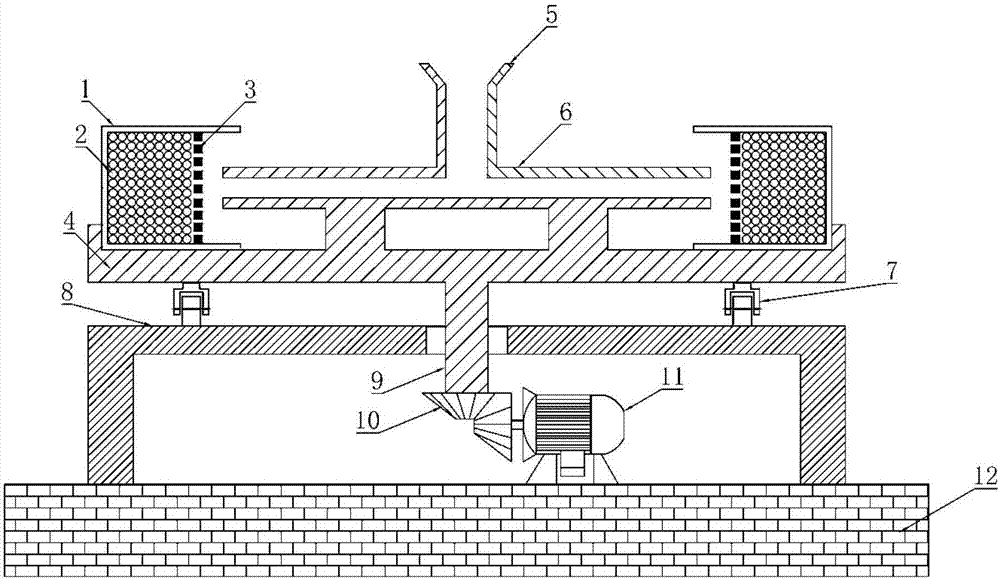

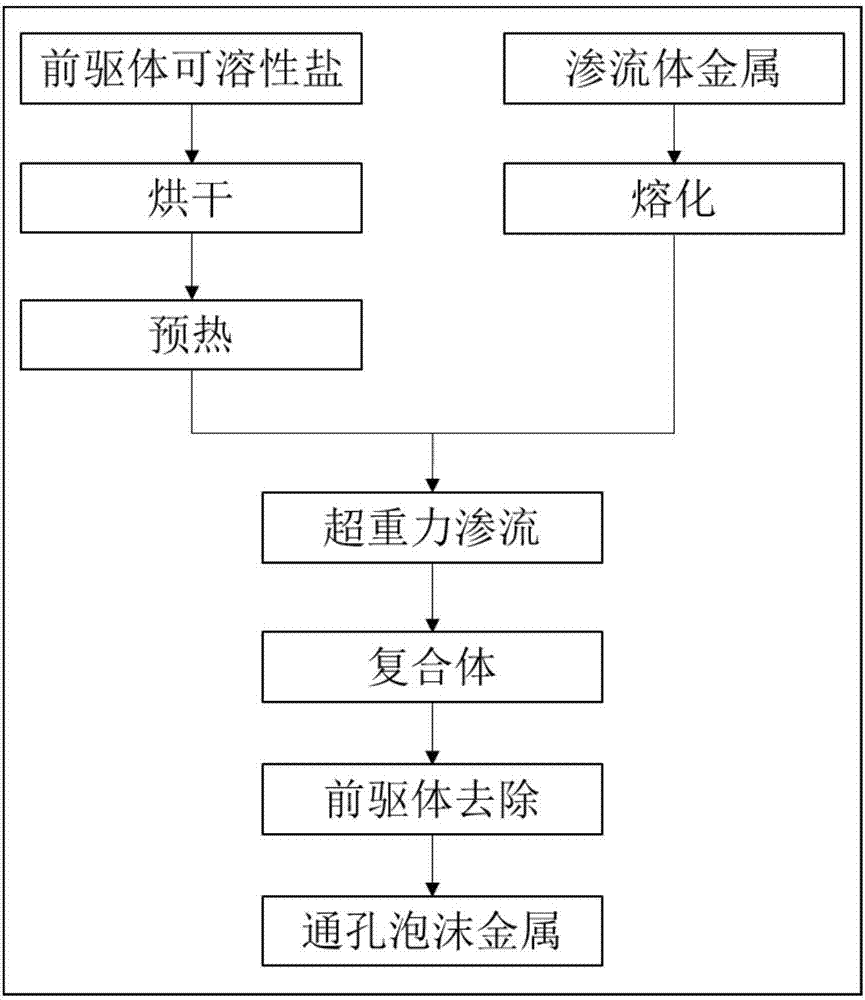

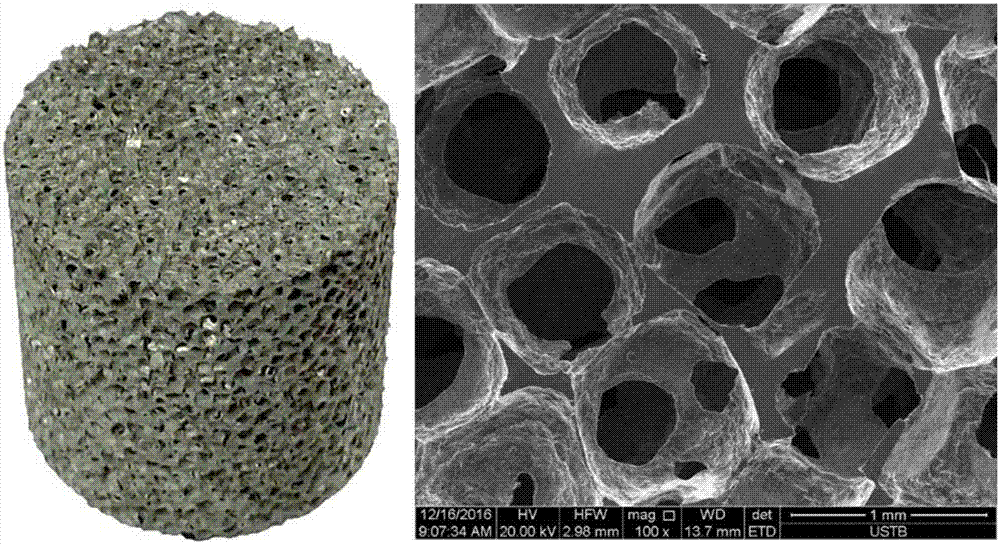

Method and device for preparing porous foam metal through super-gravity seepage

A metal foam and ultra-gravity technology, applied in the field of metal foam materials, can solve the problems of difficult removal of gypsum, difficult operation, and easy formation of depressions, etc., to achieve the effect of maintaining product shape, excellent mechanical properties, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Sodium chloride particles with a weight of 110 kg and an average particle size of 1 mm are respectively packed into two cubic centrifugal molds with a length, width and height of 0.5 m, and a commercially available porous ceramic plate with a thickness of 5 mm is fixed on the top, and the centrifugal The mold is preheated to 500°C;

[0026] Melt the Al6061 aluminum alloy weighing 190kg and keep the temperature at about 750°C;

[0027] Then install and fix the two centrifugal casting molds symmetrically on a centrifugal platform with a diameter of 2m, turn on the centrifugal equipment, adjust the rotation speed so that the supergravity coefficient of the precursor reaches more than 50, and then pour the aluminum alloy liquid into the hopper of the centrifugal equipment, and the aluminum alloy Under the action of centrifugal pressure, the liquid passes through the feeding tube and penetrates into the gap of the precursor through the porous ceramic plate. After centrifugin...

Embodiment 2

[0030] Put sodium sulfate particles with a weight of 140kg and an average particle size of 0.2mm into four cuboid centrifugal casting molds with a width and height of 0.5×0.5×0.7m, and place a layer of 2mm-thick porous stainless steel plate on the top, and use an electric furnace to separate the centrifuge The mold is preheated to about 600°C;

[0031] Melt ZA-8 zinc alloy weighing 400kg and keep it at about 580°C;

[0032] After that, the four centrifugal casting molds were symmetrically installed and fixed on the centrifugal platform with a diameter of 2m, the centrifugal equipment was turned on and the rotating speed was adjusted to make the supergravity coefficient of the porous plate reach more than 180, and then the zinc alloy liquid was poured into the hopper of the centrifugal equipment, and the zinc alloy Under the action of centrifugal pressure, the liquid passes through the feeding tube and penetrates into the gap of the precursor through the porous stainless steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com