Patents

Literature

178 results about "MAGNESIUM SULFATE MONOHYDRATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium Sulfate Monohydrate is a moderately water and acid soluble Magnesium source for uses compatible with sulfates. Sulfate compounds are salts or esters of sulfuric acid formed by replacing one or both of the hydrogens with a metal.

Magnesium sulfate production method using magnesium oxide and desulfurated waste fluid

InactiveCN1544331ASolve the problem of discharge into the seaExcellent energy consumptionDispersed particle separationWater/sewage treatmentLiquid wasteSulfur

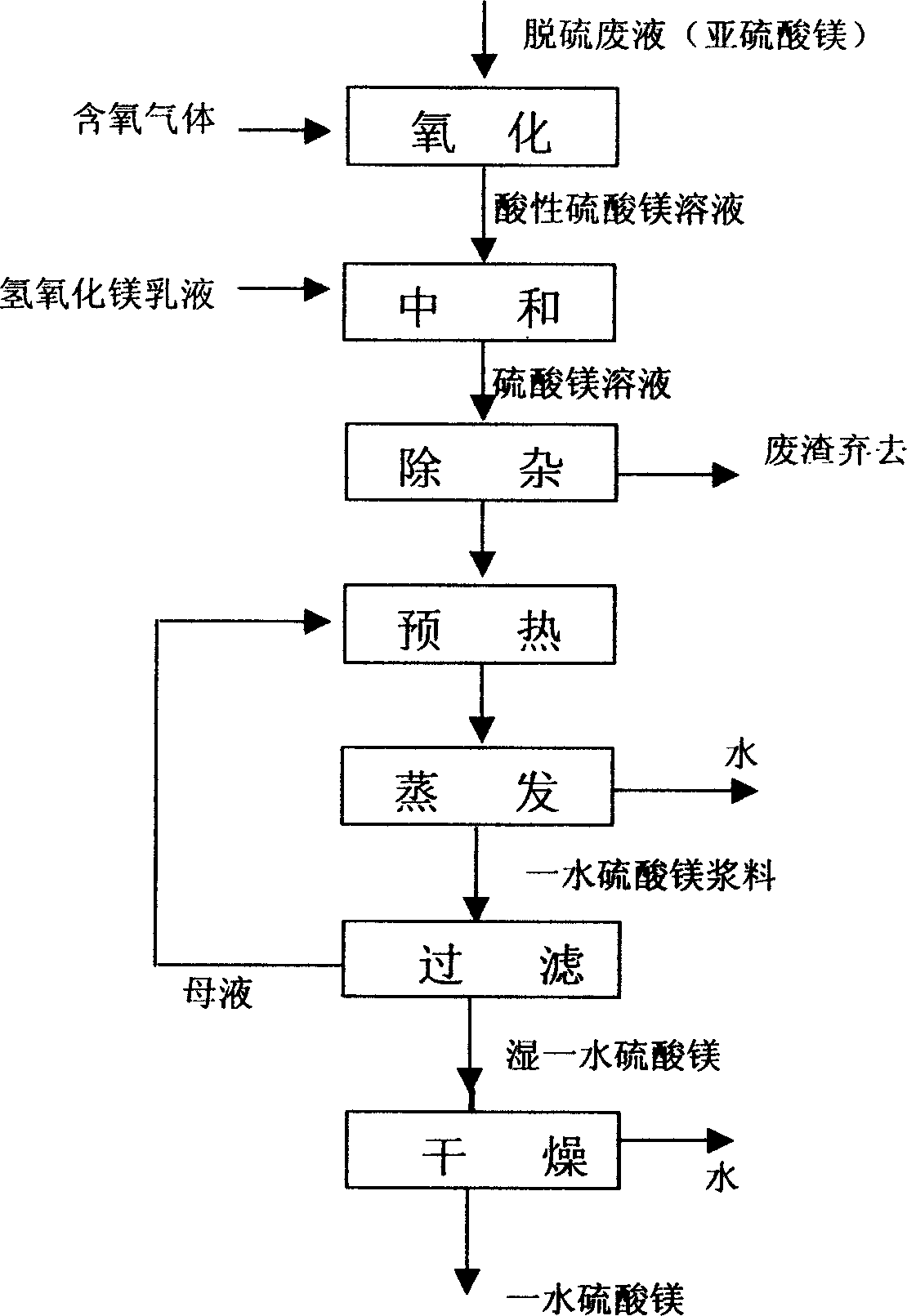

The invention provides a process for preparing magnesium sulphate by utilizing magnesium oxide desulfurized exhausted liquid comprising the steps of oxidation step, neutralization step, edulcoration step, evaporation concentration, solid-liquid separation step, drying and packing step. By controlling different evaporation temperature, discharging condition and various equipment, kieserite and magnesium sulphate can be prepared respectively.

Owner:天津市昌昊化工股份合作公司

Method for producing magnesium sulfate monohydrate by using desulfurization wastewater

ActiveCN102745725AQuality up to standardGuaranteed uptimeMagnesium sulfatesWastewaterCrystallization

The present invention discloses a method for producing magnesium sulfate monohydrate by using desulfurization wastewater. The method comprises the following steps: (1) pulping, (2) carrying out desulfurization, (3) discharging the pulp, (4) filtering, (5) carrying out concentration, and (6) carrying out crystallization. With the method of the present invention, high value byproducts can be synchronously produced during a flue gas desulfurization process by using a magnesium oxide method. In addition, with the method of the present invention, a stable running characteristic is provided, and quality of the produced magnesium sulfate monohydrate after desulfurization reaches standards.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

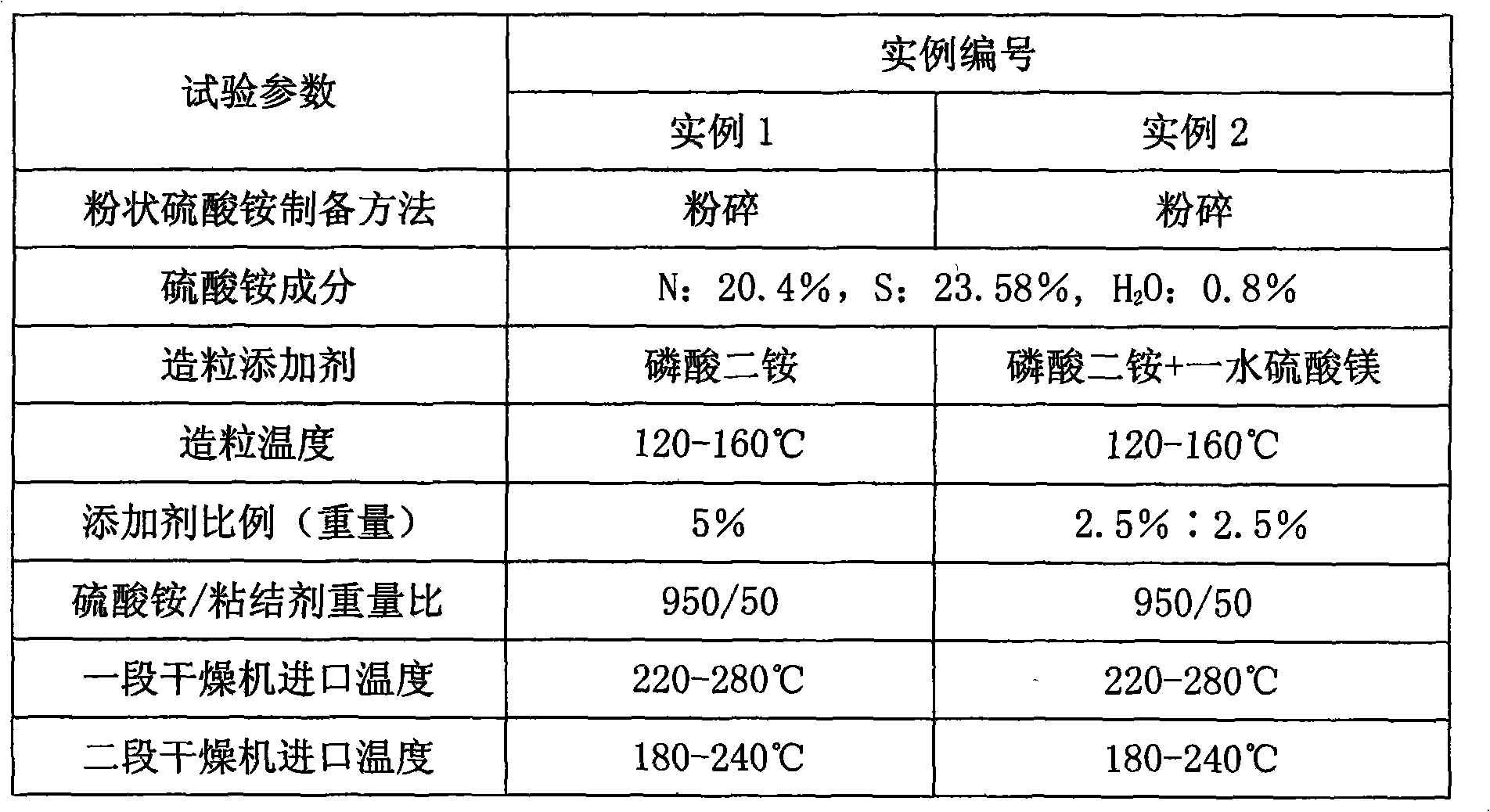

Method for preparing particle ammonium sulfate product by organic-inorganic binder

ActiveCN101570455ASimple production processEasy to operateFertiliser formsAmmonium salt fertilisersPhosphatePolyethylene glycol

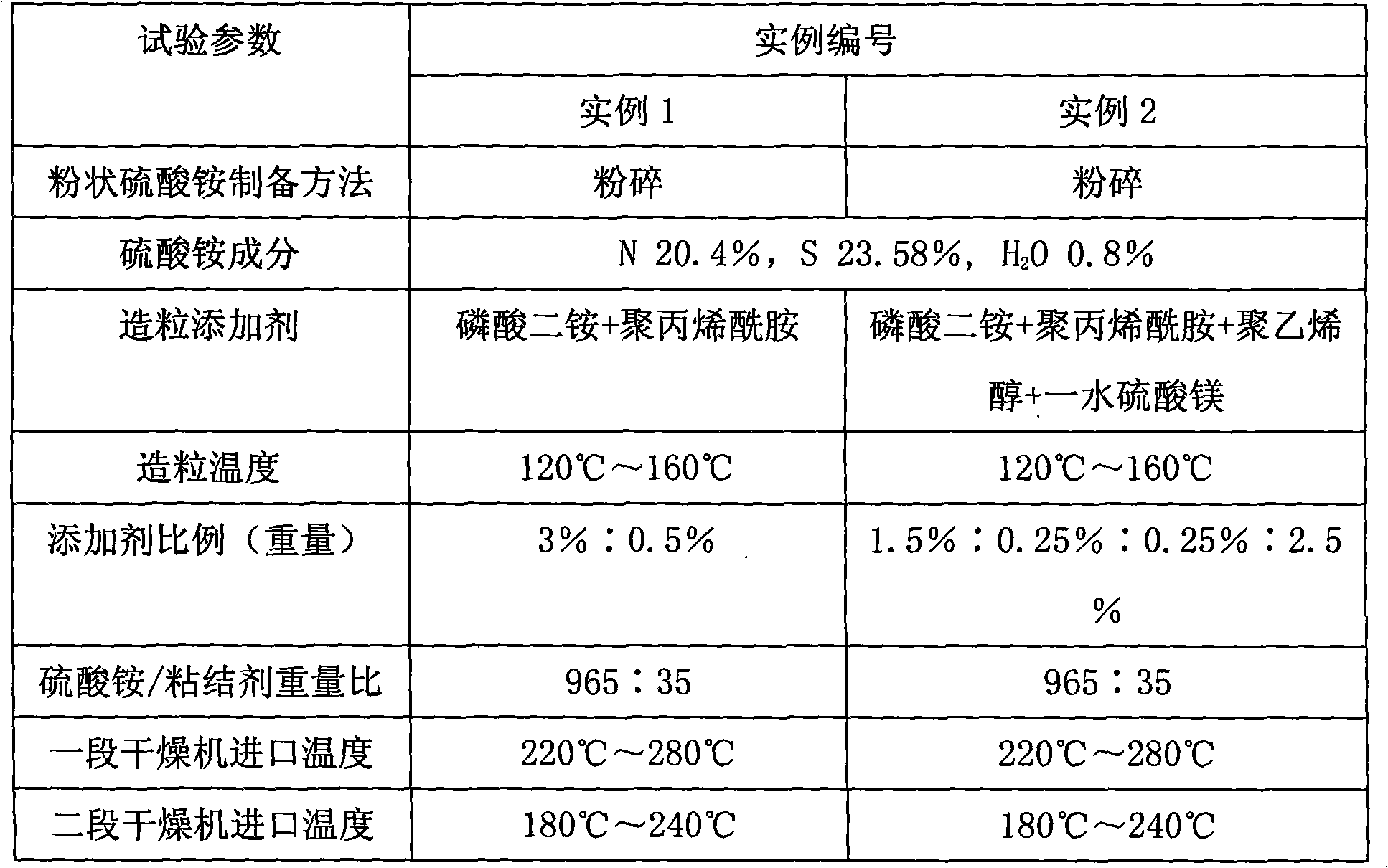

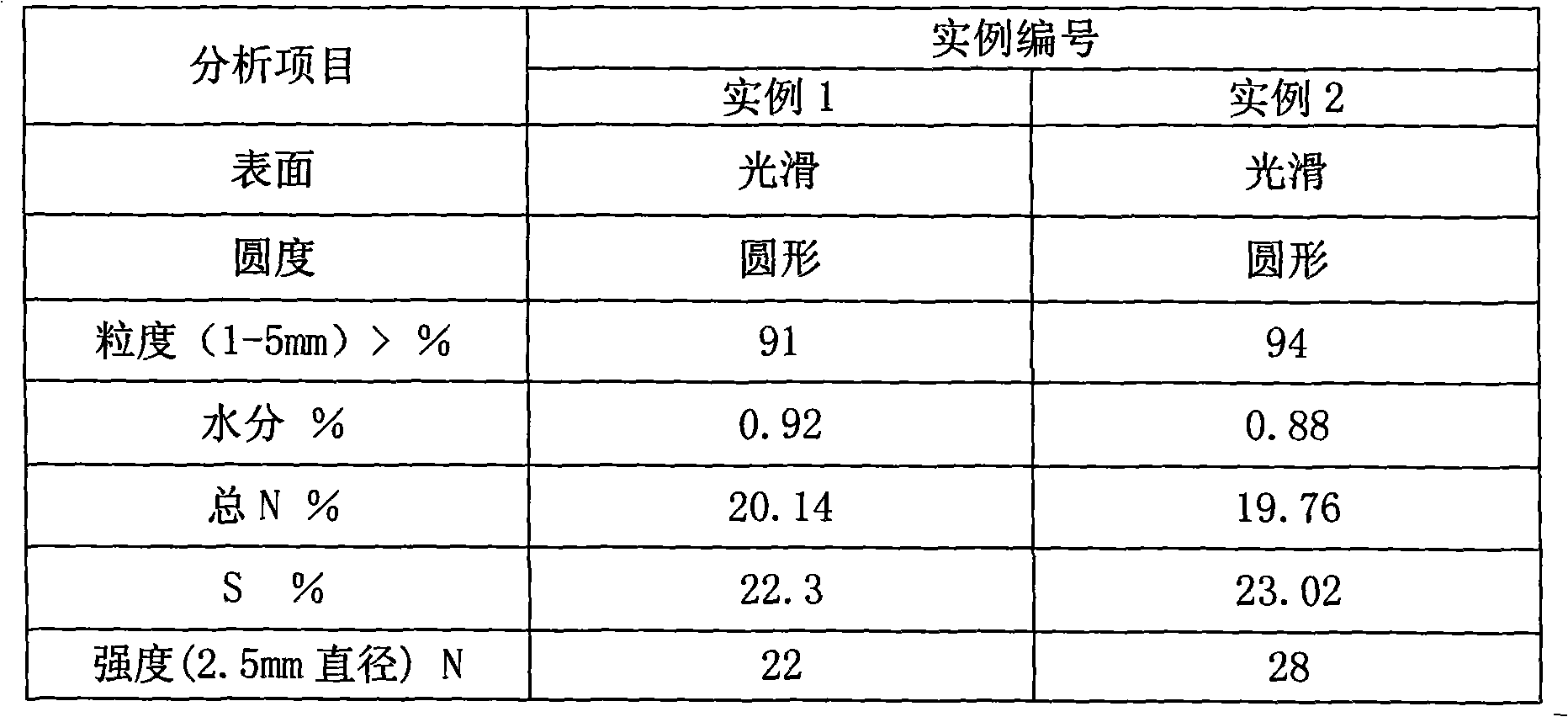

A method for preparing particle ammonium sulfate product by organic-inorganic binder, comprises the following steps: (1) polyacrylamide, polyethylene glycol and polyvinyl alcohol are selected to be organic binder; monoammonium phosphate, diammonium phosphate, ammonium bicarbonate, magnesium sulfate monohydrate, magnesium sulfate hetahydrate and heptahydrate zinc sulphate are selected to be inorganic binder; (2) crystal ammonium sulfate is crashed; (3) the one or more organic binder is dissolved, mixed evenly with the one or more inorganic binder in a solution pump and a pelletizer, and is sprayed with steam or water on the surface of ammonium sulfate to carry out pelleting to obtain semi-finished product; (4) the semi-finished product is dried; (5) dried finished product is screened after inspected particles with suitable particle sizes are selected to be the product. The invention has the following advantages: (1) the process is simple, thus facilitates operation; (2) the binder is accessible, and the product has uniform particle sizes with strength being suitable for large scale mechanized operation; (3) the mixture ratio of the binder is free, thus being capable of satisfying large scale mechanized operation. The invention is suitable for popularization in compound fertilizer production.

