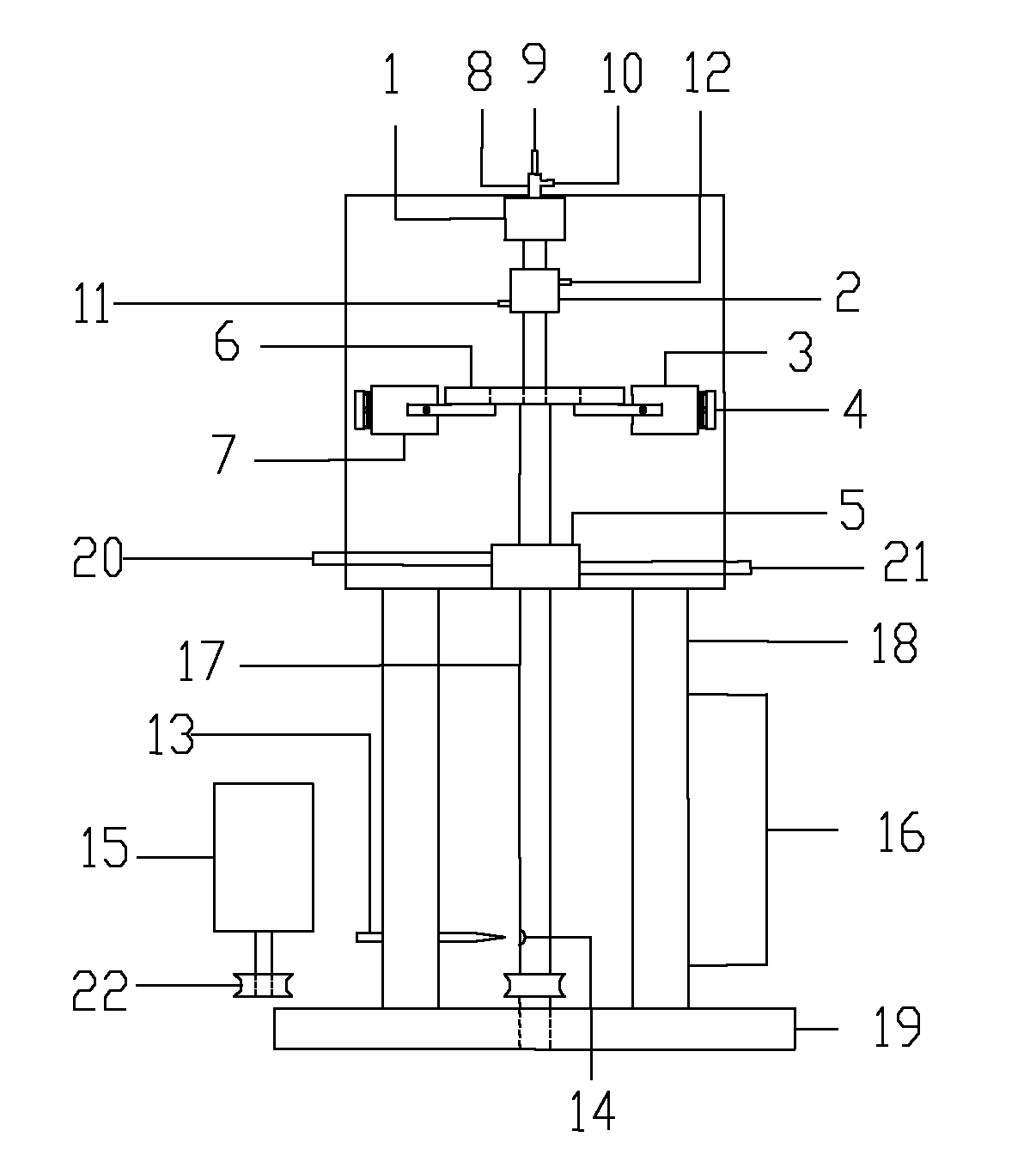

Super-gravity device used for electrochemical deposition in ionic liquid

An ionic liquid and electrochemical technology, applied in the field of electrochemical deposition, can solve the problems of easy occurrence of impurities, unstable operation of supergravity devices, and no cooling system for the centrifugal shaft, and achieve the effect of a strict speed measurement system and a speed control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

