Fruit swelling type seaweed organic liquid water soluble fertilizer and production method thereof

An organic liquid, flushing fertilization technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as stimulating rhizomes to absorb soil fertilizers, achieve good effects, promote crop growth and fruit development, and prolong fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

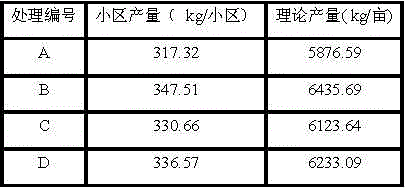

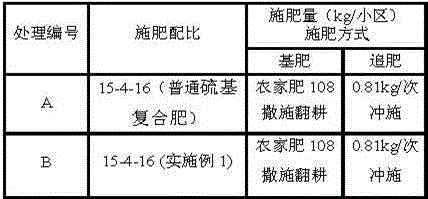

Embodiment 1

[0054] Step 1: After measuring 250 parts of the prepared enzymolysis seaweed extract, pump it into the mixer with a delivery pump;

[0055] Step 2: Mix 200 parts of urea, 100 parts of ammonium polyphosphate, 345 parts of potassium nitrate, 30 parts of magnesium sulfate monohydrate, 5 parts of EDTA chelated iron, 5 parts of EDTA chelated manganese, 5 parts of EDTA chelated zinc, and EDTA chelated 5 parts of copper, 8 parts of boric acid, 2 parts of ammonium heptamolybdate, and 45 parts of potassium fulvic acid were measured respectively, and then sent into the mixer according to a certain ratio, and stirred by double-helical fan-blade stirring technology. mix well;

[0056] Step 3: Transport the mixed liquid to the normal pressure liquid packaging machine for filling.

[0057] The specification of the obtained product is 15-4-16, containing medium and trace elements and potassium fulvic acid.

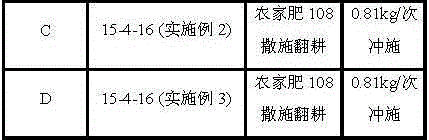

Embodiment 2

[0059] Step 1: After measuring 250 parts of the prepared enzymolysis seaweed extract, pump it into the mixer with a delivery pump;

[0060] Step 2: After measuring 200 parts of urea, 100 parts of ammonium polyphosphate, 345 parts of potassium nitrate, 45 parts of potassium fulvic acid, and 60 parts of water, they are sent into the mixer according to a certain ratio, and double-helical fan blades are used Type stirring technology for stirring, fully mixed at room temperature;

[0061] Step 3: Transport the mixed liquid to the normal pressure liquid packaging machine for filling.

[0062] The specification of the obtained product is 15-4-16, which contains potassium fulvic acid and does not contain trace elements.

Embodiment 3

[0064] Step 1: After measuring 250 parts of the prepared enzymolysis seaweed extract, pump it into the mixer with a delivery pump;

[0065] Step 2: Mix 200 parts of urea, 100 parts of ammonium polyphosphate, 345 parts of potassium nitrate, 30 parts of magnesium sulfate monohydrate, 5 parts of EDTA chelated iron, 5 parts of EDTA chelated manganese, 5 parts of EDTA chelated zinc, and EDTA chelated 5 parts of copper, 8 parts of boric acid, 2 parts of ammonium heptamolybdate, and 45 parts of water are measured respectively, and sent into the mixer according to a certain proportion, and are stirred by double-helical fan-blade stirring technology, and fully mixed at room temperature;

[0066] Step 3: Transport the mixed liquid to the normal pressure liquid packaging machine for filling.

[0067] The obtained product has a specification of 15-4-16, contains medium and trace elements, and does not contain potassium fulvic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com