Owner:WENGFU (GRP) CO LTD

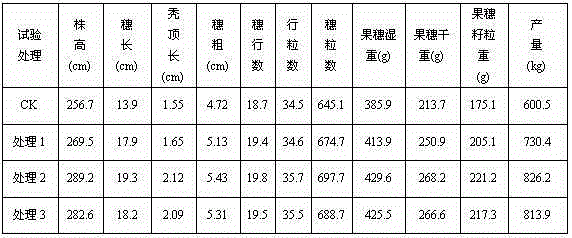

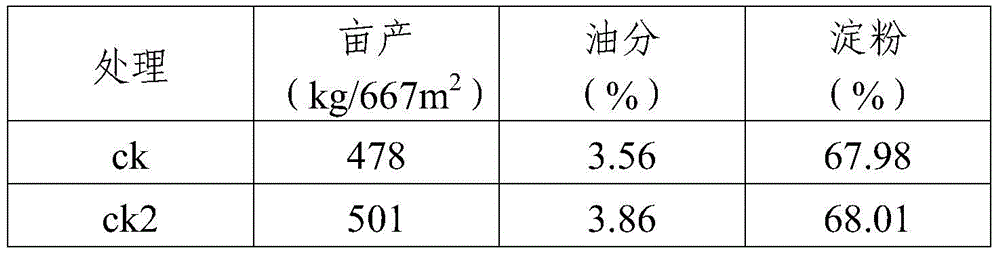

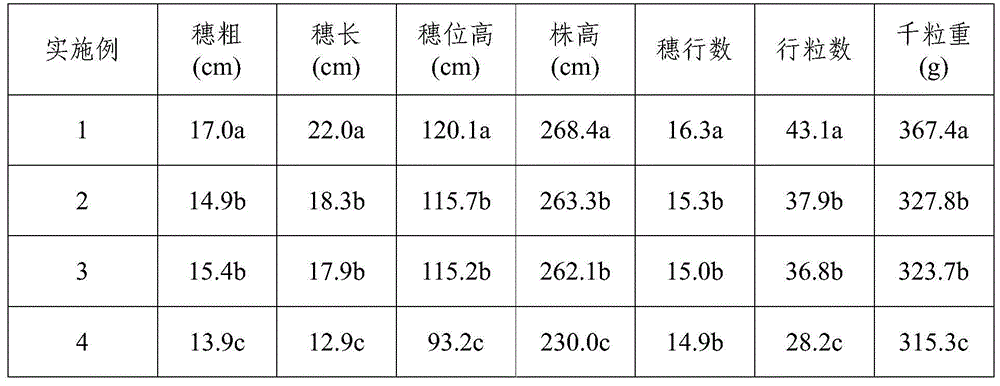

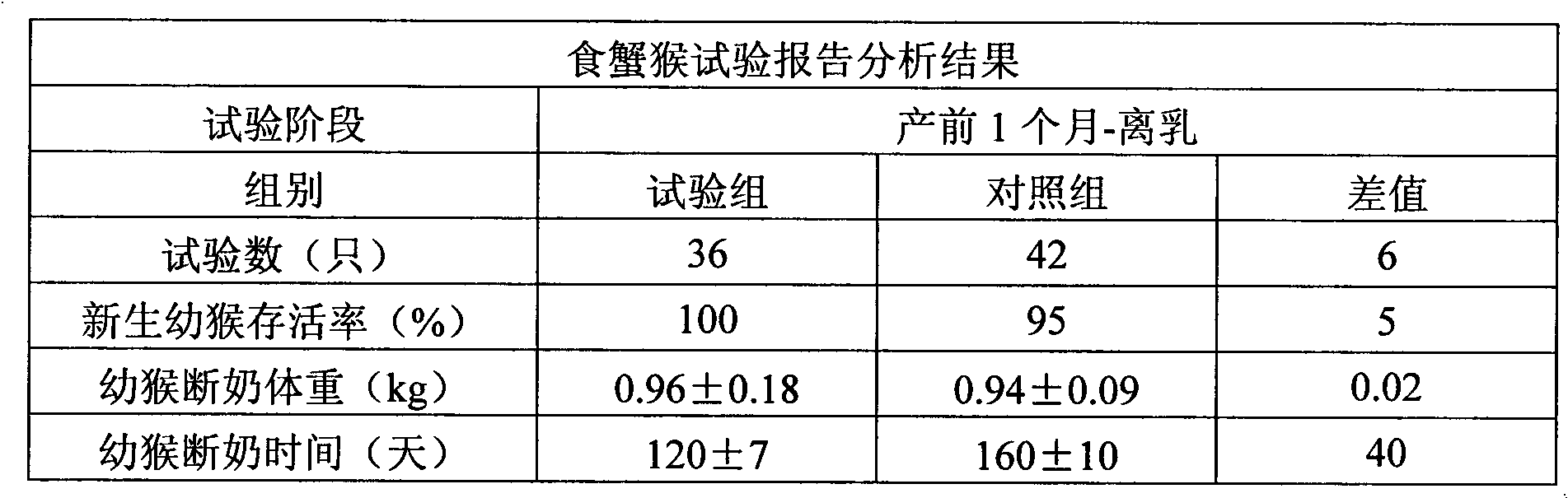

Biological-organic fertilizer special for corn and preparation method thereof

InactiveCN105085111AMeet nutrient needsEven distribution of nutrientsFertilizer mixturesChelated zincNutrition

The invention discloses a biological-organic fertilizer special for corn and a preparation method thereof, and belongs to the technical field of crop formula fertilizers. The biological-organic fertilizer special for the corn is prepared form, seaweed extracts, urea, ammonium polyphosphate, potassium nitrate, magnesium sulfate monohydrate, EDTA chelate ferrum, EDTA chelate manganese, EDTA chelate zinc, EDTA chelate cuprum, boric acid, ammonium molybdae and fulvic acid potassium. The raw materials all adopts commercially available materials except that the seaweed extracts are produced by Stanley Fertilizer Limited Company. The prepared fertilizer is comprehensive in nutrition, scientific and reasonable in formula, water-soluble, easy to apply and capable of improving soil and effectively promoting the growth of crops by combining quick acting and long acting.

Owner:生之道生态农业科技股份有限公司

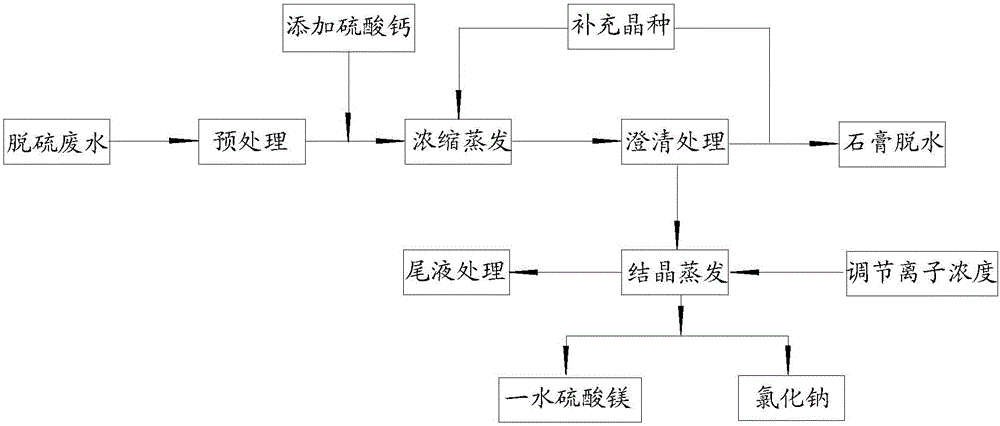

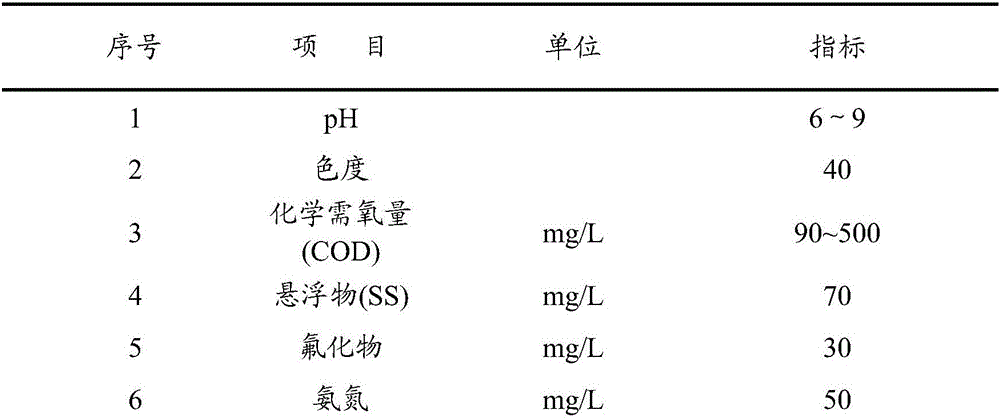

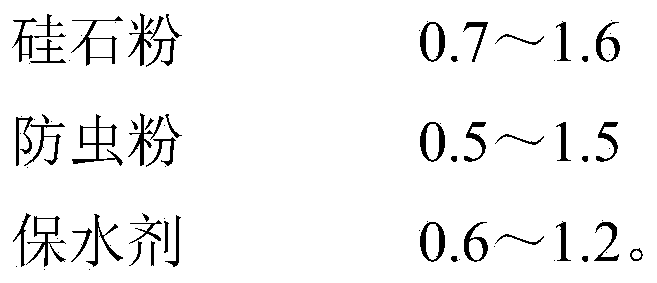

Desulfurization wastewater resourceful treatment method

ActiveCN105906125ALow running costLow investment costWaste water treatment from gaseous effluentsMultistage water/sewage treatmentEvaporationPre treatment

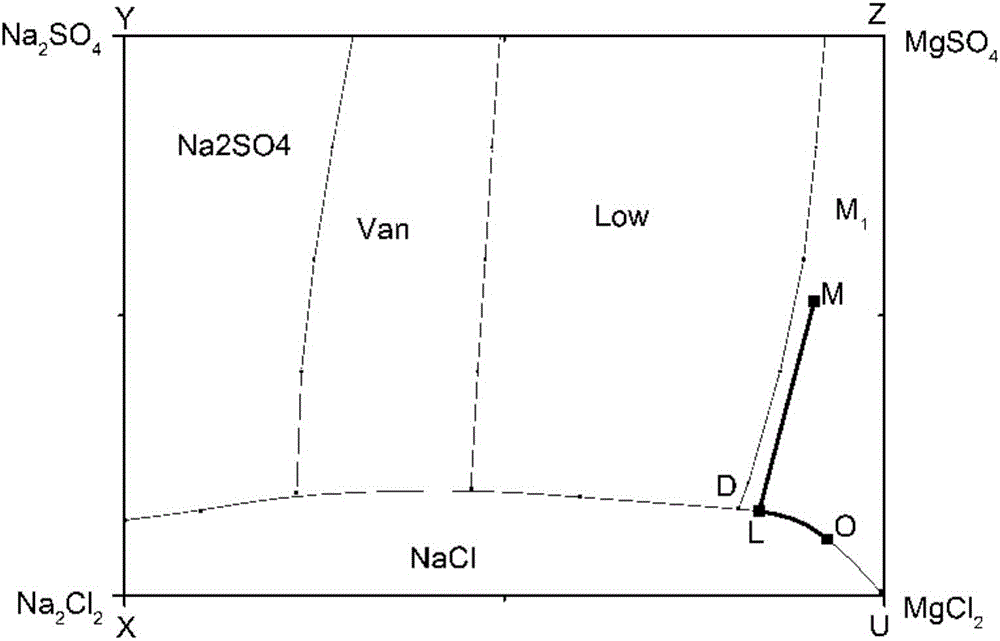

The invention relates to a desulfurization wastewater resourceful treatment method. The method comprises the following steps of 1, pretreatment, wherein suspended solids in desulfurization wastewater are removed; 2, concentration evaporation, wherein wastewater is subjected to evaporation treatment, in the initial stage of evaporation, calcium sulfate crystals are put into the wastewater, and after evaporation is ended, wastewater is cleared up; 3, crystallization evaporation, wherein the concentration of ions in wastewater is adjusted, crystallization points of the solution are made to fall into a crystallization region of a magnesium sulfate monohydrate salt or crystallization regions of magnesium sulfate monohydrate and sodium chloride salts, and then wastewater is subjected to evaporation crystallization; 4, crystallization salt separation, wherein the obtained mixed salt is separated to obtain a magnesium sulfate monohydrate crystallization salt and a sodium chloride crystallization salt. According to the desulfurization wastewater resourceful treatment method, the investment and operation costs are low, and two high-value industrial salts of magnesium sulfate and sodium chloride can be obtained.

