Method for preparing particle ammonium sulfate product by organic-inorganic binder

A technology of inorganic binder and organic binder, which is applied in the application, ammonium salt fertilizer, nitrogen fertilizer and other directions, can solve the problem of inability to produce large-particle ammonium sulfate, and achieve the improvement of product market competitiveness, simple production process and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Example 1 prepares granular ammonium sulfate with a single organic binder and a single inorganic binder

[0020] Use polyacrylamide with a molecular weight of 12 million as the organic binder, and diammonium phosphate as the inorganic binder, and grind them to 20-200 meshes for later use; use ≤2mm ammonium sulfate crystals (the active ingredients are N: 20.4%, S: 23.58%, H 2 O: 0.8%) is crushed to 20-200 mesh by a pulverizer; the crushed diammonium phosphate and crushed ammonium sulfate are evenly added into the granulator after metering; the organic solvent polyacrylamide solution dissolved in the solvent tank is mixed with the medium The pressure steam is sprayed in the granulator for granulation, the added amount is: the ratio of polyacrylamide to ammonium sulfate is 5:965, the ratio of diammonium phosphate to ammonium sulfate is 30:965; after that, it is sprayed by medium pressure steam Granulation, the granulation temperature is 120℃~160℃; it is dried by two-stage...

example 2

[0021] Example 2 Organic binder mixes with any ratio of inorganic binder to prepare granular ammonium sulfate product

[0022] The procedure is the same as that in Example 1, and the polyacrylamide with a molecular weight of 12 million and polyethylene glycol (PEG600) are mixed in a ratio of 1:1 as an organic binder, dissolved and mixed evenly. Then mix magnesium sulfate monohydrate and diammonium phosphate according to 1:1 or any ratio evenly, control the organic-inorganic binder to account for 1% of the total mass fraction; dissolve and mix evenly and add to the granulator, control the ratio and process operation parameters , to produce qualified granular ammonium sulfate products.

