Patents

Literature

32 results about "Gravity coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

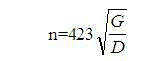

Method for producing large magnesium alloy ring by means of centrifugal casting

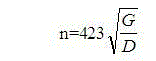

A method for producing a large magnesium alloy ring by means of centrifugal casting includes: preheating a mould; hanging thermal insulation coatings and determining centrifugal casting parameters; performing centrifugal casting and the like. The method is technically characterized by determination of rotation speed and casting speed. A centrifugal power device is started for centrifugal casting, the centrifugal rotation speed n is calculated according to the gravity coefficient formula as shown in the original text, n=29.9, wherein n refers to the centrifugal rotation speed, R refers to the radius (m) of the inner surface of a casting, and G refers to gravity coefficient. The method overcomes the shortcomings of an existing large magnesium alloy ring production process, is used for producing the large magnesium alloy ring with compact texture and high tensile strength, and has an important significance for magnesium alloy application and development of magnesium alloy centrifugal casting technology.

Owner:CHONGQING UNIV

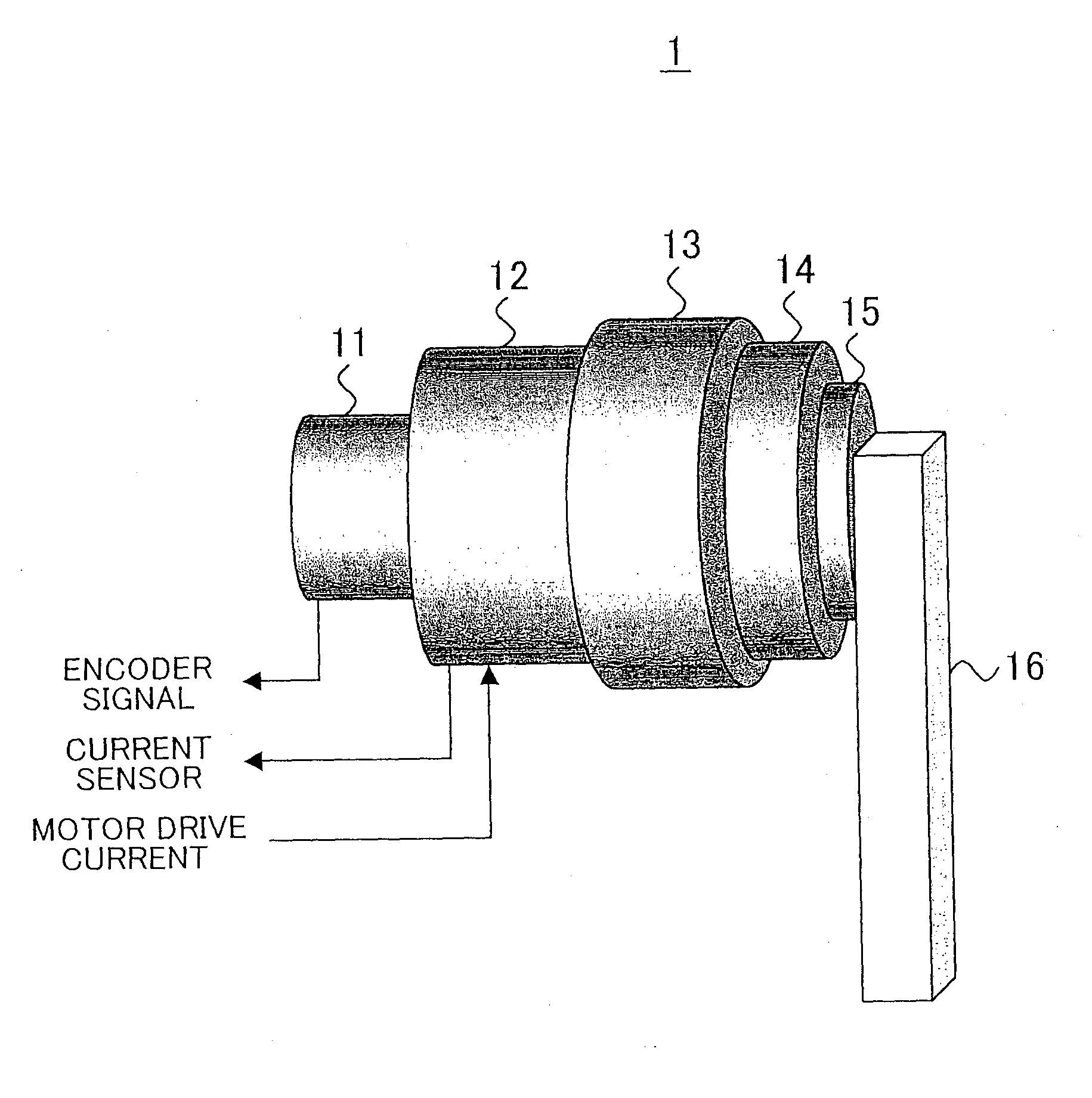

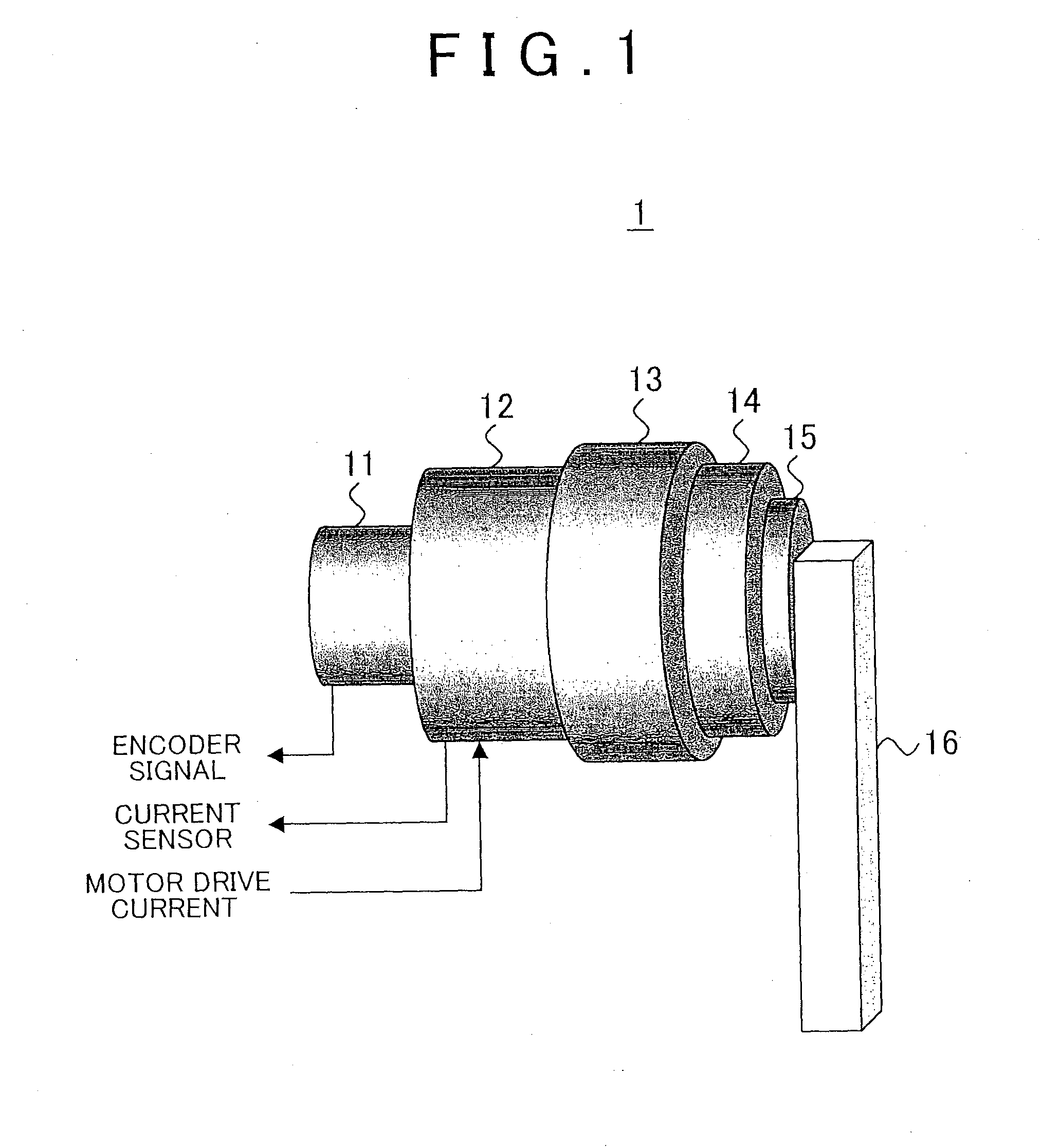

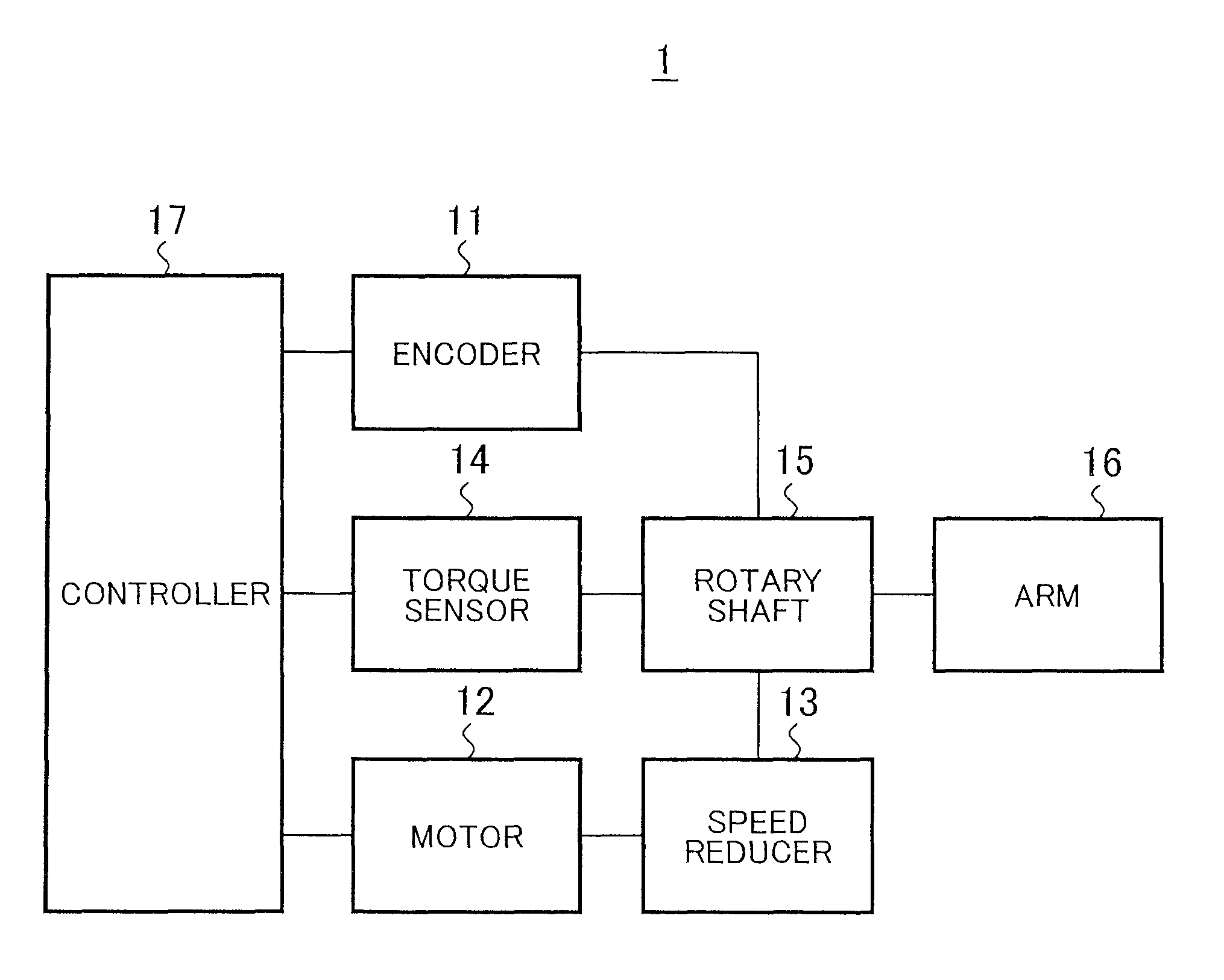

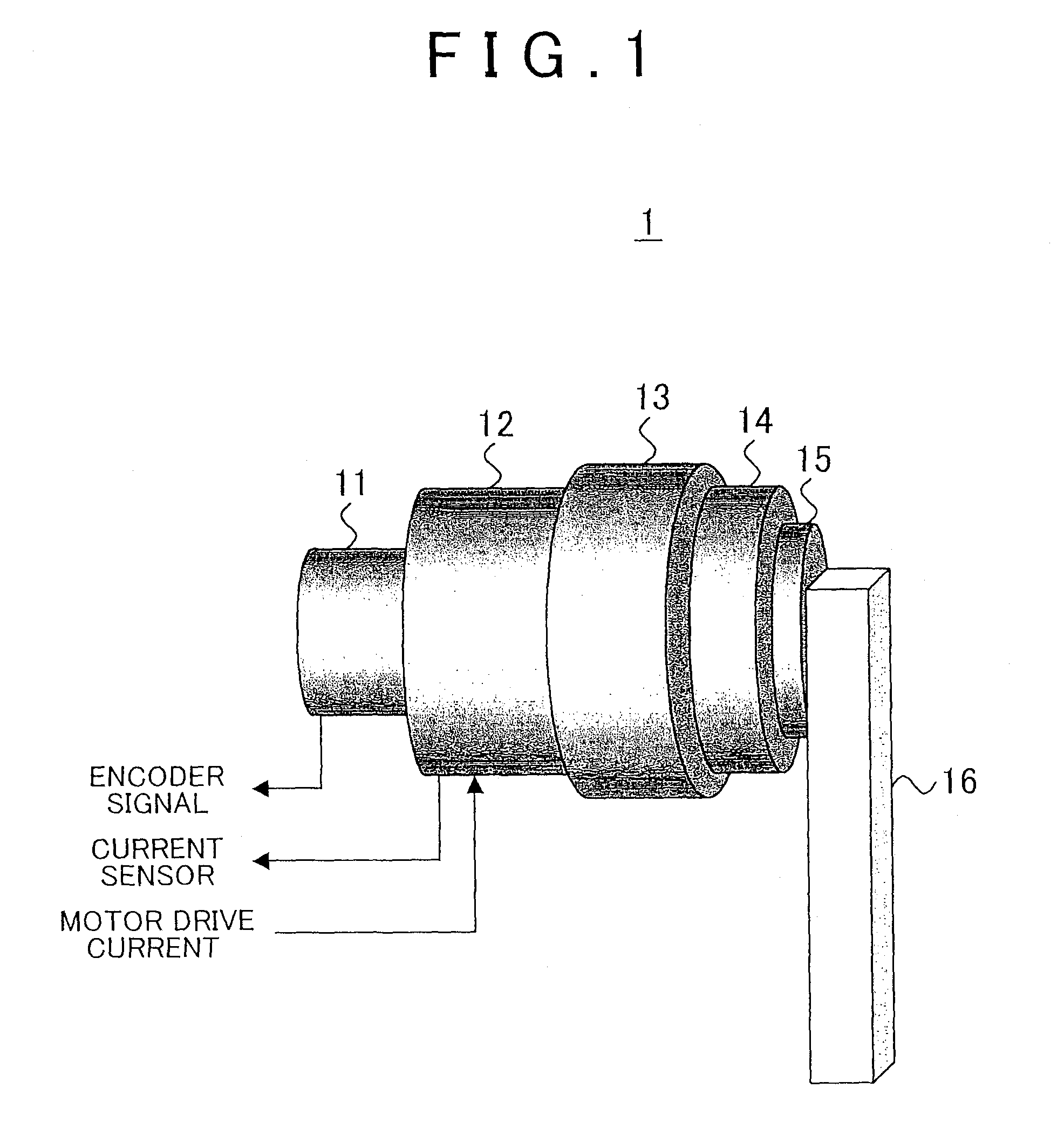

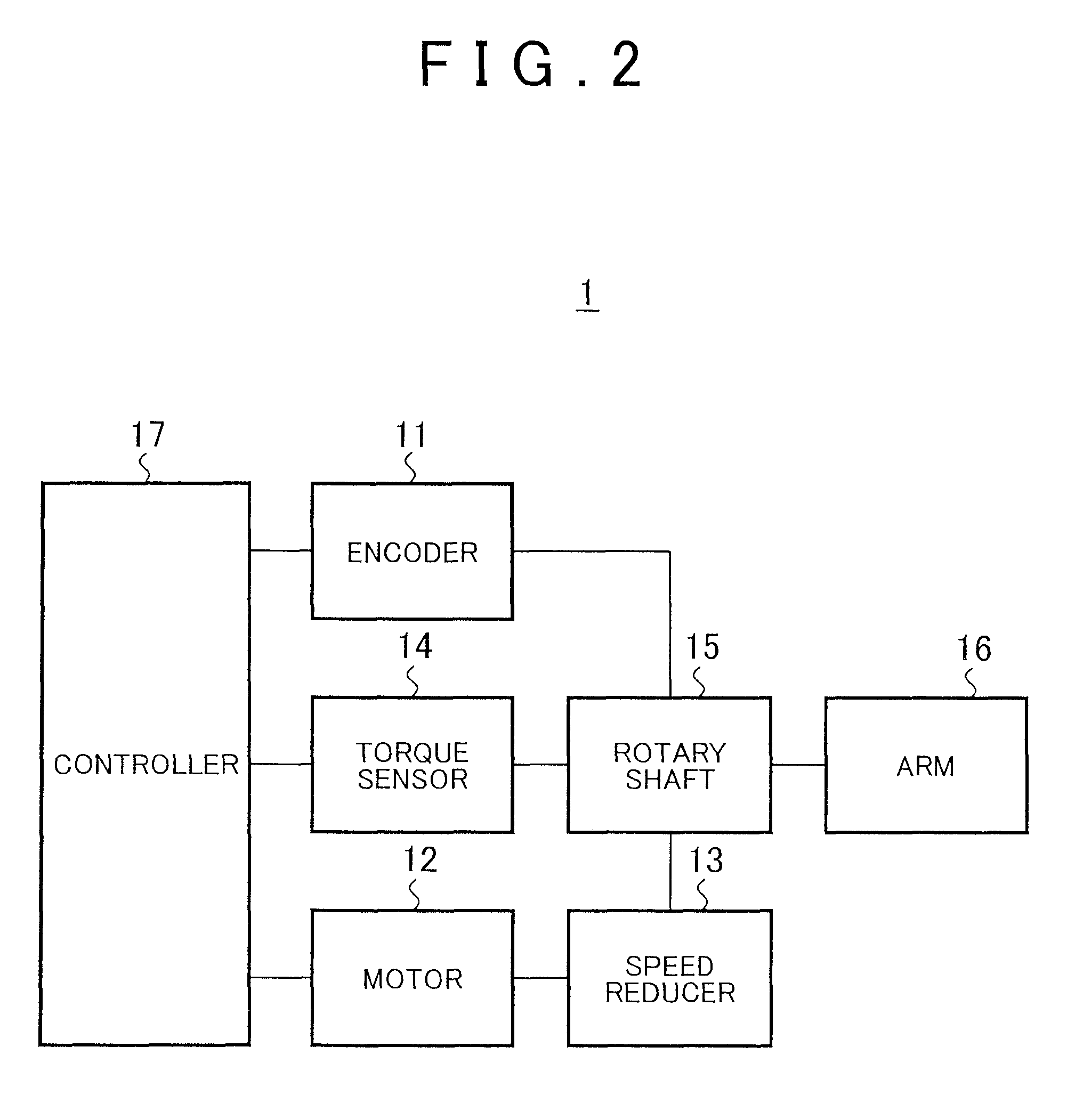

Torque detecting method and arm device

ActiveUS20150045952A1Good compensationImprove accuracyProgramme controlProgramme-controlled manipulatorGravitational forcePosition control

According to a torque detecting method, gravitational torque applied to a rotary shaft of an arm is detected in a condition where position control of the arm is stopped, when the arm is located at a first position at which the arm is oriented in a direction different from a direction of gravitational force. Then, a gravity coefficient used for calculating gravitational torque corresponding to a position of the arm is calculated, based on the gravitational torque and the first position. Then, gravitational torque during position control is calculated, based on the position of the arm detected during the position control, and the gravity coefficient. Further, an actual output torque during the position control is calculated, based on operating torque applied to the rotary shaft and detected during the position control, and the gravitational torque calculated during the position control.