Owner:GUANGDONG DEGA POWER ENVIRONMENTAL PROTECTION TECH CO LTD

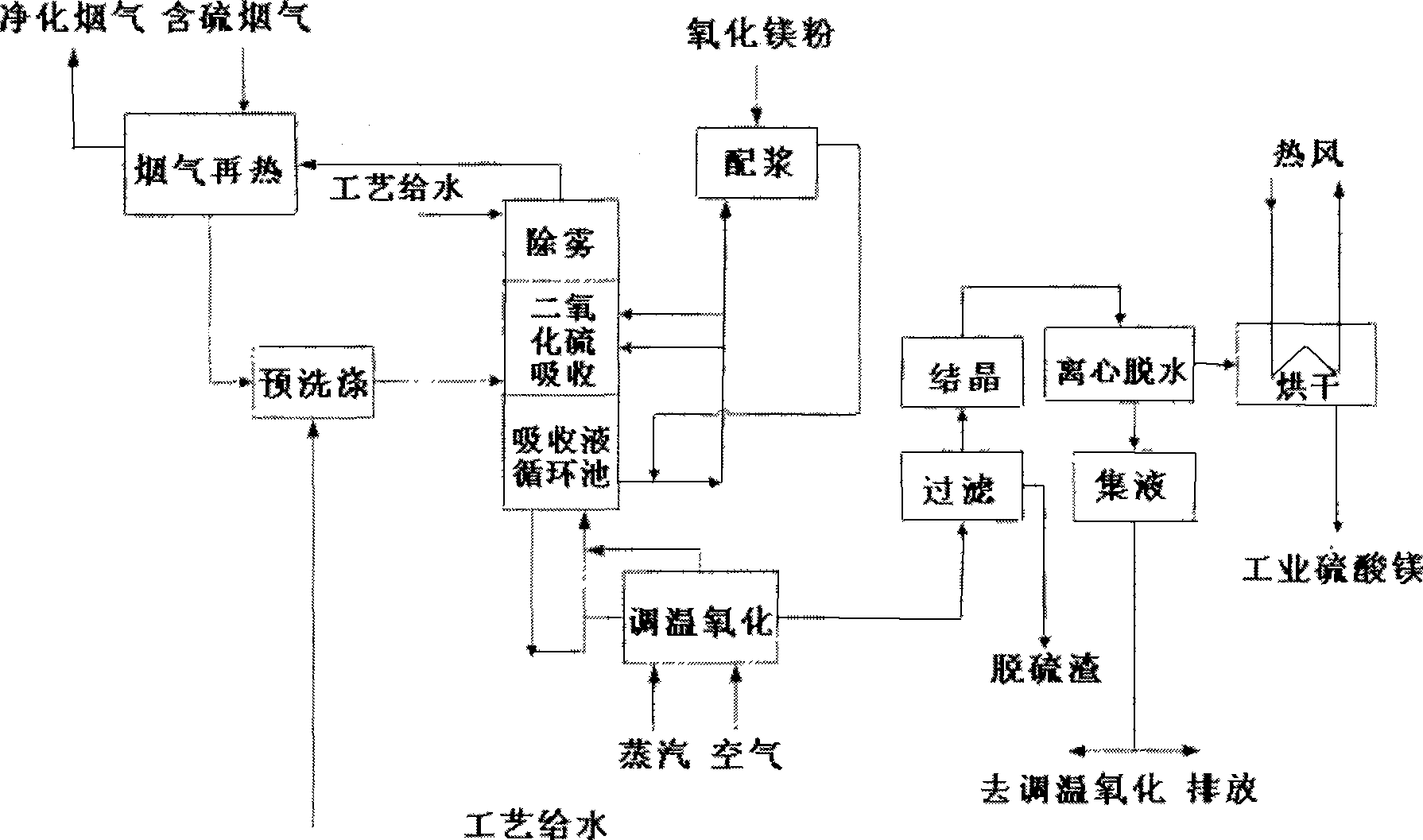

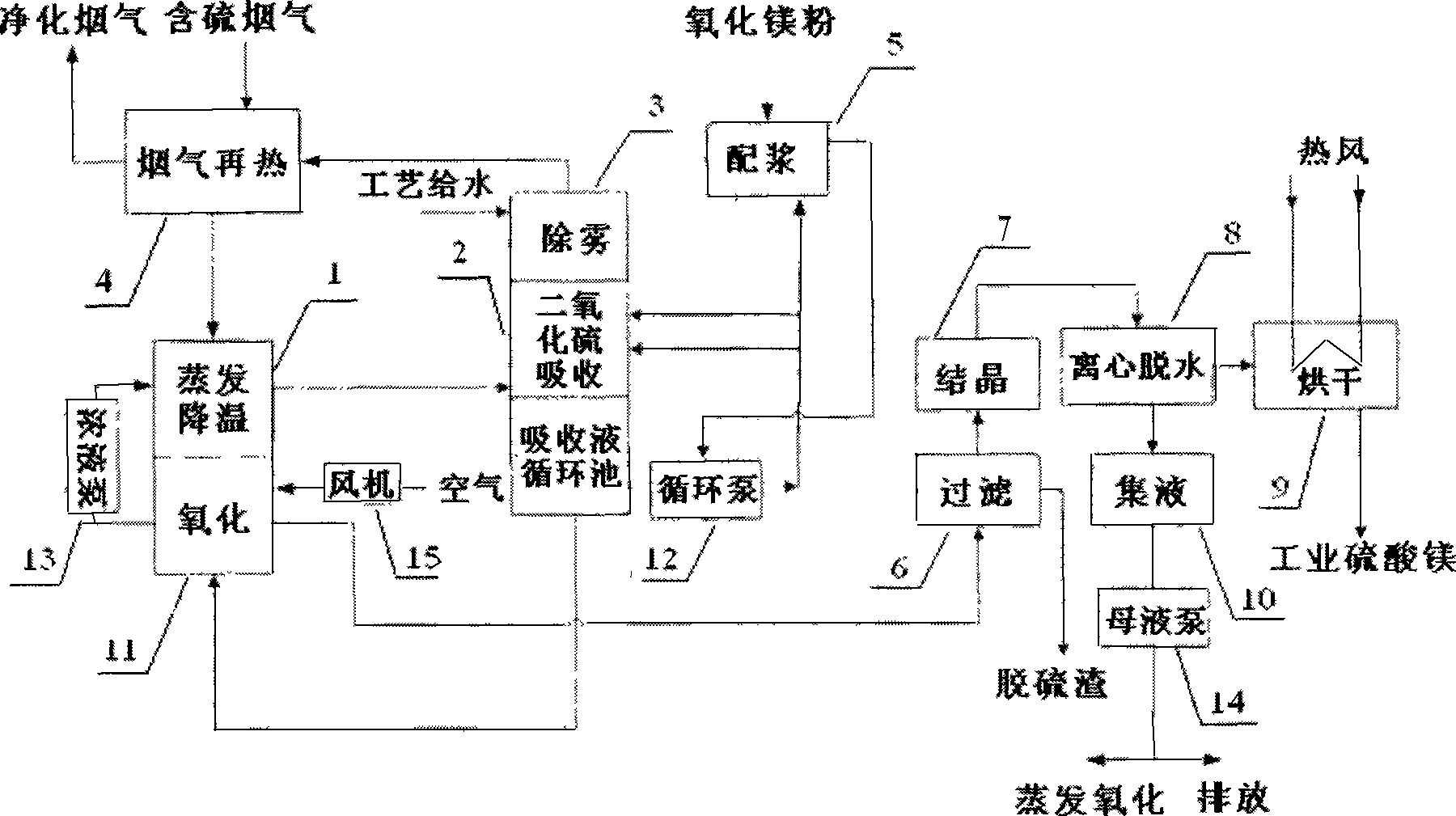

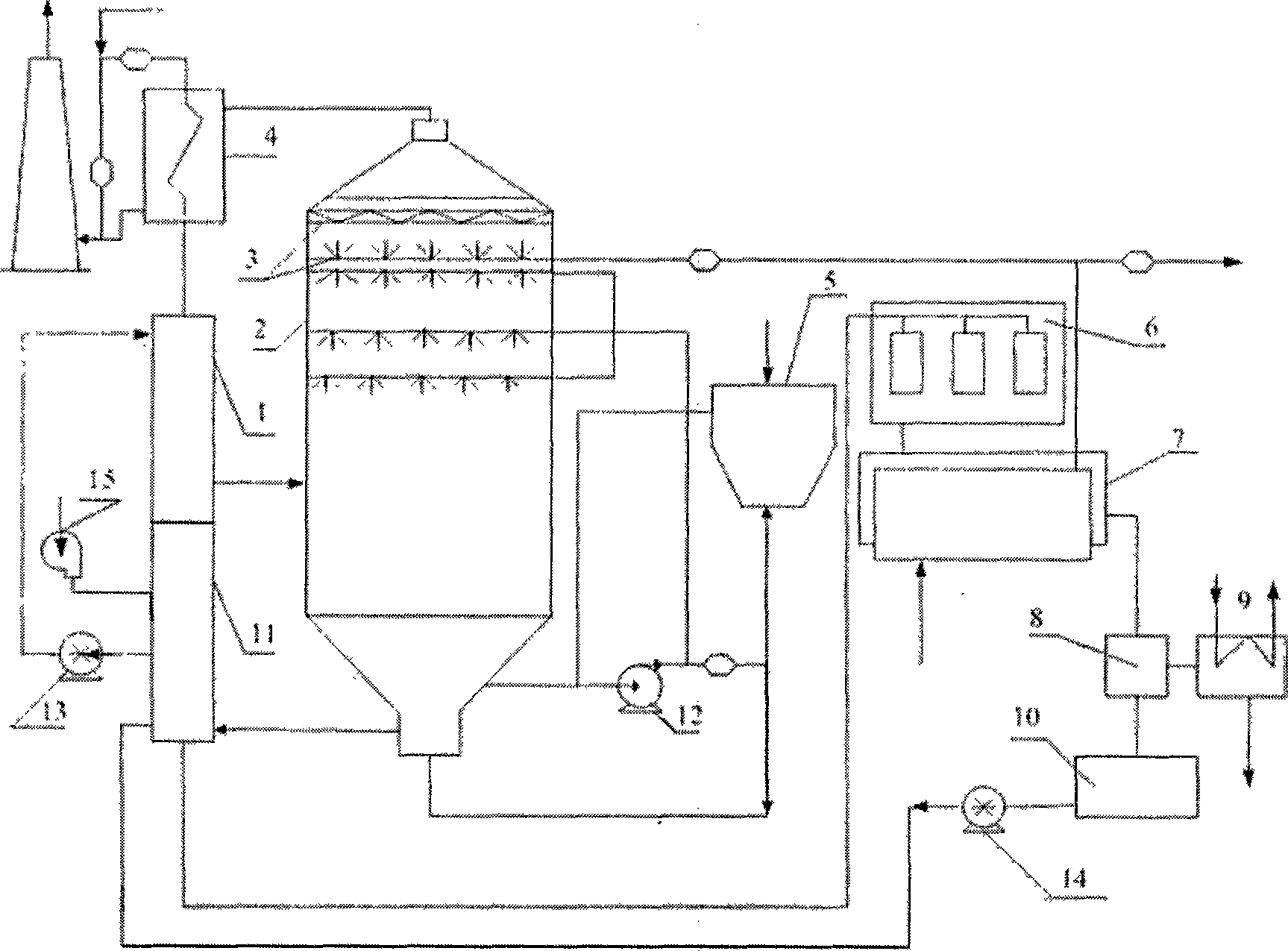

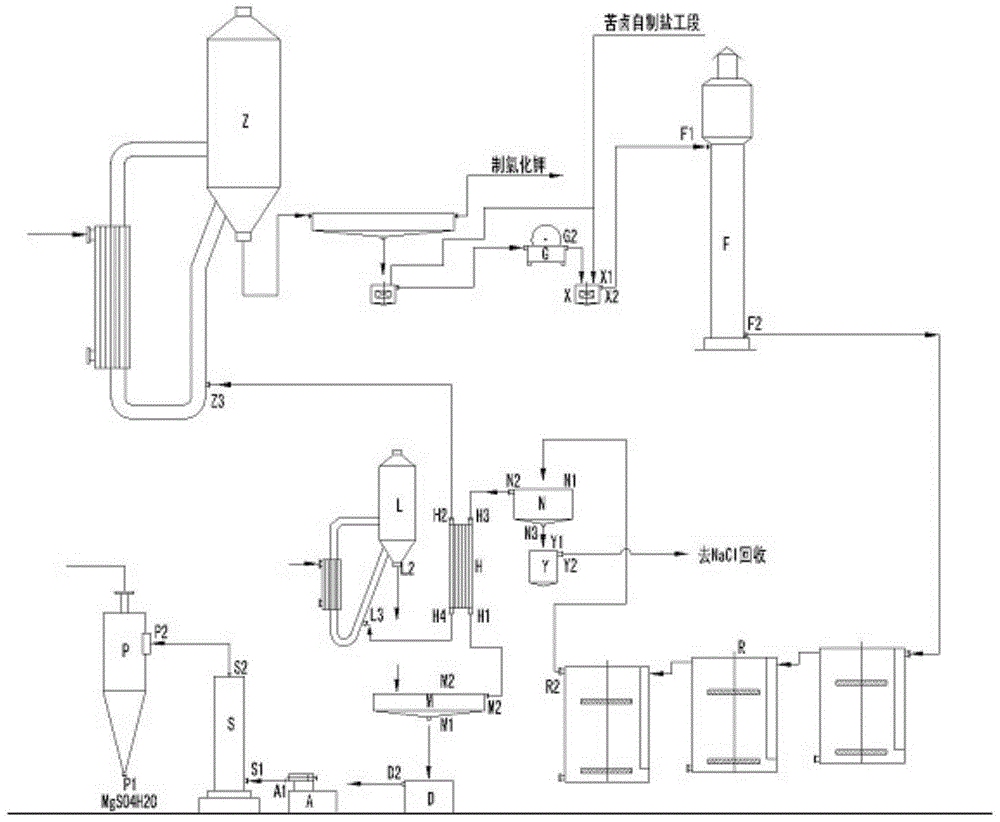

Flue gas desulfurization by magnesia wet method and recovering process of automatic concentration of product

ActiveCN101530725AAvoid intensive external energy consumptionAvoid external energy consumptionDispersed particle separationMagnesium sulfatesFiltrationSlurry

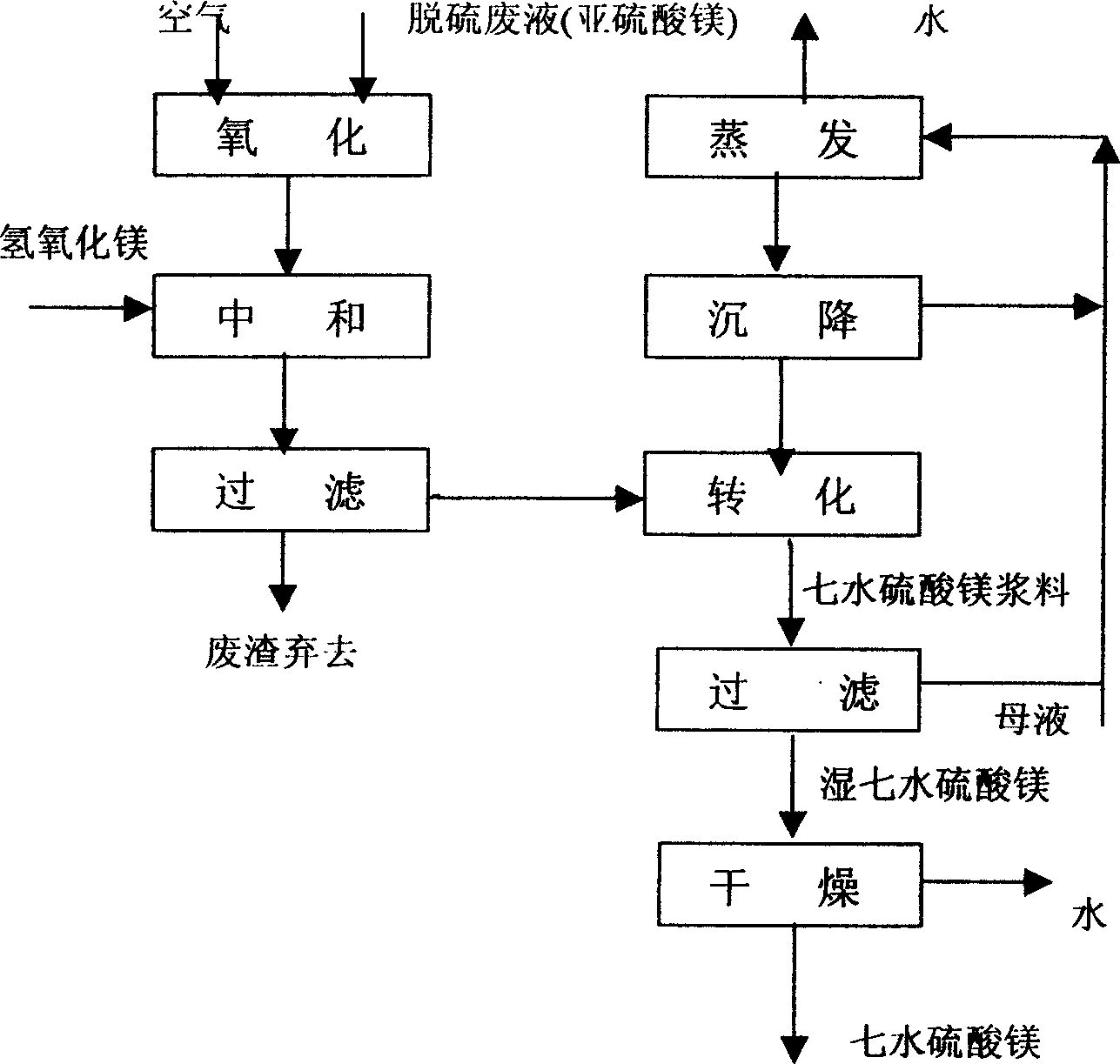

Flue gas desulfurization by the magnesia wet method and a recovering process of automatic concentration of the product relates to the improvement of the existing flue gas desulfurization by the magnesia wet method and product recovering process by the thick slurry process, belonging to the technical field of flue gas desulfurization and product recycling. The process is technically characterized in that the thick slurry is shunted in the process of recyclable absorption and desulfurization; spray cooling is carried out to cool flue gas; inspissation liquid is oxidized to generate MgSO4; then filtration, crystallize and the like are carried out to generate mm level MgSO4. 7H2O or MgSO4. H2O crystal grain. The invention not only features in low cost, but also has low spray flow rate and power consumption as well as outstanding water conservation effect; what is more, the invention avoids external power consumption of the concentration of the desulfurized product, can remarkably improve stability and economical efficiency of recovery. All steps of automatic concentration are linked with one and another, as a result, the application range of the invention is expanded to high-sulphur coal and technical support is provided for more economical, effective and direct recovery of magnesium sulfate monohydrate.

Owner:TSINGHUA UNIV

Separation method of boron, magnesium and iron in paigeite

InactiveCN1786219ASimple production processShort processProcess efficiency improvementProduced waterWater content

The invention relates to a method of separating boron, magnesium, and iron from ferroludwigite. Ludwigite powder is reacted by stirring in the 54%-80% inorganic acid for 5-10min. the reactant pH values is controlled between 1.50 and 4.50. Its temperature is automatically rose to reach 160centigrade degree by reaction. The produced water is constantly steamed to make the inorganic acid keep high density. While finishing the react the reactant is cooled to room temperature to form powder. And its water content is less than 20%. The solid material is put into boron iron saturated solution to separate iron and acid insoluble substance. The iron fine powder is gained by magnetic separation. Boric acid is separated from mono water magnesium sulfate by its floatation characteristic in saturated solution. Then they are respectively filtered to gain.

