Patents

Literature

94results about How to "Continuous stable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tubular pyrohydrolysis treatment method and device for sludge

InactiveCN101979349AShorten spin timeEffectively control pH5-7 valueSludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeHydrolysis

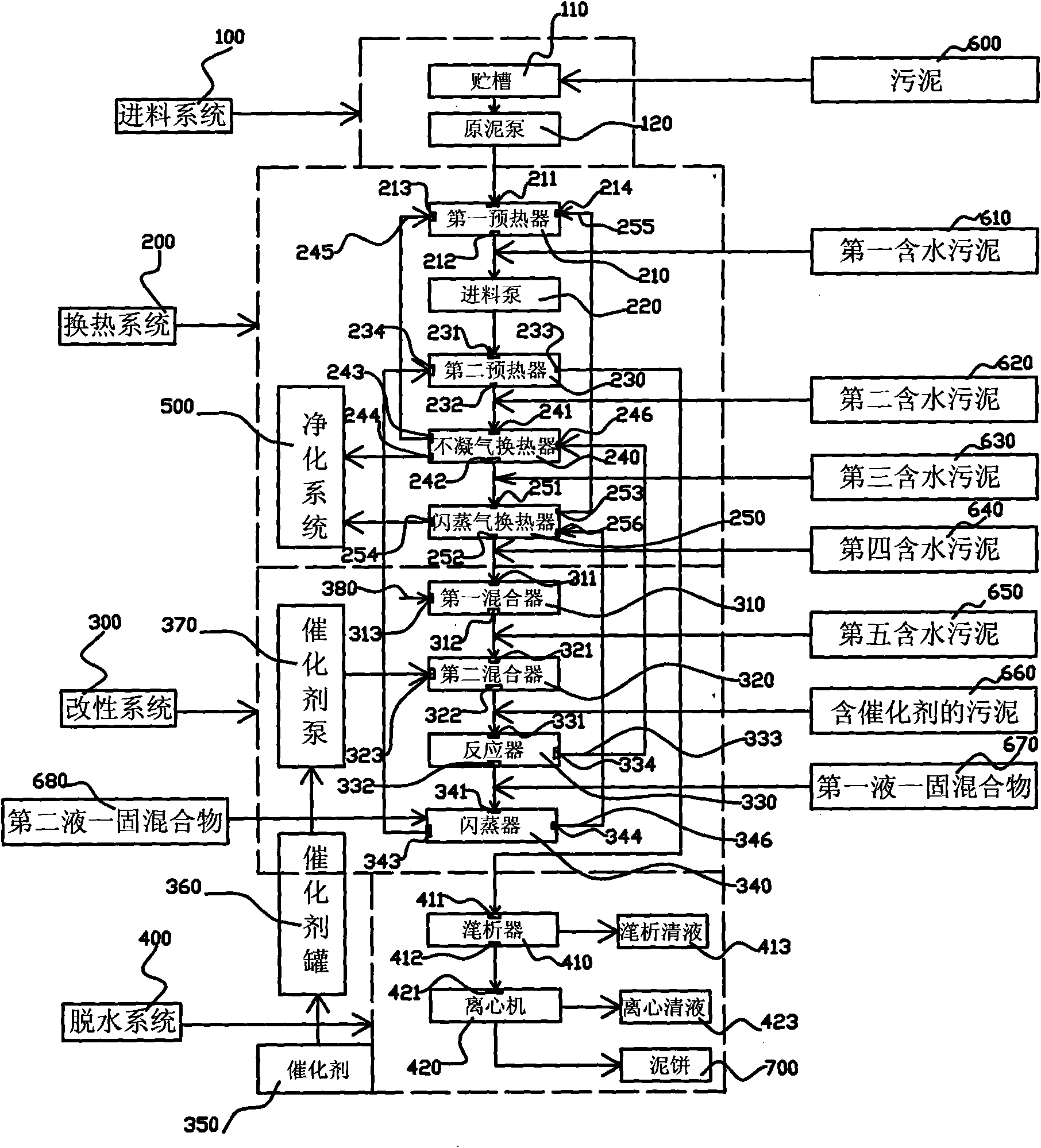

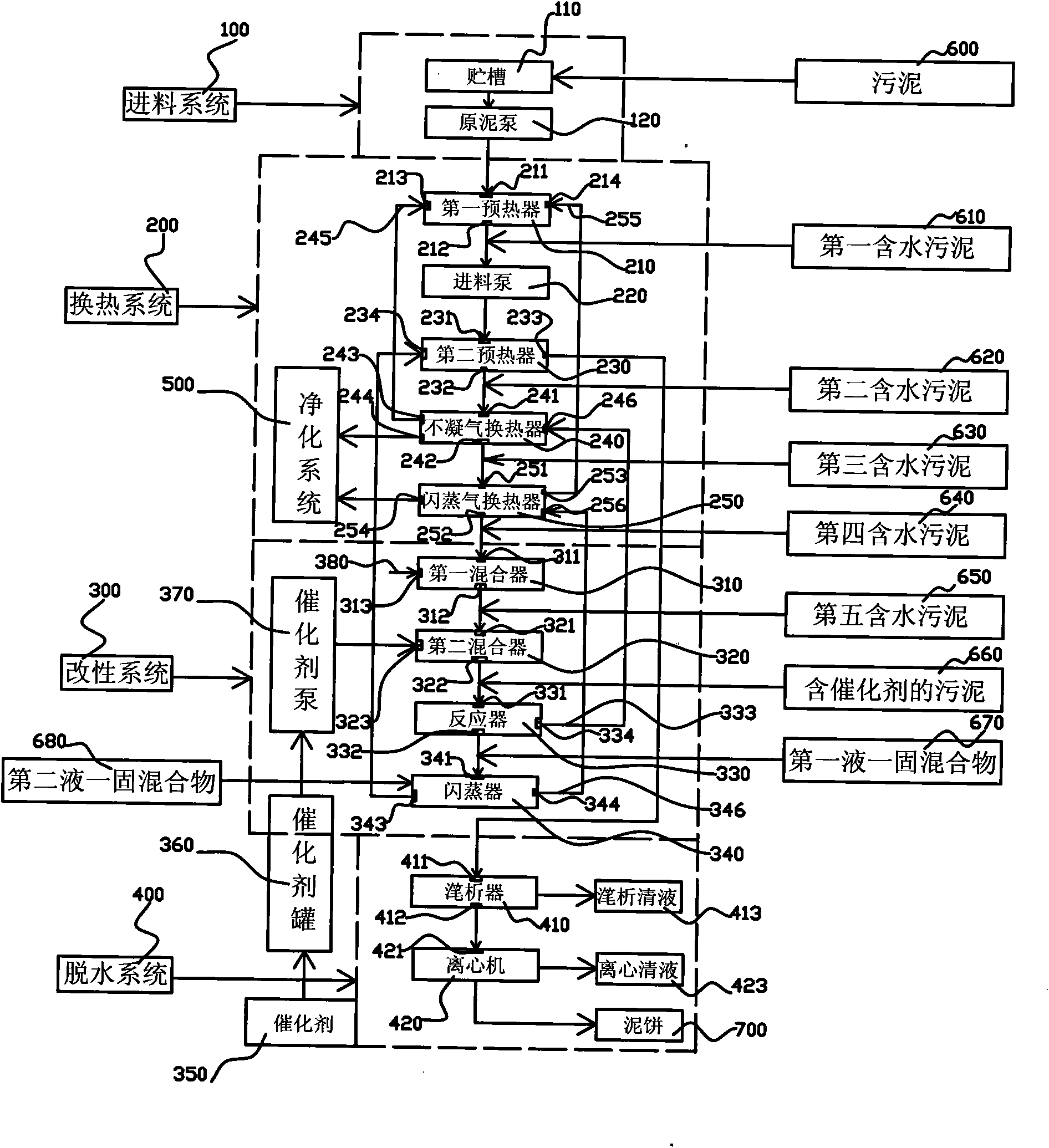

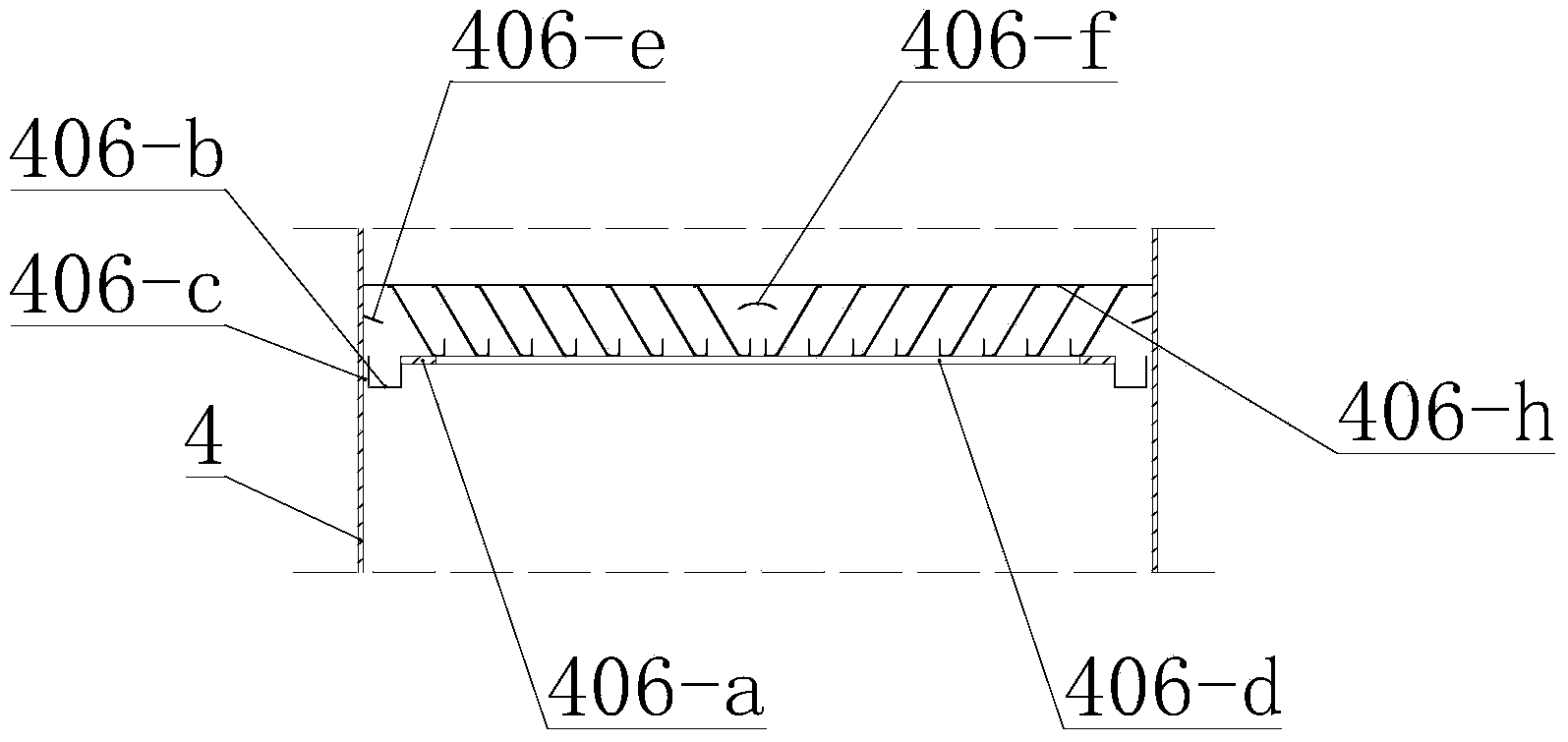

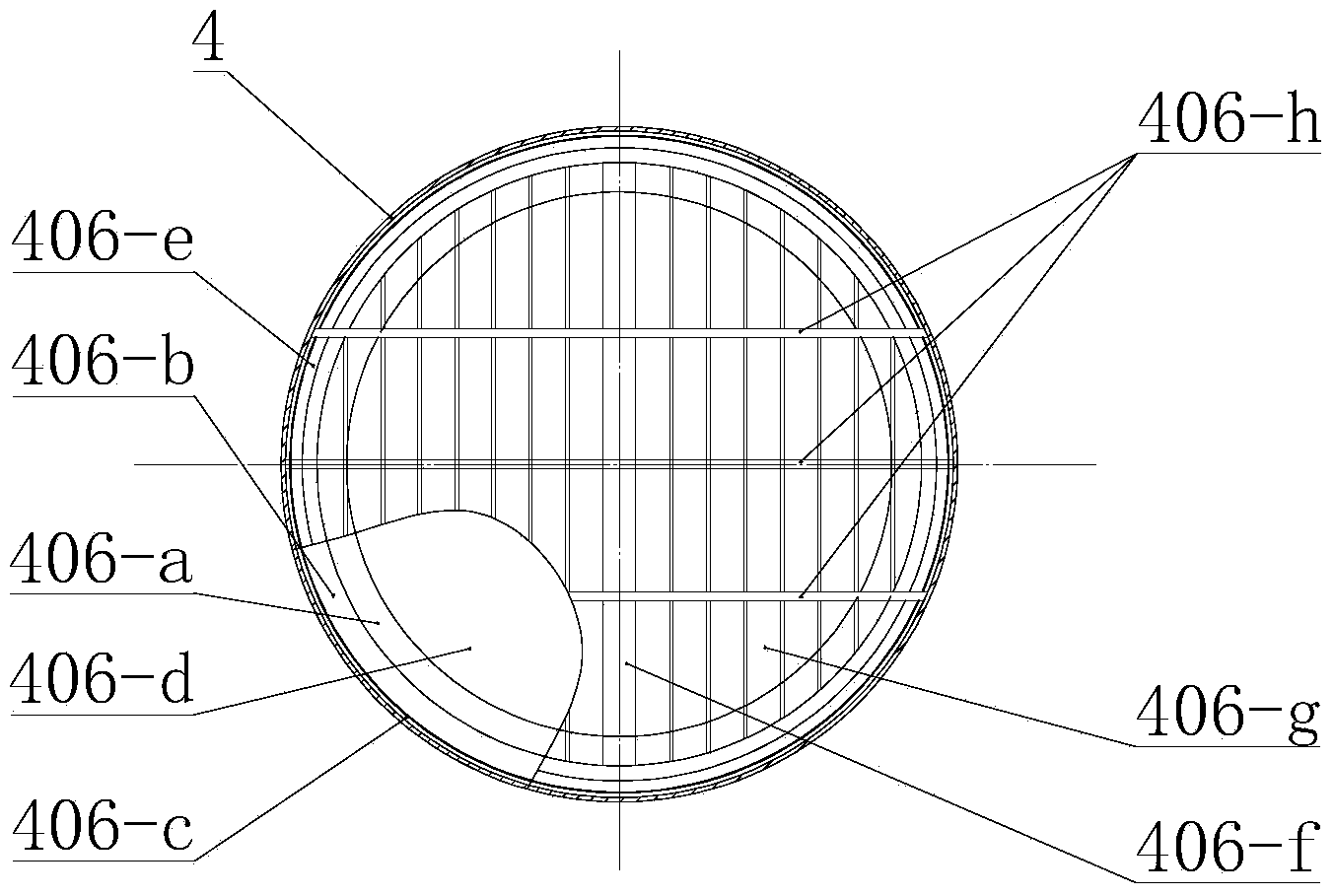