Owner:TOYOTA JIDOSHA KK

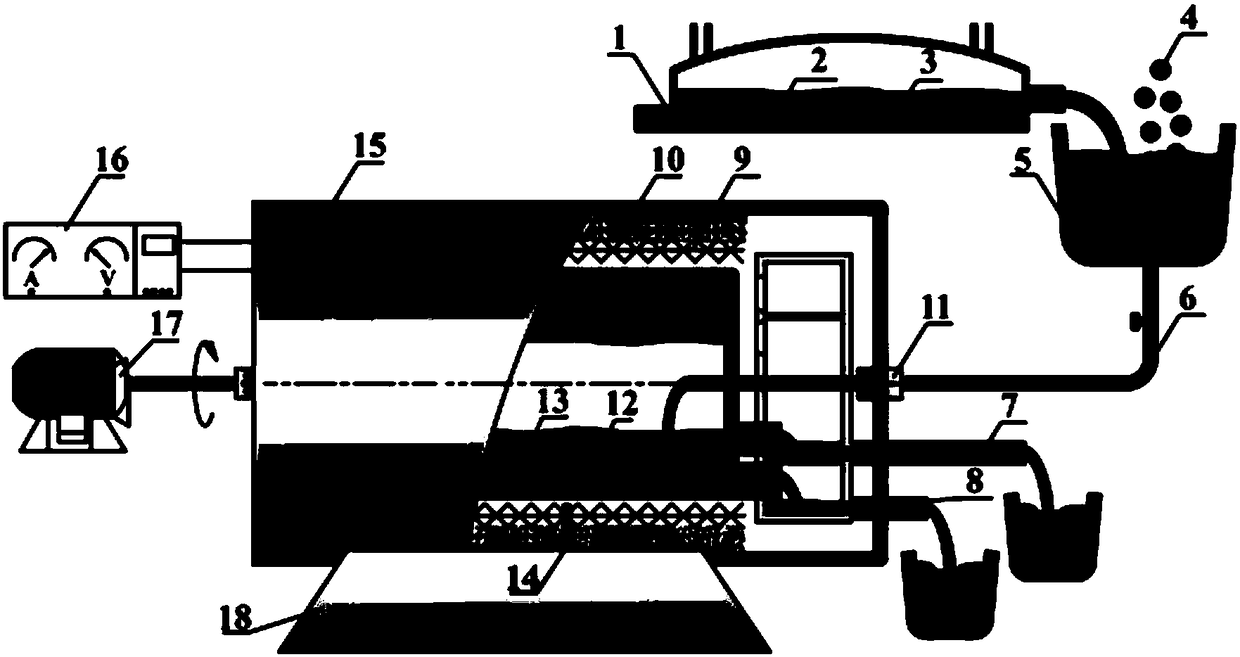

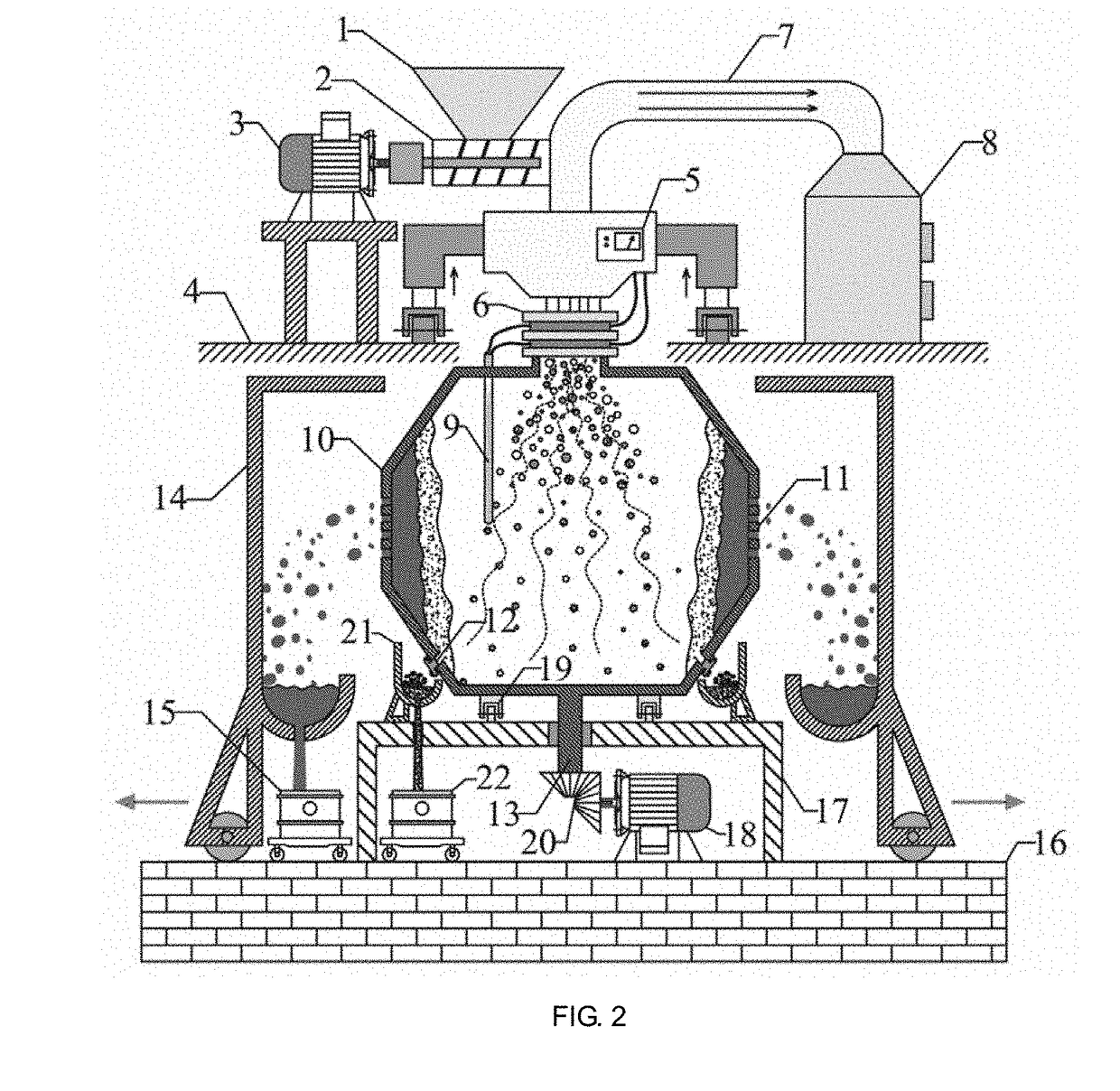

Method and device for achieving low-temperature quick separating of metallic copper in copper slag through supergravity

ActiveCN108165756AHigh purityHigh recovery rateProcess efficiency improvementMagnetiteSilicon dioxide

The invention discloses a method and device for achieving low-temperature quick separating of metallic copper in copper slag through the supergravity and belongs to the field of comprehensive utilization of resources. Firstly, 3-5% of carbon powder is added in the copper smelting slag discharging process to serve as a reducing agent to reduce magnetite particles in the slag into ferrous oxide, andthe ferrous oxide and silicon dioxide in the slag form a fayalite phase; then, copper slag melts are continuously added into a supergravity reactor through a flow guiding system, and the temperatureof the copper slag is controlled; and then, a centrifugal rotation system is started, the supergravity reactor is driven by a motor to conduct centrifugal rotation, the gravity coefficient and the separating time are controlled, and continuous separating between the metallic copper and the molten slag is achieved through the supergravity generated by centrifugal rotation. According to the method and device, under the condition of the supergravity, low-temperature quick separating between the metallic copper in the copper slag and the molten slag is achieved, the copper-slag separating efficiency is improved, the purity degree and recovery rate of the metallic copper are increased, the metallic copper with the Cu content being larger than 85% and an iron-slag-rich phase with the Cu contentbeing lower than 0.15% are obtained, and the recovery rate of Cu reaches 97% or above; and according to the method, operation is easy, the cost is low, and continuous production can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

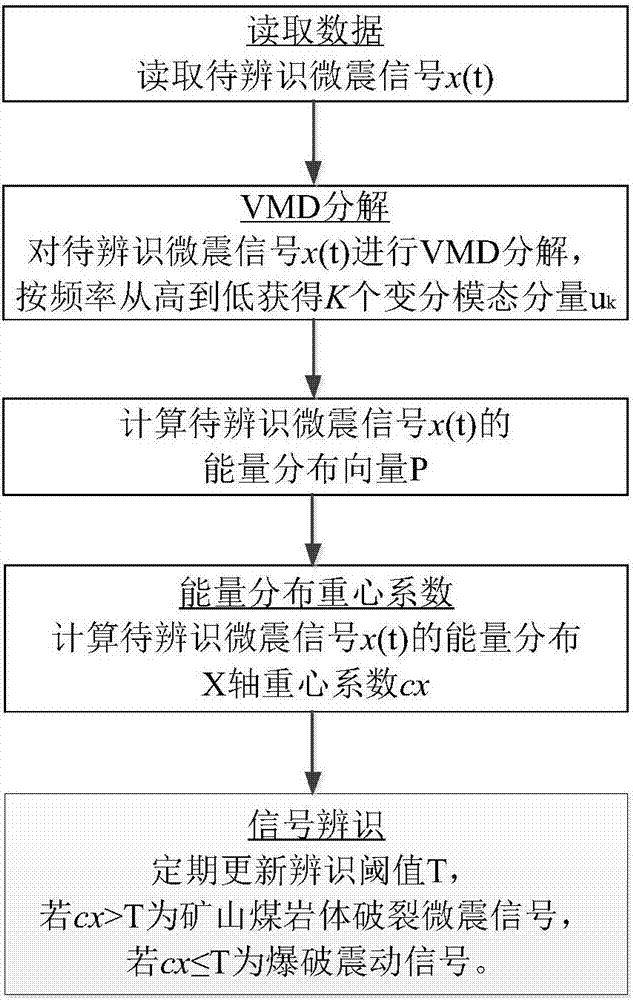

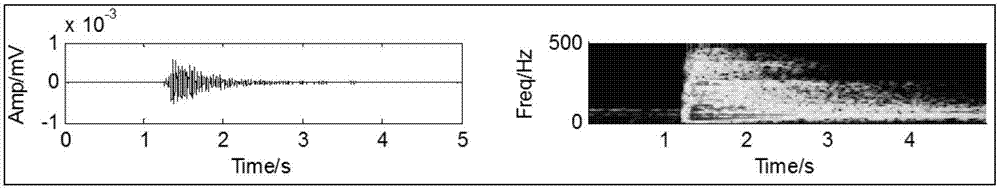

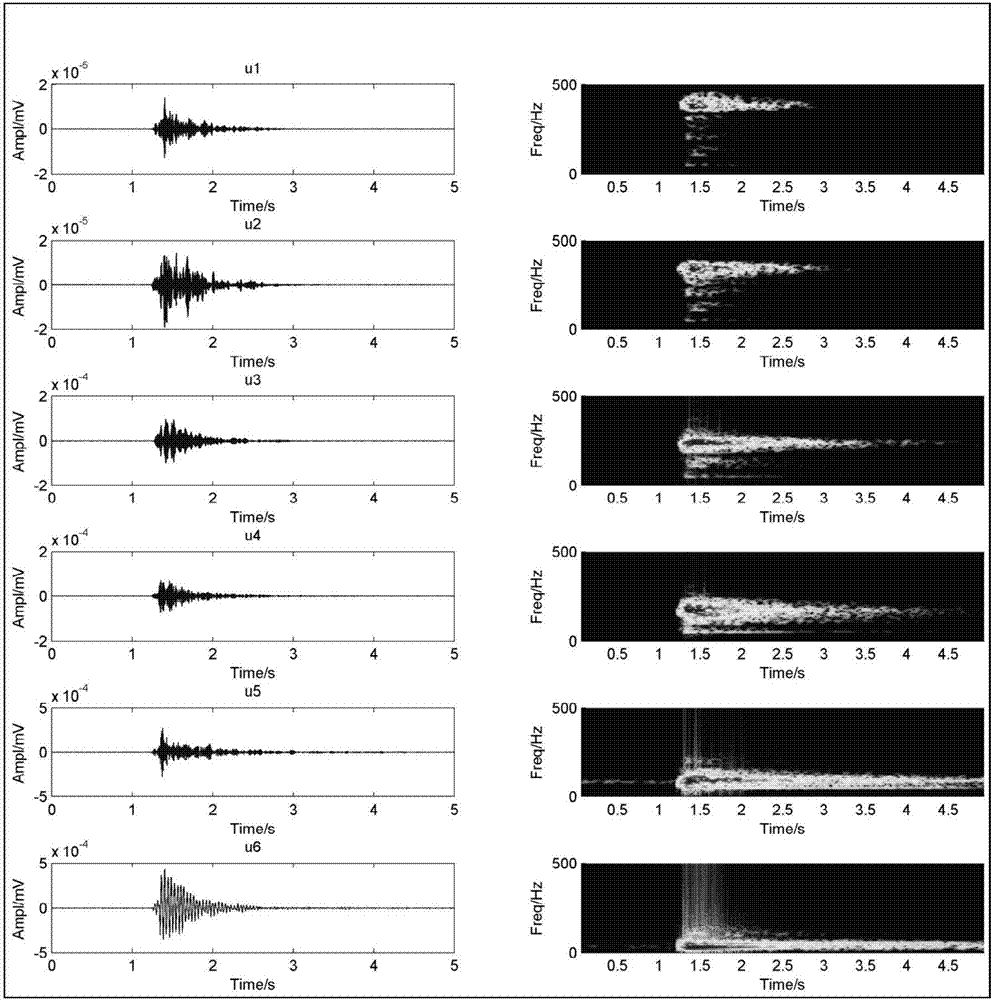

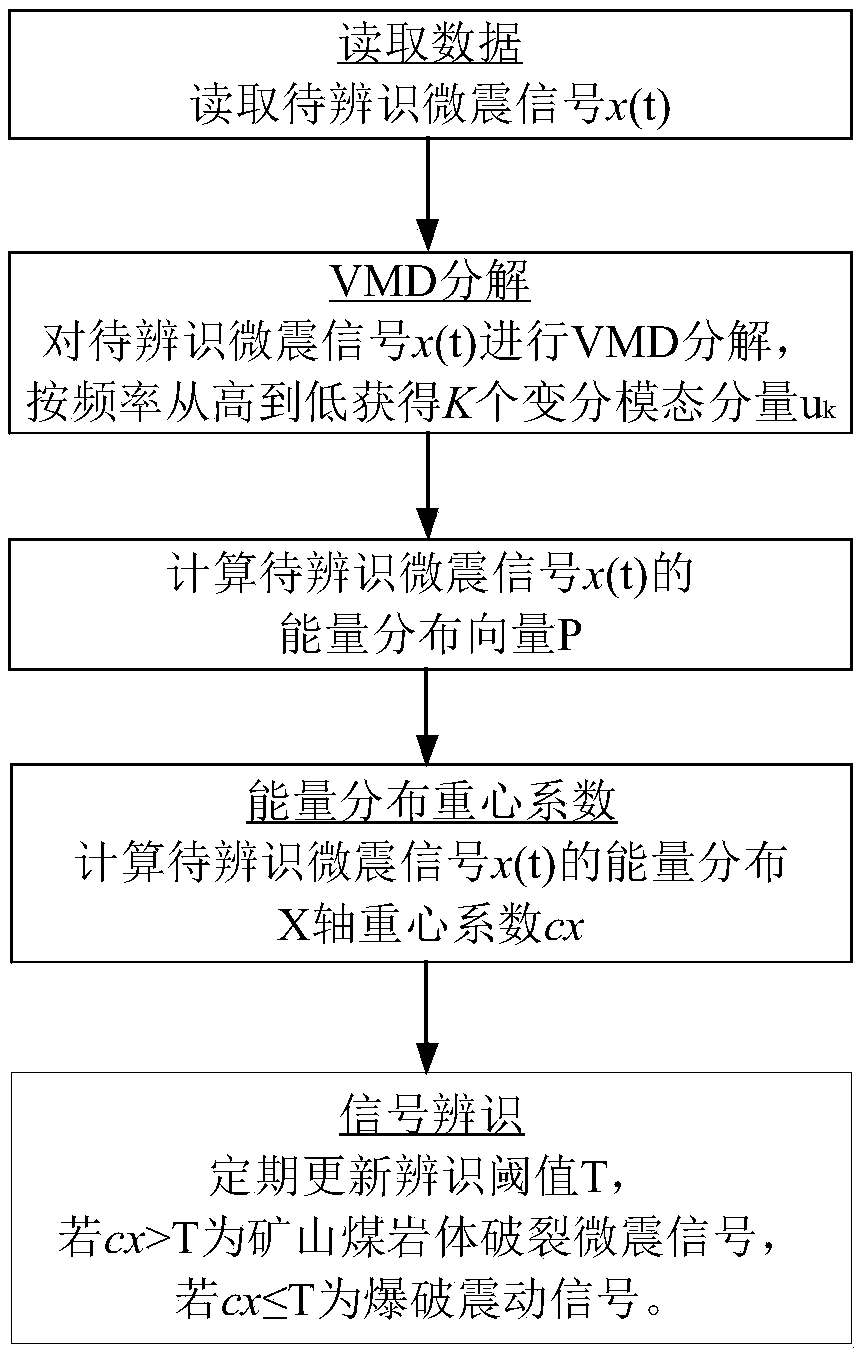

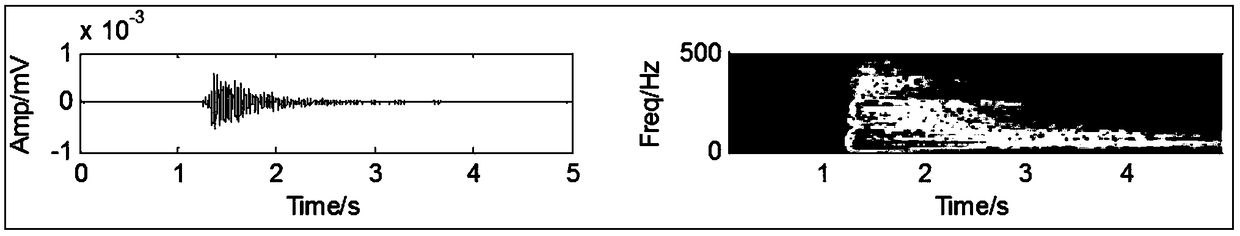

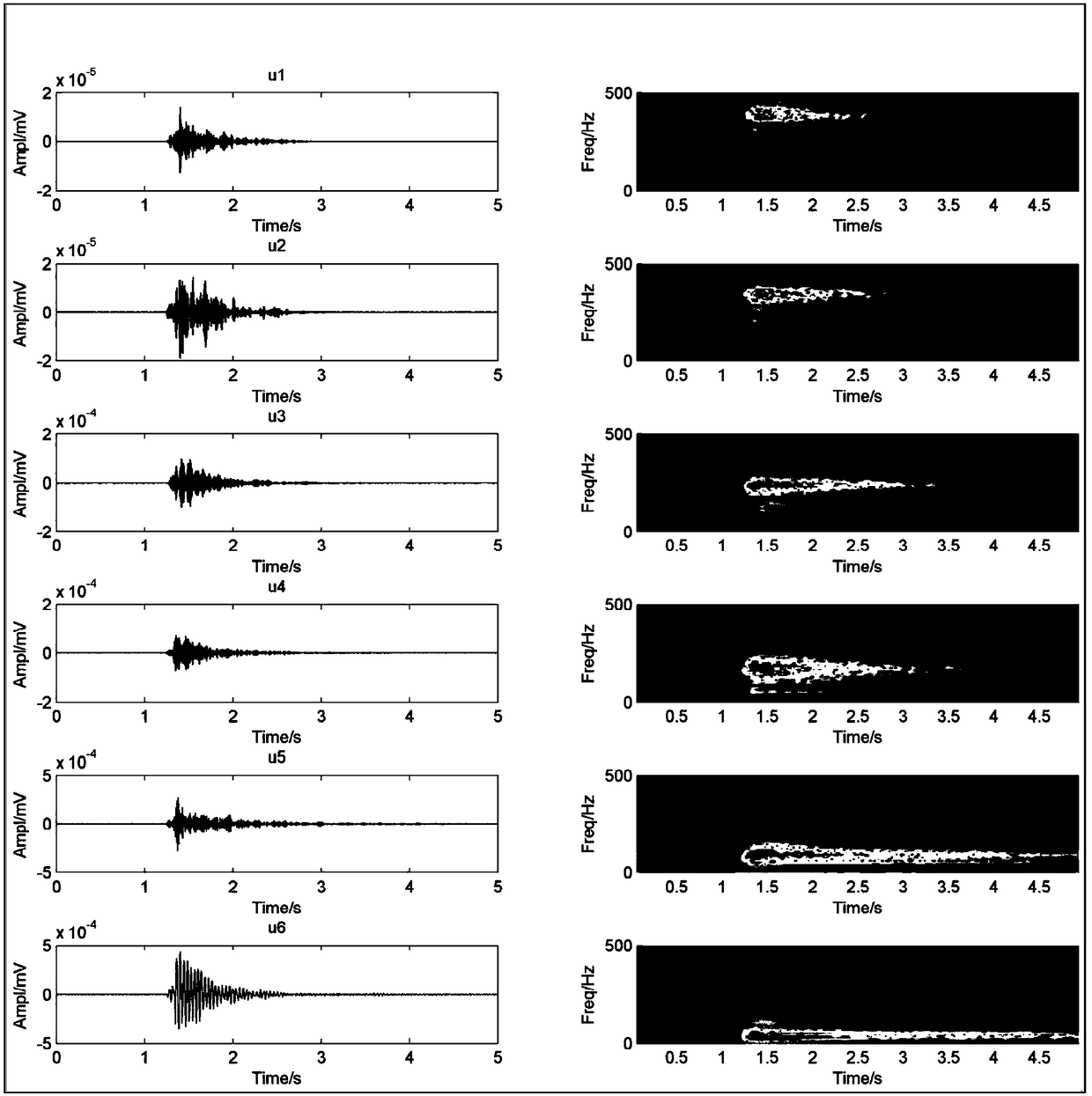

Mine micro-seismic signal identification method based on features of energy distribution

ActiveCN107505652AEfficient identificationAdaptableSeismic signal processingEnergy basedBlasting vibration

The invention discloses a mine micro-seismic signal identification method based on the features of energy distribution, which belongs to the field of signal analysis and identification. The method includes the following steps: reading a micro-seismic signal x(t) to be identified; carrying out VMD (Variational Mode Decomposition) on x(t) to get K variational modal components arranged in order according to the frequency from high to low; calculating the band energy of each modal component, and extracting the energy percentage of each modal component in the original signal to constitute an energy distribution vector P; calculating the energy distribution X-axis center-of-gravity coefficient cx on the basis of the energy distribution vector P; identifying the mine micro-seismic signal according to an identification threshold T: determining that the signal is a mine coal rock fracture micro-seismic signal if cx>T, and determining that the signal is a blasting vibration signal if cx<=T; and finally, adaptively updating the value of the identification threshold T. Through the method, a coal rock fracture micro-seismic signal and a blasting vibration signal can be distinguished. The method has the characteristics of strong adaptability, high accuracy, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

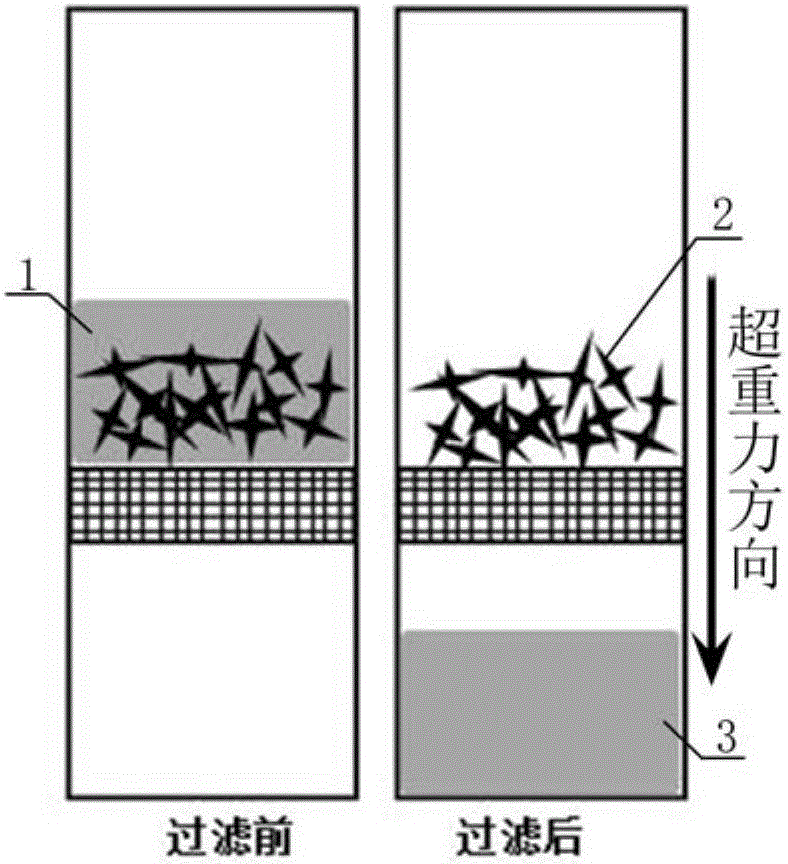

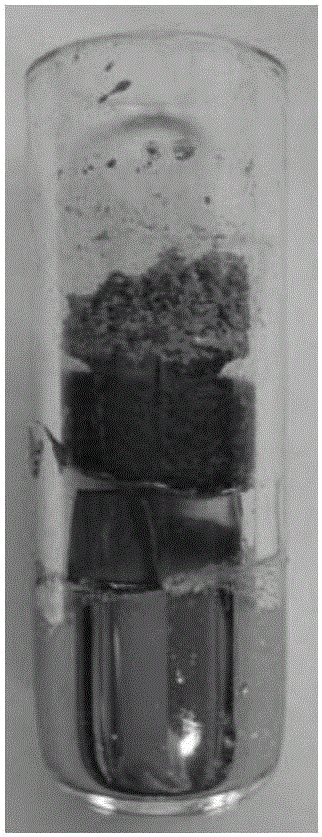

Method of removing impurity element copper in crude lead through supergravity

The invention relates to the technical field of refining of crude lead, and discloses a method of removing impurity element copper in crude lead through supergravity. The method comprises the following steps of: cooling melted crude lead melt mass at a cooling rate of less than 10 DEG C / min to obtain the pretreated crude lead; and carrying out supergravity separation treatment on the pretreated crude lead, wherein the treatment temperature is 330 DEG C-350 DEG C, the gravity coefficient is greater than 100, and the time of supergravity separation treatment is 10-20 minutes. The method has the beneficial effects that the relative movement of a solid copper phase and metallic lead liquid is greatly intensified by utilizing supergravity; the complete separation of an impurity copper phase and refined lead is completed within very short time, thereby realizing the purpose of purifying the crude lead by removing copper in the crude lead; meanwhile, the yield of metallic lead is also greatly increased, and the wasting and environmental pollution of the metallic lead are reduced; and the method is simple in technological process, low in cost, environmentally-friendly and suitable for popularization and application.

