Device, method and system for supergravity separation of boron resource in boron slag

A high-gravity, boron slag technology, applied in the field of efficient separation and utilization of symbiotic resources, can solve the problems of increased cost, long carbonization time, and low utilization rate of carbon dioxide, so as to achieve comprehensive utilization and solve the effect of environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

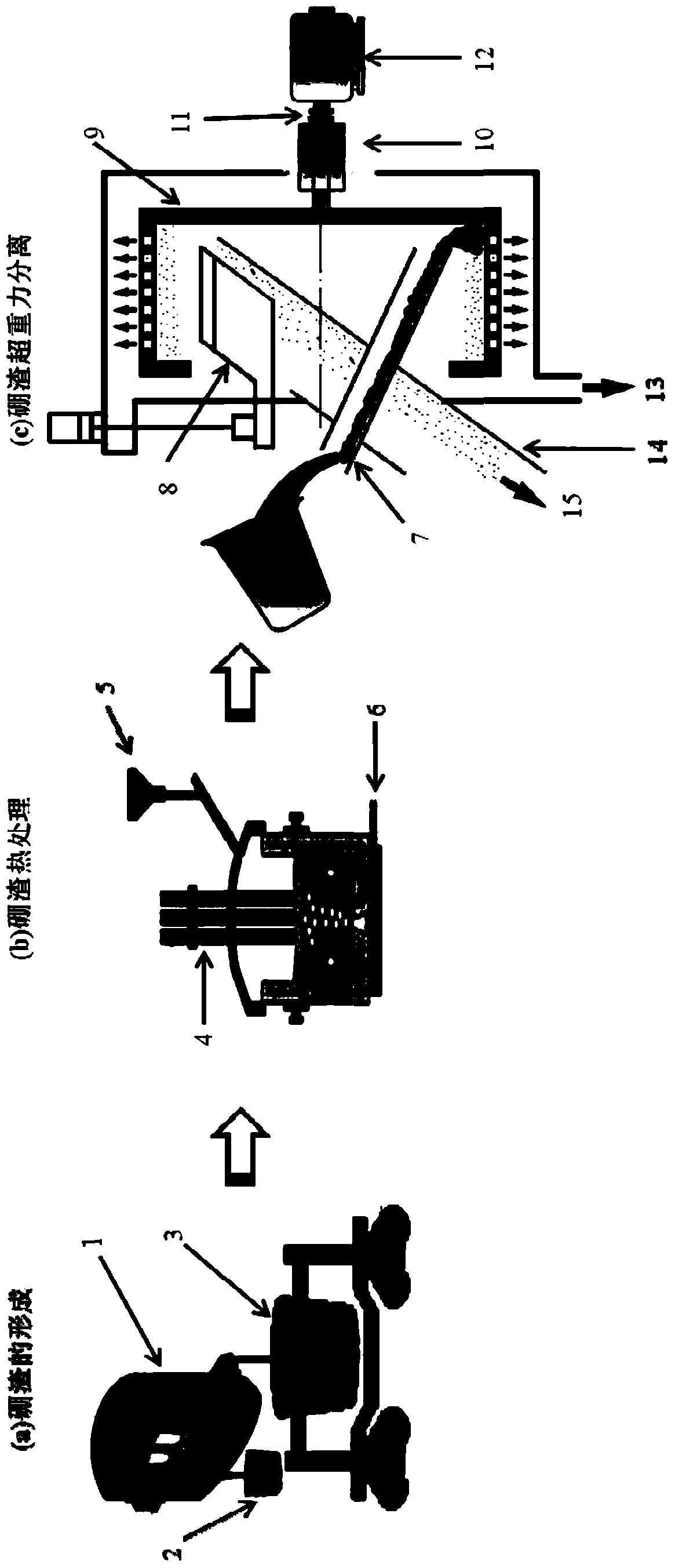

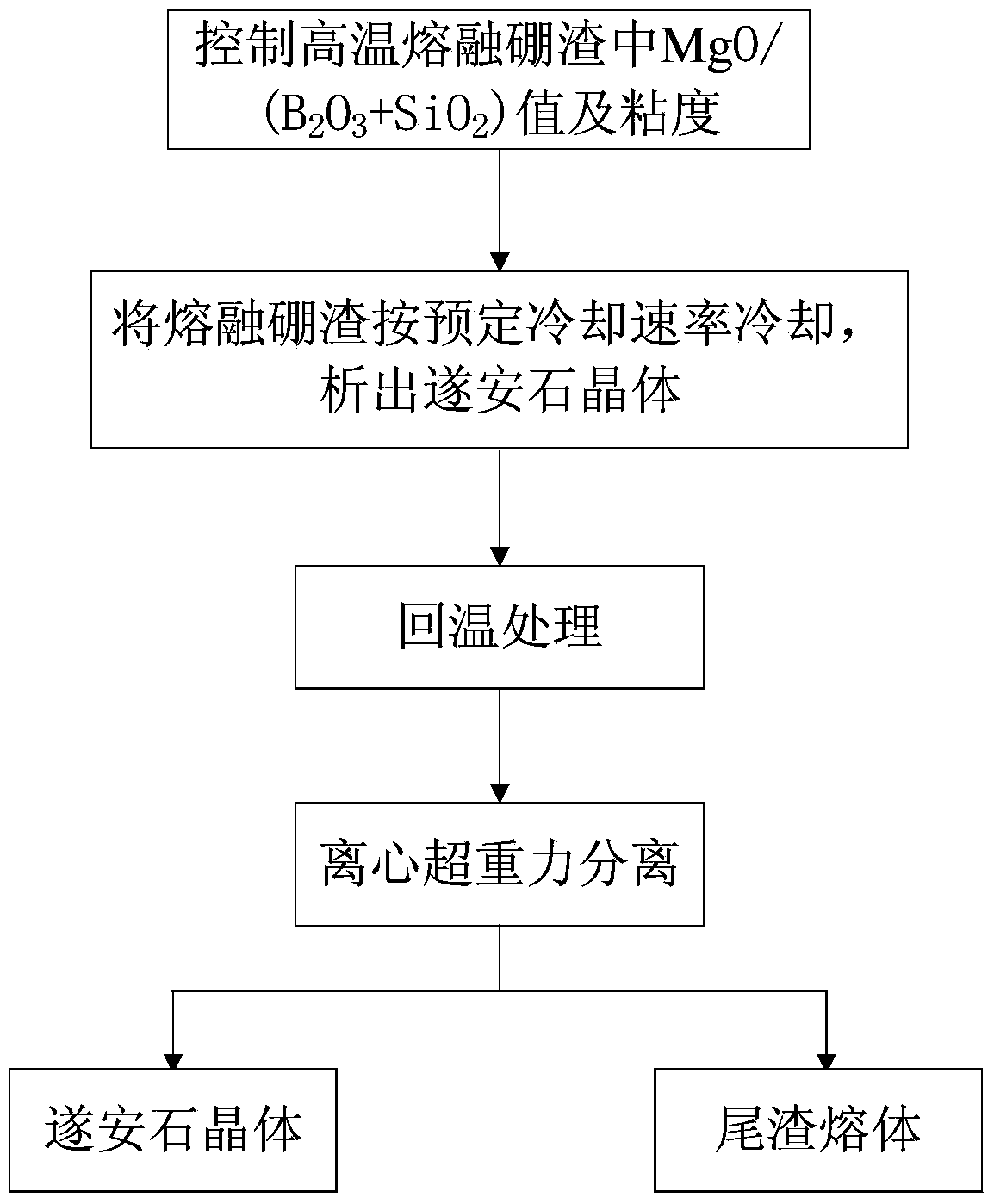

Method used

Image

Examples

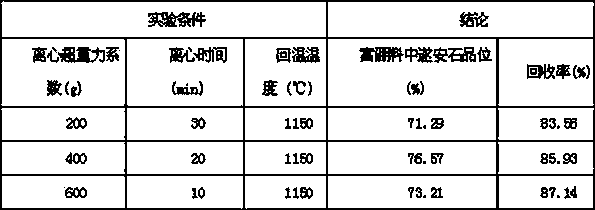

Embodiment 1

[0041] Take 10kg of electric furnace boron-rich slag (Kuandian raw ore), and grind it to below 200 mesh. After testing, the MgO and (B 2 o 3 +SiO2 2 ) The mass ratio is 1.74, so add 0.6kgMgO to the slag to make MgO and (B 2 o 3 +SiO2 2 ) was adjusted to 2.0, fully mixed and then heated to 1450°C for 30 minutes to ensure that the ingredients were evenly mixed, then rapidly cooled to 1200°C, and then at a cooling rate of 0.5°C / min to promote boron slag in the temperature range of 1200-1100°C The boron element in Suianite is enriched towards the Suianite phase, and finally precipitates and grows in the form of Suianite crystals. After the heat treatment of the slag is completed, adjust the temperature of the slag to 1150°C and start the centrifuge immediately, adjust the speed of the centrifuge so that the gravity coefficient is 400g, and after centrifuging at a constant temperature for 20 minutes, turn off the centrifuge. Grind the sample at the solid outlet end of the slag...

Embodiment 2