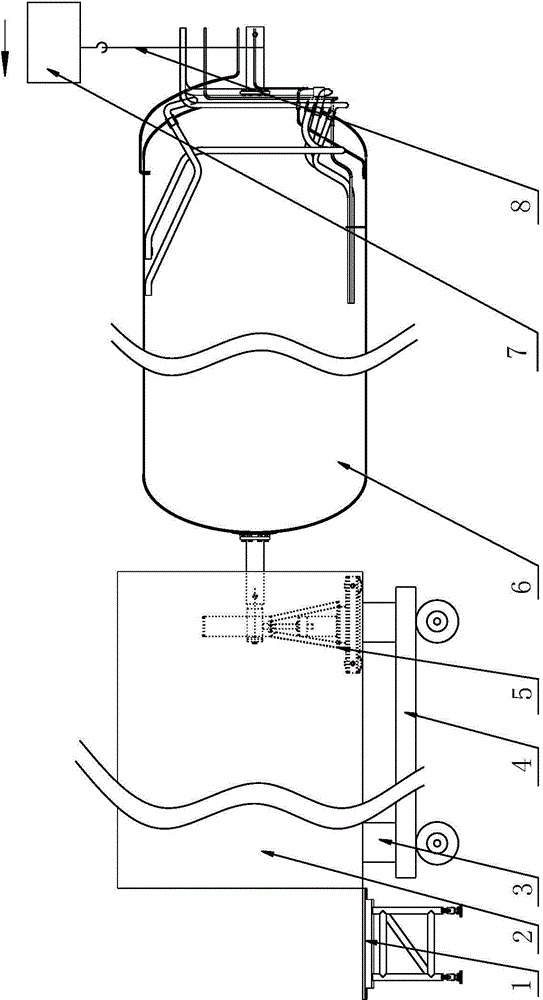

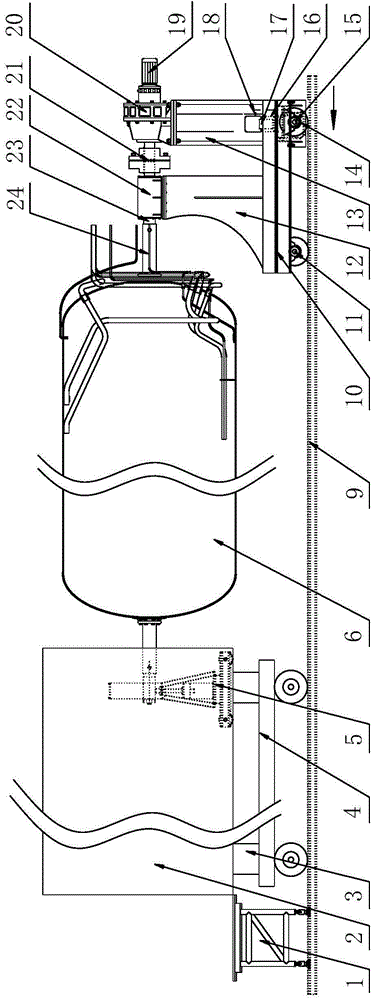

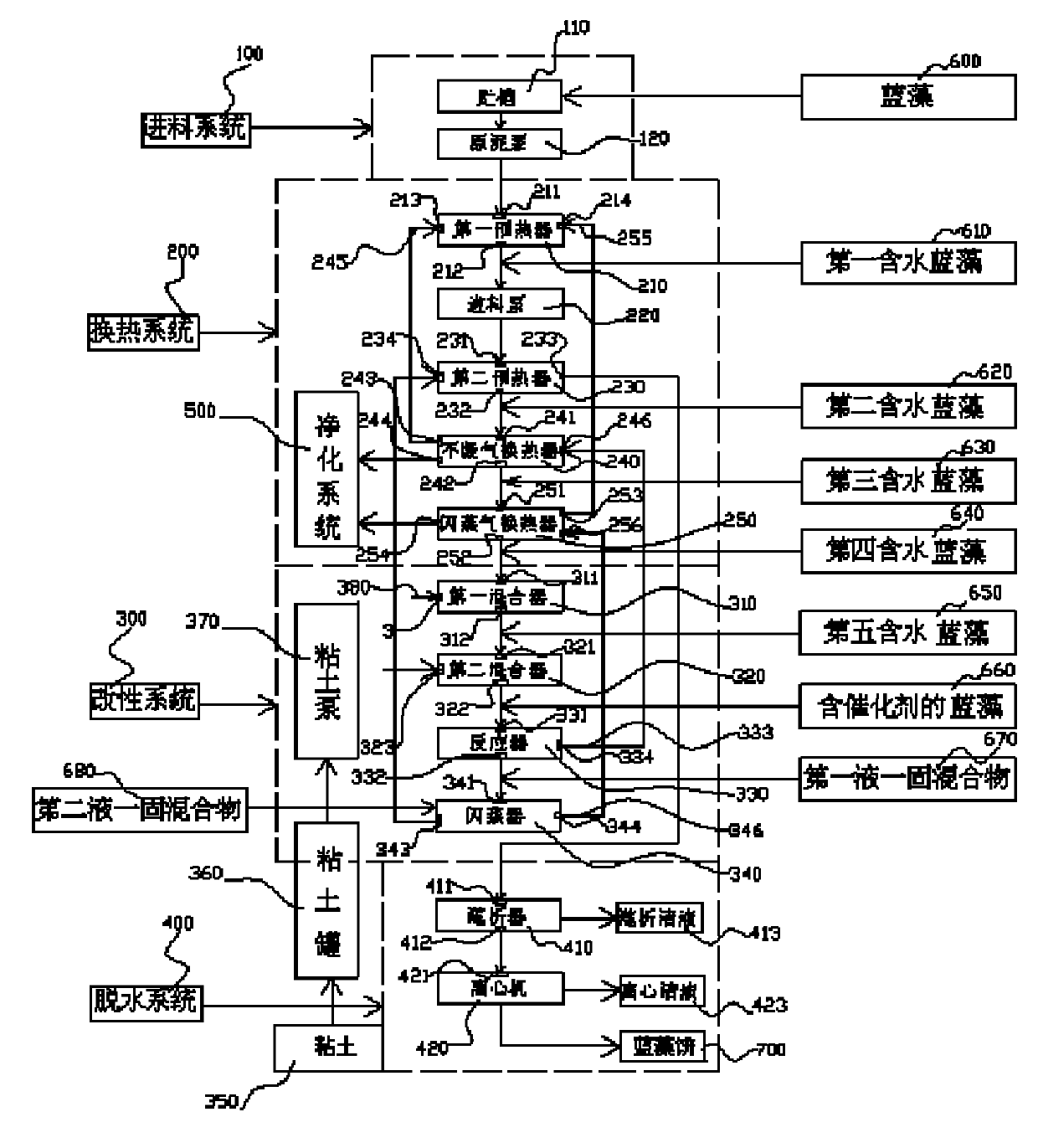

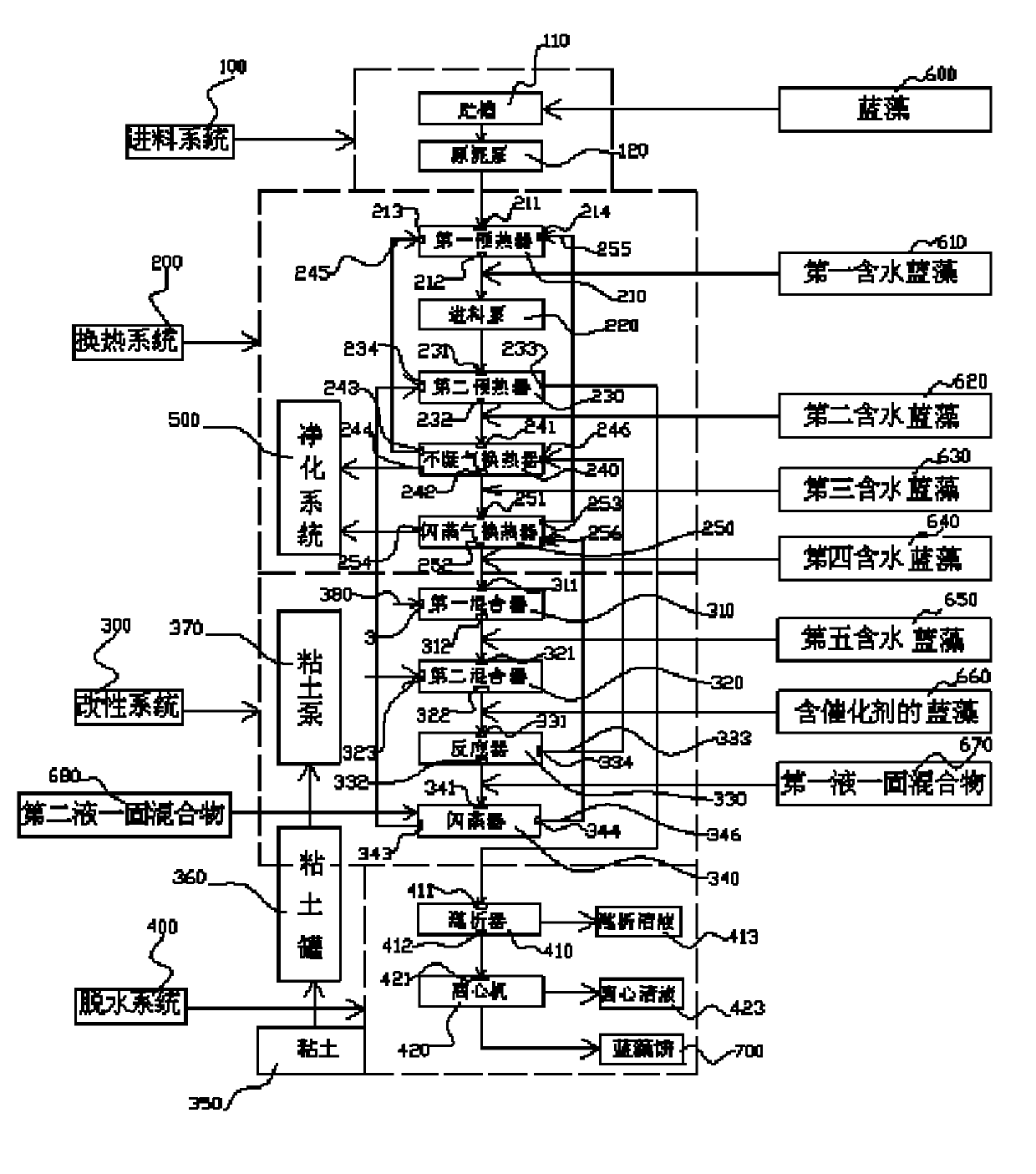

The invention provides a tubular pyrohydrolysis treatment method and device for sludge. The device consists of five main systems, namely a feeding system, a modification system, a dehydration system, a heat exchange system, and a purification system; and by adopting a catalyst injecting mode, the sludge is directly heated with medium pressure steam and is subjected to pyrohydrolysis at medium temperature, the remaining heat in the hydrolysis process is fully recycled, and a liquid-solid mixture is obtained, so not only supports of controllable components are provided for a compound fertilizer, but also a filter cake which is subjected to liquid-solid separation has an adjustable moisture content, namely the moisture content of the raw sludge can be reduced to 40 to 60 percent from about 80 percent. Compared with the prior art, the device has the advantages that: the structure is simple, the device can be continuously and stably operated, the sludge pyrohydrolysis temperature is 210 to 250 DEG C, the reaction time is 10 to 20 minutes, the reduction and harmless treatment of the sludge can be economically, quickly and effectively achieved, the sludge can be treated on a large scale, and a novel approach is provided for the sludge treatment and the energy recycling of equipment.