Owner:UNIV OF SCI & TECH BEIJING

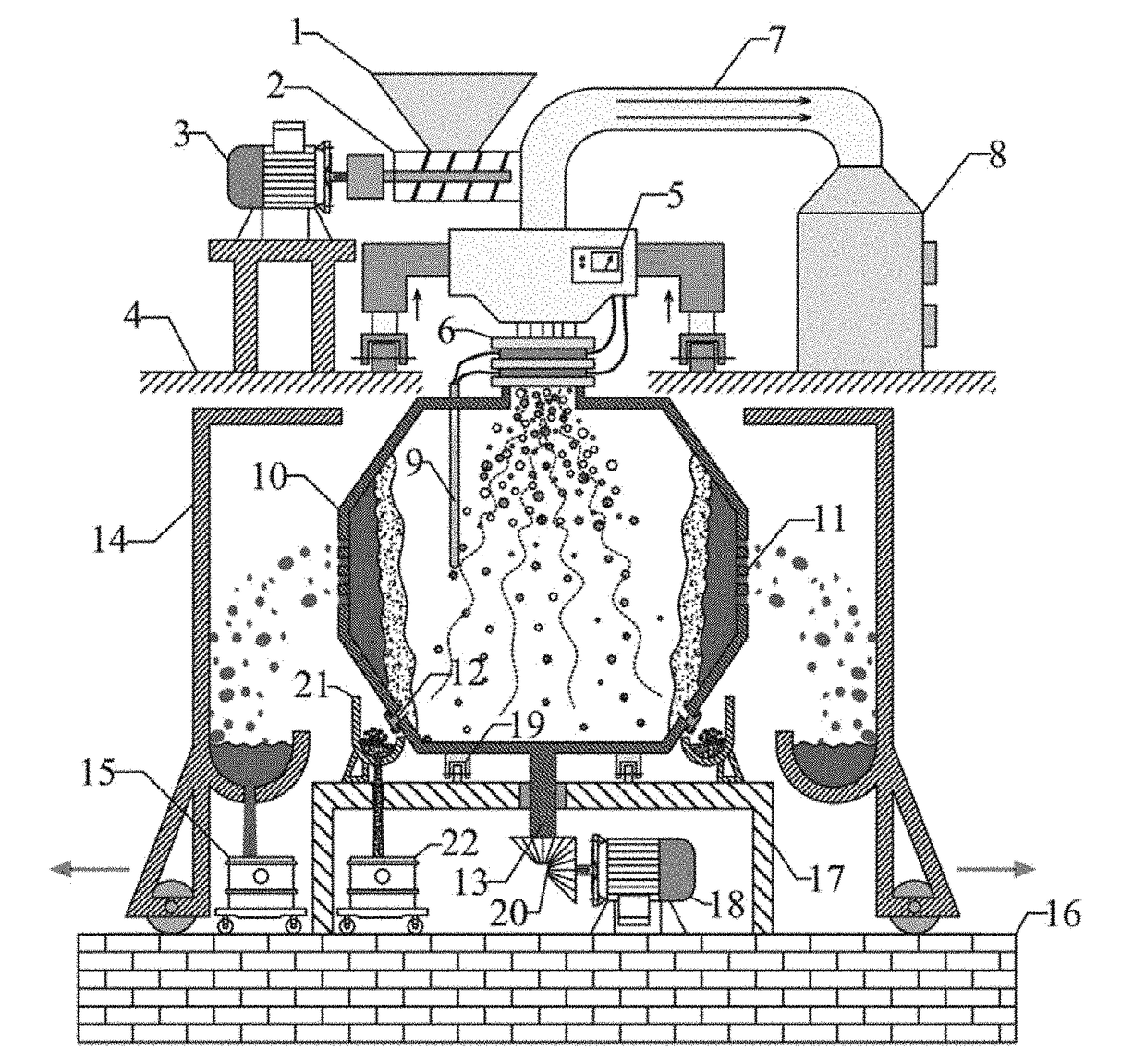

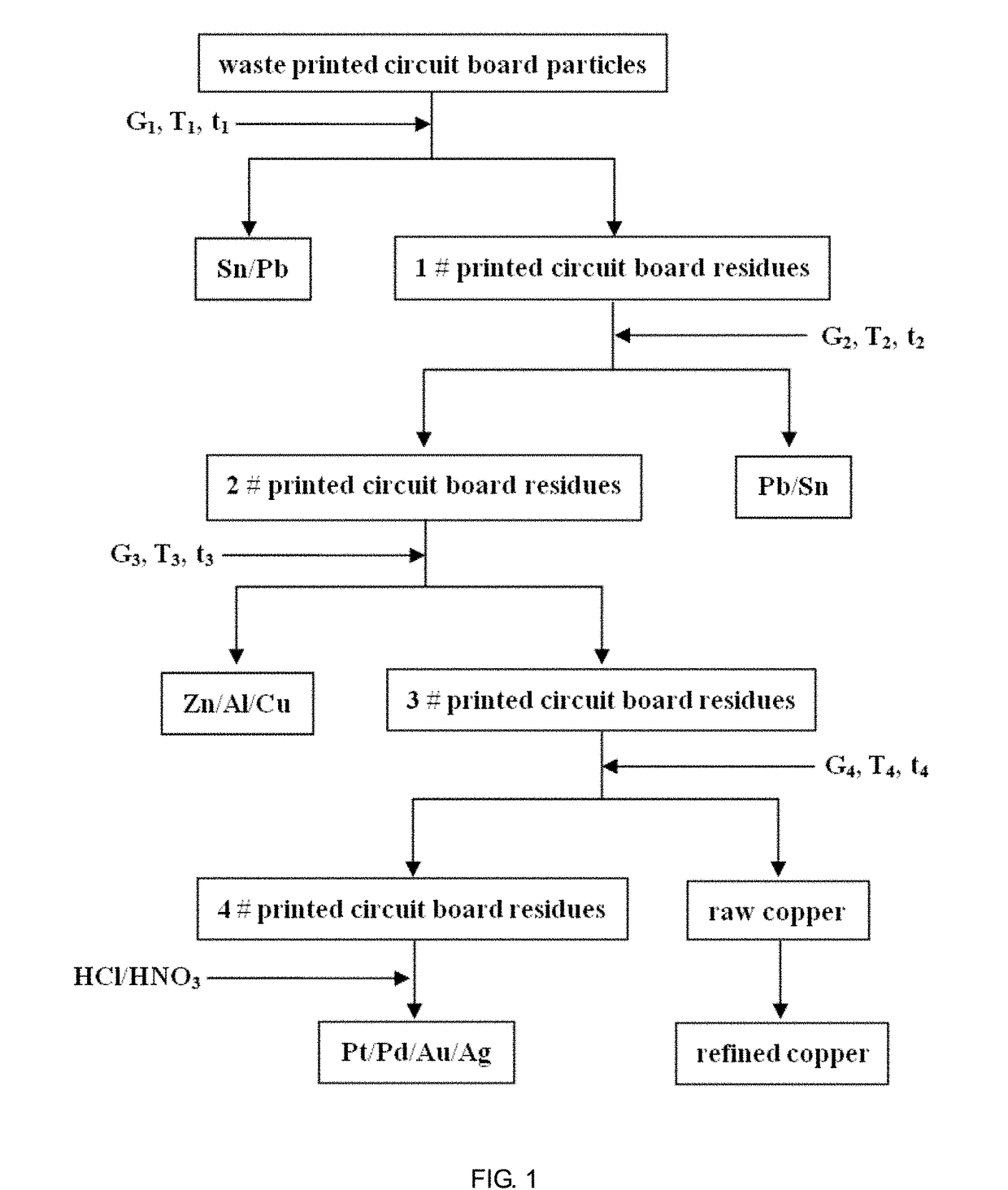

Method and apparatus for retrieving valuable metals step by step from waste printed circuit board particles

ActiveUS20180187285A1Quickly and efficiently separatedWaste of resourceSolid separationMembrane filtersAlloyElectronic waste

A method and apparatus for step-by-step retrieving valuable metals from waste printed circuit board particles. Many kinds of metals, most existing in form of elementary substance or alloy, are contained in the waste printed circuit boards. Molten metals are separated selectively by supergravity separation at different temperatures to achieve the step-by-step recovery. Tin-based alloys, lead-based alloy, zinc aluminum alloy, crude copper and precious-metal-enriched residues with different metal contents are separated out and collected on the condition of different temperatures (T=200˜300° C., 330˜430° C., 700˜900° C., 1100˜1300° C.) and controlling the gravity coefficient (G=50˜1000) and separation time (t=2˜20 min) etc. Different metals or alloys can be separated quickly and efficiently and the residue concentration of precious metals can be obtained. The process is simple and low cost to provide an efficient way to recovery the enrichment of valuable metals from electronic wastes.

Owner:UNIV OF SCI & TECH BEIJING

Torque detecting method and arm device

ActiveUS9533414B2Good compensationImprove accuracyProgramme controlProgramme-controlled manipulatorGravitational forceEngineering

According to a torque detecting method, gravitational torque applied to a rotary shaft of an arm is detected in a condition where position control of the arm is stopped, when the arm is located at a first position at which the arm is oriented in a direction different from a direction of gravitational force. Then, a gravity coefficient used for calculating gravitational torque corresponding to a position of the arm is calculated, based on the gravitational torque and the first position. Then, gravitational torque during position control is calculated, based on the position of the arm detected during the position control, and the gravity coefficient. Further, an actual output torque during the position control is calculated, based on operating torque applied to the rotary shaft and detected during the position control, and the gravitational torque calculated during the position control.

