Method and device for achieving low-temperature quick separating of metallic copper in copper slag through supergravity

A supergravity, metal copper technology, applied in the direction of improving process efficiency, can solve the problems of high viscosity of slag, high interfacial tension between slag and gold, poor fluidity, etc., and achieve the effect of improving separation efficiency, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Rapid separation of metal copper from copper slag in A copper smelter with high gravity and low temperature:

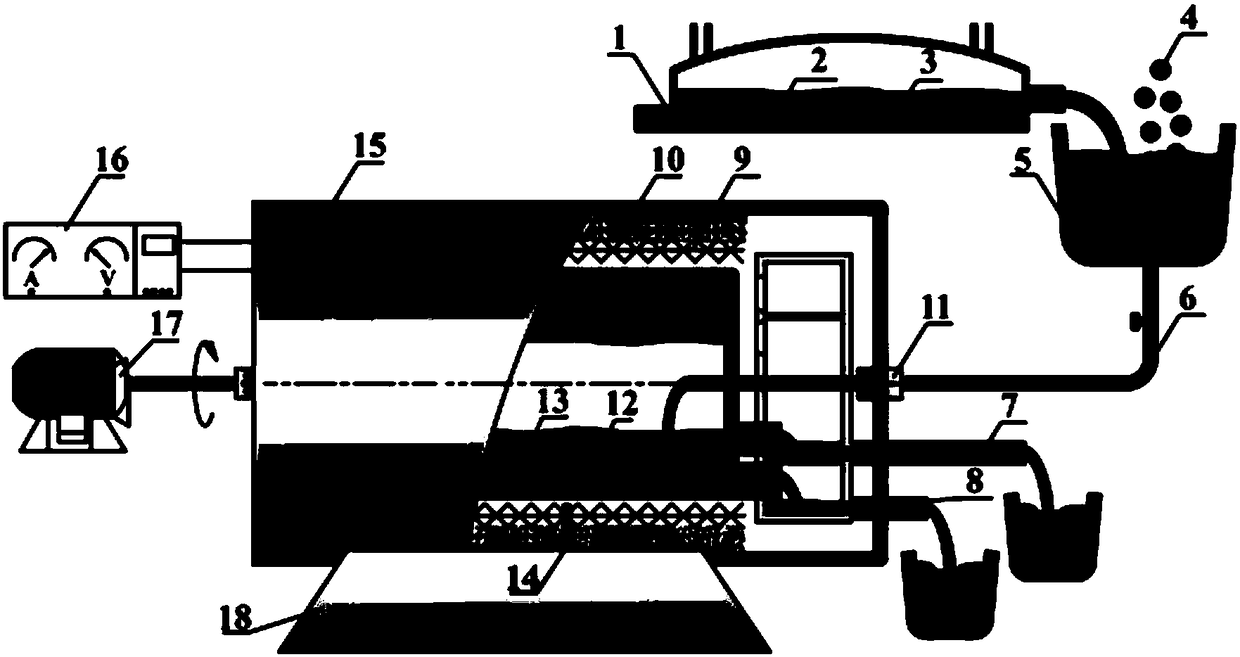

[0021] Take 200kg of copper smelting slag from A copper smelter, first heat it to 1150°C, and 3 o 4 Add 6kg of carbon powder to the slag; then, the copper slag melt is continuously added to the supergravity reactor through the diversion system, and the temperature of the copper slag is controlled to be constant at 1150 °C; then the centrifugal rotation system is turned on, and the supergravity reactor is driven by a motor The reactor is centrifugally rotated, and the gravity coefficient is controlled to be 1000g, and the separation time is 3min. The supergravity generated by the centrifugal rotation drives the reverse migration and separate aggregation between the metal copper and the slag due to the difference in density. After the high-gravity separation was completed, the motor was turned off and samples were taken for analysis. From the macroscopic and mic...

Embodiment 2

[0024] Rapid separation of metal copper from copper slag in copper smelter B by high gravity and low temperature:

[0025] Take 150kg of copper smelting slag from B copper smelter, first heat it to 1250°C, and 3 o 4Add 7.5kg of carbon powder to the slag; then, the copper slag melt is continuously added to the supergravity reactor through the diversion system, and the temperature of the copper slag is controlled to be constant at 1250°C; then the centrifugal rotation system is turned on, and the supergravity reactor is driven by a motor. The gravity reactor performs centrifugal rotation, and the gravity coefficient is controlled to 400g, and the separation time is 5min. The supergravity generated by the centrifugal rotation drives the reverse migration and separate aggregation between the metal copper and the slag due to the difference in density. After the high-gravity separation was completed, the motor was turned off, and samples were taken for analysis. The macroscopic and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com