Owner:大连市中山区鑫阳矿业化工研究所

Macroelement water soluble fertilizer having effect of improving crop growth environment and application thereof

InactiveCN105669299AImprove the ecological environmentStimulate microscopic biological activityMagnesium fertilisersAlkali orthophosphate fertiliserEcological environmentSoil properties

The invention relates to the field of fertilizers, and in particular, relates to a macroelement water soluble fertilizer having an effect of improving a crop growth environment. The macroelement water soluble fertilizer comprises the following components in parts by weight: 50-100 parts of potassium fulvate, 1-15 parts of alga oligosaccharides, 1-15 parts of chitosan oligosaccharide, 100-300 parts of potassium nitrate, 300-500 parts of potassium dihydrogen phosphate, 100-300 parts of ammonium nitrate, 200-500 parts of urea, 10-30 parts of magnesium sulfate monohydrate, 5-25 parts of boric acid, 1-15 parts of EDTA chelated manganese, 1-15 parts of EDTA chelated iron, 1-15 parts of EDTA chelated copper, and 1-15 parts of EDTA chelated zinc. The fertilizer provided by the invention has comprehensive nutrients, has the effect of improving the soil micro ecological environment and soil property components, and has the advantages of rich content of medium-trace elements, high crop-absorbed utilization efficiency, high fertilizer efficiency and excellent water-saving effect.

Owner:HUNAN TAIGU BIOTECH

Control method for preventing caking and chalking of high-tower nitro-sulfenyl compound fertilizer

ActiveCN102875216AHigh particle strengthHigh glossFertilizer mixturesPhosphoric acidAmmonium nitrate

The invention discloses a control method for preventing caking and chalking of high-tower nitro-sulfenyl compound fertilizer. The method comprises steps as follows: adding ammonium nitrate and / or nitro-phosphorus compound fertilizer and ammonium phosphate to a melting groove to be molten, so as to obtain co-melting size; transferring the co-melting size into a mixing system; and adding phosphatic fertilizer, potash fertilizer, medium trace element, magnesium sulfate monohydrate and filling materials to be uniformly mixed to obtain the mixing size; transferring the mixing size into an emulsifying system to be broken, diffused and homogenized, so as to obtain emulsion size; transferring the emulsion size into a granulation system for granulation; and then carrying out steps of heat exchange through a tower body, cooling, sieving and surface treatment and the like. According to the control method disclosed by the invention, the magnesium sulfate monohydrate is added to the mixing size, so that the particle strength of the product is averagely increased by 4 to 12N by being compared with the particle strength of the product without adding the magnesium sulfate monohydrate or without improving the melting or mixing temperature, and the free water is reduced by 0.2 to 0.4%, and the caking and chalking of the stocked product are effectively prevented, and the time of the chalking can be prolonged.

Owner:GUIGANG BATIAN ECOLOGY

Fruit swelling type seaweed organic liquid water soluble fertilizer and production method thereof

PendingCN105060986AThe formula is scientific and reasonableNutritional diversityFertilizer mixturesChelated zincNutrition

The invention discloses a fruit swelling type seaweed organic liquid water soluble fertilizer, and belongs to the technical field of formula fertilizers of crops. The fruit swelling type seaweed organic liquid water soluble fertilizer is prepared from the following raw materials: a seaweed extracting solution, urea, ammonium polyphosphate, potassium nitrate, magnesium sulfate monohydrate, EDTA chelated iron, EDTA chelated manganese, EDTA chelated zinc, EDTA chelated copper, boric acid, ammonium heptamolybdate and potassium fulvic. The fruit swelling type seaweed organic liquid water soluble fertilizer is comprehensive in nutrition, scientific and reasonable in formula, fully water-soluble and easy to apply, improves soil, integrates fast acting and long acting, and effectively promotes the crop growth.

Owner:STANLEY AGRI GRP CO LTD

Biological humic acid water soluble fertilizer

InactiveCN108218588AIncrease profitImprove disease resistanceMagnesium fertilisersAlkali orthophosphate fertiliserMicrobial agentPhosphate

The invention discloses a biological humic acid water soluble fertilizer. The biological humic acid water soluble fertilizer is composed of, by weight, 7 to 10 parts of potassium nitrate, 8 to 12 parts of ammonium nitrate, 8 to 11 parts of monoammonium phosphate, 12 to 16 parts of urea, 18 to 23 parts of humic acid, 0.04 to 0.08 part of amino acid chelated trace element, 11 to 15 parts of a composite microbial agent, 20 to 25 parts of organic matter, 6 to 9 parts of sodium sulfafe decahydrate, 3 to 5 parts of boric acid, 5 to 8 parts of magnesium sulfate monohydrate, 0.5 to 0.9 part of a biogenic stimulant, and 2 to 4 parts of an anti-caking agent. The biological humic acid water soluble fertilizer is comprehensive in nutrient composition, and reasonable in formula; mutual cooperation of the elements in the biological humic acid water soluble fertilizer is achieved; fertilizer utilization rate is increased; and the biological humic acid water soluble fertilizer is capable of improvingcrop disease resistance and stress resistance, and increasing crop yield and product quality.

Owner:湖北吾尔利生物工程股份有限公司

Process for preparing magnesium sulfate monohydrate by using water-containing magnesium sulfate heptahydrate

ActiveCN102583459ASolve the problem of easy cakingContinuous stable operationMagnesium sulfatesFree waterMagnesium sulphate heptahydrate

The invention discloses a process for preparing magnesium sulfate monohydrate by using water-containing magnesium sulfate heptahydrate, comprising the following steps of: (1) wet material feeding: delivering water-containing magnesium sulfate heptahydrate into a drying chamber of a spin flash dryer; (2) hot air delivery: heating the air to 220-320 DEG C, pressurizing by using a draught fan, and delivering the air into the spin flash dryer; (3) drying process: remaining a wet material to be dried in the drying chamber of the spin flash dryer for 2-6s to obtain finished magnesium sulfate monohydrate containing free water less than or equal to 3wt%; and (4) discharging and tail gas treatment and exhaust: delivering the dried material into a discharging device, carrying out cyclone dust removal and water film dust removal, then collecting the dried magnesium sulfate monohydrate, and exhausting tail gas. The process for preparing the magnesium sulfate monohydrate by using the water-containing magnesium sulfate heptahydrate, provided by the invention, has the advantages of easiness in controlling the drying temperature, short process flow, strong adaptability, continuous, stable and reliable drying process and good drying effect.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Complete pellet feed for preventing diarrhea of young rabbits as well as preparation method and application of complete pellet feed

ActiveCN103621783AImprove securityNo drug resistanceAnimal feeding stuffBiotechnologySodium bicarbonate

The invention discloses a complete pellet feed for preventing diarrhea of young rabbits. The complete pellet feed comprises corns, soybean meal, cottonseed meal, sunflower seed meal, wheat bran, flour, malt sprouts, rice bran meal, alfalfa, saccharose, edible salt, calcium hydrophosphate, calcium powder, sodium bicarbonate, magnesium sulfate monohydrate, L-Lysine sulphate, a complex enzyme preparation, a composite microecological agent, yellow bentonite, methionine, composite vitamins, choline chloride, a mold adsorbent and a trace element additive. The complete pellet feed for preventing the diarrhea of the young rabbits is not added with antibiotics and is high in safety; the young rabbits do not have drug resistance to the complete pellet feed, and the possibility of abnormal fermentation of hindguts is reduced; intestinal tract movement is promoted; easily digested substances can be quickly digested in the front intestinal tracts of the young rabbits, so that abnormal easy fermentation chime caused by the substances reaching the hindguts is reduced, and the diarrhea of young meat rabbits is relieved; furthermore, due to the proper processing technical parameters of the preparation method disclosed by the invention, the diarrhea occurrence rate of the young rabbits is further reduced.

Owner:武威铁骑力士饲料有限公司

Desulfurizer and application thereof

ActiveCN102755829AQuality improvementExcellent yieldDispersed particle separationMagnesium sulfatesMagnesium sulphate heptahydrateFlue-gas desulfurization

