Apparatus and method for producing potassium chloride and co-producing magnesium sulfate by mixing brine

A magnesium sulfate and potassium chloride technology, applied in the direction of magnesium sulfate, alkali metal chloride, etc., can solve the problem of no comprehensive utilization of mother liquor, and achieve the effects of reducing steam consumption, optimizing production process, and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

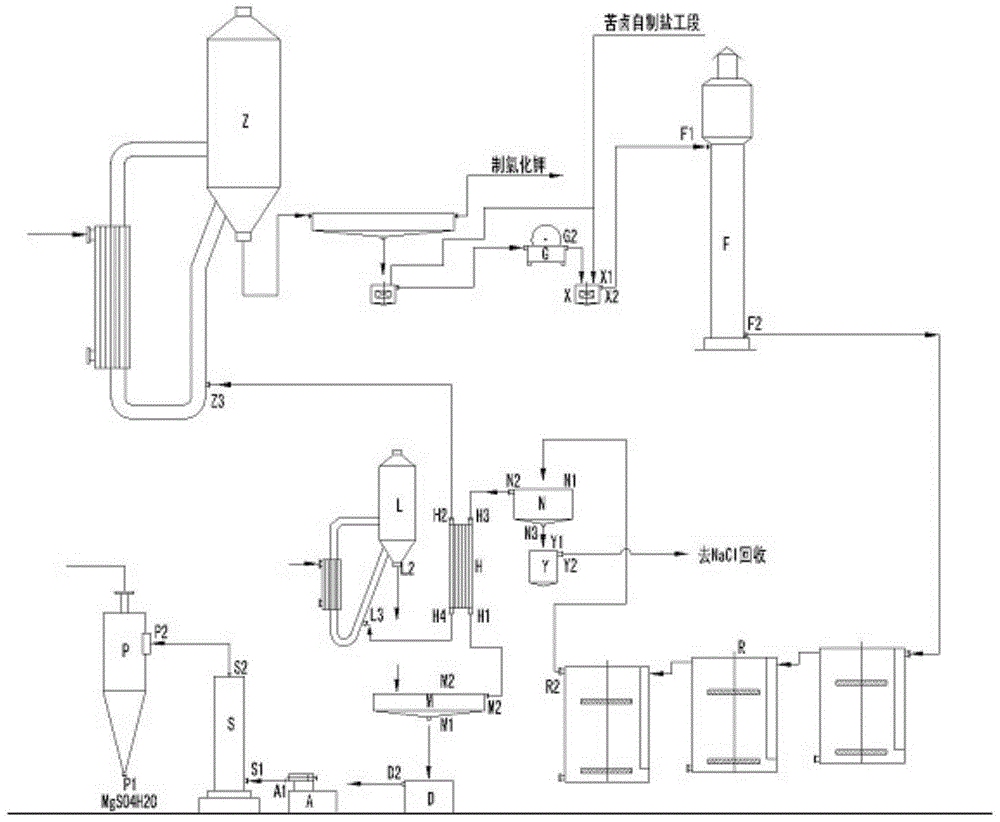

Method used

Image

Examples

example 1

[0047] Get 1000 kilograms of concentration and be the refining salt four-effect bittern of 31.3 degrees Baume, it is composed of: magnesium sulfate: 91.5g / l magnesium chloride: 161.0g / l potassium chloride: 32.0g / l sodium chloride: 105.0g / l , add 70 kilograms of high-temperature salt filter cakes, the initial mixed bittern solution is turbid, and the temperature is 43 degrees. Stirring continued for 95 minutes, and the solution bittern was transparent, indicating that the magnesium sulfate monohydrate was completely dissolved. The temperature of bittern is 28 degrees, and the concentration is 32.6 Baume degrees. Take the clarified liquid for analysis, magnesium sulfate: 115.0g / l magnesium chloride: 161.8g / l potassium chloride: 34.5g / l sodium chloride: 88.0g / l. After vacuum filtration, 42 kg of solid-phase sodium chloride was separated, and the bittern potassium, magnesium, and sulfate radicals after dissolving high-temperature salt all had a large increase. In addition to the...

example 2

[0049] Get 1000 kilograms of concentrations and be 29.1 Baume degrees normal temperature salt-making bittern, it consists of: magnesium sulfate: 73.9g / l magnesium chloride: 133.2g / l potassium chloride: 27.5g / l sodium chloride: 120.5g / l. Add 80 kg of high-temperature salt, and continue to stir for 110 minutes. The magnesium sulfate monohydrate is completely dissolved, and the solution concentration is 32.2 degrees Baume. Take the clarified liquid for analysis, magnesium sulfate: 109.0g / l magnesium chloride: 142.5g / l potassium chloride: 29.7g / l sodium chloride: 86.5g / l. 23.5 kilograms of solid-phase sodium chloride were separated out. Mother liquor composition after freezing is identical with example 1. The effect of bittern in dissolving high-temperature salt is obvious.

example 3

[0051] Get 1000 kilograms of concentration and be the normal temperature salt bittern of 28.3 degrees Baume, it is composed of: magnesium sulfate: 62.1g / l; Magnesium chloride: 110.2g / l; Repone K: 20.2g / l; Sodium chloride: 155g / l l. Add 95 kg of high-temperature salt, and continue to stir for 115 minutes until the magnesium sulfate monohydrate is completely dissolved, and the solution concentration is 31.2 degrees Baume. Take the clarified liquid for analysis, magnesium sulfate: 99.6g / l; magnesium chloride: 131.8g / l; potassium chloride: 23.8g / l; sodium chloride: 128.5g / l. 31 kilograms of sodium chloride were precipitated in solid phase. Magnesium sulfate composition is identical with example 1 in the mother liquor component after freezing. The concentration of bittern increases, and the effect of salting out is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com