Owner:安徽合协生态环境科技有限公司

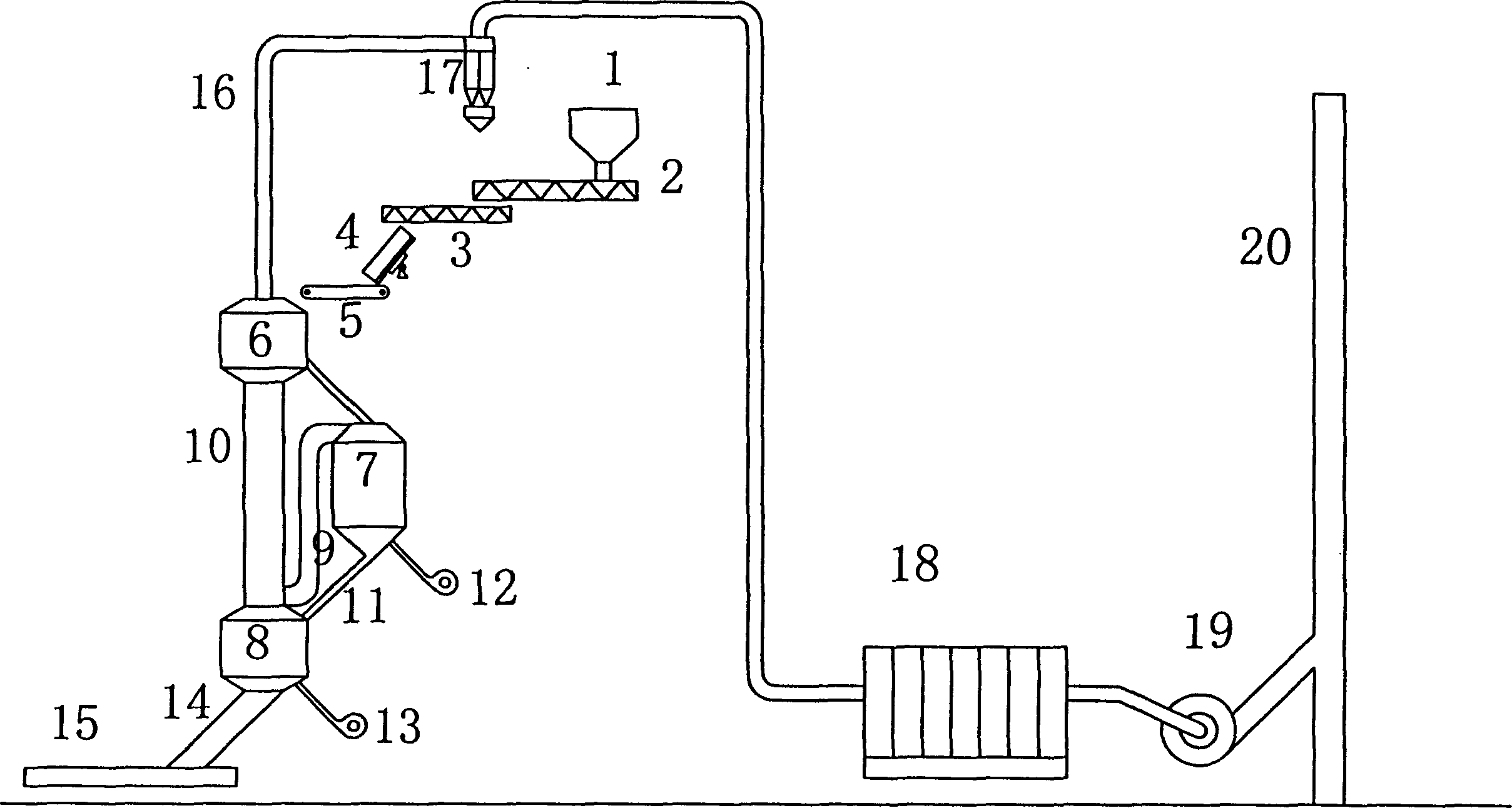

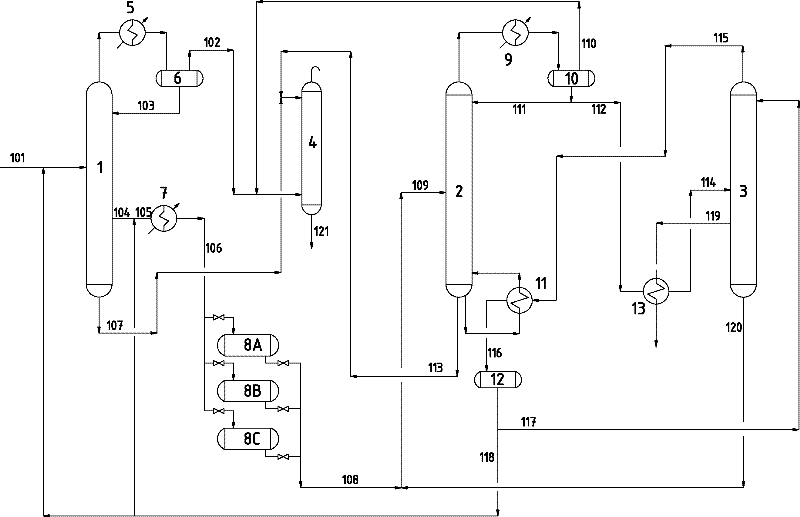

Novel fluidized bed semicoke production system and process thereof

ActiveCN101760222AFluidizing air volume is smallReduce areaDirect heating destructive distillationCoal tarPyrolysis

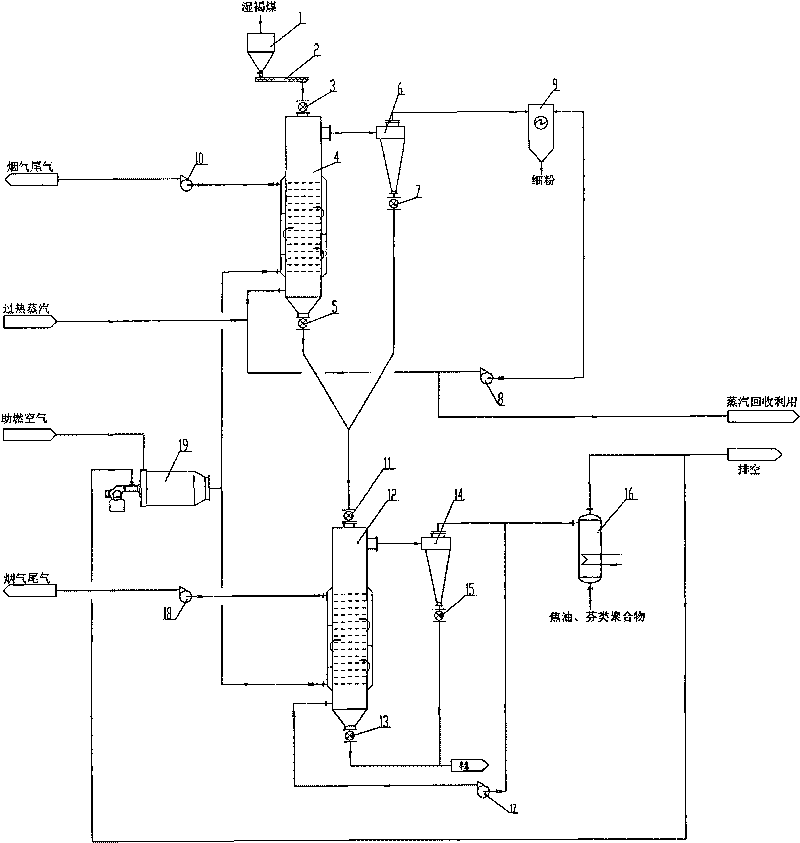

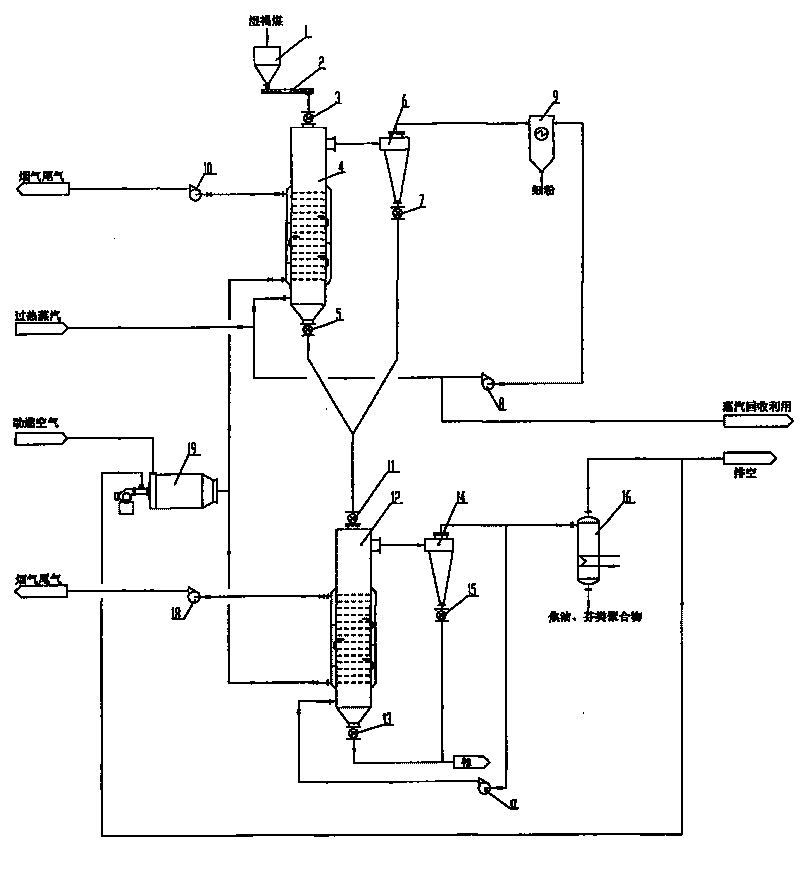

The invention discloses a novel fluidized bed semicoke production system and a process thereof. The novel fluidized bed semicoke production system comprises a drying system and a dry distillation system, wherein the feed end of the drying system is connected with a feeding device, the tail gas of the drying system is reclaimed after passing through at least one stage of drying and dust removing device, and the drying system is connected with a heat source; both the discharge end of the drying system and the discharge end of the drying and dust removing device are connected with the feed end of the dry distillation system; and after passing through at least one stage of dust removing device, one path of the pyrolysis gas of the dry distillation system is used as the fluidizing medium of the dry distillation system for closed circulation, one part of the other path passing through at least one stage of condensing device is evacuated, the other part is burnt and then used as the heat source of the system, and the discharge end of the dry distillation system is connected with a finished product area. After lignite is processed and upgraded by adopting the technology, low-temperature semicoke as solid fuel and low-temperature coal tar as a derivative with good stability, low sulfur content and high heat value can be produced. Meanwhile, the novel fluidized bed semicoke production system has high heat utilization ratio, no environment pollution and high comprehensive utilization level of resources, can be continuous and stable to operate and realizes large-scale production.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