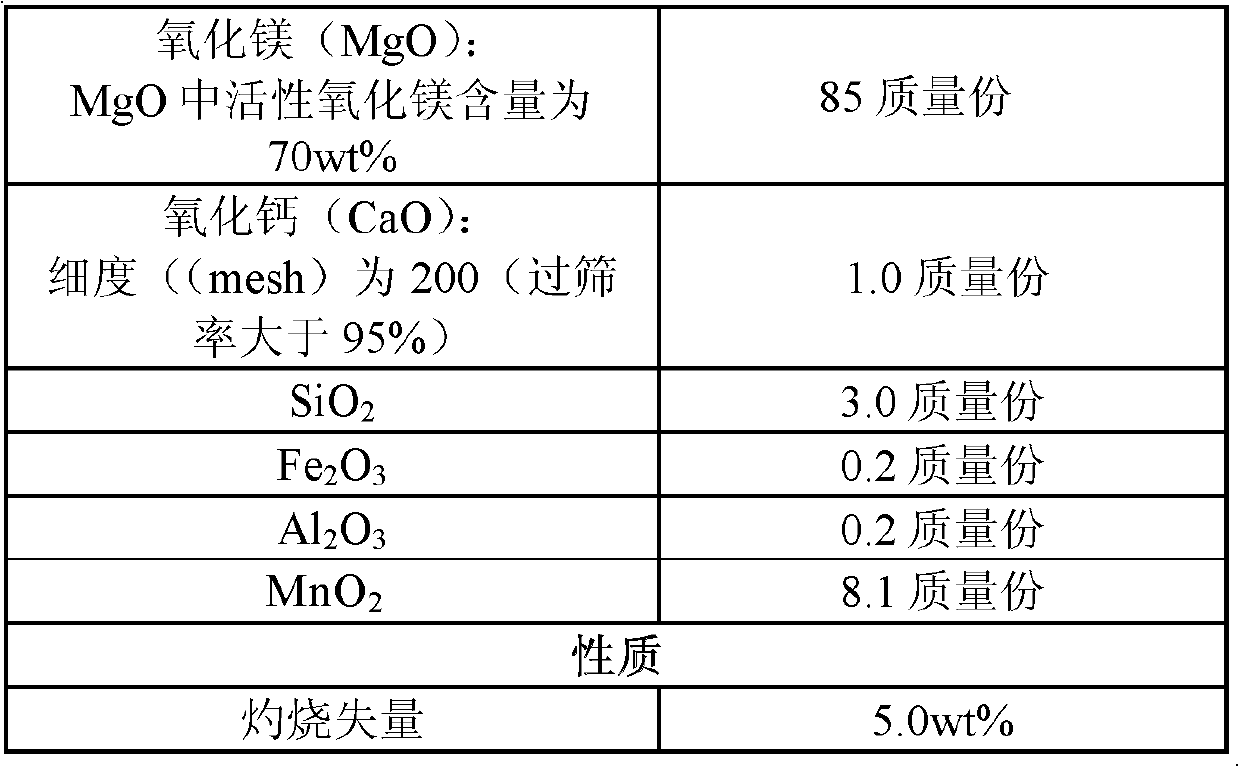

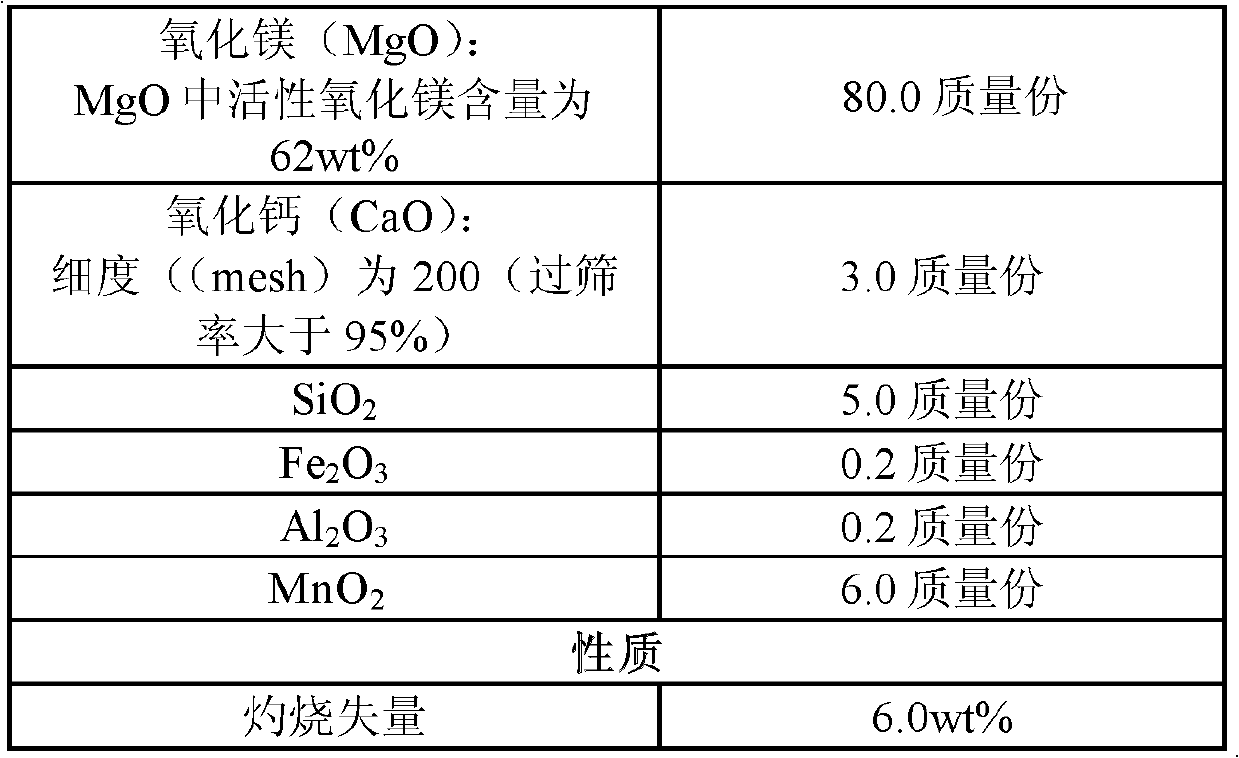

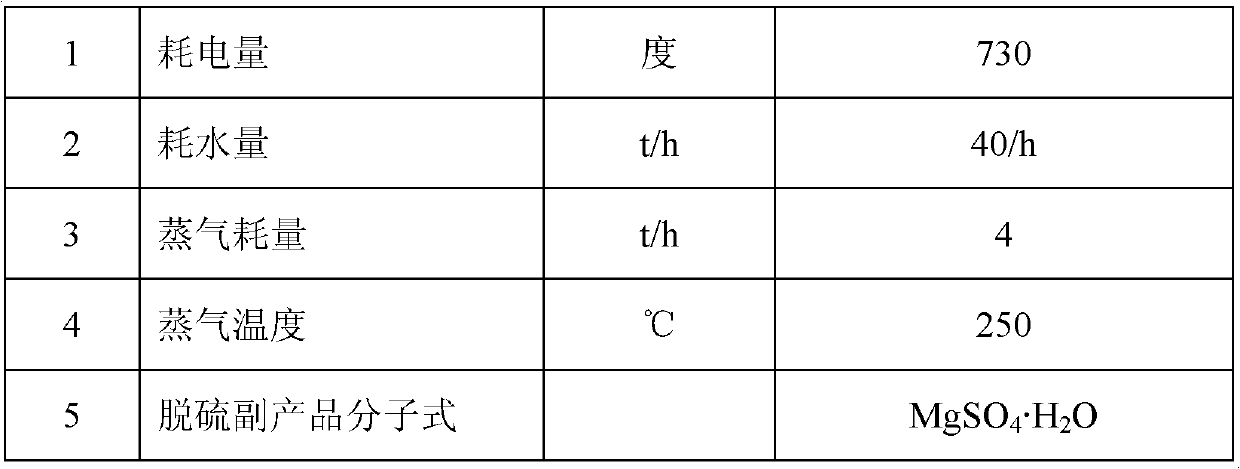

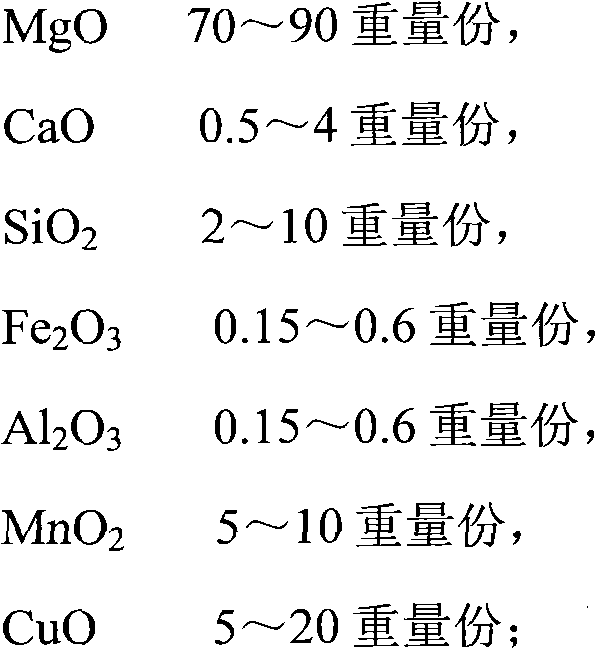

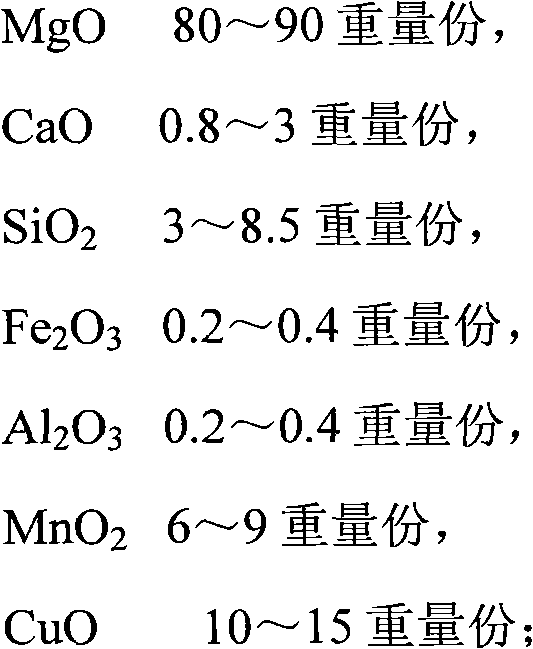

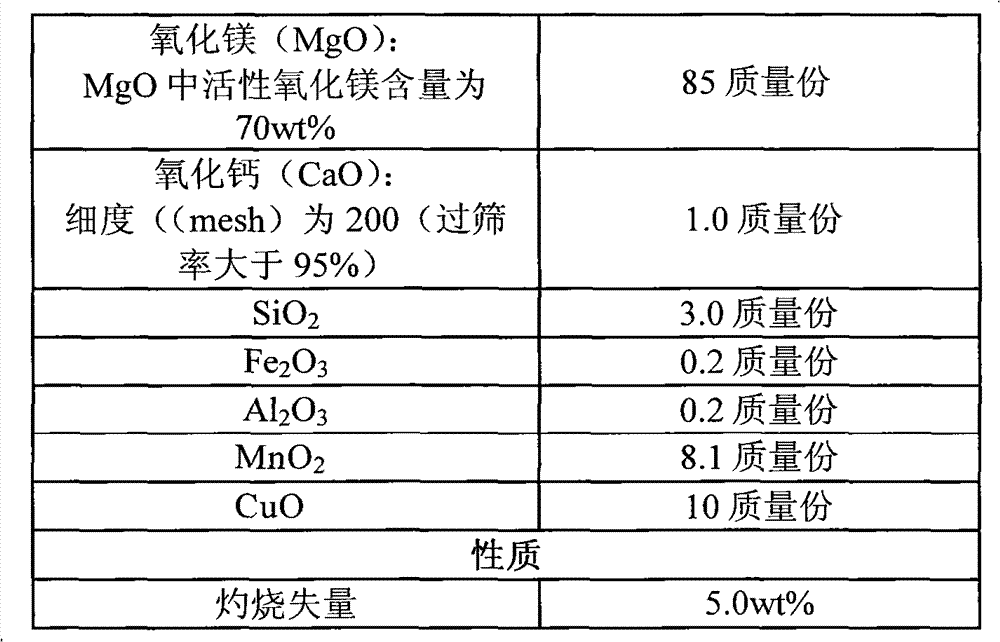

The invention discloses a desulfurizer and application thereof. The desulfurizer comprises, by weight, 70-90 parts of MgO, 0.5-4 parts of CaO, 2-10 parts of SiO2, 0.15-0.6 part of Fe2O3, 0.15-0.6 part of Al2O3, 5-10 parts of MnO2, and 5-20 parts of CuO, wherein the MgO comprises 50-75% by weight of active magnesium oxide. By means of the desulfurizer, byproducts with high valve are synchronously generated in a flue gas desulfurization process through a magnesium oxidizing method. In addition, by means of the desulfurizer, the quality of magnesium sulfate monohydrate generated after desulfurization reaches the standard.

Owner:中晶新材料有限公司

Comprehensive utilization method of silicate minerals

ActiveCN104891537ABig market demandGood market demandMagnesium sulfatesFerric oxidesFerric hydroxideHigh energy

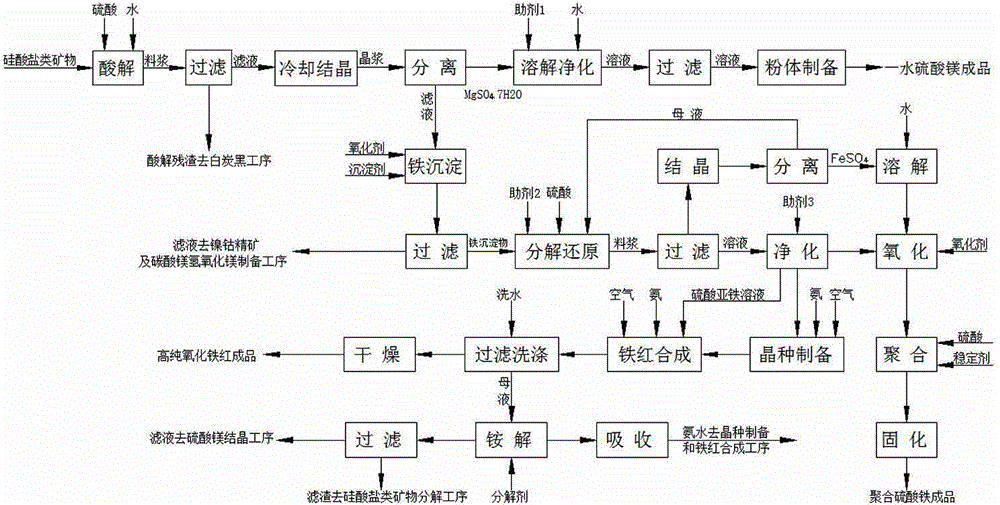

The invention discloses a comprehensive utilization method of silicate minerals. The method comprises the following steps: firstly decomposing silicate minerals by using sulfuric acid as a decomposing agent, and carrying out acid leaching of residues for preparation of white carbon black; sending an acidolysis solution into a magnesium sulfate heptahydrate crystallizer to prepare a magnesium sulfate heptahydrate product and an acidolysis solution obtained after separation of magnesium sulfate; mixing magnesium sulfate heptahydrate and water, adding an oxidizing agent, a pH regulator and an adsorbent to convert iron in the solution to a ferric hydroxide precipitate, filtering to obtain a pure magnesium sulfate solution, sending the magnesium sulfate solution into a magnesium sulfate monohydrate powder dedicated preparation system to prepare a feed-grade magnesium sulfate monohydrate product; separating an iron precipitate from the acidolysis solution by an oxidation-precipitation process, carrying out oxidation, carrying out a polymerization reaction, and solidifying to prepare a solid polymeric ferric sulfate product; and sending the acidolysis solution after separation of the iron precipitate to a follow-up process to prepare a magnesium compound. According to the invention, insufficiencies such as high energy consumption during present technical process of production, low product purity and the like are overcome; and there is no emission of ''three wastes (waste gas, waste water and industrial residue) '' during the production process, so as to minimize the influence on the environment.

Owner:河南省睿博环境工程技术有限公司

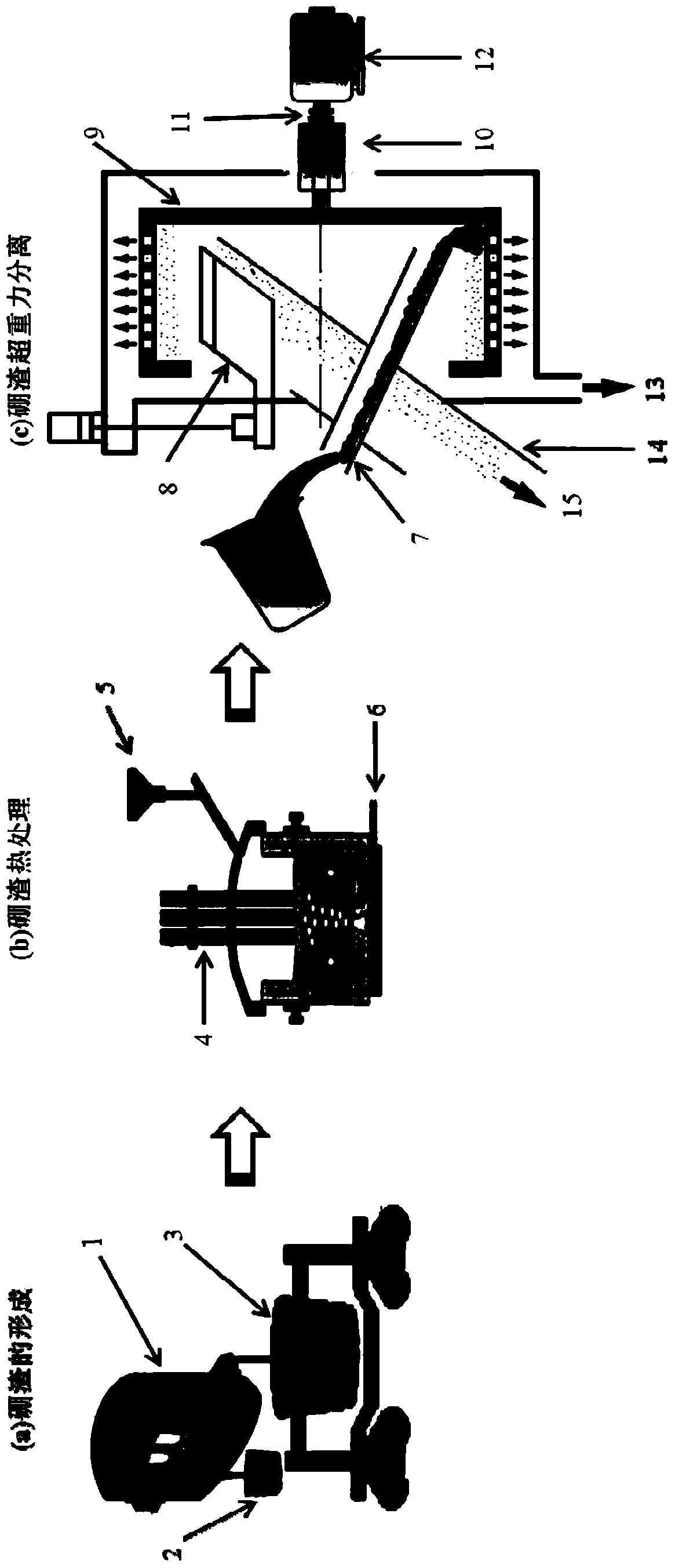

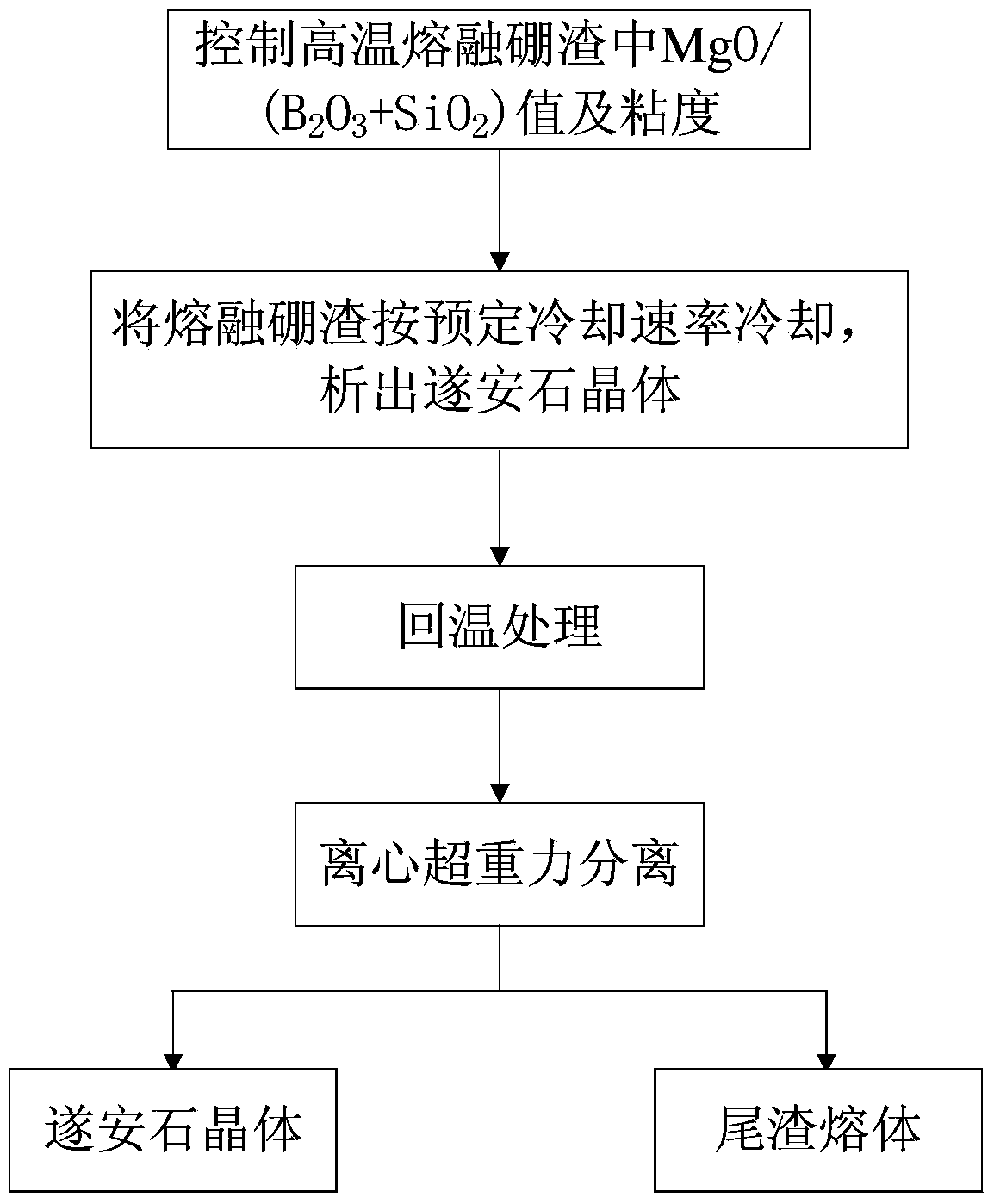

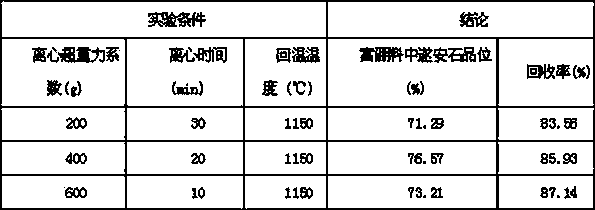

Device, method and system for supergravity separation of boron resource in boron slag

ActiveCN103639069ASolve the problem of environmental loadAchieving targeted enrichmentRotary centrifugesSlagAcid hydrolysis

The invention provides a device, method and system for supergravity separation of a boron resource in boron slag. The method comprises a first step of cooling molten boron slag at a cooling speed of 2 DEG C / min within a temperature interval of 1300-1200 DEG C, and obtaining heat treatment boron slag; and a second step of performing centrifugal supergravity separation on the heat treatment boron slag. After the centrifugal supergravity separation, refined boron slag with the suanite grade at 70-80% can be obtained, and the recovery rate of boron in the boron slag can reach 80-90%. The device, method and system for supergravity separation of the boron resource in the boron slag have the advantages that oriented enrichment of fine and scattered boron-rich phases in the boron slag is achieved by utilizing supergravity, and yields and quality of product boronic acid and borax are improved. The refined boron slag separated by the supergravity can be used for manufacturing the boronic acid in an acid hydrolysis mode, or the borax is manufactured in a carbon alkali method. A main phase in tailings is forsterite, magnesium sulfate monohydrate can be obtained in a sulfuric acid method, the problem of an environmental load of the boron slag is solved, and comprehensive utilization of the boron slag resource is also achieved.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing ammonium sulphate grain products by using inorganic caking agent

ActiveCN101575222ASimple production processEasy to operateAmmonium salt fertilisersFertilizer mixturesGranularityPhosphate

The invention discloses a method for producing ammonium sulphate grain products by using an inorganic caking agent, which comprises the steps of: (1) selecting one of diammonium phosphate or monoammonium phosphate, or the mixture of diammonium phosphate or monoammonium phosphate and magnesium sulfate monohydrate or magnesium sulfate heptahydrate as the inorganic caking agent for producing ammonium sulphate grains, and crushing the inorganic caking agent for standby; (2) crashing the ammonium sulphate crystals; (3) uniformly mixing the crashed ammonium sulphate crystals and the crashed inorganic caking agent according to the proportion between the inorganic caking agent and the ammonium sulphate, adding the mixture into a pelletizer for pelleting with middle pressure and steam to obtain the semi-finished products; (4) drying the semi-finished products; and (5) screening the dried finished products, and packaging the products which are inspected to be qualified. The method for producing ammonium sulphate grain products by using the inorganic caking agent has the advantages that: (1) the technique is simple and the operation is convenient; (2) the caking agent is easy to be obtained and the weight percentage of the product nutrition is above 90 percent, the granularity is uniform and the strength is suitable for large mechanized operation; and (3) the organic caking agent is free to be mixed according to the granulating requirement, and can meet large mechanized production. The method of producing ammonium sulphate grain products by using the inorganic caking agent is suitable to be popularized and used in producing compound fertilizers.