[0044] Take 10kg of electric furnace boron-rich slag (Kuandian raw ore), and grind it to below 200 mesh. After testing, the MgO and (B 2 o 3 +SiO2 2 ) The mass ratio is 1.74, so add 0.6kgMgO to the slag to make MgO and (B 2 o 3 +SiO2 2 ) was adjusted to 2.0, fully mixed and then heated to 1450°C for 30 minutes to ensure that the ingredients were evenly mixed, then rapidly cooled to 1200°C, and then at a cooling rate of 0.5°C / min to promote boron slag in the temperature range of 1200-1100°C The boron element in Suianite is enriched towards the Suianite phase, and finally precipitates and grows in the form of Suianite crystals. After the heat treatment of the slag is completed, adjust the temperature of the slag to 1150°C and start the centrifuge immediately, adjust the speed of the centrifuge so that the gravity coefficient is 400g, control the cooling rate at about 1-5°C / min, and turn off the centrifuge after the temperature drops to 1050°C , natural cooling. The sample ...

Embodiment 3

[0046] Take 10kg of electric furnace boron-rich slag (Kuandian raw ore), and grind it to below 200 mesh. After testing, the MgO and (B 2 o 3 +SiO2 2 ) The mass ratio is 1.74, so add 0.6kgMgO to the slag to make MgO and (B 2 o 3 +SiO2 2 ) was adjusted to 2.0, fully mixed and then heated to 1450°C for 30 minutes to ensure that the ingredients were evenly mixed, then rapidly cooled to 1200°C, and then at a cooling rate of 0.5°C / min to promote boron slag in the temperature range of 1200-1100°C The boron element in Suianite is enriched towards the Suianite phase, and finally precipitates and grows in the form of Suianite crystals. After the slag heat treatment is completed, adjust the slag temperature to 1150°C and start the centrifuge immediately, adjust the speed of the centrifuge so that the gravity coefficient is 600g, and control the cooling rate in the centrifuge to 2.5°C / min, and turn off the centrifuge after the temperature drops to 1050°C , natural cooling. The sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com