Owner:TOYOTA JIDOSHA KK

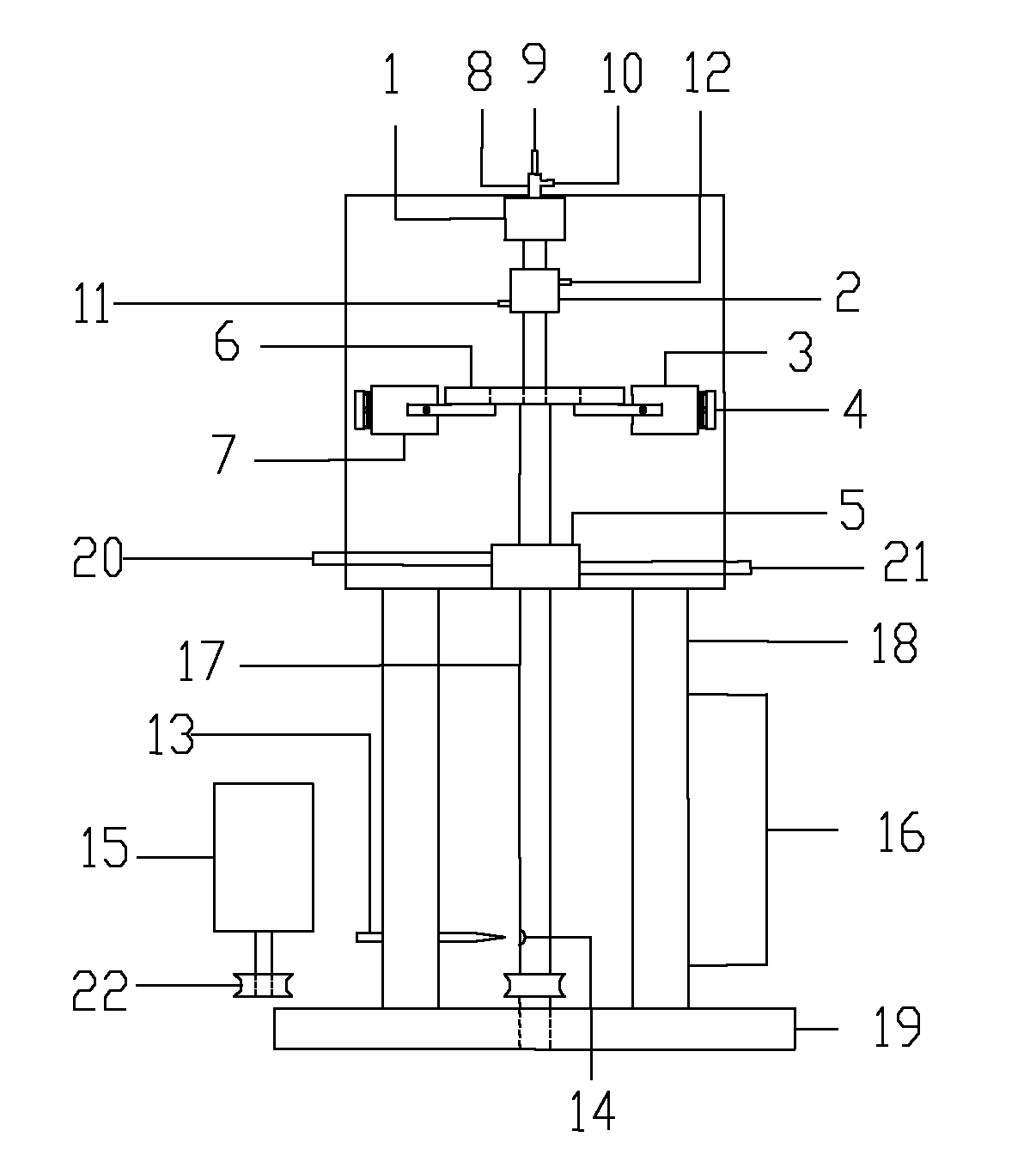

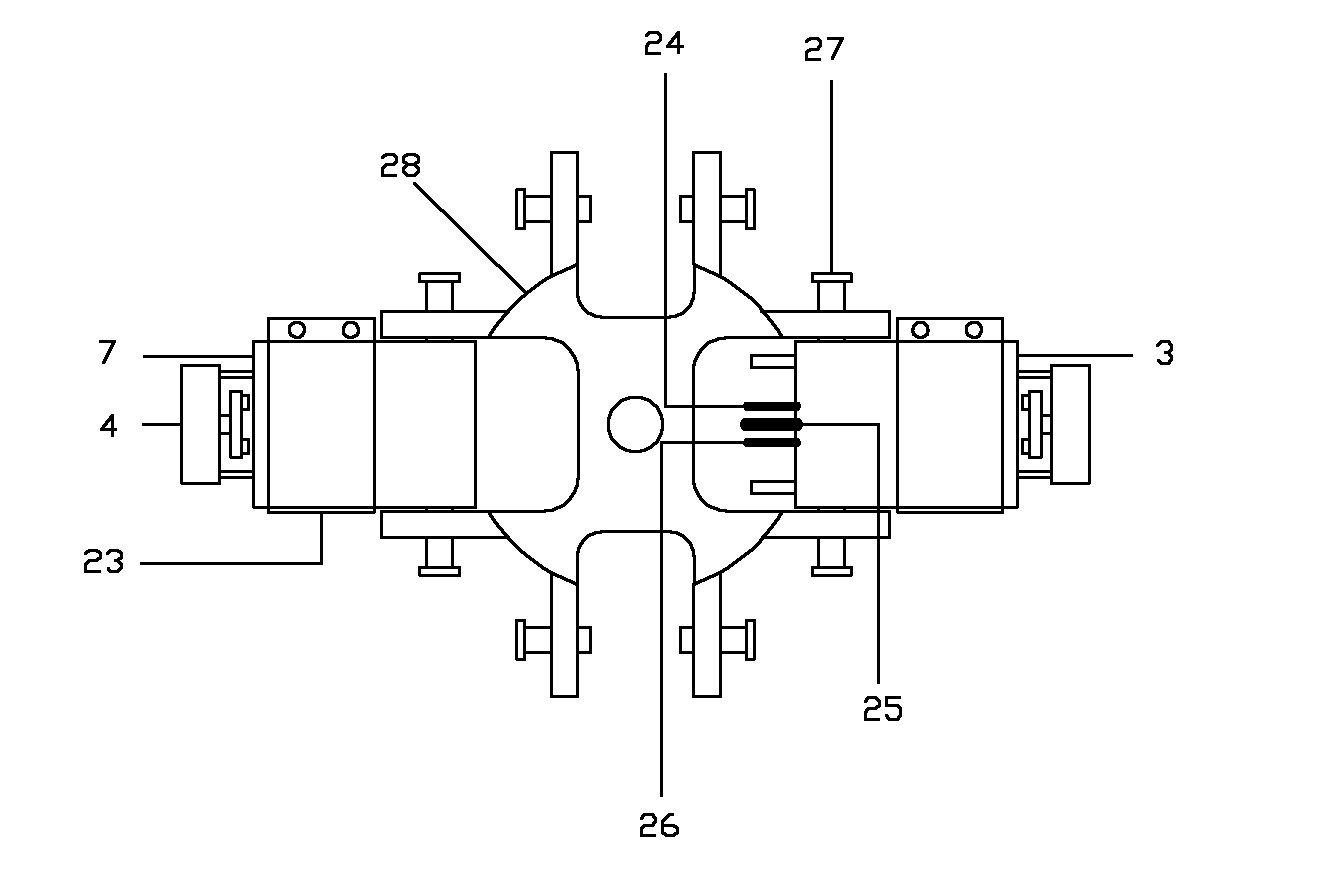

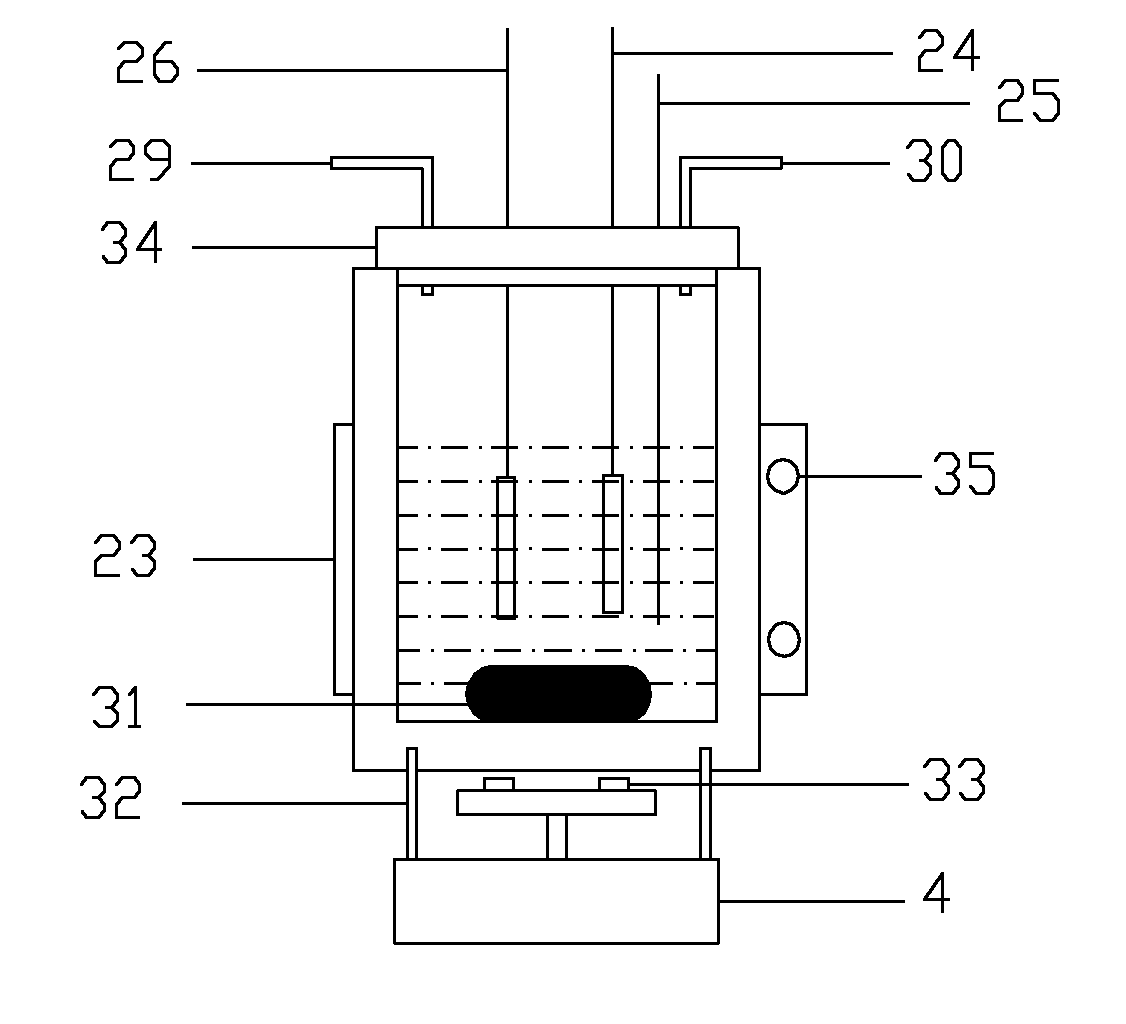

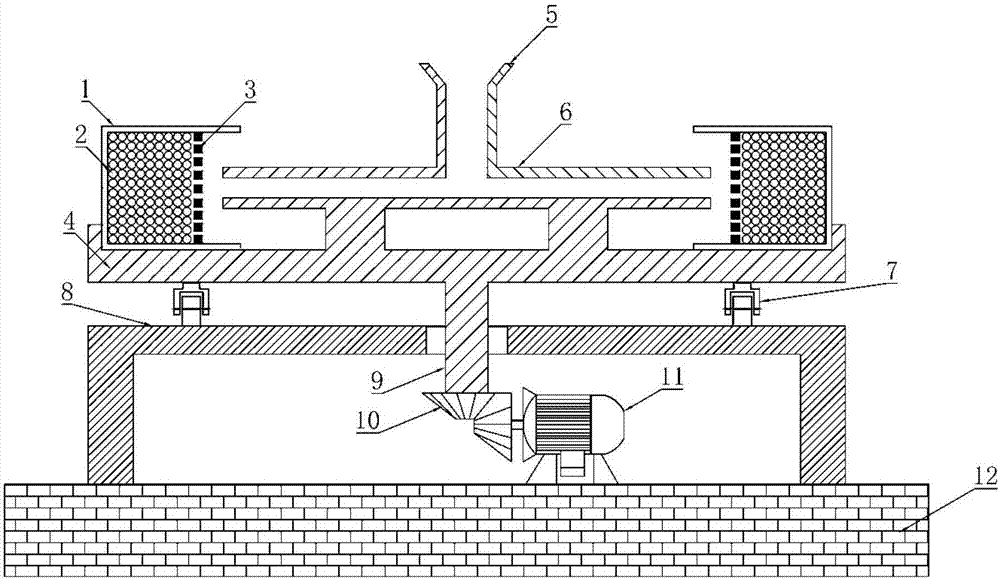

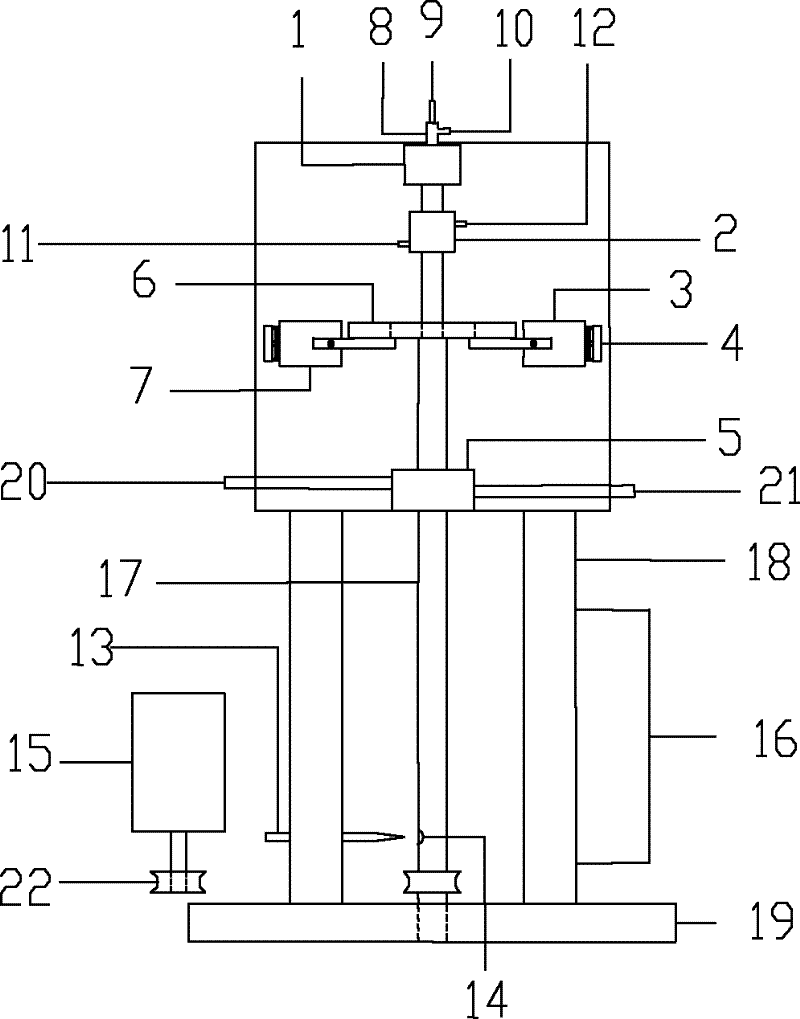

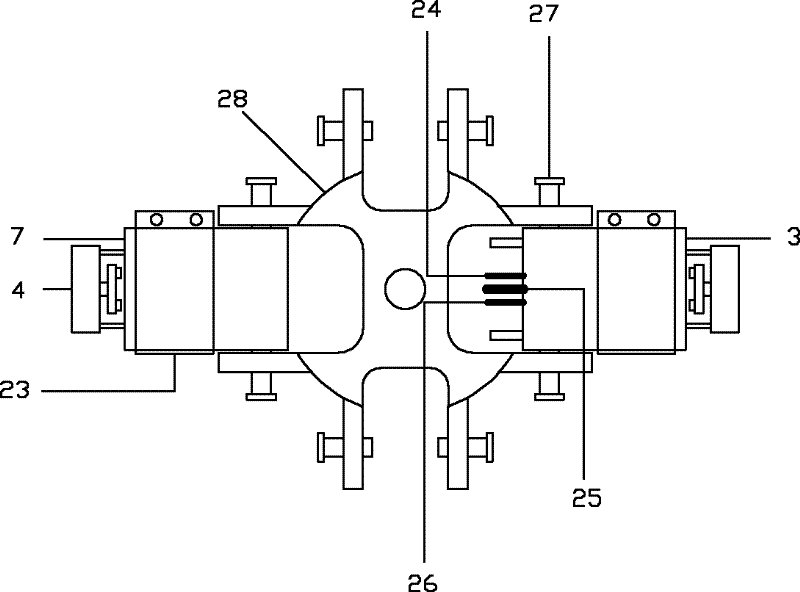

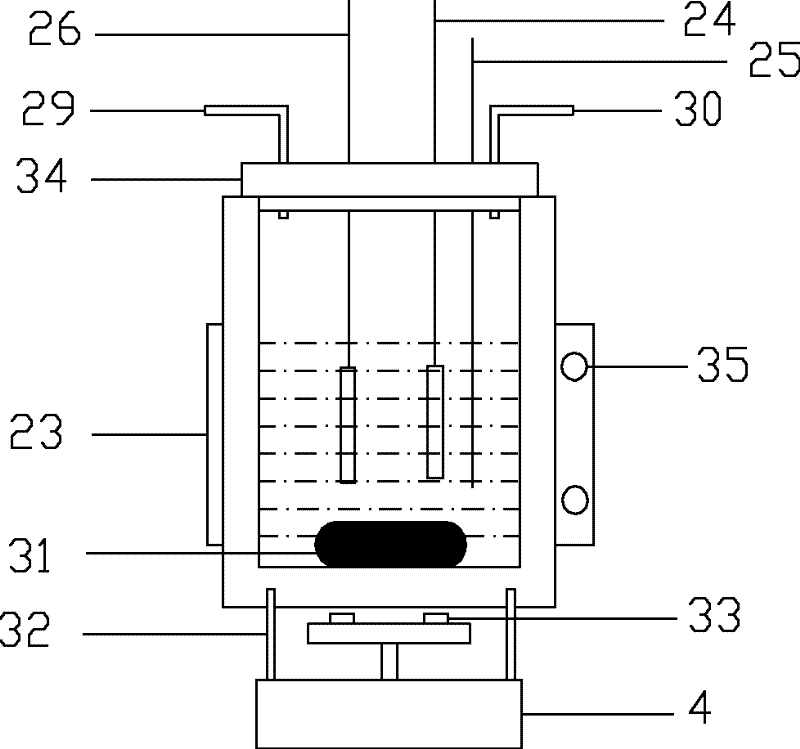

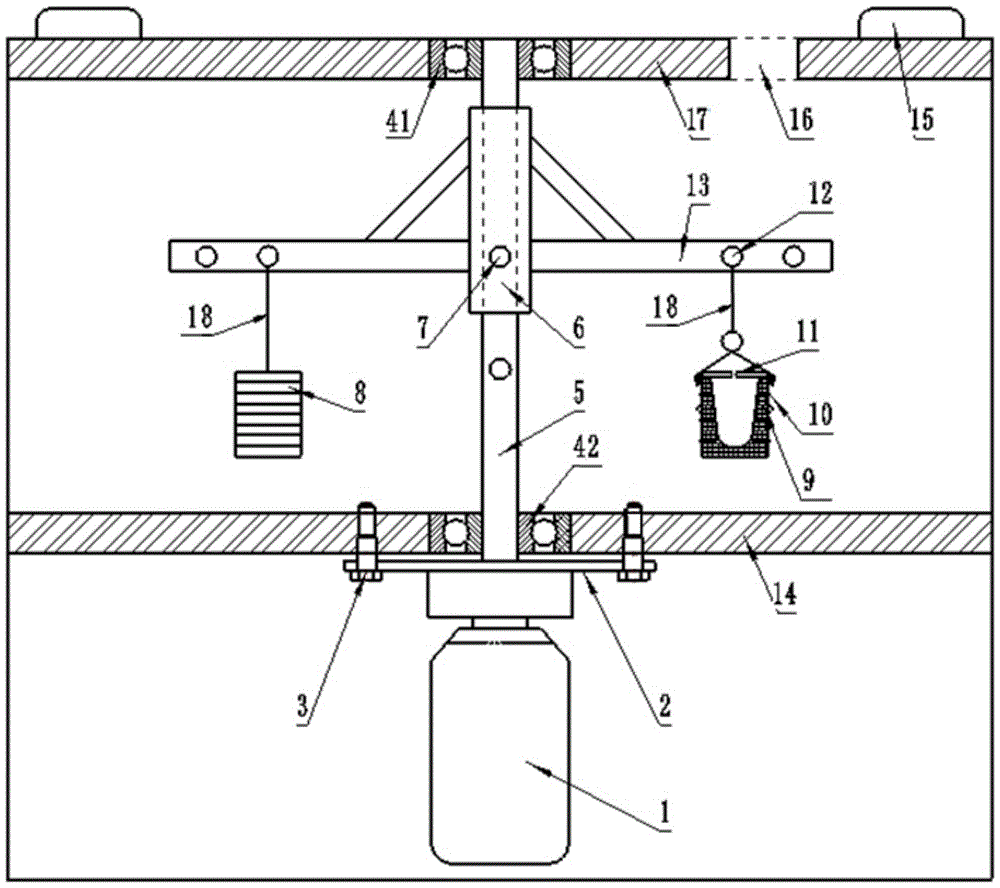

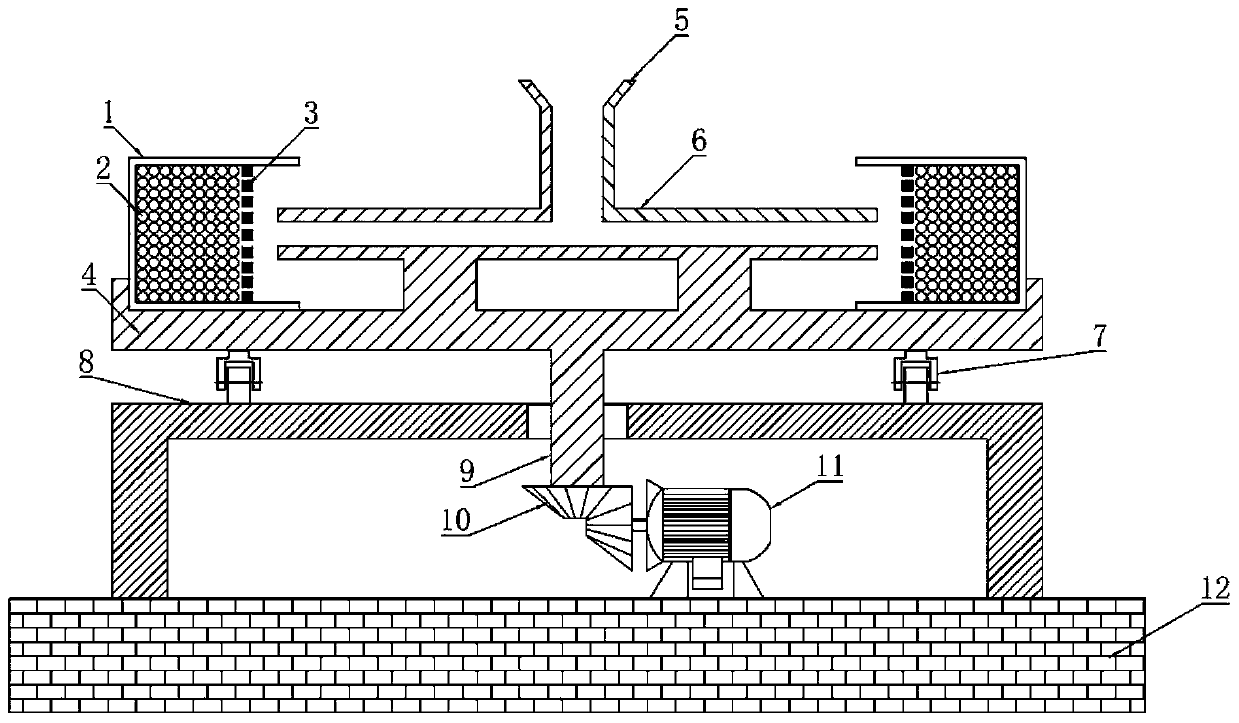

Super-gravity device used for electrochemical deposition in ionic liquid

InactiveCN102181888AGuaranteed normal operationResistance sensitivityElectrolysis componentsElectrolysisDynamic balance

The invention discloses a super-gravity device used for electrochemical deposition in ironic liquid, and belongs to the field of the electrochemical deposition under a special condition. The super-gravity device comprises an electrolytic tank, a balance weight system, a shaft cooling system, a shielding gas transmission system, a speed measurement system, a rotating speed and temperature control display system and a conducting slip ring system. In the reaction process, a motor drives a shaft to rotate to supply required centrifugal force; the centrifugal force is measured by a super-gravity coefficient; the super-gravity coefficient is calculated by the speed measurement system; the temperature in the electrolytic tank is controlled by the temperature control system; the dynamic balance of the electrolytic tank in a centrifugal field is realized through the balance weight system; an inert gas atmosphere required by the reaction is realized through the shielding gas transmission system; the shaft cooling of the super-gravity device is realized through the shaft cooling system; and the current required in the electro-deposition process is supplied by the conducting slip ring system.

Owner:BEIJING UNIV OF CHEM TECH

Method for manufacturing bearing ring by adopting centrifugal casting technique

InactiveCN101530899AImprove efficiencySmall machining allowanceFoundry mouldsFoundry coresTemperature controlGravity coefficient

The invention relates to a method for manufacturing a bearing ring by adopting a centrifugal casting technique, wherein the preheating temperature of charging materials is between 150 and 300 DEG C; the gravity coefficient for the start-up of a centrifugal machine is controlled to be between 50 and 60; and the centrifugal pouring adopts a bottom pouring type and a movable type, the pouring temperature is controlled to be between 1,640 and 1,680 DEG C, and the pouring time is between 5 and 10 minutes. Compared with the prior art, the method has the advantages of reducing the admittance, saving raw materials, reducing the cost effectively, and improving the benefits of enterprises.

Owner:HAICHENG ZHONGXING HEAVY MACHINERY

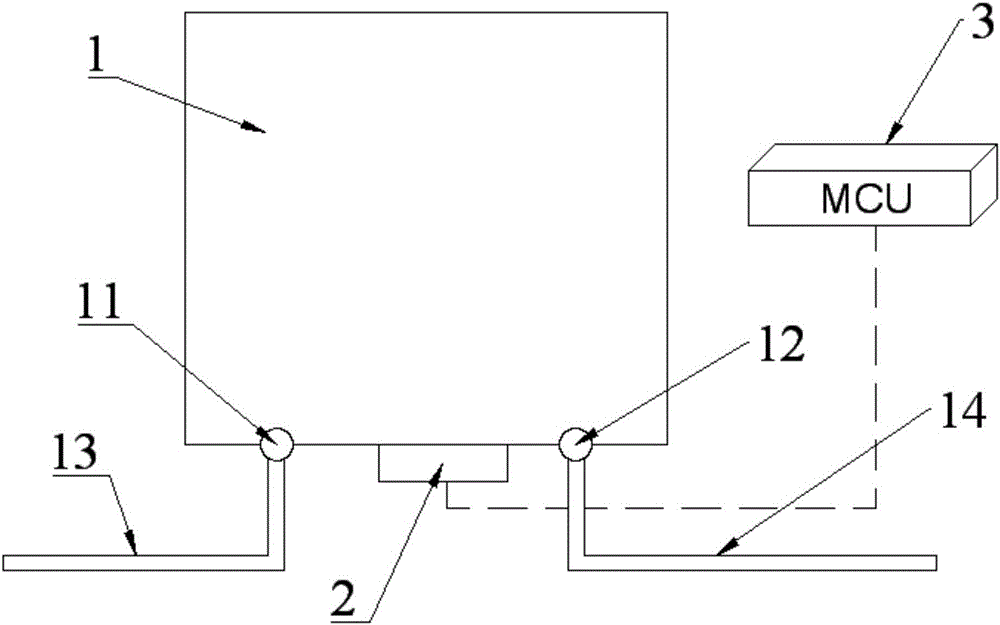

Water tank with gravity sensing function and direct drinking machine with water tank

InactiveCN106284525AGood technical effectAvoid secondary pollutionService pipe systemsWater mainsControl systemSlope angle

The invention relates to a direct drinking machine, and discloses a water tank with the gravity sensing function and the direct drinking machine with the water tank. The water tank comprises a water tank body (1), and a water inlet (11) and a water outlet (12) are formed in the water tank body (1); the water tank also comprises a control system, a gravity sensor (2) connected with the control system is arranged at the bottom of the water tank body (1) and used for collecting a water level gravity signal in the water tank and transmitting the water level gravity signal to the control system, the control system is used for processing the received signal to obtain water level information, and the water level information comprises a gravity value, the water level height and the slope angle of the water level relative to the horizontal plane of water in the water tank body (1). According to the water tank with the gravity sensing function and the direct drinking machine with the water tank, a gravity sensing system is combined to the direct-drinking-machine water tank, and the secondary pollution problem of water can be effectively solved; as the obtained gravity coefficients are different, the water tank can be freely subjected to multipoint testing, filtered water of the direct drinking machine can be more reasonably and effectively controlled through the gravity sensing system, energy is saved, and the efficiency is achieved.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

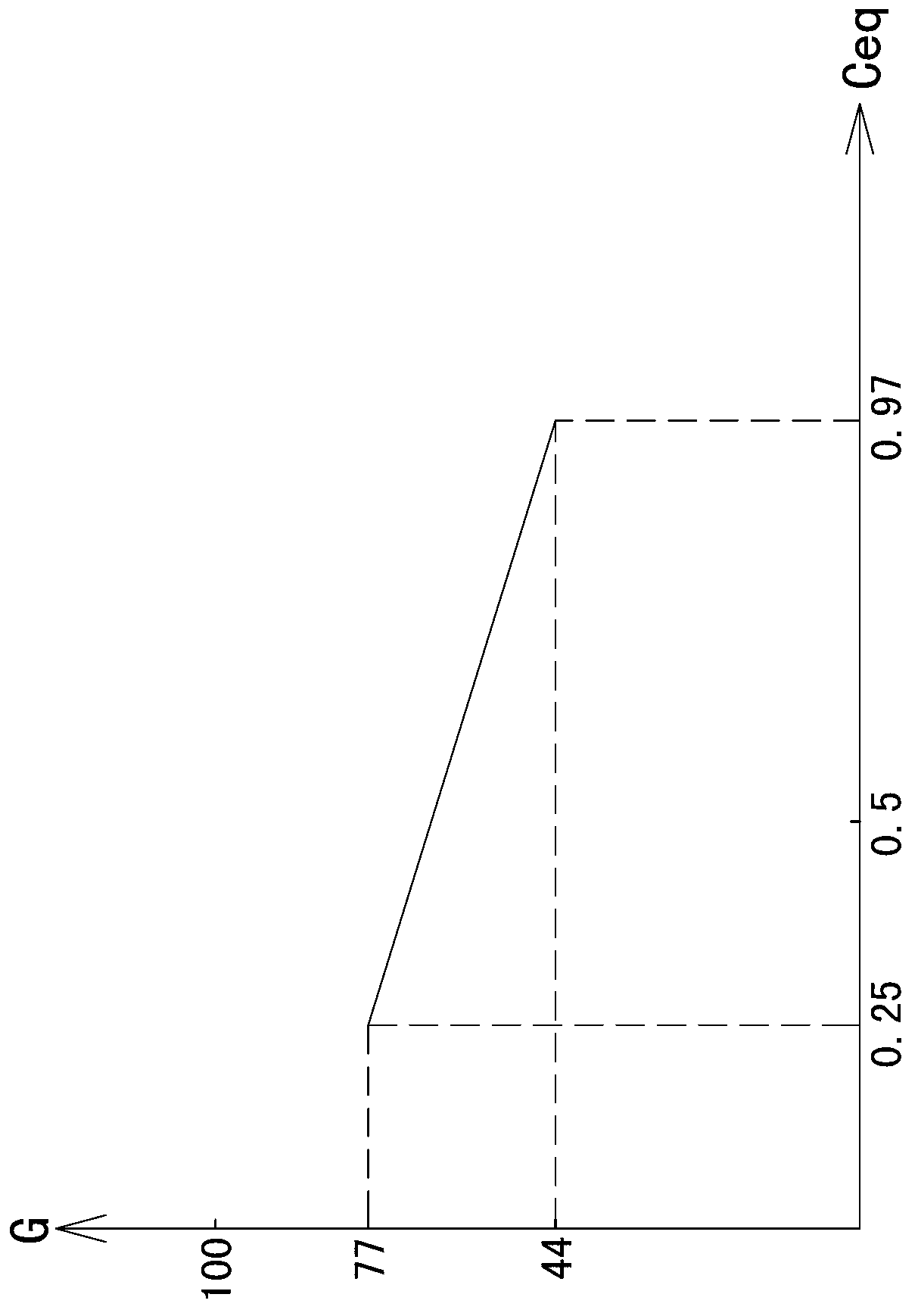

High-quality centrifugal casting method for steel pipe blank

The invention discloses a high-quality centrifugal casting method for a steel pipe blank, belonging to a centrifugal casting process. The high-quality centrifugal casting method comprises the following steps of: calculating centrifugal rotation speed of a cavity according to a formula of N=20*(G / r)1 / 2, wherein N is the centrifugal rotation speed of the cavity, r is internal radius of the steel pipe blank, and G is gravity coefficient of the steel pipe blank and is taken to be 44-77; after rotating the cavity at the calculated centrifugal rotation speed, pouring molten steel into the cavity from a ladle; guaranteeing that the molten steel is sealed and is not oxidized by gas during pouring, wherein the pouring temperature is 20-30 DEG C greater than liquidus temperature of the molten steel, and the pouring time is 3-10 minutes; and demolding after pouring, cooling the centrifugal steel pipe blank to room temperature, measuring contents of sulfur and oxygen included in the steel pipe blank, and removing impurities of an inner surface layer through an inner boring machining method. According to the high-quality centrifugal casting method, quantification of the rotation speed of the cavity can be realized, the machining is convenient, the control is easy and the influence of segregation of elements is extremely low.

