Method for removing sulfur dioxide in flue gas and preparing magnesium sulfate by utilizing phosphorus floatation tailings

A technology of sulfur dioxide and phosphorus tailings, applied in the direction of magnesium sulfate, chemical instruments and methods, separation methods, etc., can solve problems such as complex operation, high operating costs, and complicated process flow, and achieve high economic benefits, energy saving, and reduction of pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

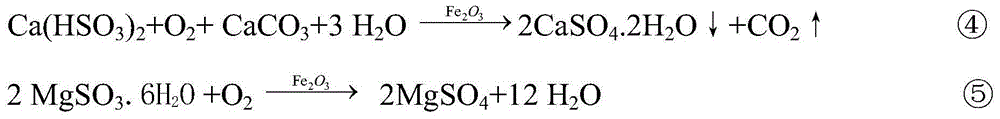

[0022] Use a thickener to thicken the flotation phosphorus tailings into a desulfurization slurry with a liquid-solid mass fraction ratio of 3:1. The main chemical components of the flotation phosphorus tailings are: calcium oxide 35%, magnesium oxide 10.3%, trioxide Fe 0.17% and Al 2 O 0.2% are pumped into the absorption section of the desulfurization tower with a centrifugal pump and the SO in the flue gas is mixed with a spray device. 2 Countercurrent contact mass transfer, reaction to generate magnesium sulfite and calcium sulfite, the desulfurized slurry after reaction is discharged to the oxidation circulation tank, and air is blown into the oxidation circulation tank with a blower at the same time, magnesium sulfite and calcium sulfite are in the tailings Fe 2 o 3 Under the action of catalysis, it is oxidized into magnesium sulfate and calcium sulfate solids. The temperature of the reaction in the oxidation circulation tank is controlled at 30°C and the pH is 4. At th...

Embodiment 2

[0024] Thicken the flotation phosphate tailings with a thickener to form a desulfurization slurry with a liquid-solid mass fraction ratio of 2:1. The main chemical components of the phosphate tailings are: 25% calcium oxide, 24% magnesium oxide, Iron 0.24%, aluminum oxide 0.06%. The absorption section of the desulfurization tower driven into the desulfurization tower by a centrifugal pump adopts a spray device to interact with the SO in the flue gas 2 Countercurrent contact mass transfer, reaction to generate magnesium sulfite and calcium sulfite, the desulfurized slurry after reaction is discharged to the oxidation circulation tank, and air is blown into the oxidation circulation tank with a blower at the same time, magnesium sulfite and calcium sulfite are in the tailings Fe 2 o 3 Under the action of catalysis, it is oxidized into magnesium sulfate and calcium sulfate solids. The temperature of the reaction in the oxidation circulation tank is controlled at 70°C and the pH...

Embodiment 3

[0026] Thicken the flotation phosphorus tailings with a thickener into a desulfurization slurry with a liquid-solid mass fraction ratio of 2.5:1. The main chemical components of the phosphorus tailings are: 40% calcium oxide, 12% magnesium oxide, Iron 0.12%, aluminum oxide 0.21%. The absorption section of the desulfurization tower driven into the desulfurization tower by a centrifugal pump adopts a spray device to interact with the SO in the flue gas 2 Countercurrent contact mass transfer, reaction to generate magnesium sulfite and calcium sulfite, the desulfurized slurry after reaction is discharged to the oxidation circulation tank, and air is blown into the oxidation circulation tank with a blower at the same time, magnesium sulfite and calcium sulfite are in the tailings Fe 2 o 3 Under the action of catalysis, it is oxidized into magnesium sulfate and calcium sulfate solids. The reaction temperature of the oxidation circulation tank is controlled at 50°C and the pH is 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com