reclaiming cyclohexanol from cyclohexanone plant waste liquid is as figure 1 Shown, the mass percent of each component of waste liquid is:

[0031]

[0032] Take the waste liquid and enter the extraction tower T-101. The theoretical plate number of the extraction tower T-101 is 20. The desalted water and waste liquid are fed from the top and bottom of the tower respectively, and the feed amount is 0.2m 3 / h and 0.5m 3 / h, where the density of waste liquid is 967kg / m 3 ; The number of theoretical plates of the drying tower T-102 is 20, the feed at the top of the tower is operated under normal pressure, and the operating temperatures of the top and bottom of the tower are 65 ° C and 87 ° C respectively; 50, feed material at the 20th theoretical plate, the operating pressure at the top of the tower is 50kPa, the control reflux ratio is 5, the temperature at the top of the tower and the bottom of the tower are 57°C and 140°C respec...

Embodiment 3

[0034] A kind of method technical process of reclaiming cyclohexanol from cyclohexanone plant waste liquid is as figure 1 Shown, the mass percent of each component of waste liquid is:

[0035]

[0036] Take the waste liquid and enter the extraction tower T-101. The theoretical plate number of the extraction tower T-101 is 20. The desalted water and waste liquid are fed from the top and bottom of the tower respectively, and the feeding amount is 1.0m 3 / h and 0.5m 3 / h, where the density of waste liquid is 967kg / m 3; The theoretical plate number of the drying tower T-102 is 20, the feed at the top of the tower is operated under normal pressure, and the operating temperatures of the tower top and the bottom of the tower are respectively 68 ° C and 92 ° C; the theoretical plate number of the light removal tower T-103 is 50, feed material at the 20th theoretical plate, the operating pressure at the top of the tower is 50kPa, the control reflux ratio is 10, the temperature at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com