Owner:WUHU XINXING DUCTILE IRON PIPES

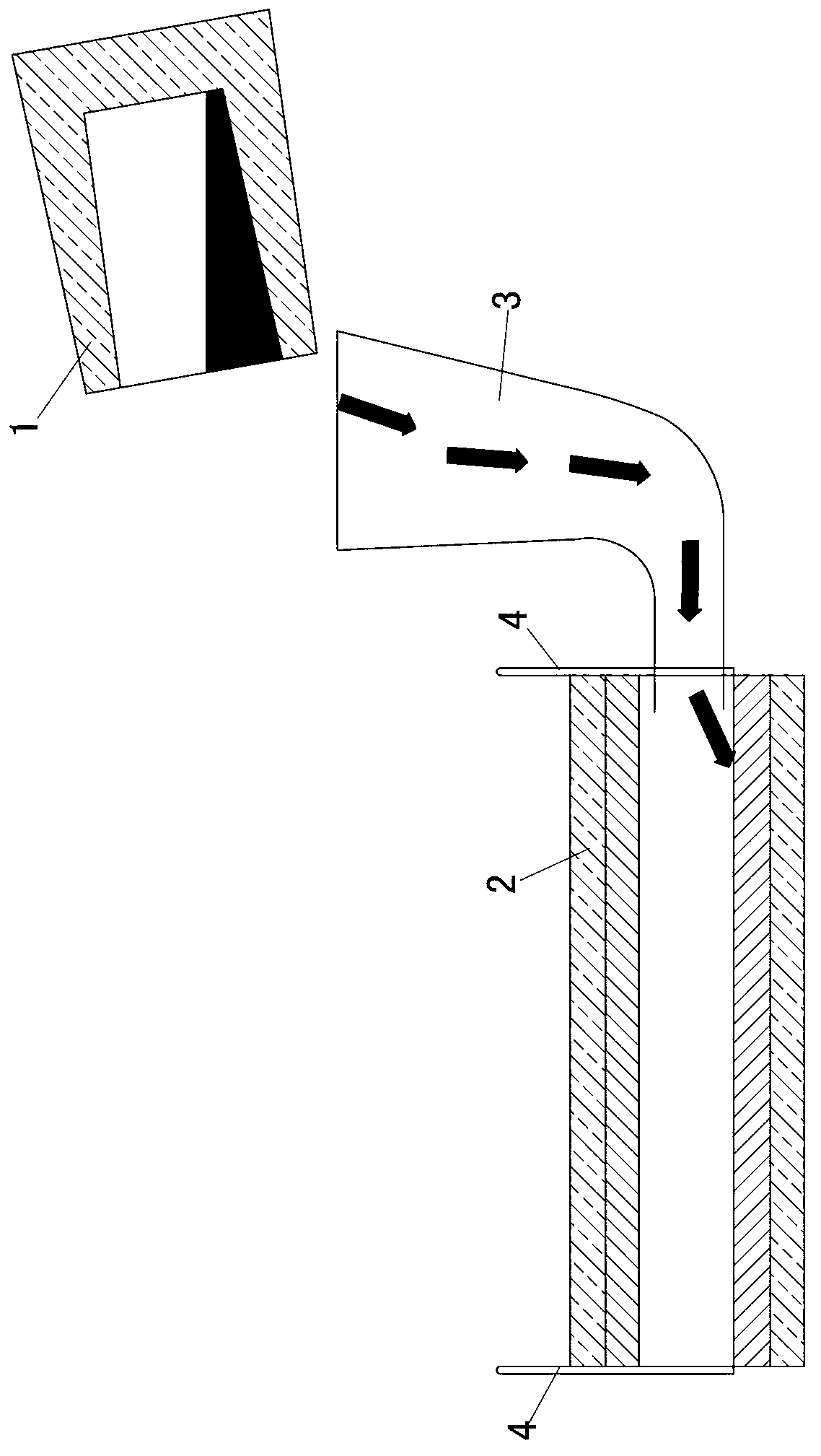

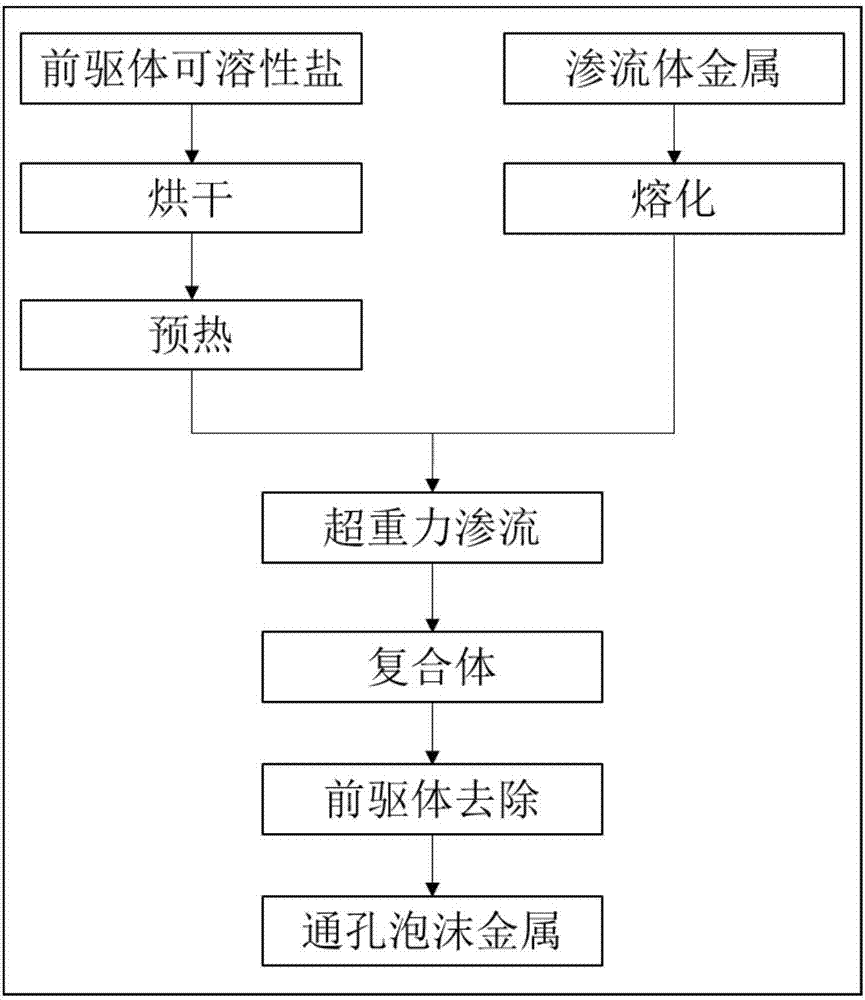

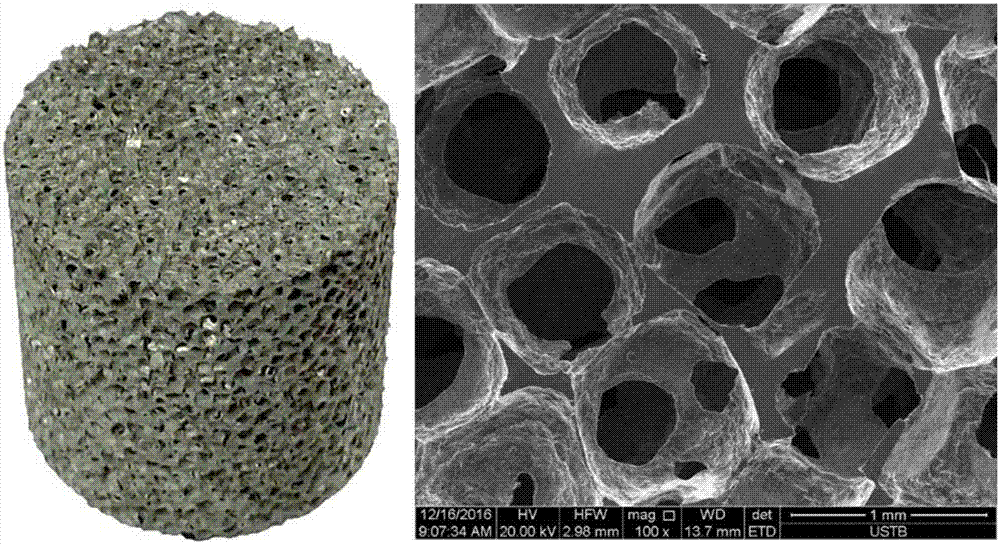

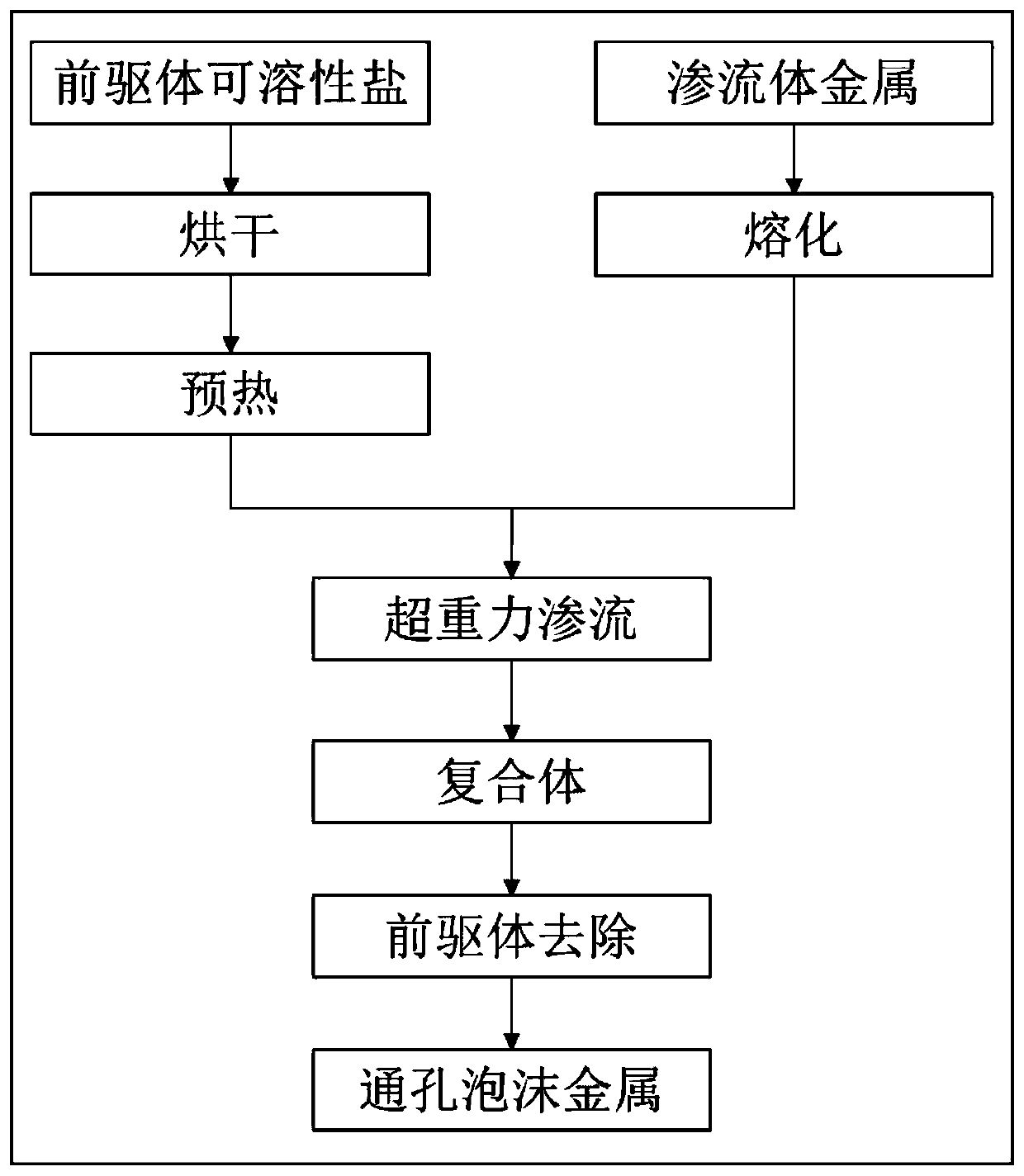

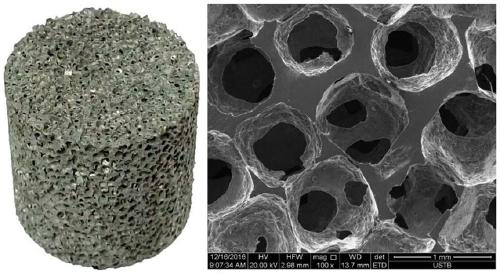

Method and device for preparing porous foam metal through super-gravity seepage

The invention provides a method and a device for preparing porous foam metal through super-gravity seepage and belongs to the field of foam metal material preparation. In the invention, soluble salt particles of which the average particle size is 0.1-5mm are used as a precursor, and metal is used as a seepage body. A centrifugal casting mold is filled with the soluble salt particles which are dried and sieved, and a porous plate is fixed at the top of the precursor. The centrifugal casting mold which is preheated is assembled on a centrifugal platform, centrifugal equipment is started, and molten metal which is pre-molten is poured into a feeding hopper of the centrifugal equipment. The molten metal being driven by super-gravity seeps into gaps of the precursor via the porous plate, and the super-gravity coefficient of the process is controlled above 20-180 from the big to the small according to the average particle size of the soluble salt particles, namely the precursor. After the metal is solidified, the centrifugal casting mold is disassembled, a compound body is taken out, and cutting processing is carried out. The soluble salt particles are dissolved by using water and removed from the compound body, and the porous foam metal is obtained. The method is simple in technology and low in cost, and the prepared foam aluminum alloy is even in structure, proper in size and excellent in mechanical properties.

Owner:UNIV OF SCI & TECH BEIJING

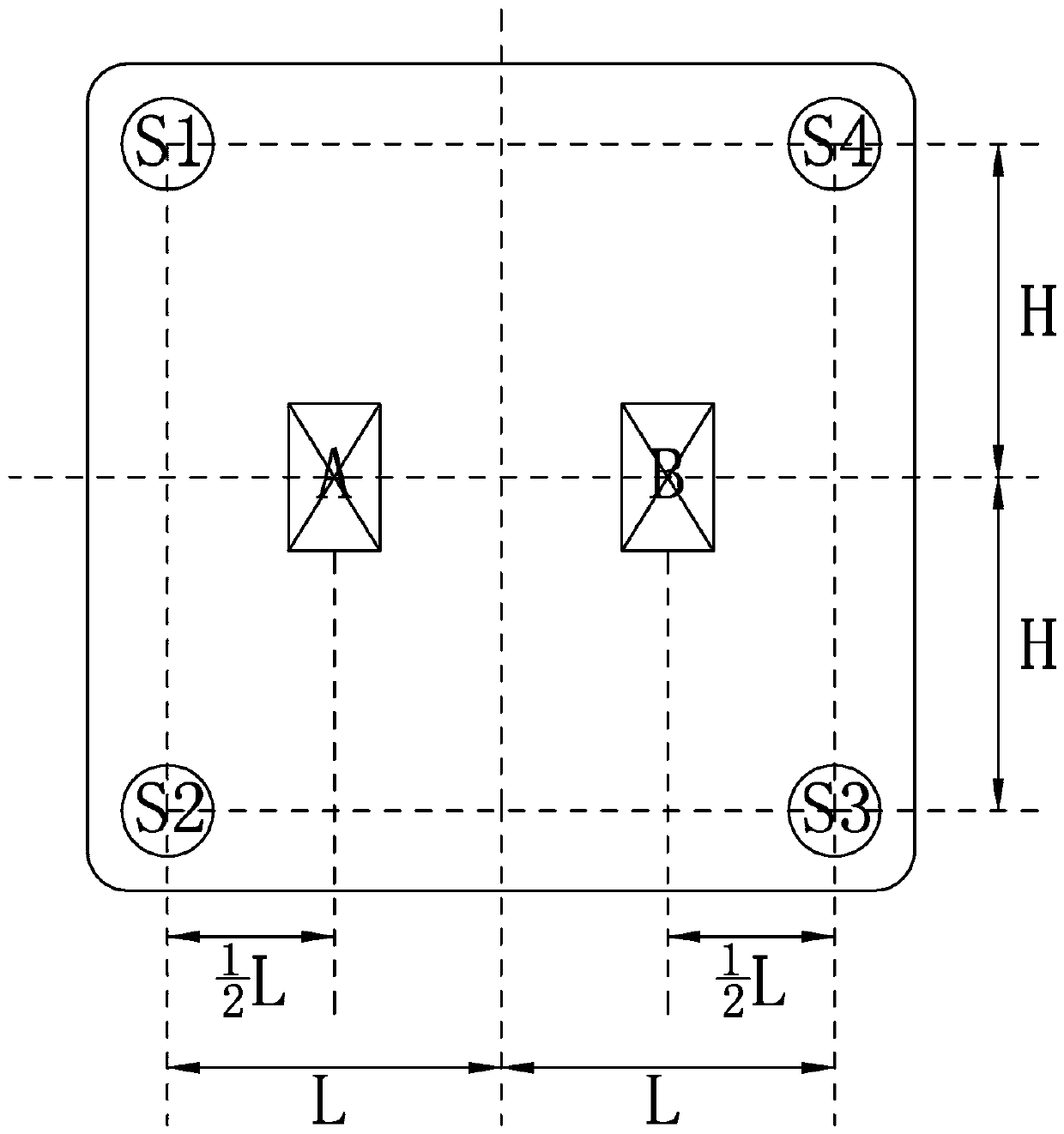

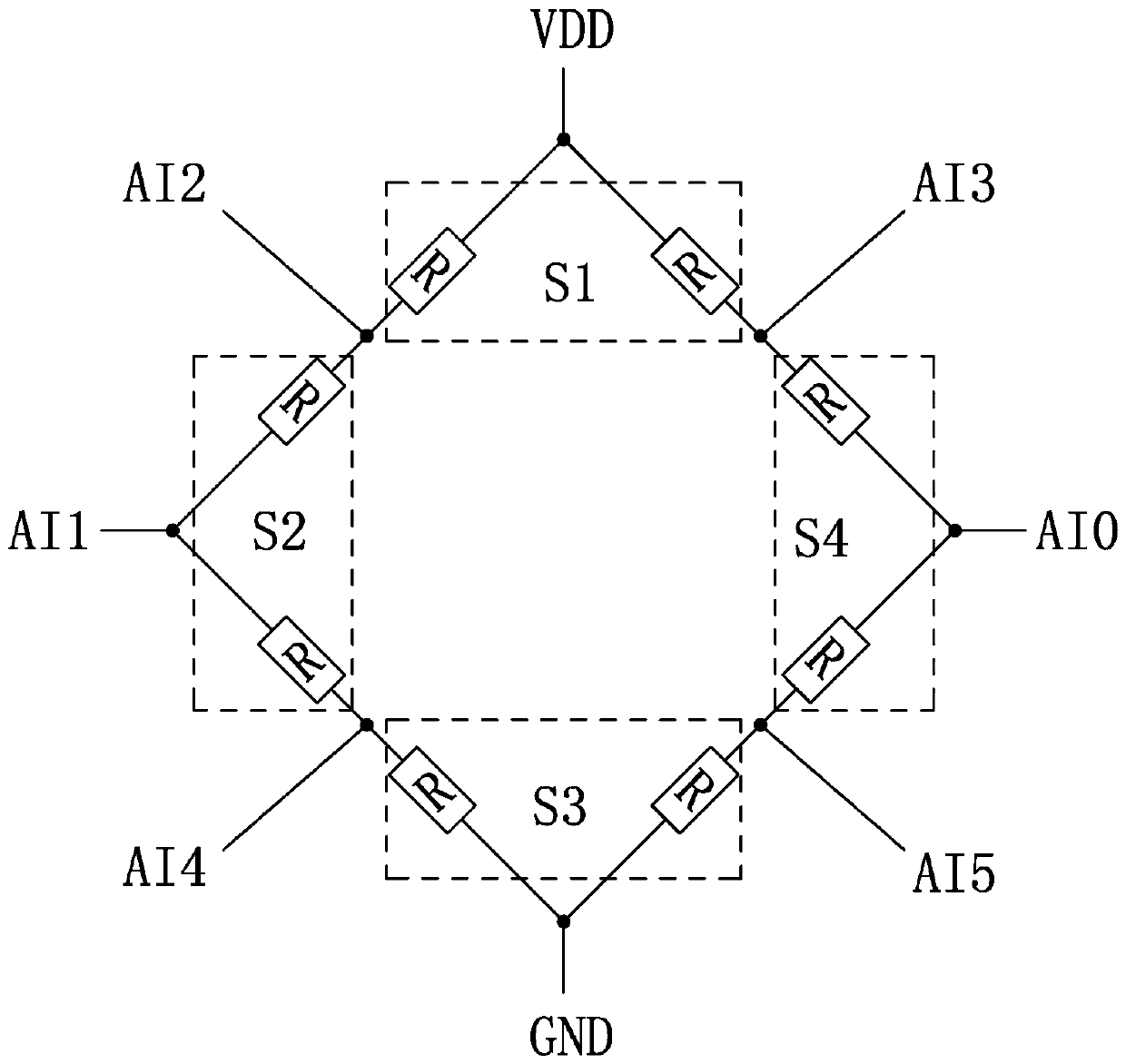

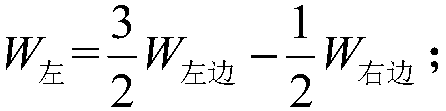

Center-of-gravity measurement human body electronic scale and measurement method

InactiveCN107894273ASimple structureReduce manufacturing costWeighing auxillary devicesSpecial purpose weighing apparatusMeasurement pointEngineering

The invention discloses a center-of-gravity measurement human body electronic scale and a measurement method. The electronic scale includes a scale surface. The scale surface is provided with a standing position A and a standing position B. A sensor S1, a sensor S2, a sensor S3 and a sensor S4 are respectively arranged at the upper left corner, the lower left corner, the lower right corner and theupper right corner of the bottom of the scale surface sequentially. The four sensors are connected in series to form a bridge with a power supply contact point and six signal measurement points. No additional center-of-gravity measurement sensor is required, the circuit structure is simple and the production cost is low. The bridge constituted by the four sensors can be measured, and output relationships among the four sensors can also be respectively measured to obtain the respective outputs of the four sensors. By setting an algorithm, the weight of a human body can be calculated, a human body center-of-gravity coefficient and a human body center-of-gravity position can further calculated. The invention is very helpful for people to pay attention to health and prevent diseases, and hasa very important significance especially for the prevention of spinal cord bending and correction.