Owner:WENGFU (GRP) CO LTD

Special slow-release bulk blending fertilizer for wheat and preparation method of fertilizer

InactiveCN106699338AIncrease profitImprove soil functionCalcareous fertilisersMagnesium fertilisersCoated ureaRoot system

The invention discloses special slow-release bulk blending fertilizer for wheat and a preparation method of the fertilizer. The special slow-release bulk blending fertilizer for wheat is mainly prepared from components in percentage by weight as follows: 16%-18% of resin coated urea granules, 4%-6% of urea particles, 39%-41% of diammonium phosphate granules, 14%-16% of resin coated potassium nitrate granules, 4%-6% of potassium chloride granules, 10%-13% of anhydrous calcium chloride granules, 7%-10% of magnesium sulfate monohydrate granules, 0.4%-0.5% of zinc sulfate monohydrate granules, 0.2%-0.3% of boric fertilizer granules and 0.2%-0.3% of additive granules, wherein the mass ratio of available nitrogen to slow-release nitrogen is (1-1.1): 1, and the mass ratio of available potassium to slow-release potassium is 1: (3-1.4). The special slow-release bulk blending fertilizer for the wheat is prepared on the basis of soil nutrient characteristics in Shanghai area, adopts the reasonable and comprehensive nutrient proportion, facilitates absorption and utilization by the wheat, can improve the soil granular structure, improve root system activity and soil fertility, promote the wheat to grow robustly and increase the fertilizer utilization rate and is convenient to use, the preparation process is simple, the fertilizer is efficient, low in consumption, low in cost, energy-saving and environment-friendly.

Owner:上海永通生态工程股份有限公司

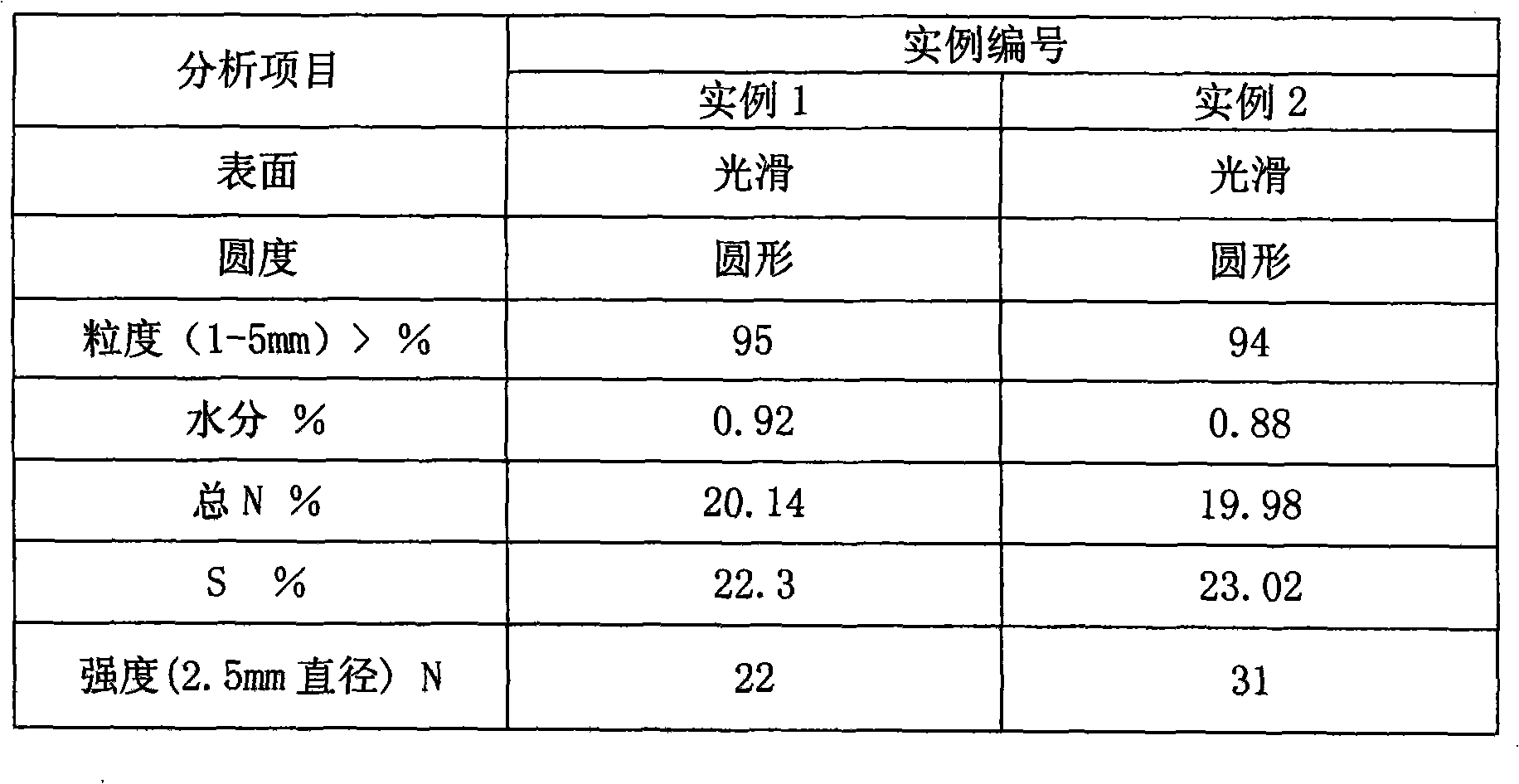

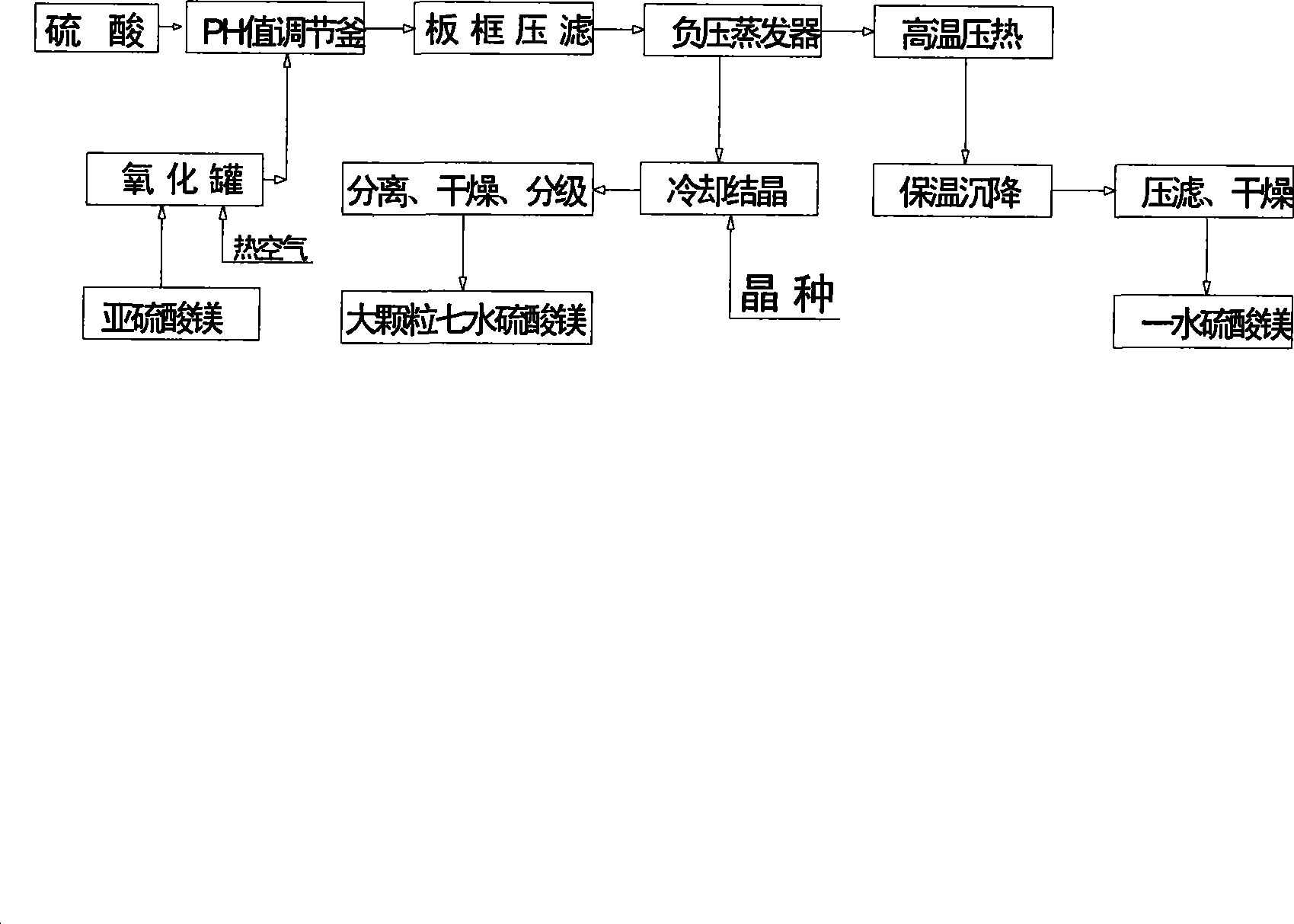

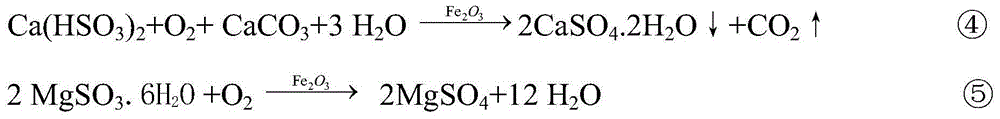

Method for producing large particles of heptahydrate magnesium sulfate and monohydrate magnesium sulfate from magnesium sulfate solution

InactiveCN101214980AImprove product qualityQuality improvementMagnesium sulfatesSocial benefitsPhysical chemistry

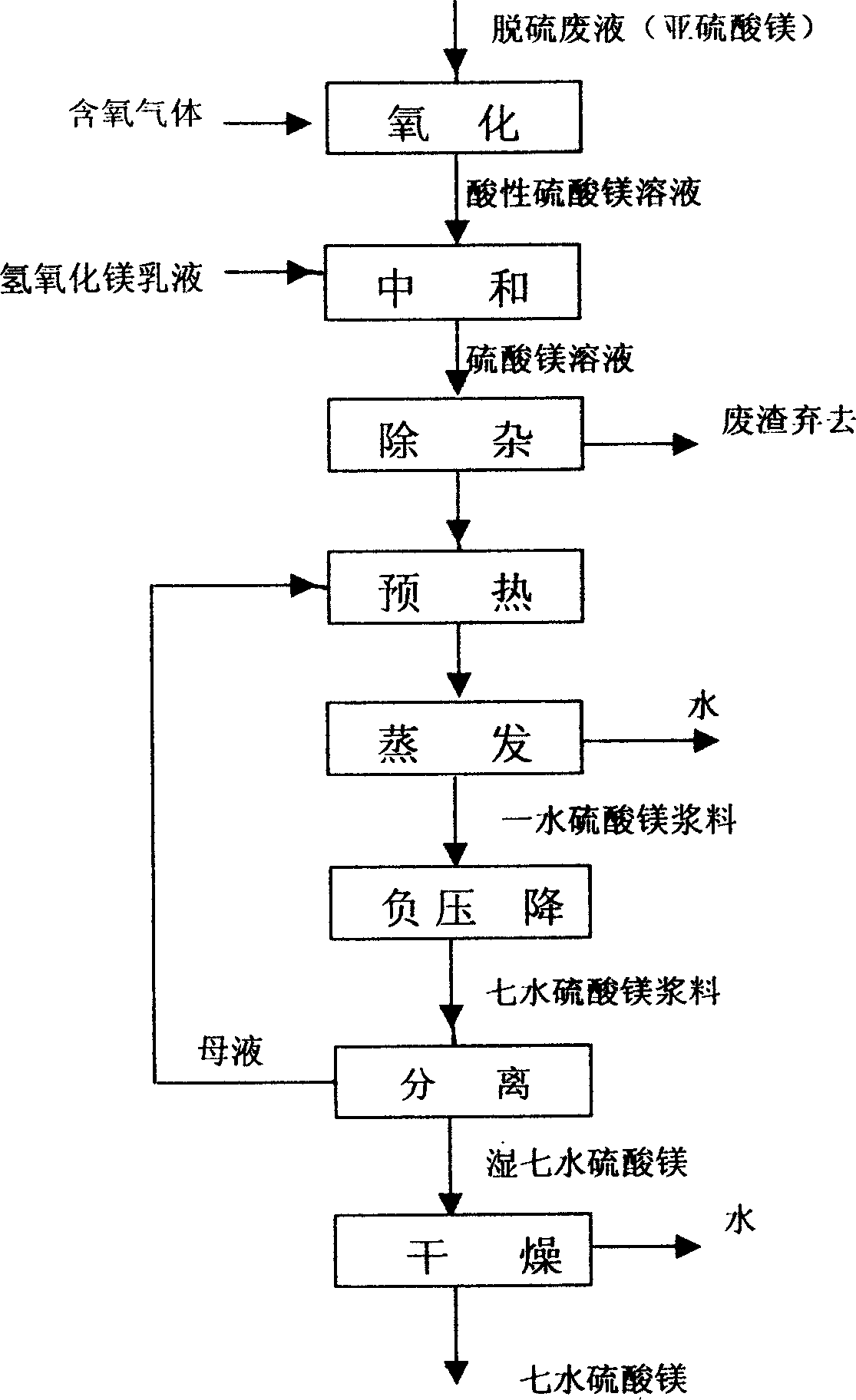

The invention discloses a method for producing magnesium sulfate, which is a method for producing macroaggregated magnesium sulfate heptahydrate and magnesium sulfate mono-hydrate from magnesium sulfate solution, in particular to a method for producing macroaggregated magnesium sulfate heptahydrate and magnesium sulfate mono-hydrate by employing solid containing magnesium sulfite (the chemical name is MgSO3) to obtain solution containing magnesium sulfate after oxidation treatment. The method of the invention comprises high temperature oxidizing magnesium sulfite, adding acid to adjust pH value, filtering solution, negative pressure evaporating and high temperature heating or seeding cooling for producing magnesium sulfate heptahydrate. The invention is simple in method and easy in operation. The product of magnesium sulfate produced by the method is high in product quality, and the selling price is increased. The method sufficiently employs byproduct of desulphurization process with magnesium as raw material, thereby decreasing the investment of environmental equipment in the desulphurization process with magnesium and operation cost, also decreasing the production cost of magnesium sulfate industry and achieving the win-win purpose of social benefit and economic benefit. The problems that in the existing method the product quality is low and macroaggregated magnesium sulfate heptahydrate can not be produced are resolved.