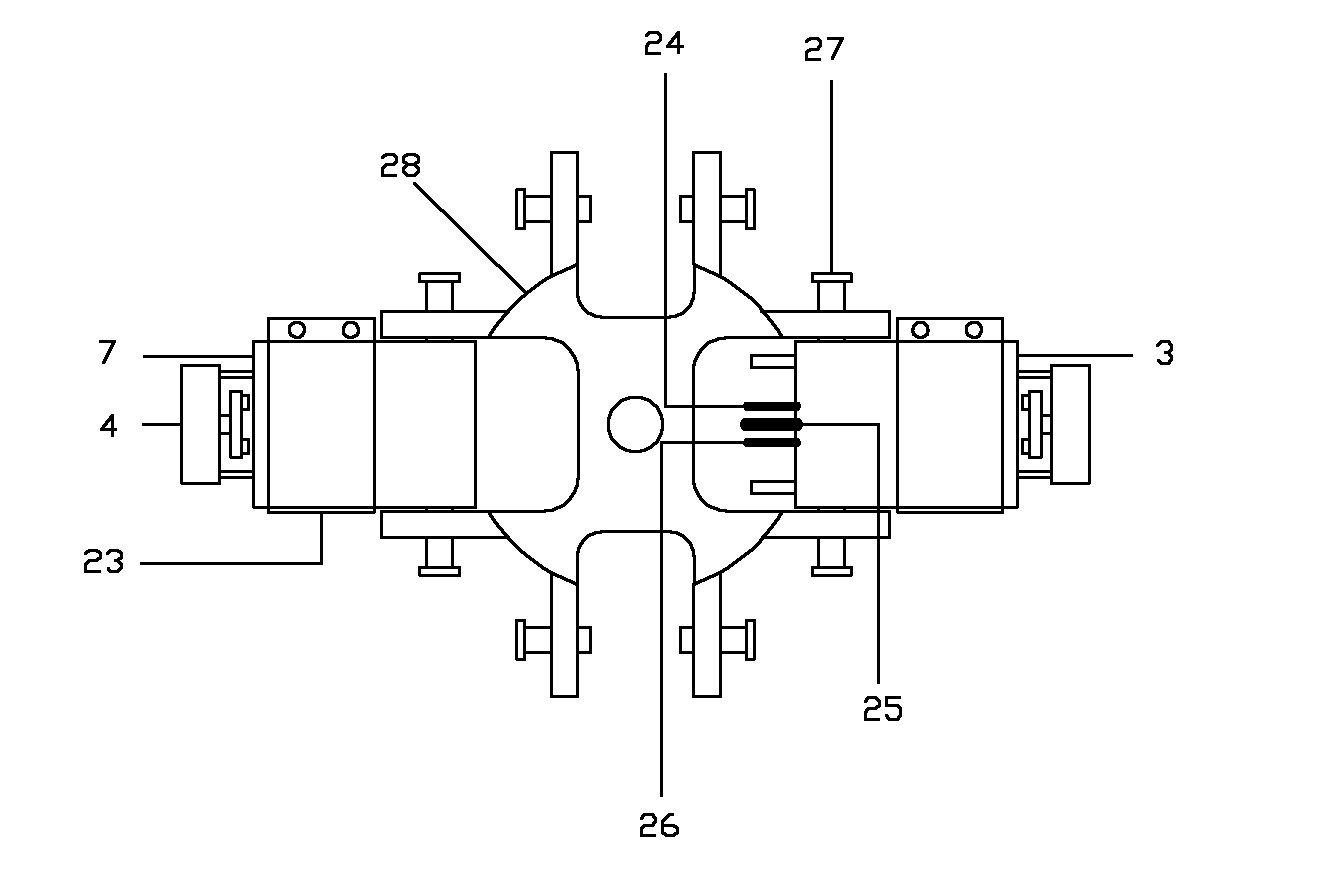

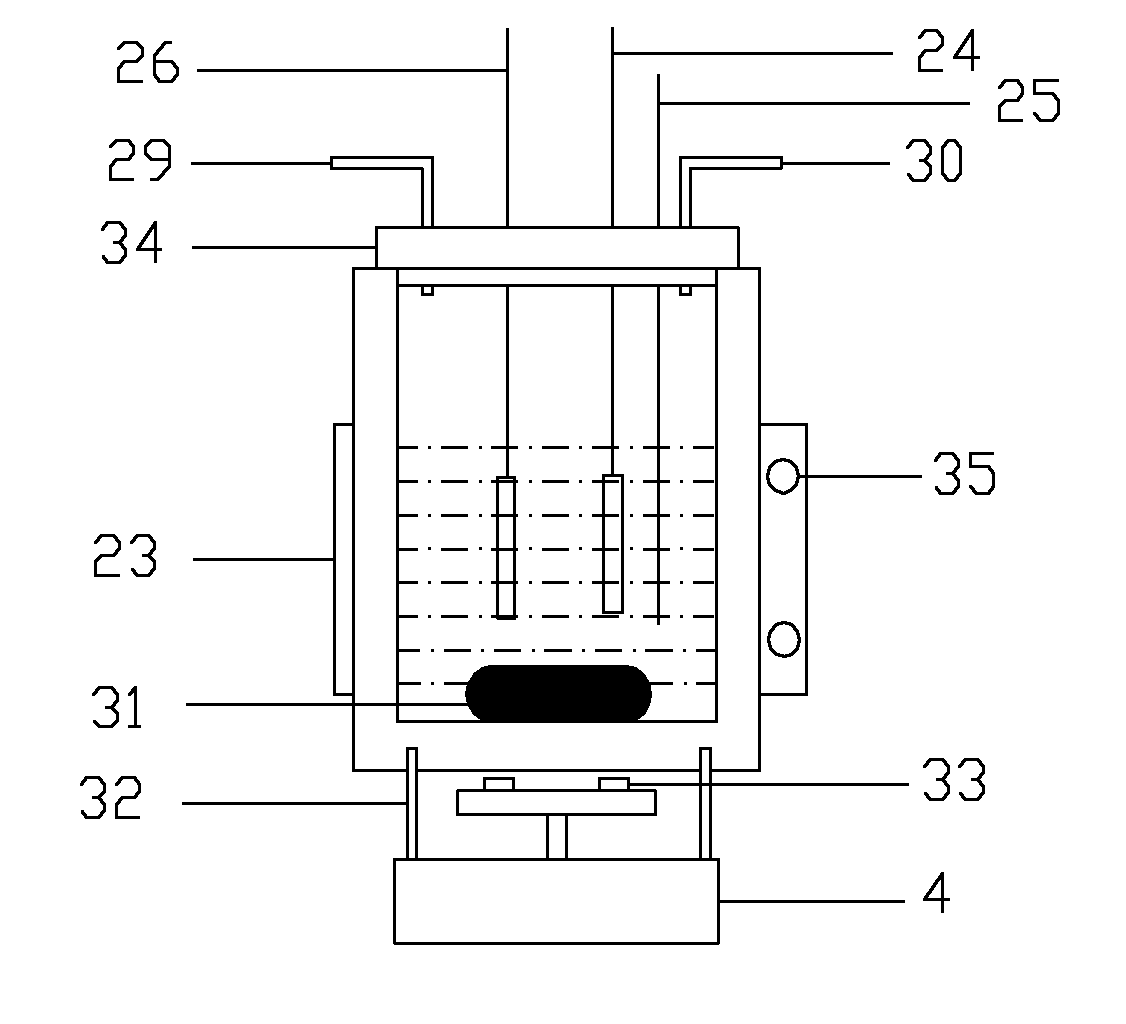

Method used

Image

Examples

Embodiment 1

[0037] Utilize the hypergravity device described in the present invention, in AlCl 3 The experiment of electrodepositing aluminum was carried out in the ionic liquid with the molar ratio of TMPAC and TMPAC being 2:1. First, under the protection of high-purity argon, at a temperature of 60°C, accurately weighed anhydrous AlCl 3 Add it to TMPAC several times in small amounts, and stir at 80°C for 2-3 hours after the addition to obtain an ionic liquid. Then, the ionic liquid is used as the electrolyte, the copper sheet is used as the cathode, and the aluminum-based composite material is used as the anode. The two electrodes are placed parallel to the direction of the centrifugal force, the distance between the cathode and the anode is fixed at 1.5 cm, and the electrodeposition time is fixed at 2 hours. Effects of density, temperature and rotational speed on electrodeposition experiments.

[0038] Before the experiment started, the pretreatment process of the electrode sheet was...

example 2

[0044] Utilize the hypergravity device described in the present invention, in AlCl 3 The experiment of electrodepositing aluminum was carried out in the ionic liquid with the molar ratio of BMIC and BMIC being 2:1. The ionic liquid was first synthesized by the experimental method in Example 1. In the experiment, a copper sheet was used as the working electrode, and an aluminum-based composite material was used as the counter electrode. The treatment method of the electrode sheet and the deposited material obtained after the electrodeposition were all adopted the method in Example 1. The electrodes were weighed with an electronic balance before and after deposition.

[0045] At a temperature of 80°C, an electrodeposition time of 2h, and a current density of 11mA / cm 2 , AlCl 3 The electrodeposition experimental conditions and experimental conclusions carried out in the ionic liquid with a molar ratio of BMIC of 2:1 are as follows:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com