Owner:GUANGDONG ICOMON TECH CO LTD

Super-gravity device used for electrochemical deposition in ionic liquid

InactiveCN102181888BGuaranteed normal operationResistance sensitivityTanksElectrolysisDynamic balance

The invention discloses a super-gravity device used for electrochemical deposition in ironic liquid, and belongs to the field of the electrochemical deposition under a special condition. The super-gravity device comprises an electrolytic tank, a balance weight system, a shaft cooling system, a shielding gas transmission system, a speed measurement system, a rotating speed and temperature control display system and a conducting slip ring system. In the reaction process, a motor drives a shaft to rotate to supply required centrifugal force; the centrifugal force is measured by a super-gravity coefficient; the super-gravity coefficient is calculated by the speed measurement system; the temperature in the electrolytic tank is controlled by the temperature control system; the dynamic balance of the electrolytic tank in a centrifugal field is realized through the balance weight system; an inert gas atmosphere required by the reaction is realized through the shielding gas transmission system; the shaft cooling of the super-gravity device is realized through the shaft cooling system; and the current required in the electro-deposition process is supplied by the conducting slip ring system.

Owner:BEIJING UNIV OF CHEM TECH

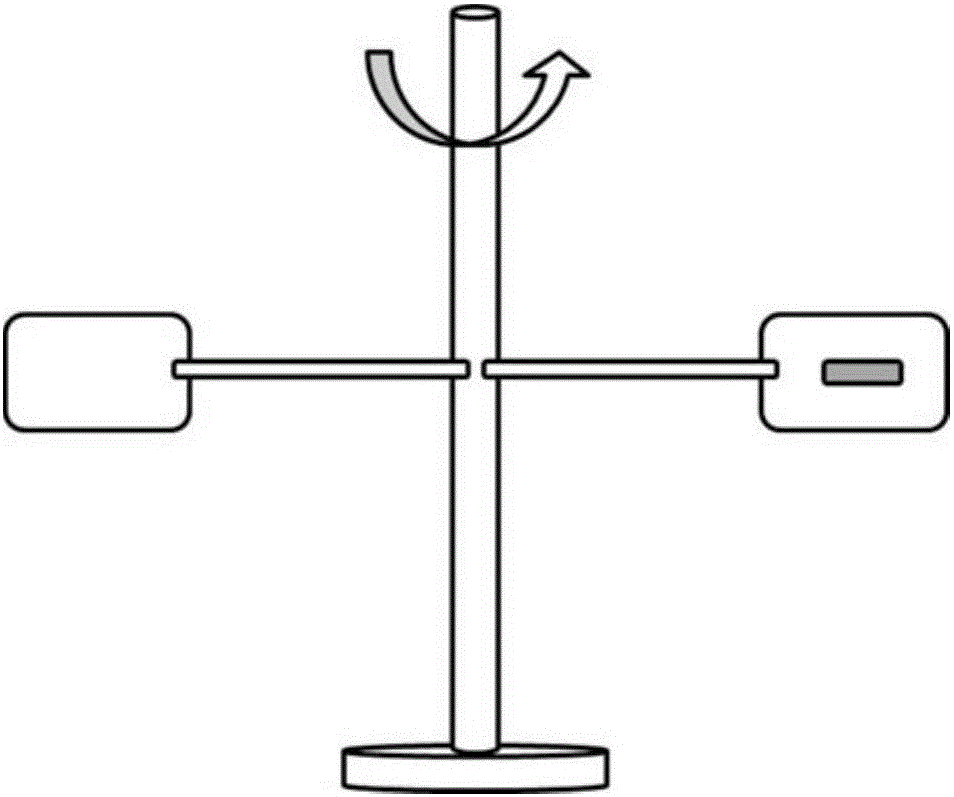

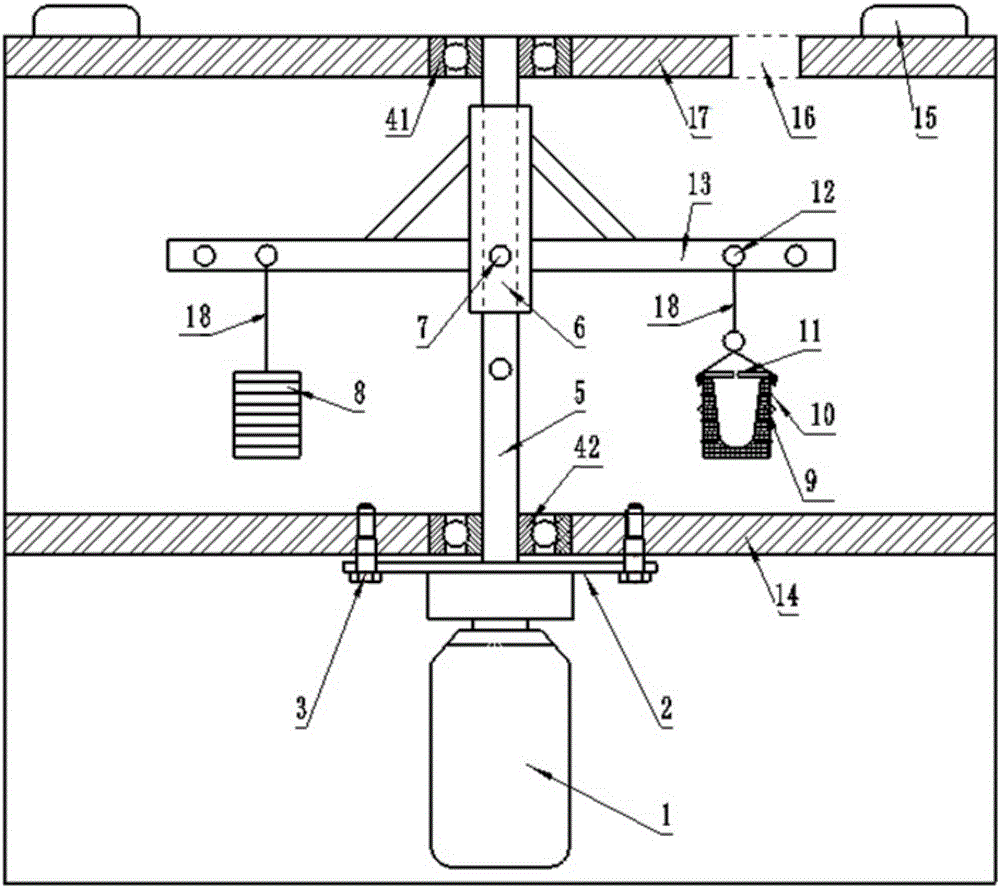

Preparation method and preparation device of titanium-aluminum alloy

The invention discloses a preparation method and preparation device of a titanium-aluminum alloy, and belongs to the field of preparation of the titanium-aluminum alloy by an aluminothermic reduction method. The invention provides a preparation method and a corresponding preparation device of the titanium-aluminum alloy, which can improve the residue-metal separation effect and the quality of the titanium-aluminum alloy; the titanium-aluminum alloy is prepared through an aluminothermic reduction reaction under a super-gravity system environment, so that the residue-metal separation effect can be improved. The preparation device comprises a reaction tank and a super-gravity generating system, wherein the super-gravity generating system comprises a support frame, a central rotating shaft, a rotating cross arm and a driving mechanism, the reaction tank is in hanging connection to the free end part, which is away from the central rotating shaft, of the rotating cross arm, through a steel rope. The reaction tank is driven by the driving mechanism to rotate around the axis of the central rotating shaft, so that performing an aluminothermic reaction in the reaction tank under the super-gravity field environment is realized. The preparation device disclosed by the invention is simple in structure, and super-gravity coefficients can convenient to regulate as needed.

Owner:蚌埠市众成压铸机机械制造有限公司

Casting method of high-magnesium aluminum alloy

The invention discloses a casting method of a high-magnesium aluminum alloy, and belongs to the field of alloy preparation. The casting method comprises the following steps that S1, materials are prepared, and an aluminum ingot, a magnesium ingot and other required alloy elements are prepared; S2, the aluminum ingot is smelted, and other required alloy elements are added after the aluminum ingot is molten; S3, a refining agent is added, and after fully stirred, the refining agent stands, and the magnesium ingot is added until the magnesium ingot is completely molten; S4, a grain refining agentis added and slag is removed; and S5, a high-magnesium aluminum alloy cast ingot is prepared by adopting a rotary crystallization method, and when rotary crystallization is carried out, the rotatingspeed is 300-3000 rpm, the gravity coefficient G is 50-300, and the casting temperature is 700-760 DEG C; and the prepared ingot is cooled to the room temperature. The casting method has the advantagethat the high-magnesium aluminum alloy casting mode is provided, and the aluminum alloy with higher casting performance and deformation performance is prepared.

Owner:TSINGHUA UNIV

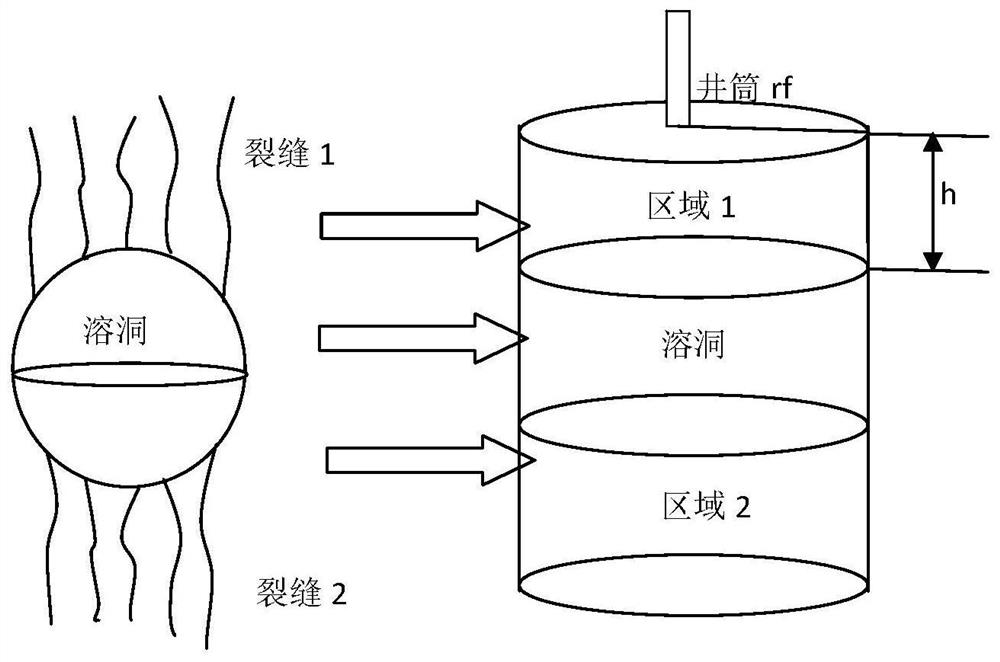

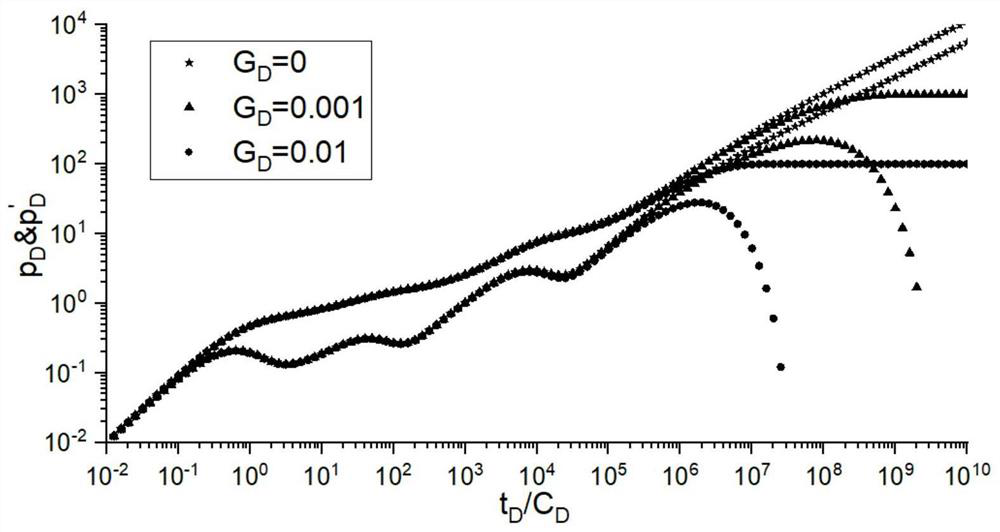

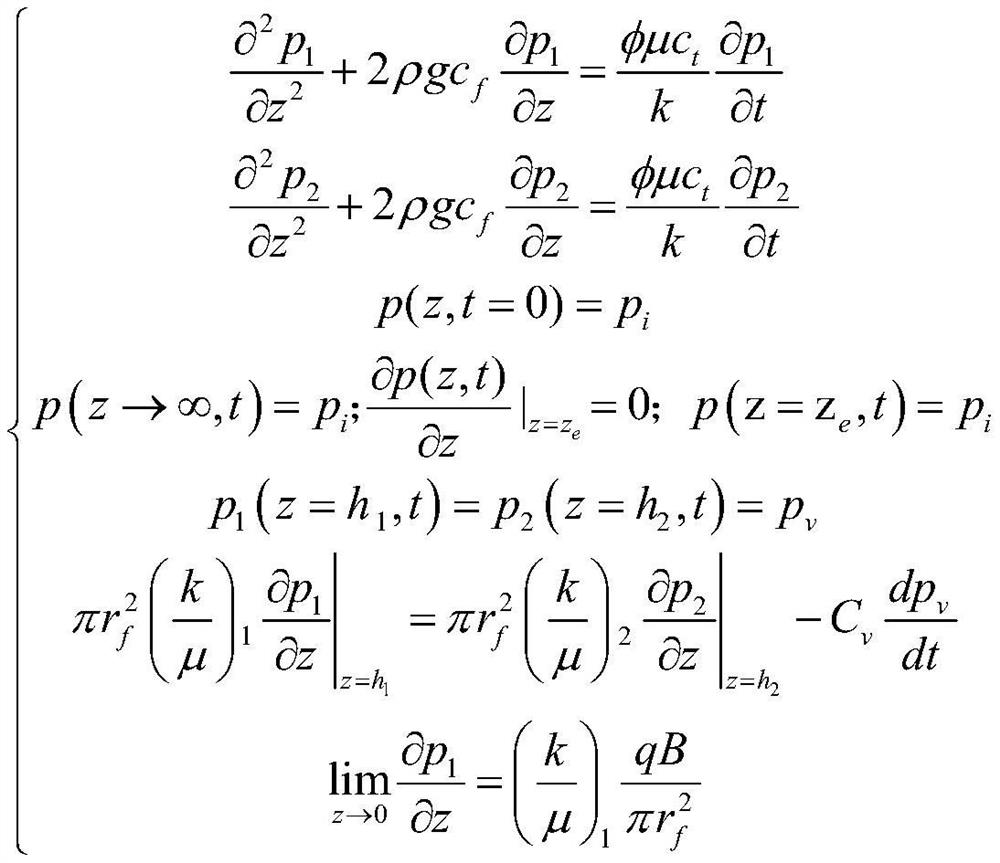

Single-hole type fault solution reservoir well testing interpretation method considering gravity factor influence

PendingCN113294147ASimple modelEasy to solveBorehole/well accessoriesComplex mathematical operationsMathematical modelClassical mechanics

The invention discloses a single-hole type fault solution reservoir well testing interpretation method considering gravity factor influence. The method comprises the following steps that 1, a single-hole type fault solution reservoir well testing mathematical model considering the gravity factor is built, and a karst cave and crack combined system is regarded as a simultaneous cylindrical region; 2, the well testing mathematical model is subjected to dimensionless processing to obtain dimensionless gravity coefficient definition; 3, solving is performed on a Laplace space after Laplace transformation is adopted, and an expression of the pressure in a stratum hole changing along with time under the gravity factor influence is obtained; and 4, curve parameters and time and pressure fitting values are obtained by adopting a well testing method, and the influence of the gravity factor on well testing curve interpretation is obtained. By adopting the method, the technical problem that some parameters directly serving oil field development cannot be determined by adopting a well testing interpretation method in the prior art is solved, meanwhile the influence of gravity on a well testing curve is analyzed, and technical support is provided for oil field development.

Owner:CHINA PETROLEUM & CHEM CORP +1

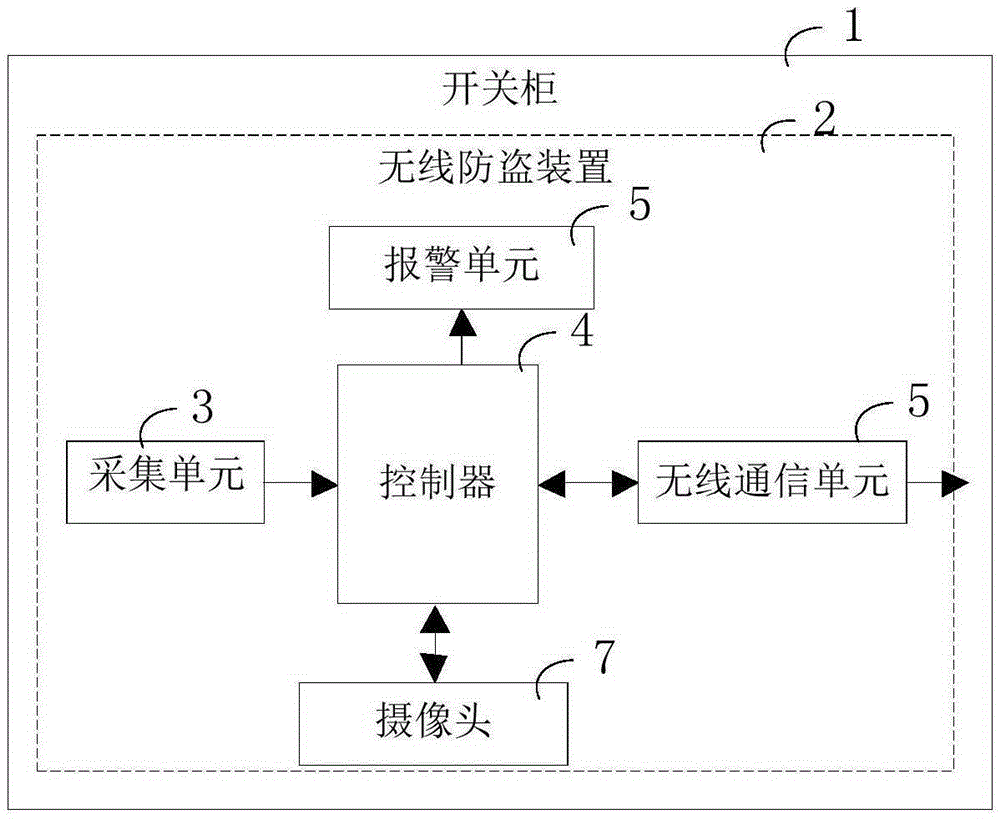

Antitheft switch cabinet monitoring device

InactiveCN105427495APrevent theftEasy to moveBurglar alarm electric actuationBurglar alarm by pressureCommunication unitCurrent sensor

The invention provides an antitheft switch cabinet monitoring device. The antitheft switch cabinet monitoring device comprises a switch cabinet and a wireless antitheft apparatus which is arranged in the switch cabinet, wherein the wireless antitheft apparatus includes an acquisition unit, a wireless communication unit, a warning unit and a controller; the acquisition unit comprises a current sensor and a gravity sensor; an input end of the controller is connected with an output end of the current sensor and an output end of the gravity sensor; an output end of the controller transmits the acquired switch cabinet gravity coefficient and the current coefficient to a monitor room through the wireless communication unit; the output end of the controller is connected with the warning unit; the controller controls whether the warning unit gives an alarm according to the received gravity coefficient and the current coefficient; and when the controller detects that the current coefficient is 0 and the gravity coefficient fluctuates, the warning unit and a camera are started, and at the same time the controller transmits the acquisition information to the monitor room synchronously so as to realize the antitheft effect.