Owner:张荣阳 +2

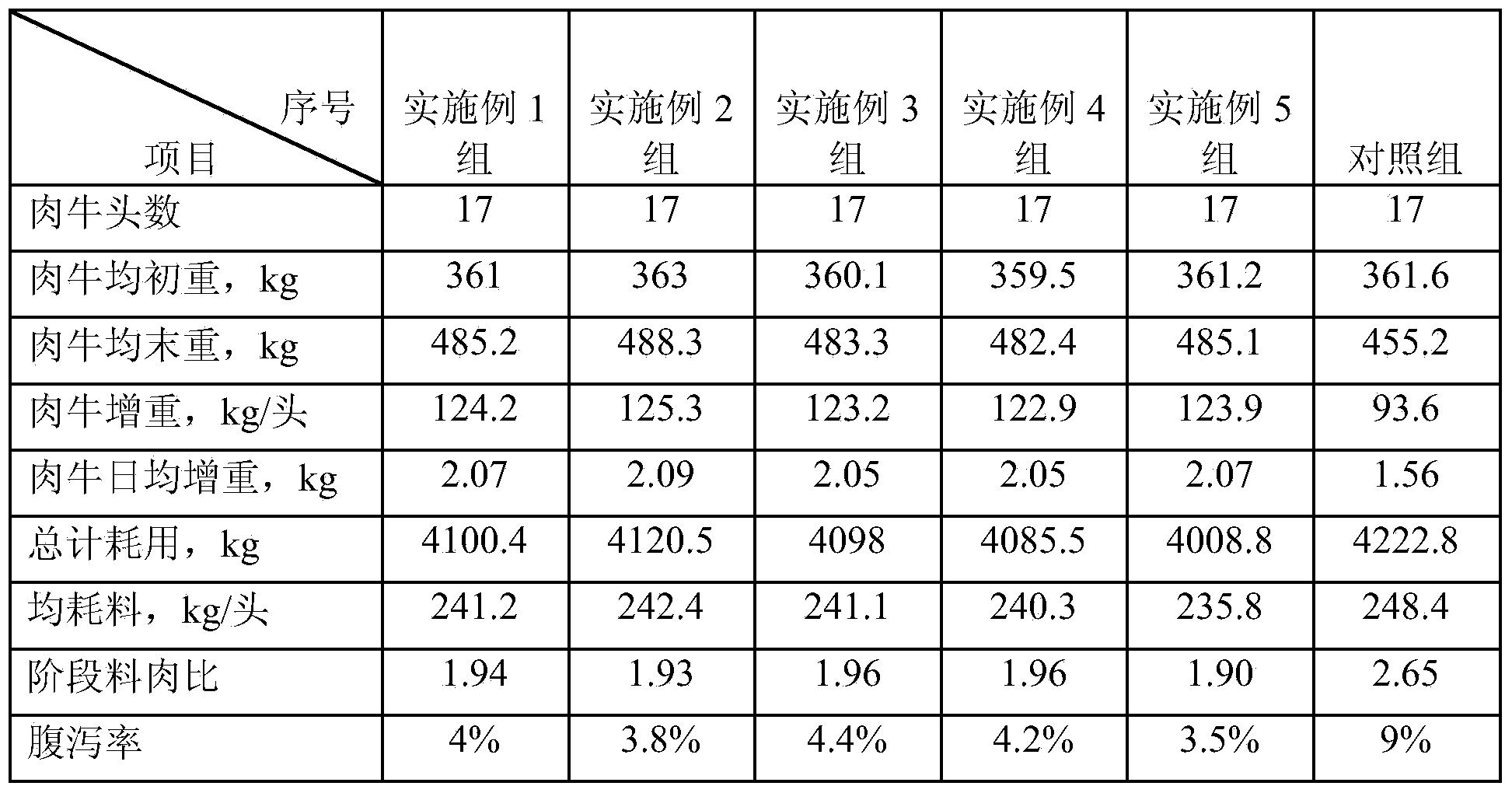

Core compound feed for beef cattle

ActiveCN103404702AImprove immunityReduce diarrhea rateAnimal feeding stuffDrug additiveCopper sulfate

The invention relates to a feed, in particular to a core compound feed for beef cattle. The core compound feed comprises a core material which comprises the following components in parts by weight: 1-6 parts of 500000IU / g vitamin A, 1-5 parts of 500000IU / g vitamin D3, 2-10 parts of 50 percent vitamin E, 15-30 parts of manganese sulfate, 5-15 parts of copper sulfate, 4-15 parts of zinc oxide, 100-200 parts of magnesium sulfate, 150-250 parts of magnesium sulfate monohydrate, 20-50 parts of ferrous sulfate monohydrate, 5-15 parts of 1 percent calcium iodate, 2-6 parts of 1 percent sodium selenite, 0.2-2 parts of 1 percent cobalt chloride, 30-60 parts of 60 percent choline chloride, 1-3 parts of ethoxy quinoline, 300-600 parts of dephenolized cottonseed protein, 10-20 parts of a urease inhibitor and 80-150 parts of saccharicterpenin. According to the core compound feed, the saccharicterpenin extracted from plants is used for replacing a conventional growth promotion medicated additive for beef cattle, the feed intake increases, the immunity of the beef cattle is improved, the daily gain and the feed efficiency are improved, the diarrhea rate of the beef cattle in a fattening stage is reduced, and after the beef cattle is fed by the compound feed disclosed by the invention, the gain effect of the beef cattle is remarkable.

Owner:山东邦基科技股份有限公司

Completely-water-soluble organic-inorganic biological bacterial fertilizer and preparation method thereof

The invention discloses completely-water-soluble organic-inorganic biological bacterial fertilizer. The water-soluble fertilizer is composed of amino acid, yeast powder, amino acid chelated trace element fertilizer, boric acid, magnesium sulfate monohydrate and functional biological bacterial agent. The preparation method includes the steps of chelating reaction, mixing reaction, drying and smashing to obtain biological organic water-soluble fertilizer. The amino acid, the yeast powder and the amino acid chelated trace element fertilizer provide other nutrient elements and can provide sufficient carbon elements for crop growing, so that input-output ratio is higher with same input, and yield is increased by 30% averagely. The preparation method is simple in preparation process and simple in processing equipment, utilization rate of trace elements at a later stage is increased, and loss of other nutrient elements of the fertilizer during processing is avoided.

Owner:JIANGXI RUIBOTE FERTILIZER CO LTD

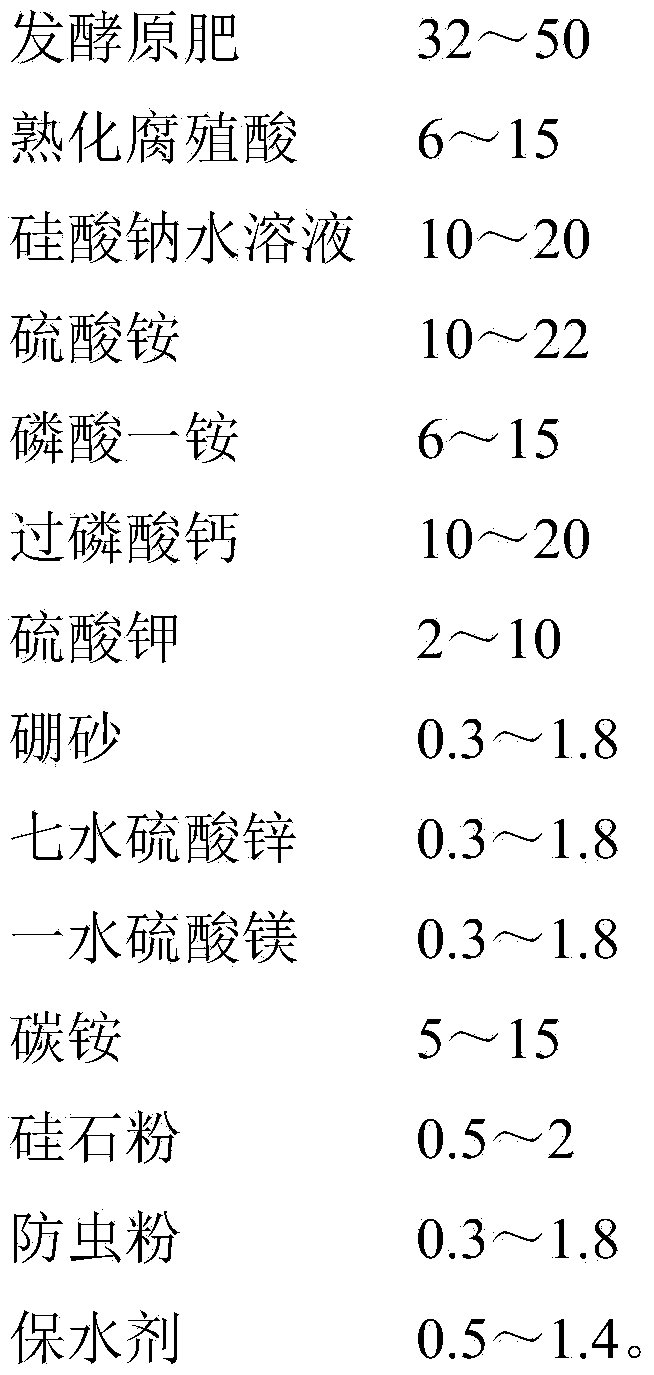

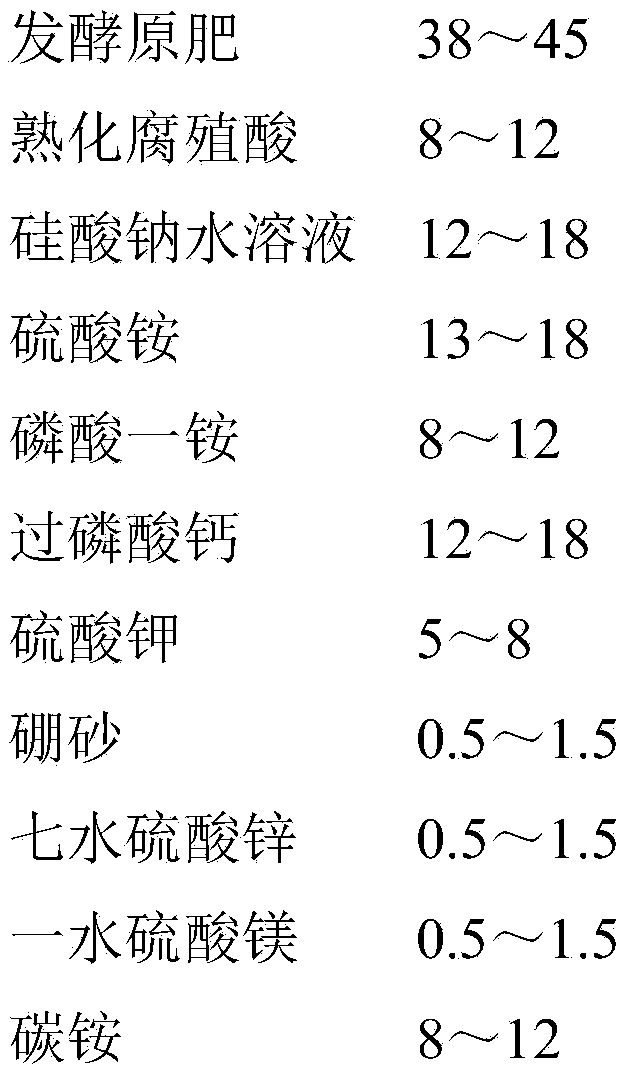

Bamboo-willow compound fertilizer and preparation method

InactiveCN103896677AMeet the needs of medium and trace elementsSimple materialFertilizer mixturesPhosphatePhosphoric acid

The invention discloses a bamboo-willow compound fertilizer, including the following raw materials in parts by weight: 32-50 parts of raw fermentation manure, 6-15 parts of ripening humic acid, 10-20 parts of sodium silicate aqueous solution, 10-22 parts of ammonium sulfate, 6-15 parts of monoammonium phosphate, 10-20 parts of calcium superphosphate, 2-10 parts of potassium sulfate, 0.3-1.8 parts of borax, 0.3-1.8 parts of zinc sulfate heptahydrate, 0.3-1.8 parts of magnesium sulfate monohydrate, 5-15 parts of ammonium bicarbonate, 0.5-2 parts of silica powder, 0.3-1.8 parts of mothproof powder and 0.5-1.4 parts of water-retaining agent. The fertilizer disclosed by the invention can be used for improving the permeability of the soil, dissolving toxins in the soil, improving the absorption of bamboo and willow on nutrients and water, prompting cell division and growth, strengthening a series of internal biochemical activities and promoting the transformation and accumulation of organic matters in vivo, so as to promote the quick growth of the bamboo and willow.

Owner:广西启农生物科技开发有限公司

Process for recycling boric acid and magnesium sulfate from boric acid mother solution

ActiveCN103708487ASolving the disadvantages of natural drying methodsSolve the problem of high energy consumption of single-effect evaporationEnergy inputMagnesium sulfatesVacuum evaporationPollution

The invention relates to a process for recycling boric acid and magnesium sulfate from a boric acid mother solution. The heat is fully utilized by adopting multi-effect heat pump vacuum evaporation. The process comprises the following steps: entering the boric acid mother solution into a multi-effect evaporator to concentrate to obtain 380-420g / L of magnesium sulfate, crystallizing in a cooling crystallizer, performing gravity stratification on the crystallization solution, wherein the upper layer is the boric acid solution, and the lower layer is the magnesium sulfate solution; performing centrifugal separation on the upper boric acid solution in a centrifugal machine, entering allowing the crystal into a dryer, wherein the drying temperature is 100-130 DEG C, packaging the finished product, returning the boric acid mother solution to a boric acid evaporator for concentrating again; performing centrifugal separation on the lower magnesium sulfate solution in another centrifugal machine, entering the crystal into the dryer at the drying temperature is 110-150 DEG C, thereby obtaining magnesium sulfate monohydrate, and packaging the finished product. According to the process, the magnesium sulfate monohydrate with high value is prepared, the recycling rate of the boric acid is improved, the magnesium sulfate is recycled, the process is high in production efficiency, adapts to large-scale production and has high economic benefits and social benefits, the pollution of the boric acid mother solution on the environment is avoided, and the cost is reduced.

Owner:HEBEI UNIV OF TECH

Humic acid-containing complete-element water soluble fertilizer, and preparation method and application thereof

InactiveCN105669297AIncrease profitPromote growthMagnesium fertilisersAlkali orthophosphate fertiliserSolubilityPhosphate

Owner:HUNAN TAIGU BIOTECH

Novel potash magnesium sulphate fertilizer and preparation method thereof

The invention relates to a novel potash magnesium sulphate fertilizer and a preparation method thereof applied to the field of agriculture and forestry production. The novel potash magnesium sulphate fertilizer comprises a macro-element, i.e., potassium, medium elements including sulphur and magnesium, trace elements including manganese, zinc and boron and a plant nutrient absorption enhancer. Compared with other potash magnesium fertilizers, the novel potash magnesium sulphate fertilizer has the advantages of high fertilizer efficiency, comprehensive nutrient and simplicity and convenience in application. The product provided by the invention is produced through the following steps of: with potassium sulphate as a main raw material and magnesium sulfates and zeolite powder as auxiliary raw materials, adding the trace elements such as the manganese, the zinc and the boron according to a certain scientific proportion, meanwhile, adding a certain dose of plant nutrient absorption enhancer, and sufficiently and uniformly mixing all the materials, wherein the magnesium sulfates include magnesium sulfate heptahydrate, magnesium sulfate pentahydrate and magnesium sulfate monohydrate. The product is simple in production process, has easily obtained raw materials and is comprehensive in nutrient; and the pH value of the product is between 7 and 9, so that the product is more suitable for acidic soil and also has the functions of improving the soil and protecting the ecological environment.

Owner:GUANGXI NEW ORIENTATION CHEM IND

Method for removing sulfur dioxide in flue gas and preparing magnesium sulfate by utilizing phosphorus floatation tailings

A disclosed method for removing sulfur dioxide in flue gas and preparing magnesium sulfate by utilizing phosphorus floatation tailings is characterized by comprising: concentrating phosphorus floatation tailings slurry to obtain a desulfurized slurry with the liquid-solid mass ratio of 2-3:1; injecting the desulfurized slurry into a desulfurization tower, contacting with SO2 in flue gas for reaction, then sending to an oxidation circulation tank, supplementing air and oxidizing to obtain a solid precipitate; performing solid-liquid separation, and concentrating the separated magnesium sulfate solution to have a mass concentration of 30-40%; and cooling the magnesium sulfate solution, crystallizing, performing solid-liquid separation, and drying and dewatering the solid, so as to obtain magnesium sulfate monohydrate. The method for removing low-concentration sulfur dioxide in flue gas and preparing magnesium sulfate by utilizing phosphorus floatation tailings helps to remove sulfur dioxide in tail gas and reduce pollution of sulfur dioxide to environment, also is capable of cyclically utilizing phosphorus floatation tailings to produce a medium element magnesium sulfate fertilizer, fully utilizes afterheat of tail gas, saves energy, saves resource, reduces cost and is simple in operation.