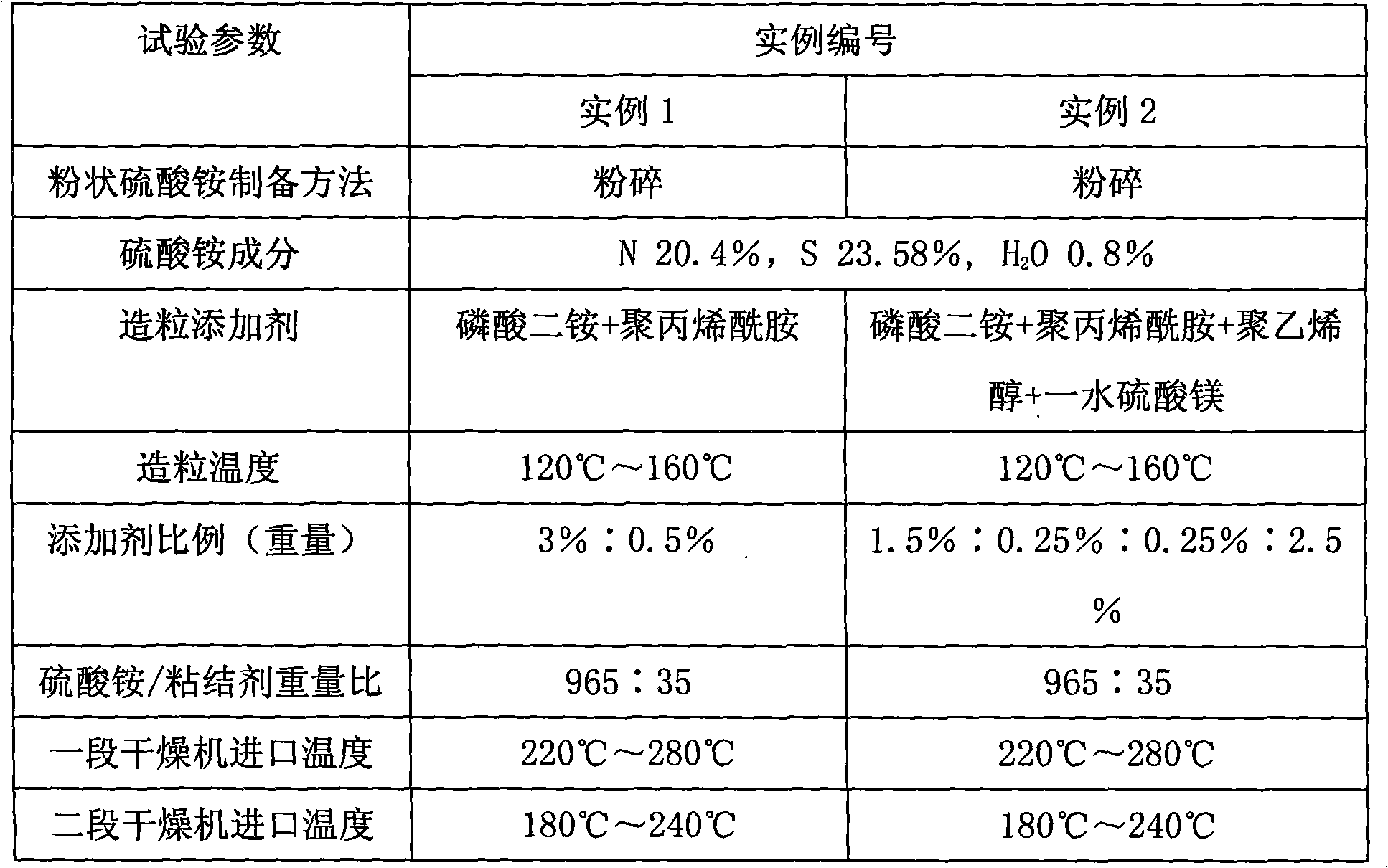

[0023] The following table lists the process parameters and product quality details

[0024] Table 1 list of process parameters

[0025]

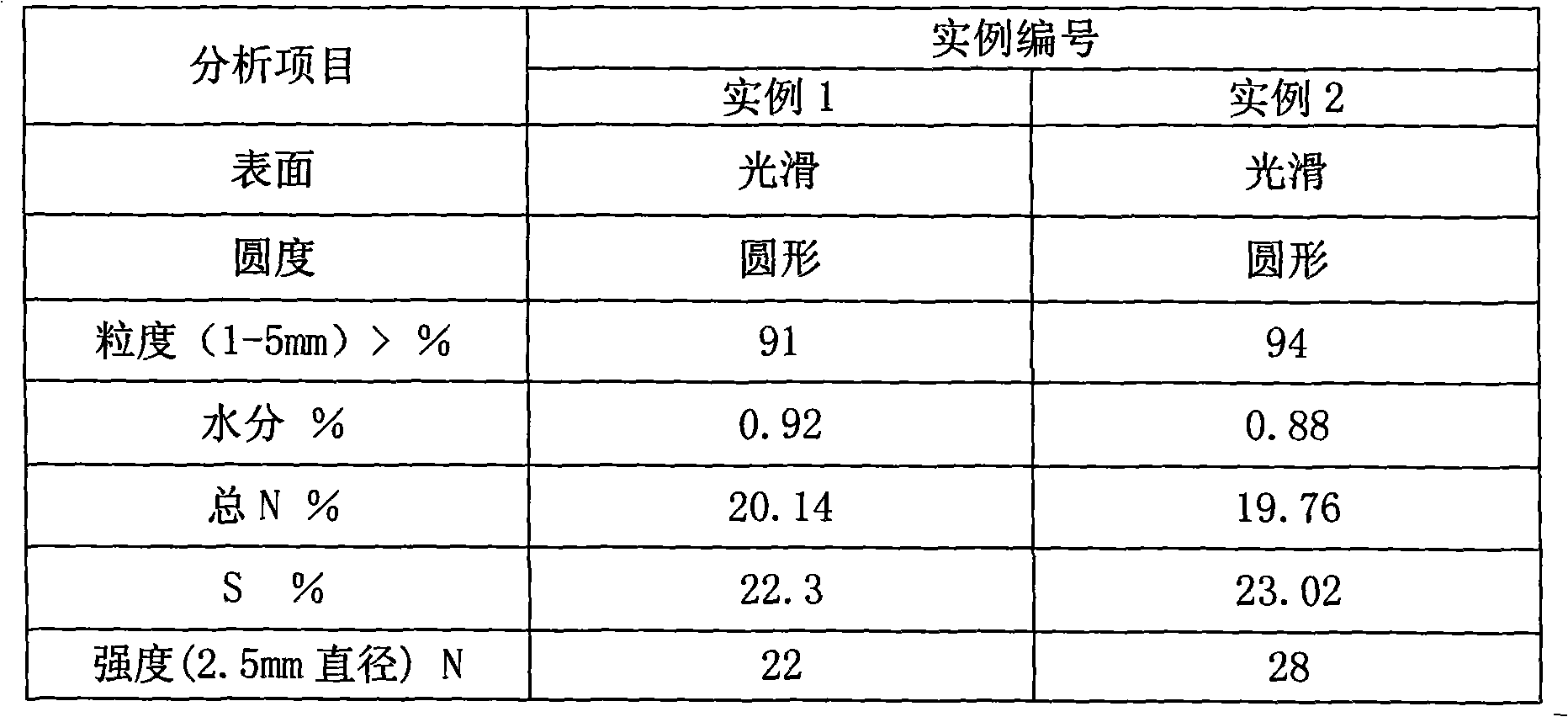

[0026] Table 2 List of final product quality indicators

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com