Owner:CHONGQING ZHENYUAN ELECTRICAL CO LTD

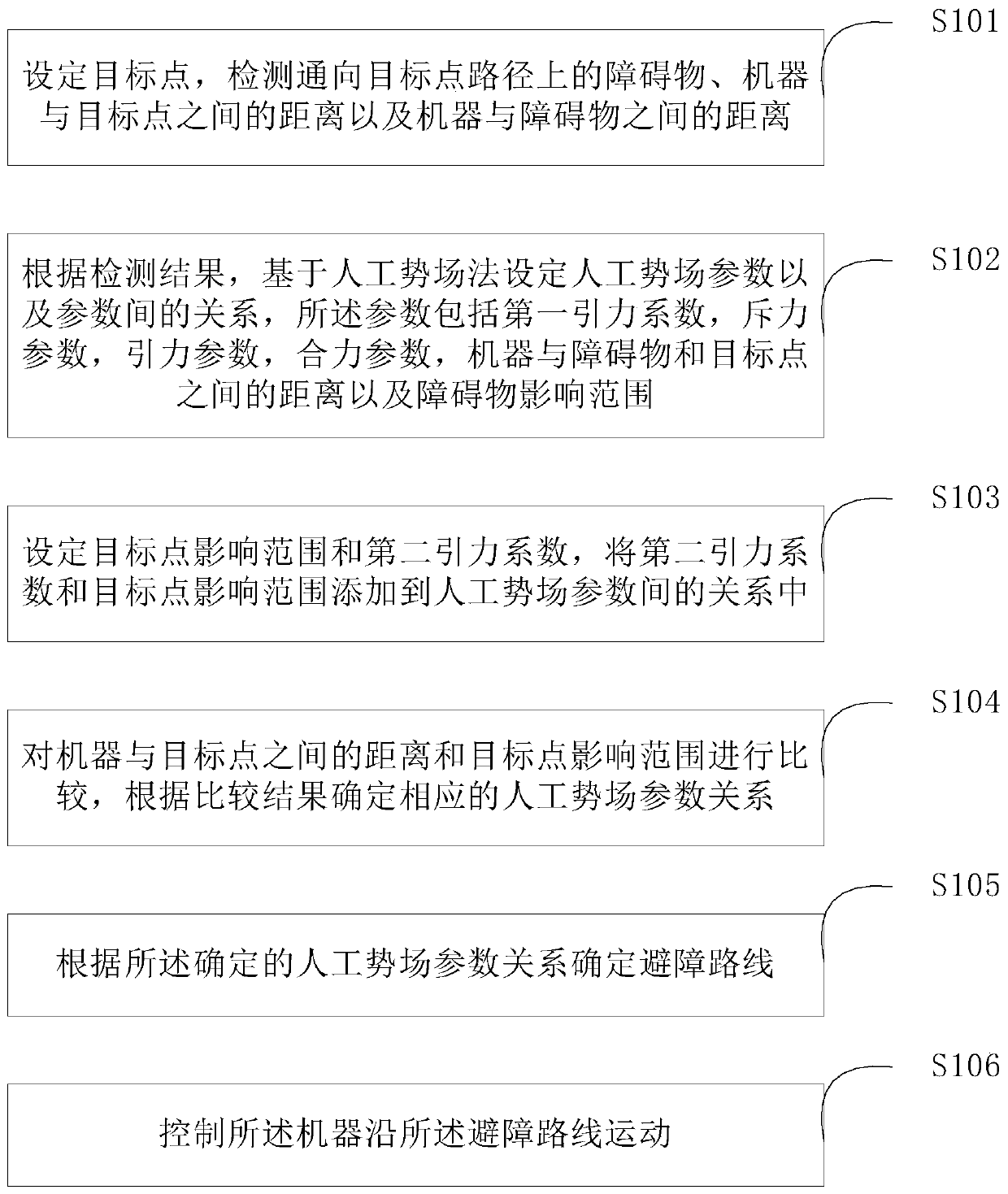

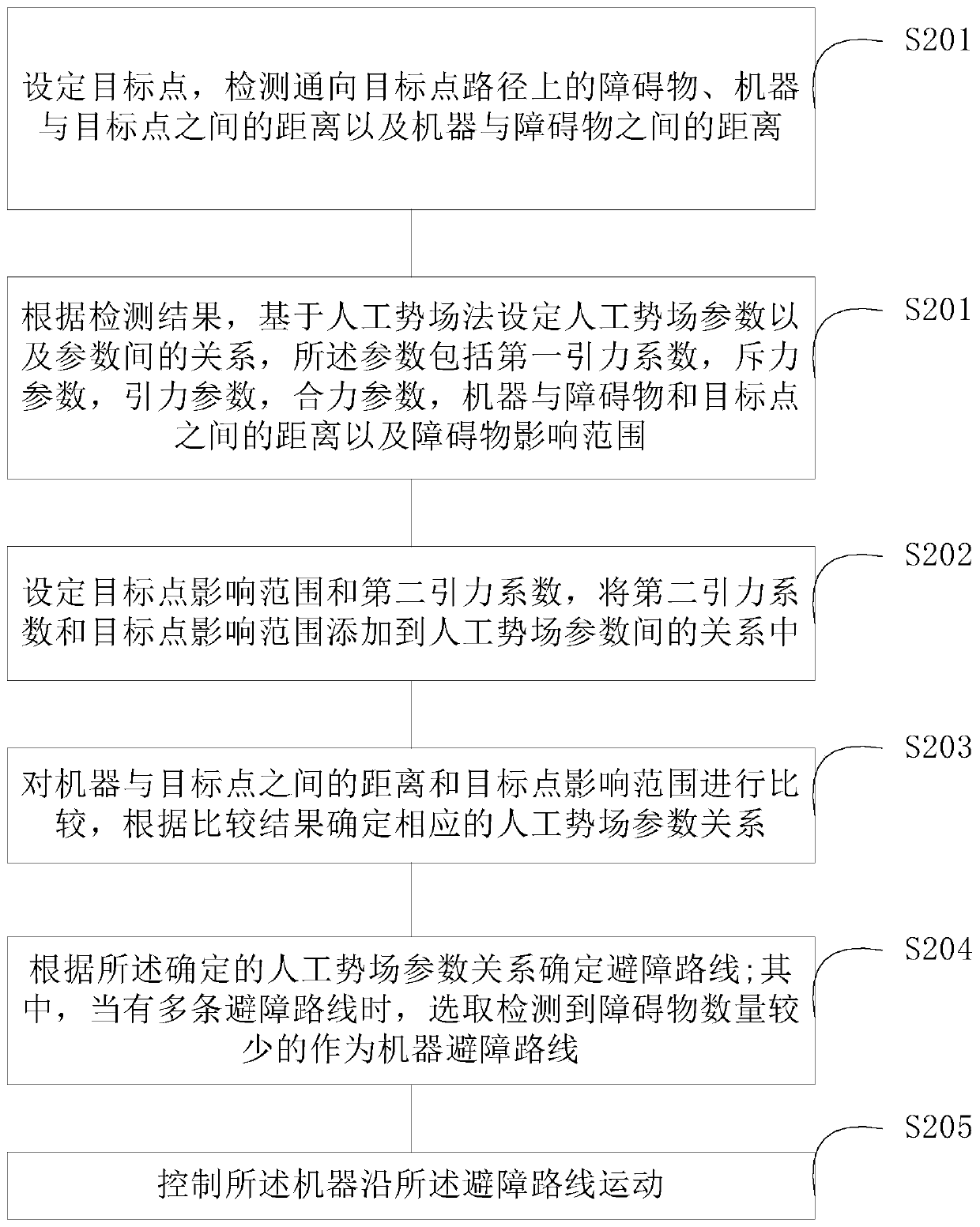

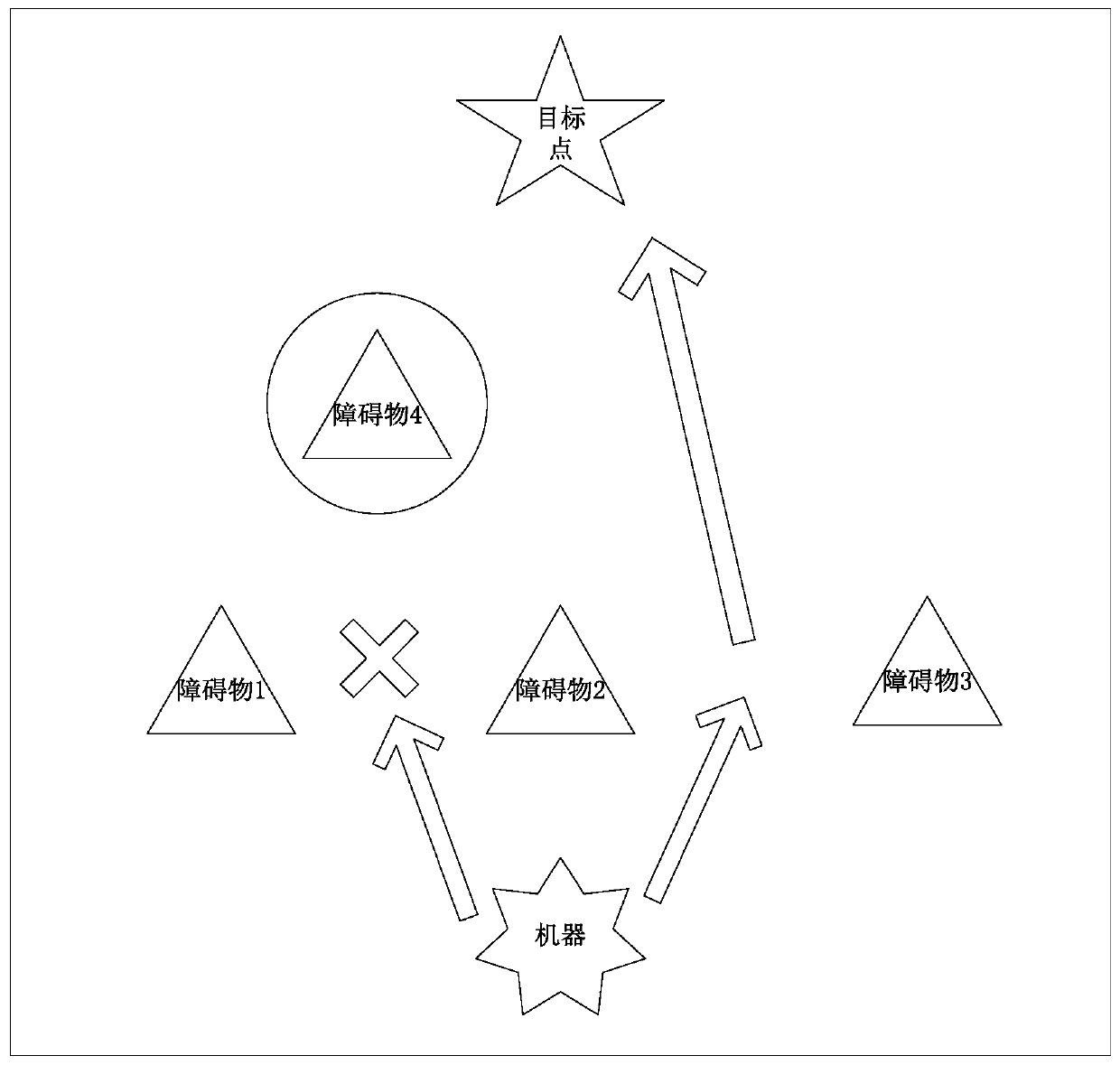

Artificial potential field method-based machine obstacle avoidance method and device

ActiveCN110471420AModify the gravitational potential field parametersAvoid the problem that the minimum value is not at the target positionPosition/course control in two dimensionsPotential fieldEngineering

The embodiments of the invention disclose an artificial potential field method-based machine obstacle avoidance method and device. With the method and device adopted, a GNRON problem in a machine obstacle avoidance technology can be solved. The method comprises the following steps that: a target point is set, and an obstacle which is located on a path leading to the target point, a distance between a machine and the target point, and a distance between the machine and the obstacle are detected; artificial potential field parameters and relations between the artificial potential field parameters are set based on an artificial potential field method according to detection results, wherein the parameters comprise a first gravity coefficient, a repulsive force parameter, a gravity parameter, aresultant force parameter, the distance between the machine and the obstacle, the distance between the machine and the target point and an obstacle influence range; a target point influence range anda second gravity coefficient are set, and the second gravity coefficient and the target point influence range are added into the relations between the artificial potential field parameters; the distance between the machine and the target point is compared with the target point influence range, and corresponding artificial potential field parameters are determined according to a comparison result;an obstacle avoidance route is calculated according to the determined artificial potential field parameters; and the machine is controlled to move along the obstacle avoidance route.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

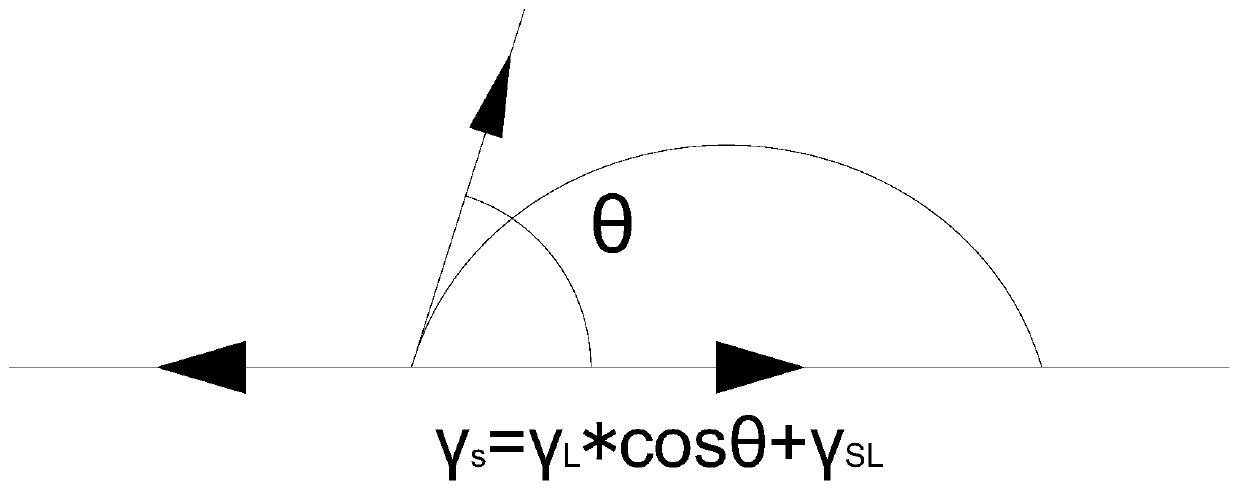

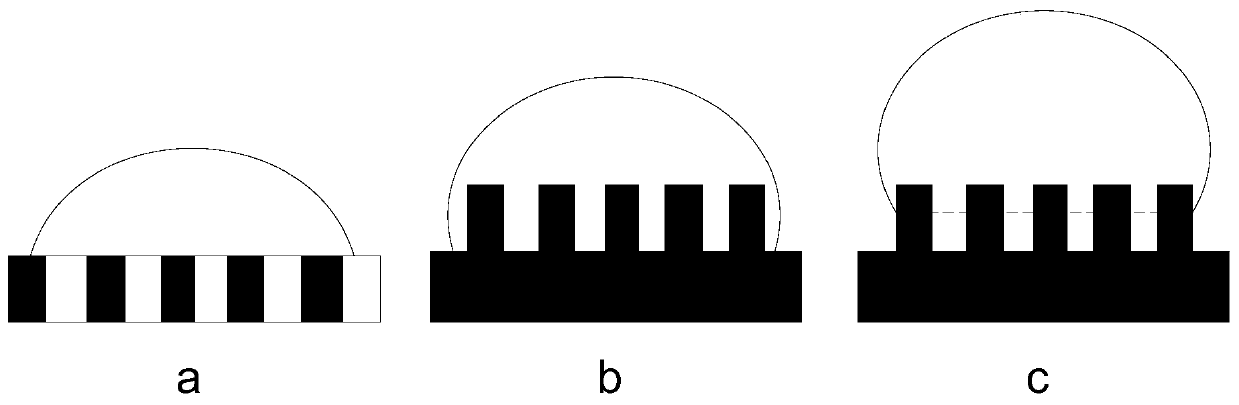

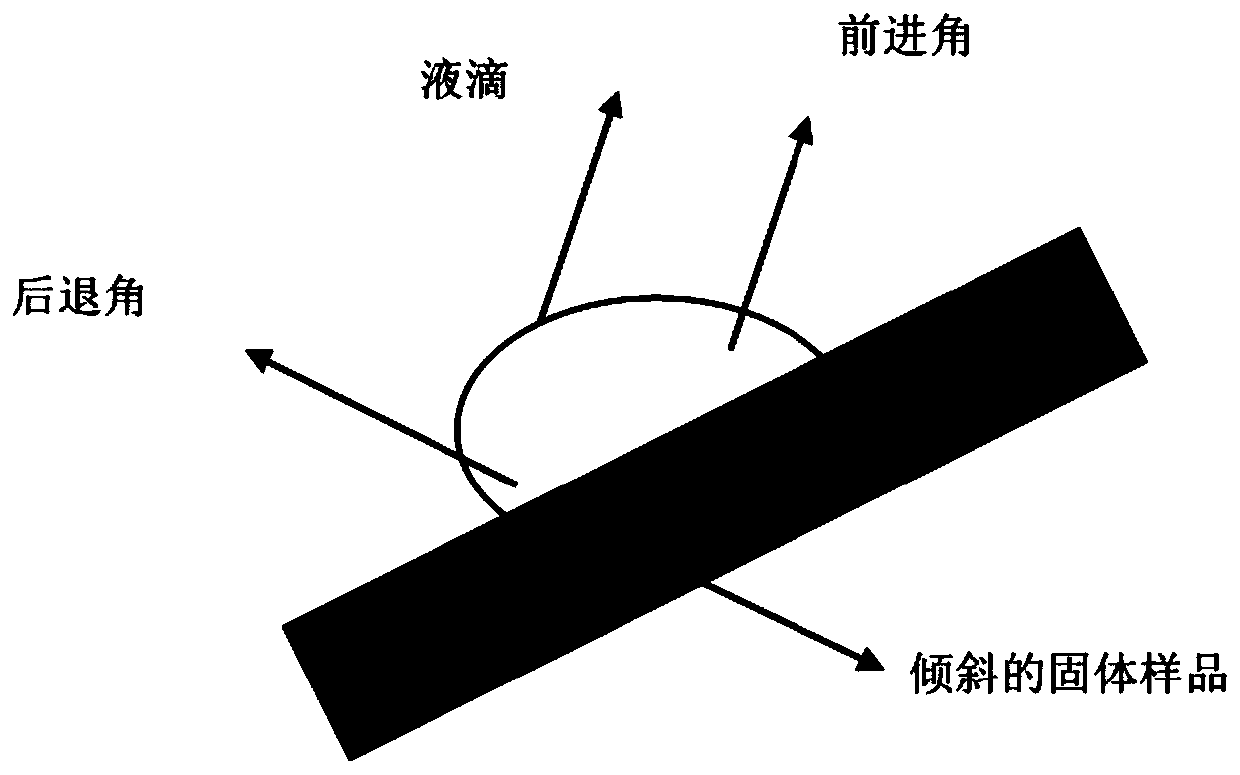

Testing method for intrinsic contact angle measurement based on three-dimensional space inclination angle correction

The invention belongs to the technical field of interface chemistry analysis and testing, and discloses a testing method for intrinsic contact angle measurement based on three-dimensional space inclination angle correction. The method comprises the following steps: establishment of a simultaneous contact angle calculation equation set, acquisition of an inclination angle, correction of the inclination angle, and calculation of an intrinsic contact angle, wherein during the calculation of the contact angle, the inclination angle of the surface of a sample is corrected, and an intrinsic contactangle value of a drop is obtained after a correction gravity coefficient is adopted. The method disclosed by the invention has the advantages that the problem of the conventional apparent contact angle measurement that a real contact angle of a solid material cannot be accurately evaluated is solved, the precision of the measured contact angle value is improved, and the phenomenon of contact anglehysteresis of the solid material caused by surface roughness, chemical diversity and heterogeneity can be evaluated.