Owner:SINOCHEM AGRI LINYI R&D CENT CO LTD

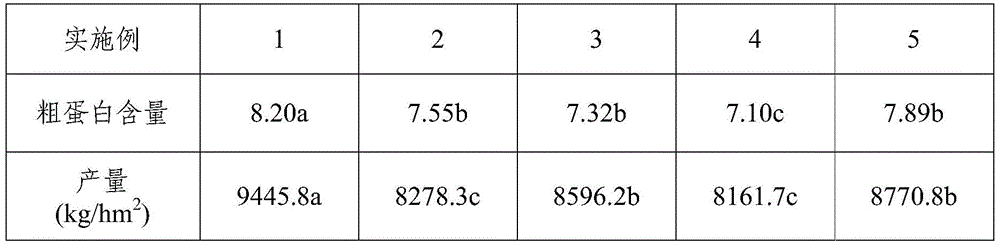

Feed for machin in lactation period

InactiveCN103636976AIncrease feed intakeIncrease milk productionAnimal feeding stuffAnimal scienceBeta-Carotene

The invention provides a feed for machin in the lactation period. The feed provides good nutrition for machin in the lactation period so as to improve the milk quality of breeding machin, improves the growth speed and immunity of infant monkeys, and shortens the weaning time; at the same time the feed can largely reduce the physical power loss of female machin, and thus the female machin can recover as quickly as possible so as to improve the yield. The feed is composed of the following components in parts by weight: 180 to 240 parts of animal protein fish meal, 10 to 20 parts of lysine, 10 to 20 parts of threonine, 2 parts of folic acid, 3 parts of beta-carotene, 2 parts of vitamin E, 3 parts of HY.D, 5.6 to 6.4 parts of chromium picolinate, 4 parts of selenium yeast, 25 to 30 parts of magnesium sulfate monohydrate, 25 to 30 parts of calcium formate, 1 to 3 parts of rice bran oil, and 0.1 to 0.3 part of salt.

Owner:GUANGXI WEIMEI BIOTECH

Granulated magnesium sulfate fertilizer and preparation method thereof

InactiveCN104446677AModerate intensityLow costMagnesium fertilisersSolid/semi-solid fertilisersPrillWater soluble

The invention relates to a granulated magnesium sulfate fertilizer and a preparation method thereof. The granulated magnesium sulfate fertilizer is prepared from 70-95 parts of powdery magnesium sulfate monohydrate, 0-25 parts of powdery light calcined magnesia and 5-10 parts of powdery magnesite. The preparation method of the granulated magnesium sulfate fertilizer comprises the following steps: (1) mixing materials, namely adding the raw materials to a double shaft agitator for agitation; (2) preparing a binder; (3) pelleting, namely putting the dry materials obtained in the step (1) into an aggregate type pelletizer, and adding the binder in the step (2) to obtain a granular material; (4) drying; (5) cooling; (6) sieving, namely feeding the cooled material to a vibrating screening machine to obtain the fertilizer having the grain size of 2-4mm. The granulated magnesium sulfate fertilizer has the following beneficial effects that the granule strength is moderate, the cost is low, each granule contains magnesium in three forms, namely water-soluble magnesium, citric acid-soluble magnesium and slightly soluble magnesium, and the nutrients are released reasonably in a balanced manner and advantageous for crops to absorb.

Owner:营口菱镁化工集团有限公司

Apparatus and method for producing potassium chloride and co-producing magnesium sulfate by mixing brine

InactiveCN104528766AIncrease concentrationSimple production processMagnesium sulfatesAlkali metal chloridesBromineSlurry

The invention relates to an apparatus and a method for producing potassium chloride and co-producing magnesium sulfate by mixing brine; high-temperature salt filter cake or magnesium sulfate monohydrate suspending in mother liquid recovered from the production of a magnesium sulfate monohydrate product is dissolved by virtue of salt-producing brine; by dissolving magnesium sulfate in solid phase and by separating and recovering sodium chloride in solid phase, bittern concentration is improved to 29.5-33.0 Baume degrees from 28.0-31.5 Baume degrees, which is to say, by adding the mixed salt slurry of high-temperature salt, the initial Baume degree of salt-producing bittern is improved by 1.5-2.5 Baume degrees, so that the output of frozen magnesium sulfate is doubled on the premise of same energy consumption. Crystallization water is directly evaporated from magnesium sulfate crystal, so that the magnesium sulfate monohydrate is produced. In the bittern, the concentrations of potassium, bromine and magnesium chloride are improved while the concentration of sodium chloride is remarkably reduced. Entering into a potassium chloride system, the bittern can be used for reducing steam consumption in an evaporating process. The blending amount of old brine in the potassium chloride evaporating process can be gradually reduced until the old brine is not blended. Production process of the potassium chloride is optimized.

Owner:李树生

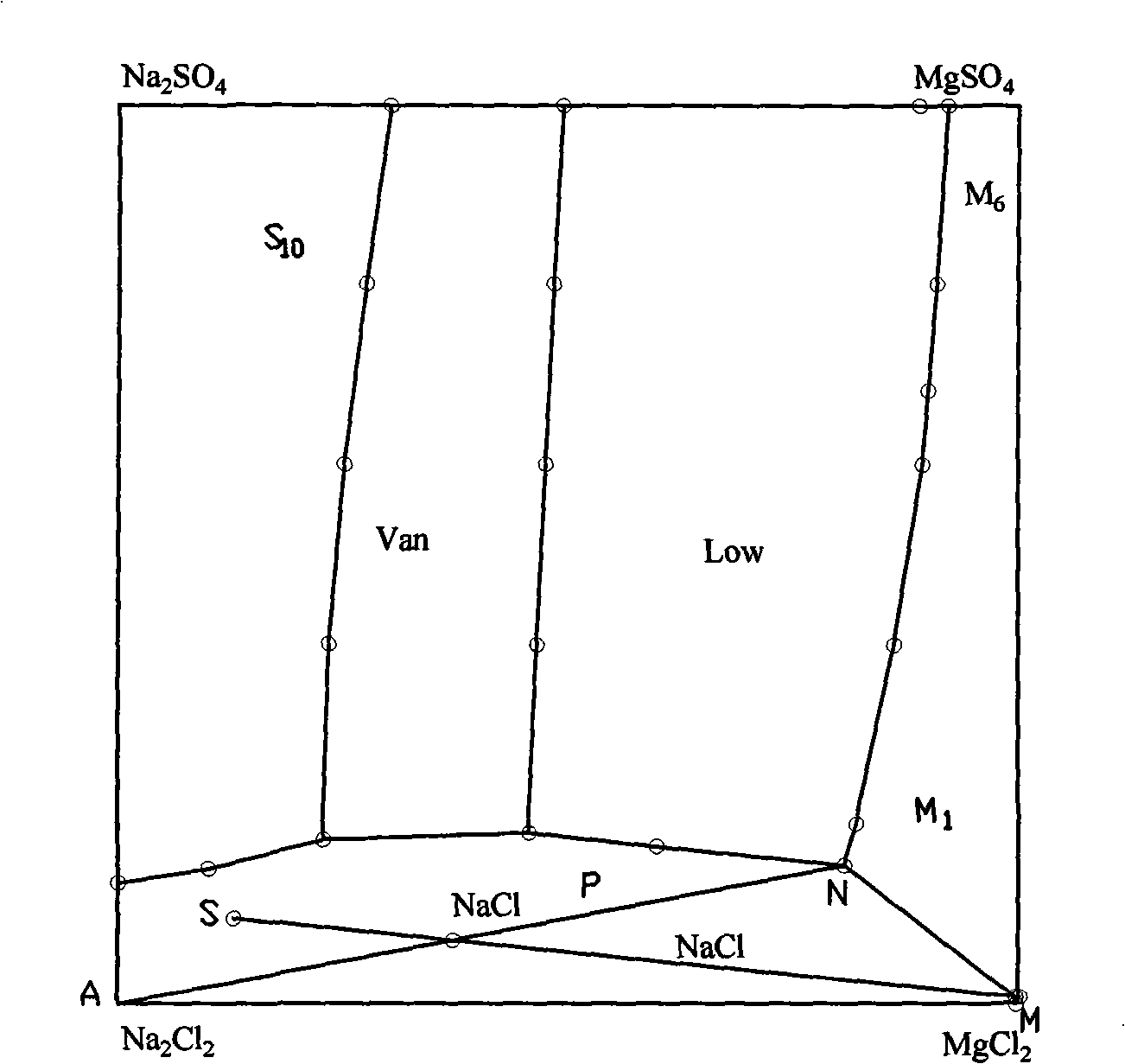

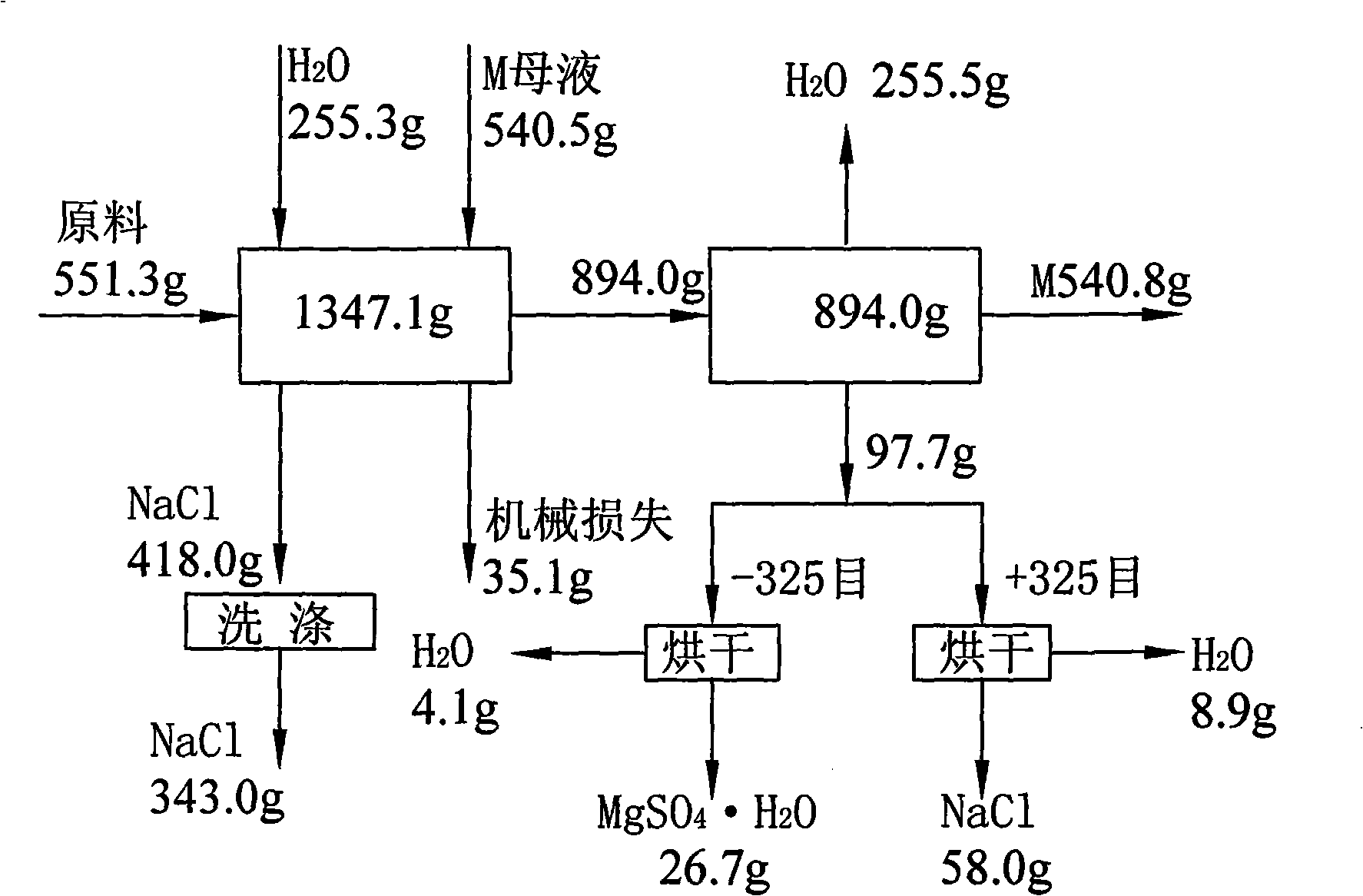

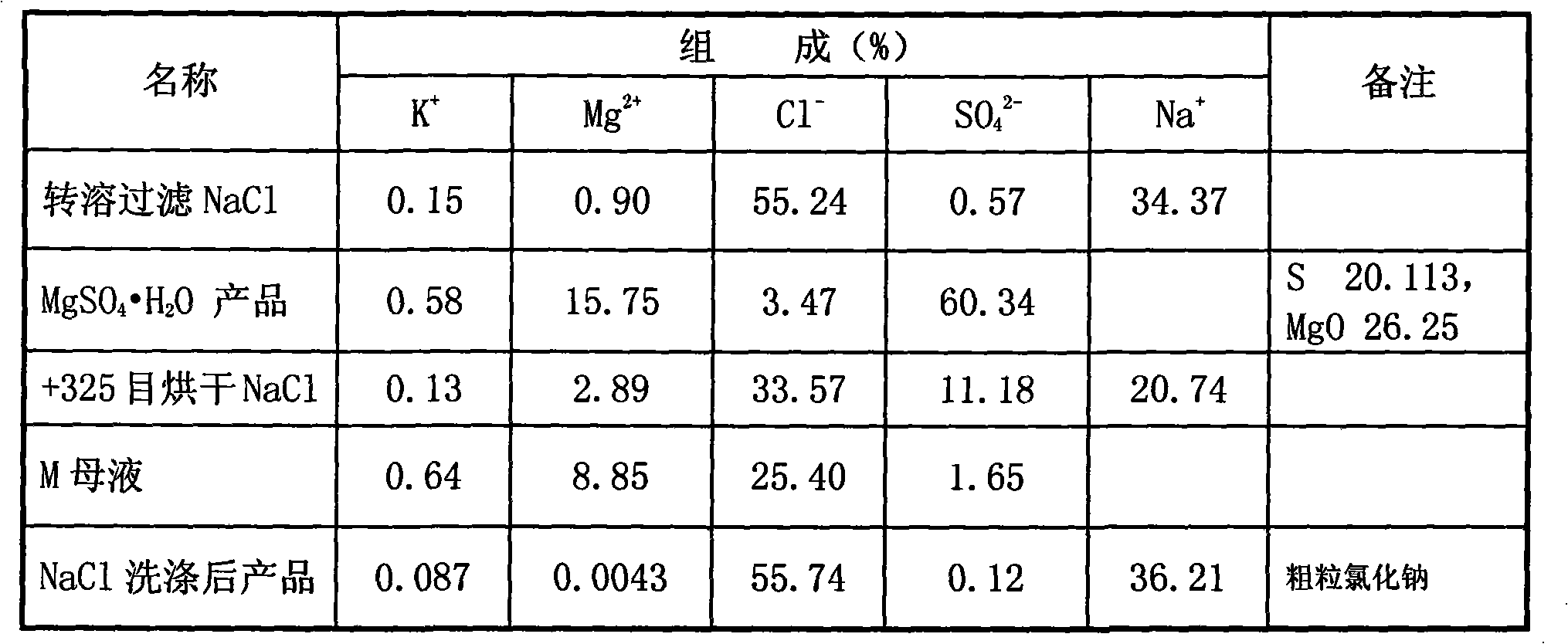

Method for preparing magnesium sulfuric acid monohydrate with mixture salt of sodium chloride and epsomite

The invention relates to a method for preparing magnesium sulfate monohydrate by utilization of salt-mixture of sodium chloride and epsomite, comprising the following steps: firstly, the salt-mixture of raw materials sodium chloride and epsomite is uniformly mixed; secondly, mixture is prepared by the following raw materials by weight portion: 545 to 555 portions of the salt-mixture, 246 to 256 portions of water and 535 to 545 portions of brine; thirdly, the prepared mixture material is heated up to between 74 and 76 DEG C so as to promote dissolution of the salt-mixture; fourthly, undissolved NaCl is filtered; fifthly, mother liquor after the undissolved NaCl is filtered is heated up to between 74 and 76 DEG C and then evaporated and concentrated until fine grains, namely the magnesium sulfate monohydrate, and rough grains, namely the sodium chloride are crystallized; sixthly, after filtration, mixture of the fine grains, namely the magnesium sulfate monohydrate, and the rough grains, namely the sodium chloride is obtained; and seventhly, a standard sieve with 325 meshes is adopted for sieving at a temperature of between 74 and 76, with the sodium chloride as oversize materials, and undersize materials are dried at a temperature of between 74 and 76 so as to obtain the magnesium sulfate monohydrate product. The method has mild operating conditions, low energy consumption, low production cost, no liquid waste emission, and no environmental pollution.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com