Wall building robot

A wall-laying robot and skeleton technology, applied in the field of machinery, can solve the problems of inconvenient operation, labor consumption, low efficiency, etc., and achieve the effect of large demand market and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

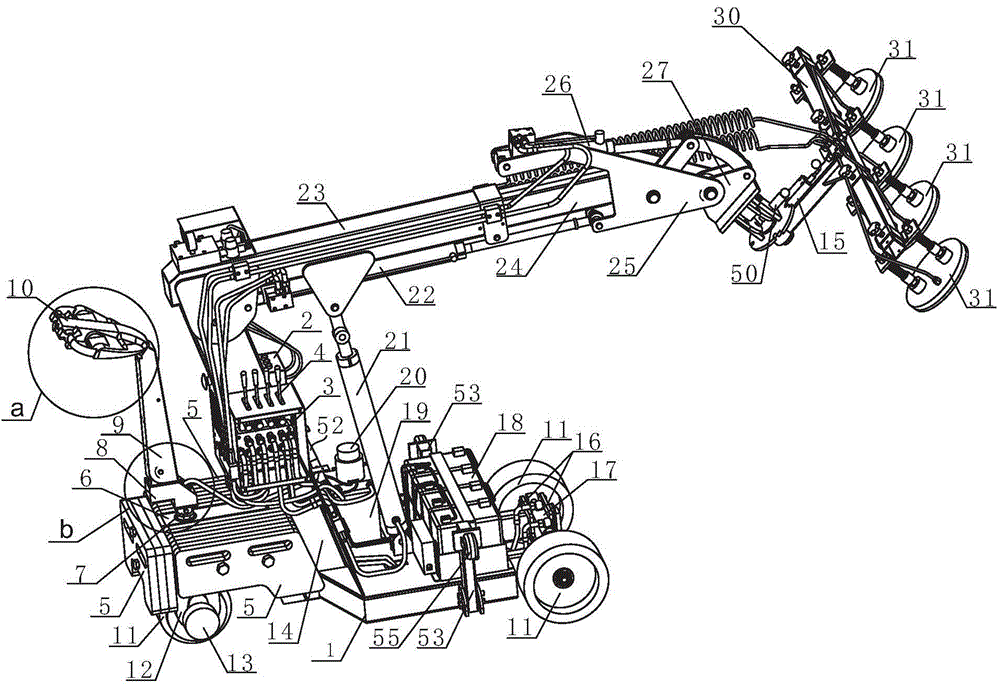

[0029] The described wall-building robot will be further elaborated below in conjunction with the accompanying drawings.

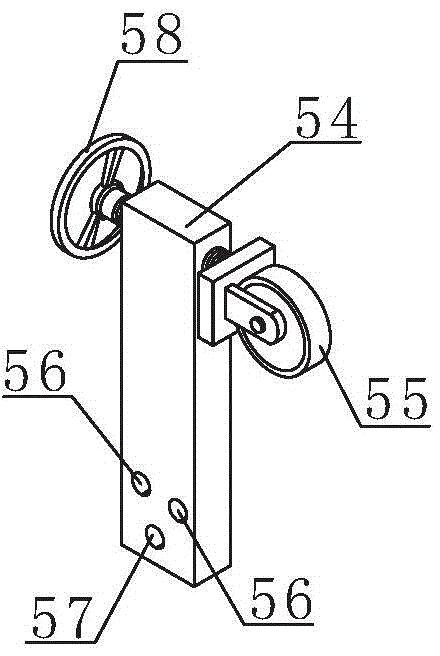

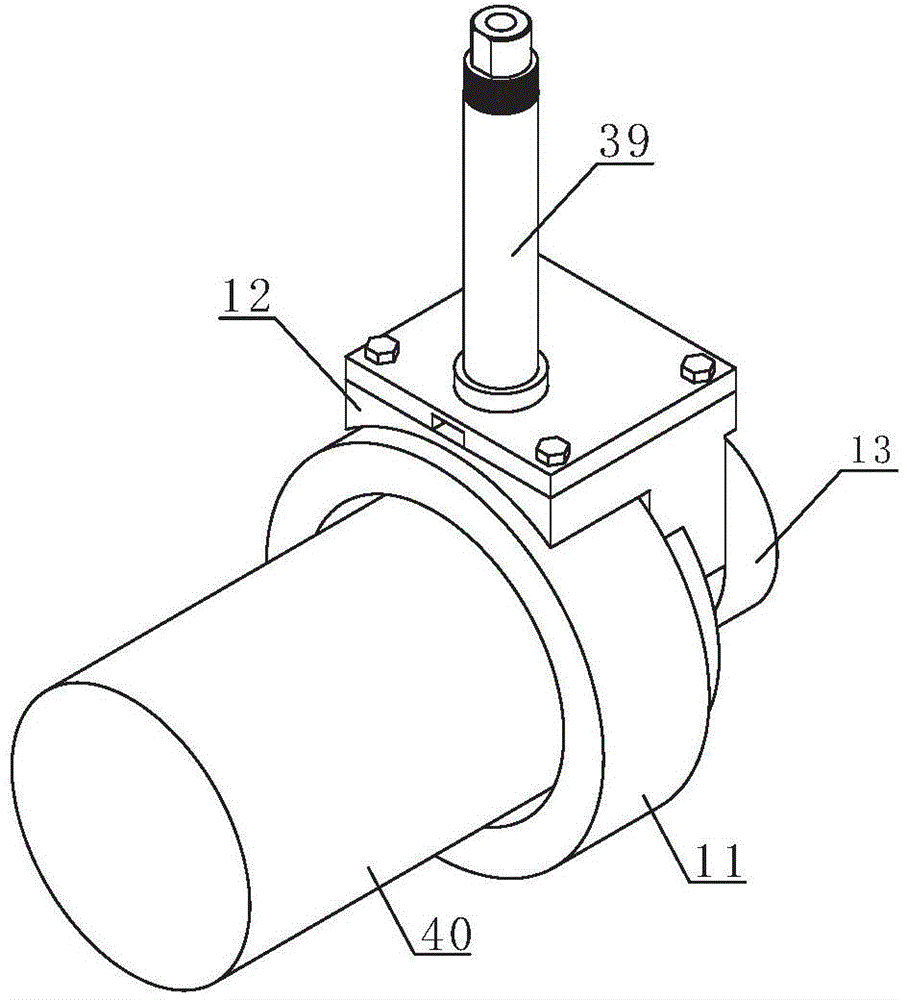

[0030] refer to figure 1 , 3 , 4, 6, 7, as shown in the figure, the wall-building robot includes a skeleton 1, a wheel 11, a steering wheel 10, and a telescopic arm mounted on the skeleton, a power device, a power source, an oil circuit system, and an air circuit system and electronic control system; the telescopic arm is composed of a movable arm 24 sleeved on a slide rail in the inner cavity of the fixed arm 23, and the fixed arm 23 is hinged on the top of the column 14 of the skeleton 1, and is connected with the piston rod of the first oil cylinder 21 , under the action of the oil cylinder, the entire telescopic arm rotates around its link axis with the column; the free end of the boom 24 is hinged with the piston rod of the second oil cylinder 22 and the position adjusting member 27 through the connecting plate 25, and the position adjusting member 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com