Owner:上海梭伦信息科技有限公司

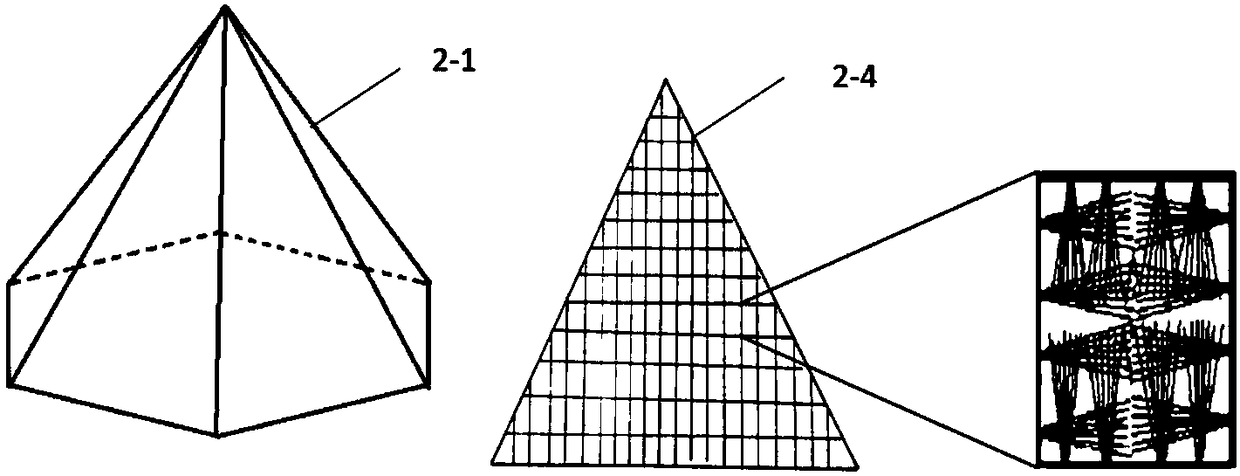

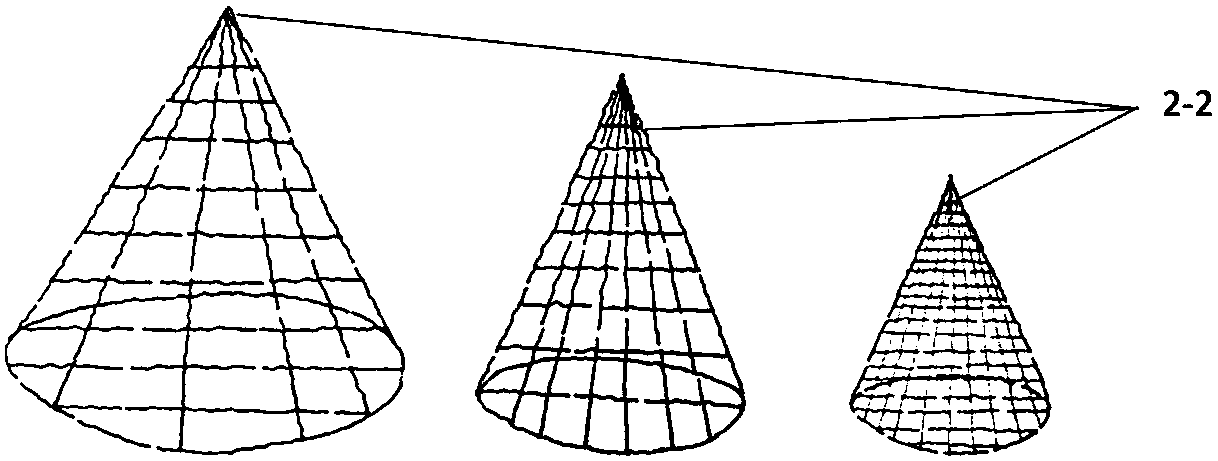

Hydraulic power spread wetland plant seed capturing device and method

ActiveCN108377723ACaptive breeding is goodLarge amount of collectionClimate change adaptationHarvestersPlanting seedEngineering

The invention provides a 'hydraulic power spread wetland plant seed capturing device and method', and belongs to the technical field of ecological engineering. The capturing device is characterized bycomprising a buoyancy base and at least one conical net cover; the conical net cover is a conical structure of which the bottom surface is open, and a plurality of meshes are distributed in a conicalsurface of the conical net cover; a structure which can allow water and a plant seed to penetrate in but can stop the plant seed from penetrating out is arranged on each mesh; the bottom surface of the conical net cover is connected with the top surface of the buoyancy base; the capturing device can be fixed at a certain position in water through a fixing component; and buoyance F provided by thebuoyance base meets the following conditions: device G-0.8* water rho g device V< / = buoyance F< / = device G-0.4* water rho g device V; the device G means the weight of the capturing device, water rhomeans water density, g is a gravity coefficient, and device V means the volume of the capturing device. Compared with an existing device, the device and method have the advantages that the number of the captured seeds is greater by multiple times.

Owner:中国林业科学研究院生态保护与修复研究所

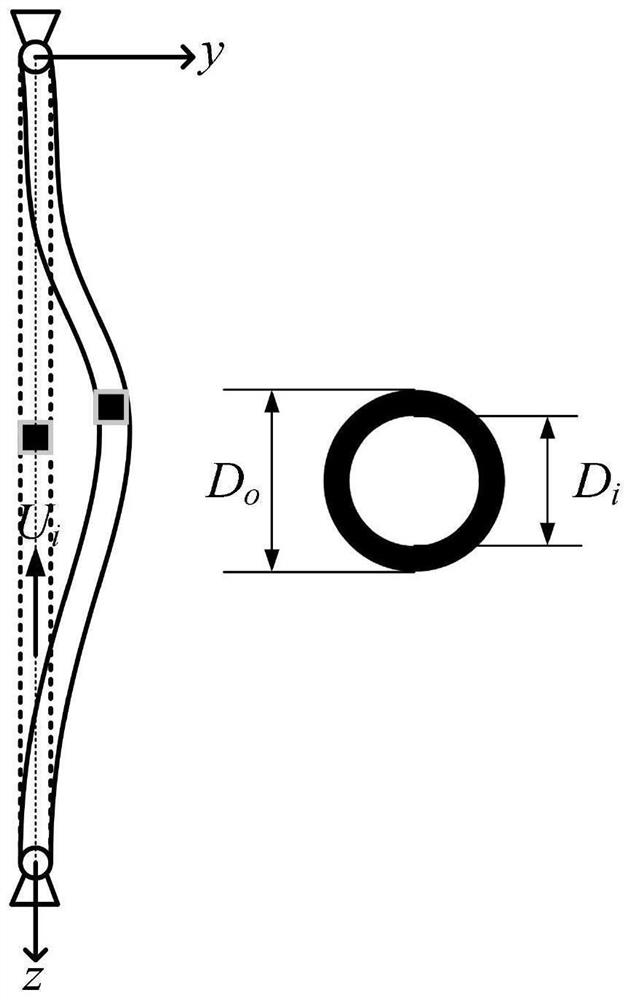

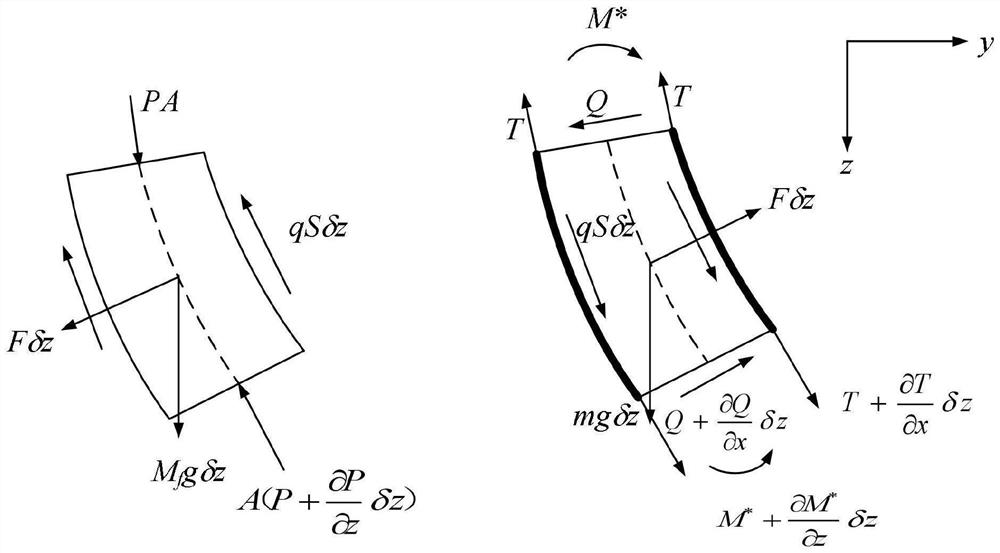

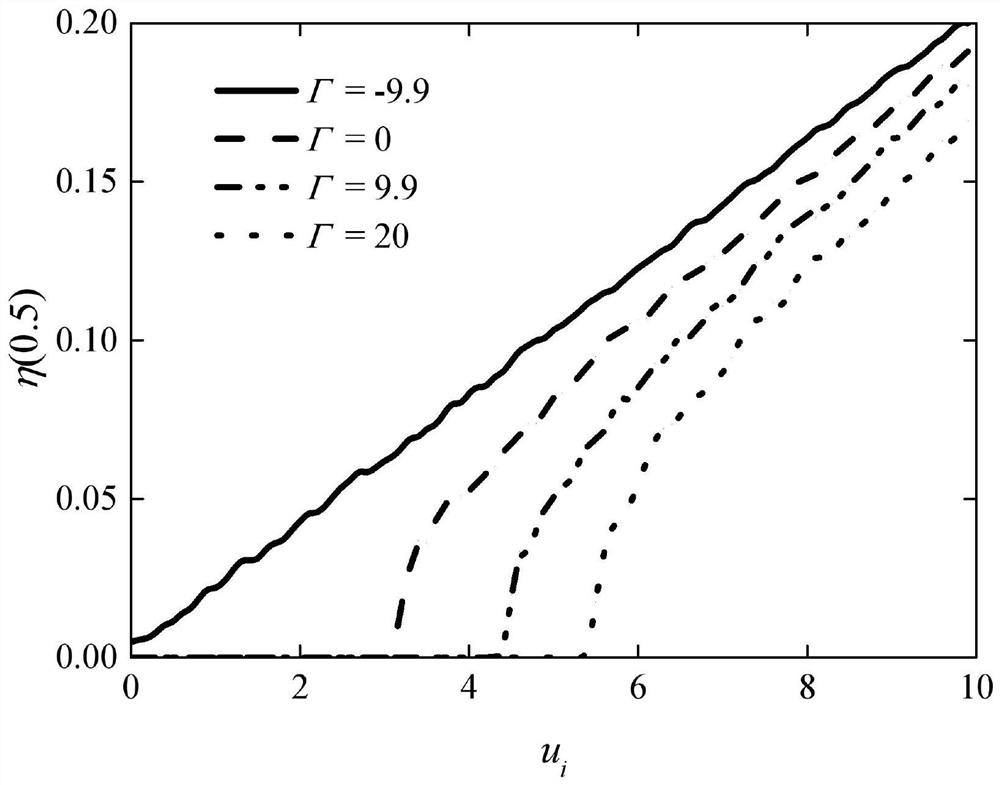

Method, system and device for predicting nonlinear response of flexible pipeline under internal flow action

The invention discloses a method, a system and a device for predicting the nonlinear response of a flexible pipeline under the internal flow action, and belongs to the technical field of pipeline design and prediction. The invention aims to solve the problem that many key information of structural vibration response cannot be obtained due to the fact that the stability analysis of a pipeline is based on a linear theory at present. According to the method, numerical research is carried out for the flexible pipeline nonlinear response problem of internal fluid movement, and a complete numerical prediction model of flexible pipeline movement under the internal flow action is established and used for analyzing the internal flow speed and the flexible pipeline nonlinear response under different system parameters; The numerical forecasting model can well simulate the influence of different internal flow velocities, different axial forces, different fluid pressures, different gravity coefficients and different axial flexibility on the vibration response of the flexible structure; The dynamic characteristics of the structural instability can be well disclosed, and the problems existing in actual engineering can be well described. The method is mainly applied to flexible pipeline nonlinear response prediction.

Owner:HARBIN INST OF TECH AT WEIHAI

Titanium-aluminum alloy preparation method and preparation device

The invention discloses a preparation method and preparation device of a titanium-aluminum alloy, and belongs to the field of preparation of the titanium-aluminum alloy by an aluminothermic reduction method. The invention provides a preparation method and a corresponding preparation device of the titanium-aluminum alloy, which can improve the residue-metal separation effect and the quality of the titanium-aluminum alloy; the titanium-aluminum alloy is prepared through an aluminothermic reduction reaction under a super-gravity system environment, so that the residue-metal separation effect can be improved. The preparation device comprises a reaction tank and a super-gravity generating system, wherein the super-gravity generating system comprises a support frame, a central rotating shaft, a rotating cross arm and a driving mechanism, the reaction tank is in hanging connection to the free end part, which is away from the central rotating shaft, of the rotating cross arm, through a steel rope. The reaction tank is driven by the driving mechanism to rotate around the axis of the central rotating shaft, so that performing an aluminothermic reaction in the reaction tank under the super-gravity field environment is realized. The preparation device disclosed by the invention is simple in structure, and super-gravity coefficients can convenient to regulate as needed.

Owner:蚌埠市众成压铸机机械制造有限公司

A mine microseismic signal identification method based on energy distribution characteristics

ActiveCN107505652BEfficient identificationAdaptableSeismic signal processingDecompositionBlasting vibration

The invention discloses a mine microseismic signal identification method based on energy distribution characteristics, belonging to the field of signal analysis and identification, comprising the following steps: reading the microseismic signal x(t) to be identified; performing VMD decomposition on x(t) to obtain K Variational modal components arranged in order of frequency from high to low; calculate the frequency band energy of each modal component, and extract the energy percentage value of each modal component in the original signal to form an energy distribution vector P; take the energy distribution vector P as Calculate the center of gravity coefficient cx of the X-axis of the energy distribution based on the basis; identify the microseismic signal of the mine according to the identification threshold T, if cx>T is the microseismic signal of the coal rock mass rupture in the mine, and if cx≤T is the blasting vibration signal; finally the value of the identification threshold T Adaptive update. The invention can effectively distinguish the microseismic signal of coal rock mass rupture and the blasting vibration signal, and has the characteristics of strong adaptability, high accuracy and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Managed pressure drilling pulling method

The invention relates to the technical field of managed pressure drilling pulling, in particular to a managed pressure drilling pulling method. The managed pressure drilling pulling method is carriedout according to the following steps that first, before managed pressure drilling pulling, according to the actual formation pressure and the under-pressure pulling height, the heavy slurry density isdesigned through the formula that the heavy slurry density=(the formation pressure-the light slurry density*the under-pressure pulling height*the gravity coefficient) / [(the well depth-the under-pressure pulling height)*the gravity coefficient]. Through the managed pressure drilling pulling method, the situation that when drilling liquid in a drilling tool flows to a drilling floor, the drilling floor is wet and slippery can be effectively avoided, in this way, the operation risk of drilling floor workers can be reduced, meanwhile, waste of the drilling liquid is also avoided, and the cost issaved; and pulling is conducted through the managed pressure drilling pulling method, if taking a well with the well depth being 3000 m as an example, the pulling time only needs 10-12 h, compared with an existing managed pressure drilling technology, the pulling time is shortened by 3-6 h, and thus the managed pressure drilling pulling time efficiency can be effectively improved through the managed pressure drilling pulling method.

Owner:CNPC XIBU DRILLING ENG

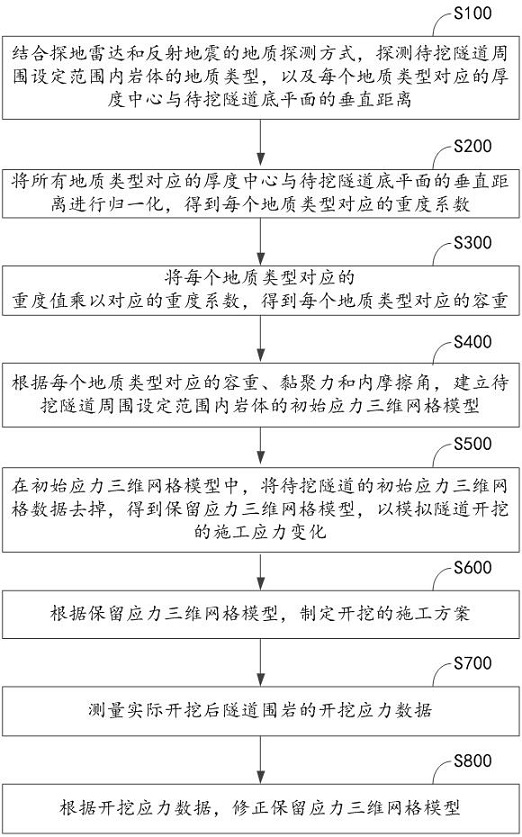

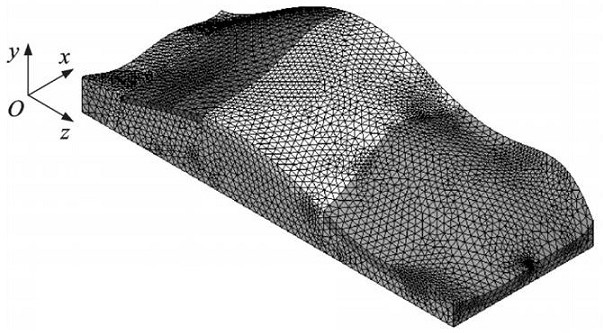

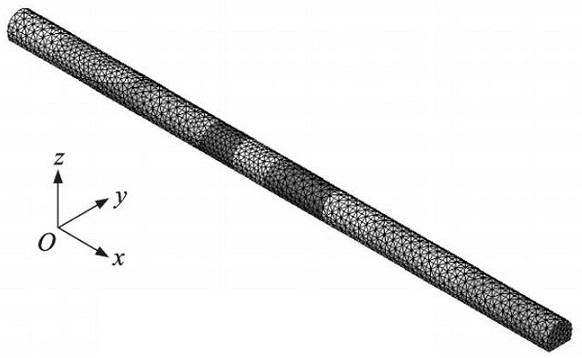

A method and related equipment for analyzing stress data of surrounding rock during full-section tunnel excavation

ActiveCN112989480BAccurate analysisAccurate detectionGeometric CADDesign optimisation/simulationStructural engineeringFriction angle

The application discloses a method and related equipment for analyzing the stress data of the surrounding rock in full-section excavation of a tunnel. The vertical distance of the tunnel bottom plane; normalize the vertical distance between all thickness centers and the tunnel bottom plane to be excavated to obtain the gravity coefficient; multiply the gravity value by the corresponding gravity coefficient to obtain the bulk density; according to the bulk density, cohesion and content Friction angle, establish the initial stress 3D grid model of the rock mass within the set range around the tunnel to be excavated; in the initial stress 3D grid model, remove the initial stress 3D grid data of the tunnel to be excavated, and obtain the retained stress 3D grid model; formulate the construction plan for excavation; measure the excavation stress data of the surrounding rock of the tunnel after actual excavation; and correct the three-dimensional mesh model of the retained stress according to the excavation stress data. It can analyze the surrounding rock stress data of complex geological types and structures.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

Method for manufacturing bearing ring by adopting centrifugal casting technique

InactiveCN101530899BImprove efficiencySmall machining allowanceFoundry mouldsFoundry coresTemperature controlGravity coefficient

The invention relates to a method for manufacturing a bearing ring by adopting a centrifugal casting technique, wherein the preheating temperature of charging materials is between 150 and 300 DEG C; the gravity coefficient for the start-up of a centrifugal machine is controlled to be between 50 and 60; and the centrifugal pouring adopts a bottom pouring type and a movable type, the pouring temperature is controlled to be between 1,640 and 1,680 DEG C, and the pouring time is between 5 and 10 minutes. Compared with the prior art, the method has the advantages of reducing the admittance, savingraw materials, reducing the cost effectively, and improving the benefits of enterprises.

Owner:HAICHENG ZHONGXING HEAVY MACHINERY

A method and device for preparing through-hole metal foam by supergravity seepage

ActiveCN107574329BRealize semi-continuous productionUniform structureMaterials preparationMetallic materials

The invention provides a method and a device for preparing porous foam metal through super-gravity seepage and belongs to the field of foam metal material preparation. In the invention, soluble salt particles of which the average particle size is 0.1-5mm are used as a precursor, and metal is used as a seepage body. A centrifugal casting mold is filled with the soluble salt particles which are dried and sieved, and a porous plate is fixed at the top of the precursor. The centrifugal casting mold which is preheated is assembled on a centrifugal platform, centrifugal equipment is started, and molten metal which is pre-molten is poured into a feeding hopper of the centrifugal equipment. The molten metal being driven by super-gravity seeps into gaps of the precursor via the porous plate, and the super-gravity coefficient of the process is controlled above 20-180 from the big to the small according to the average particle size of the soluble salt particles, namely the precursor. After the metal is solidified, the centrifugal casting mold is disassembled, a compound body is taken out, and cutting processing is carried out. The soluble salt particles are dissolved by using water and removed from the compound body, and the porous foam metal is obtained. The method is simple in technology and low in cost, and the prepared foam aluminum alloy is even in structure, proper in size and excellent in mechanical properties.

Owner:UNIV OF SCI & TECH BEIJING

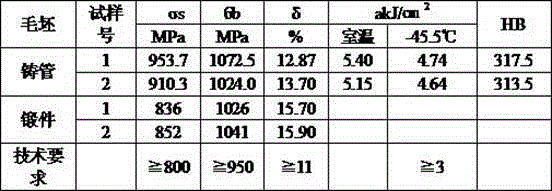

Production method for multi-element alloy steel

InactiveCN102912210AAchieve mechanical propertiesImprove the mechanical properties of the inner tubeFoundry mouldsFoundry coresWater basedMechanical property

The invention discloses a production method for multi-element alloy steel, relating to the technical field of production processes of alloy steel. The production method comprises a smelting step, a centrifugal casting step and a thermal treatment step, wherein the smelting step specifically comprises a melting step, a slagging step, a pre-deoxidation step, a final deoxidizing step and a tapping step. The production method comprises the following implementation steps of: during smelting, adding vanadium iron before final deoxidizing to enable the percentage of V in a product to be 0.10-0.15 percent; during centrifugal casting, taking 103 as a gravity coefficient G in a calculation formula of the rotating speed n of a centrifugal machine; taking a cast coating as a zircon powder water-based coating; when the casting is about to carry out, enabling the temperature of the cast outer wall to be 220DEG C, the casting temperature of molten steel to be 1,520DEG C and the casting speed to be 40kg / s; during pre-deoxidation, respectively inserting 0.75kg of aluminum and 0.75kg of calcium iron silicate in steel of each ton in the furnace; during final deoxidizing, respectively inserting 0.75kg of aluminum and 0.75kg of calcium iron silicate in steel of each ton in the furnace; enabling the tapping temperature to be 1,550-1,570DEG C; and during thermal treatment, normalizing, oil extracting and tempering. According to the production method disclosed by the invention, the mechanical property of an inner tube can be improved and favorable mechanical properties of products, such as yield strength, tensile strength and toughness at low temperature are obtained.

Owner:徐宏亮

Method for producing large magnesium alloy ring by means of centrifugal casting

A method for producing a large magnesium alloy ring by means of centrifugal casting includes: preheating a mould; hanging thermal insulation coatings and determining centrifugal casting parameters; performing centrifugal casting and the like. The method is technically characterized by determination of rotation speed and casting speed. A centrifugal power device is started for centrifugal casting, the centrifugal rotation speed n is calculated according to the gravity coefficient formula as shown in the original text, n=29.9, wherein n refers to the centrifugal rotation speed, R refers to the radius (m) of the inner surface of a casting, and G refers to gravity coefficient. The method overcomes the shortcomings of an existing large magnesium alloy ring production process, is used for producing the large magnesium alloy ring with compact texture and high tensile strength, and has an important significance for magnesium alloy application and development of magnesium alloy centrifugal casting technology.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com