Method of removing impurity element copper in crude lead through supergravity

A technology of impurity elements and supergravity, which is applied in the field of crude lead refining, can solve the problems of long operation time, complicated process route, metal lead waste, etc., achieve the effect of reducing waste and environmental pollution, simple process flow, and suitable for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

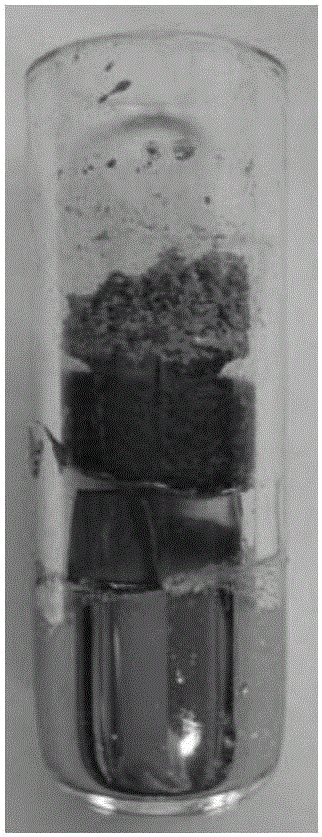

[0041] In actual industrial production, the content range of copper impurities is 0.6-3.25wt%. Pure Cu (copper) is melted to prepare Pb-Cu binary crude lead, and the method of the present invention is applied to the above-mentioned Pb-Cu binary crude lead to process it.

[0042] In this embodiment, the commercially pure Pb used may be any metal Pb material known to those skilled in the art, and there is no special requirement. For example, the metal Pb block used can be commercially pure Pb block purchased from Beijing Cui Platinum Nonferrous Metals Technology Development Center, with a purity of 99.99%.

[0043] The industrially pure Cu used may be any industrially pure Cu material known to those skilled in the art, and there is no special requirement. For example, the industrially pure Cu used may be an industrially pure Cu block purchased from Beijing Cuibolin Nonferrous Metals Technology Development Center, with a purity of 99.99%.

[0044] In the preparation of Pb-Cu bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com