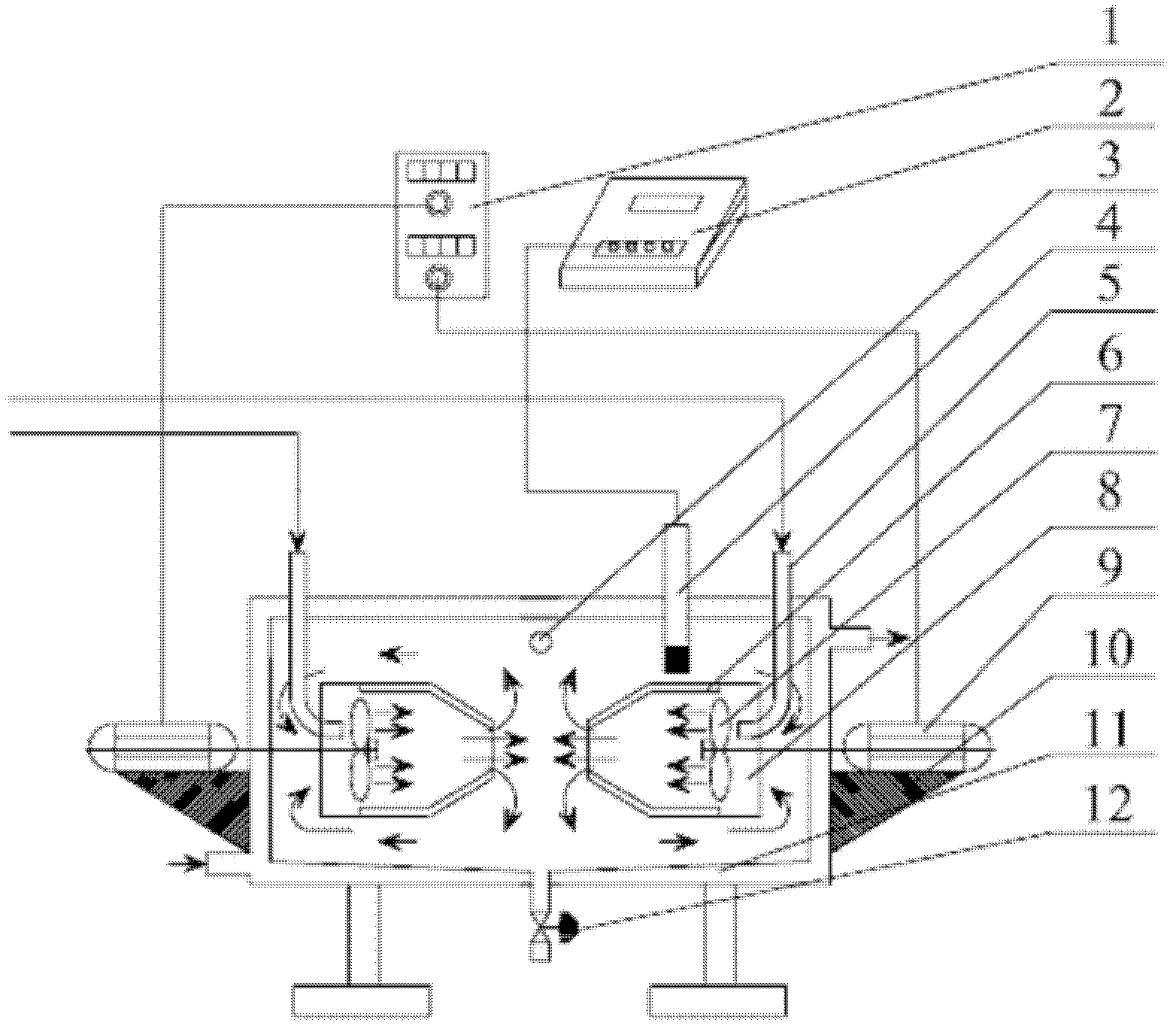

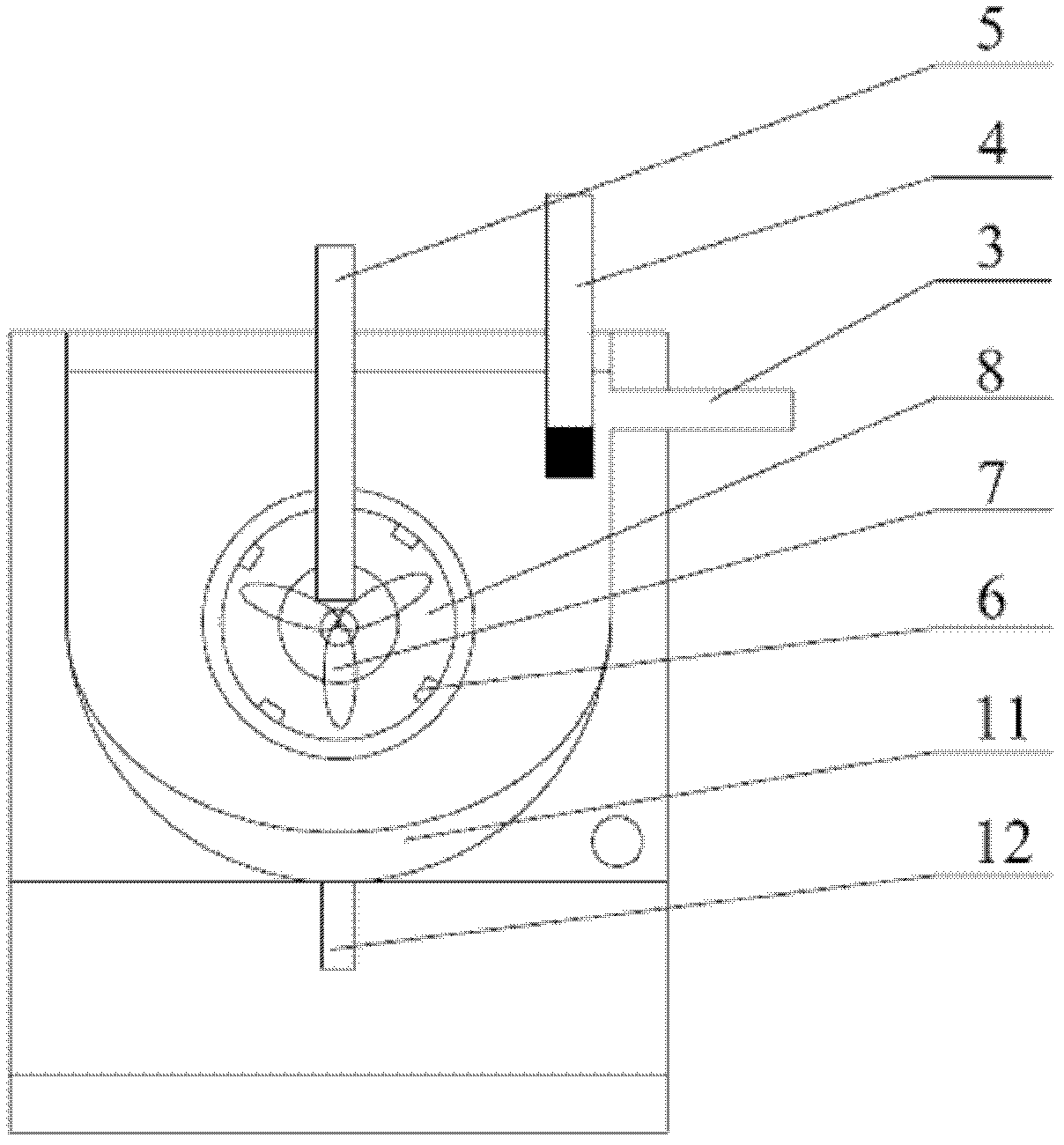

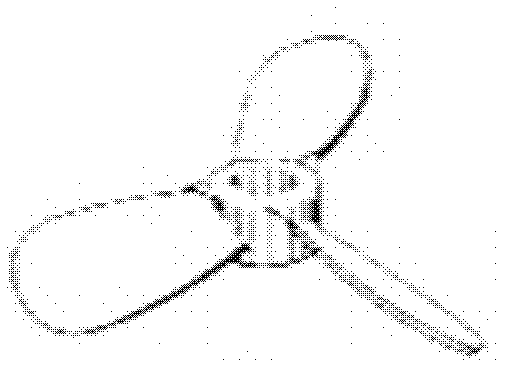

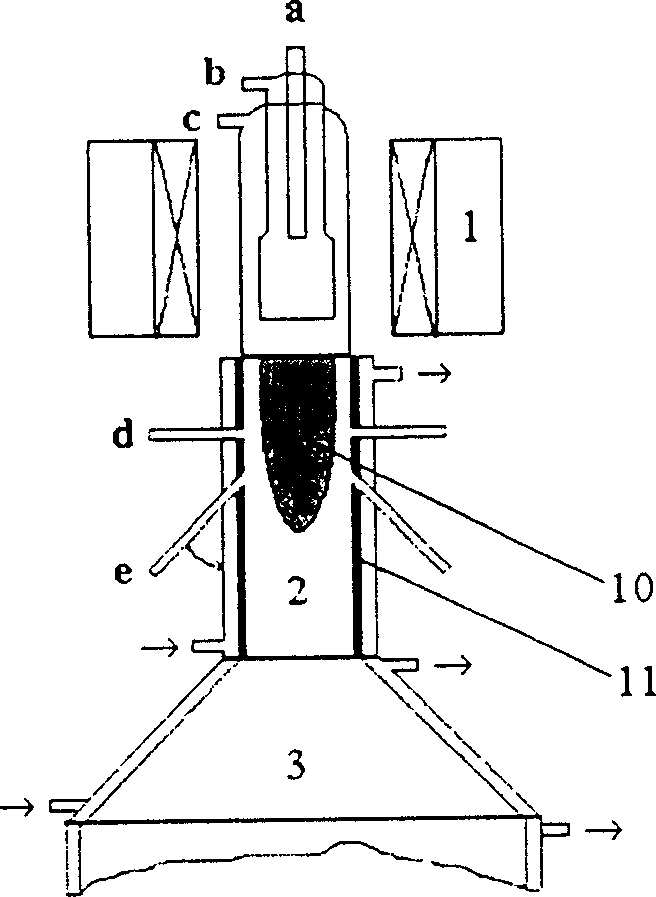

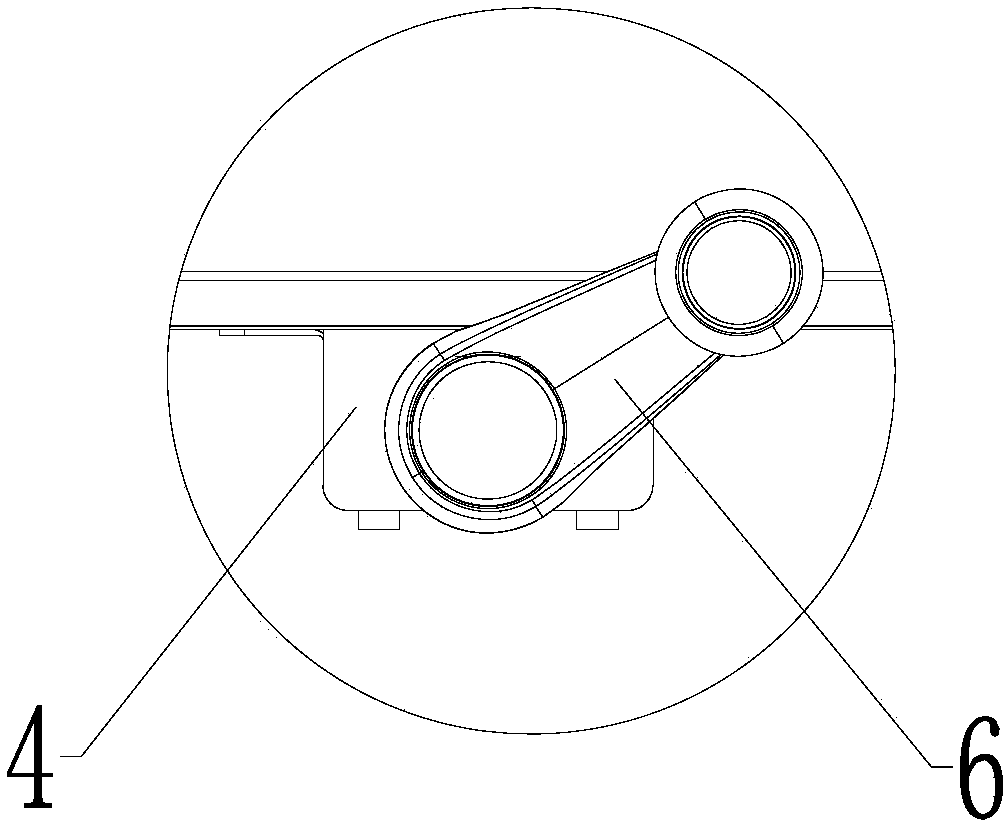

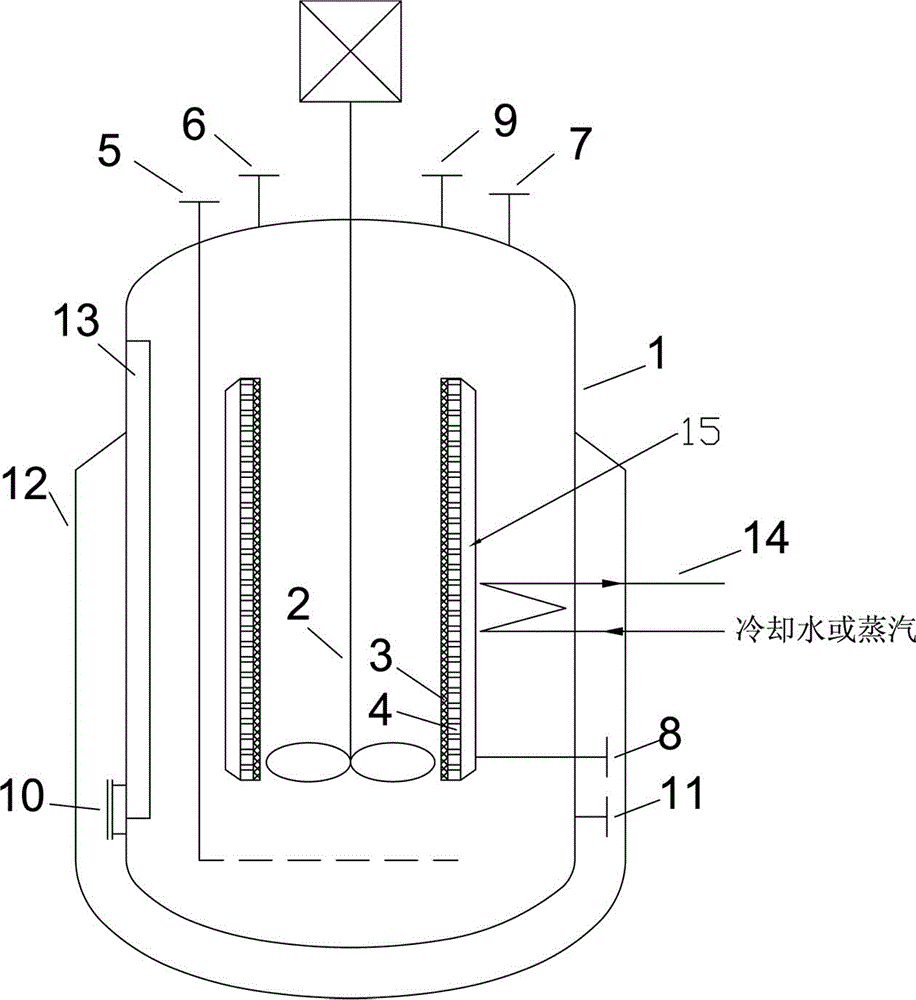

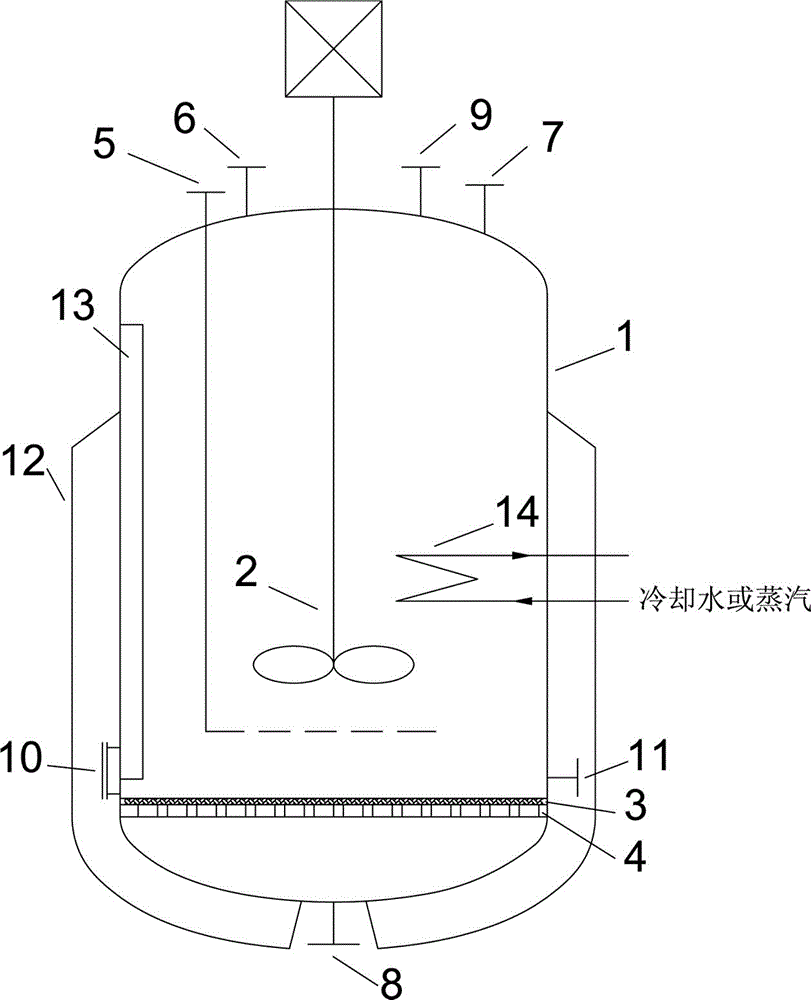

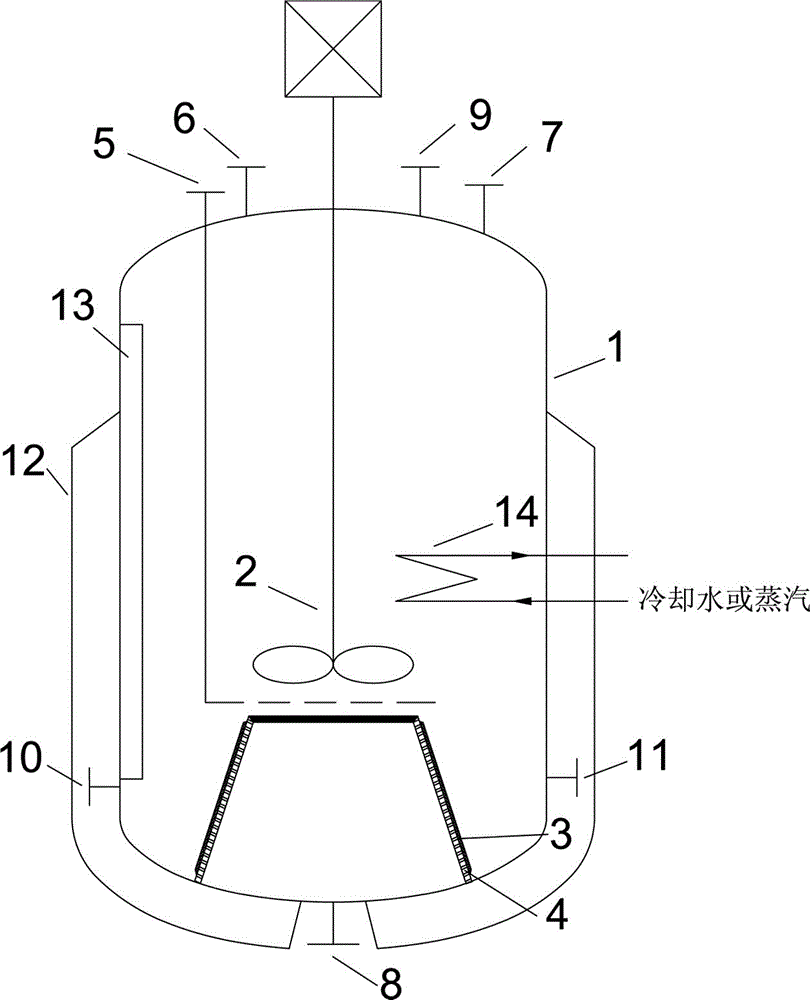

Liquid phase impinging stream reactor with controllable acidity

ActiveCN103203213AIncrease impact speedSuppress swirlChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

The invention discloses a liquid phase impinging stream reactor with controllable acidity, belonging to the field of chemical reaction technical equipment. In the reactor, 1-6 pairs of draft tubes with changeable diameters are horizontally arranged coaxially and oppositely; raw materials are introduced by feeding tubes with curved nozzles; fluid is accelerated by push-type three-blade stirrers at the entrance of the draft tubes; the rotation speed of the push-type three-blade stirrers is controlled by a controller; rotational flow is inhibited by deflection baffles; the inner diameters of the draft tubes become smaller gradually; cross-section area of a flow channel is decreased; flow speed is increased; the flow speed at the exits of the draft tubes is the maximum; two fluids impinge face to face at a high speed in the container and mixed efficiently and rapidly; the fluids flow to the entrance of the draft tubes from central impinging areas through the outer sides of the draft tubes, thus realizing circulation; motors are fixed and anti-vibrated by triangle support plates, the acidity of a reaction system is on-site monitored by a pH meter probe and displayed in real time by a pH meter display; constant acidity of the reaction system is realized by adjusting liquid inlet flow quantity; and materials in the contained are discharged from a material-discharging port after the reaction is finished. The liquid phase impinging stream reactor can be heated or cooled, and can be operated continuously, intermittently or semi-continuously.

Owner:TSINGHUA UNIV

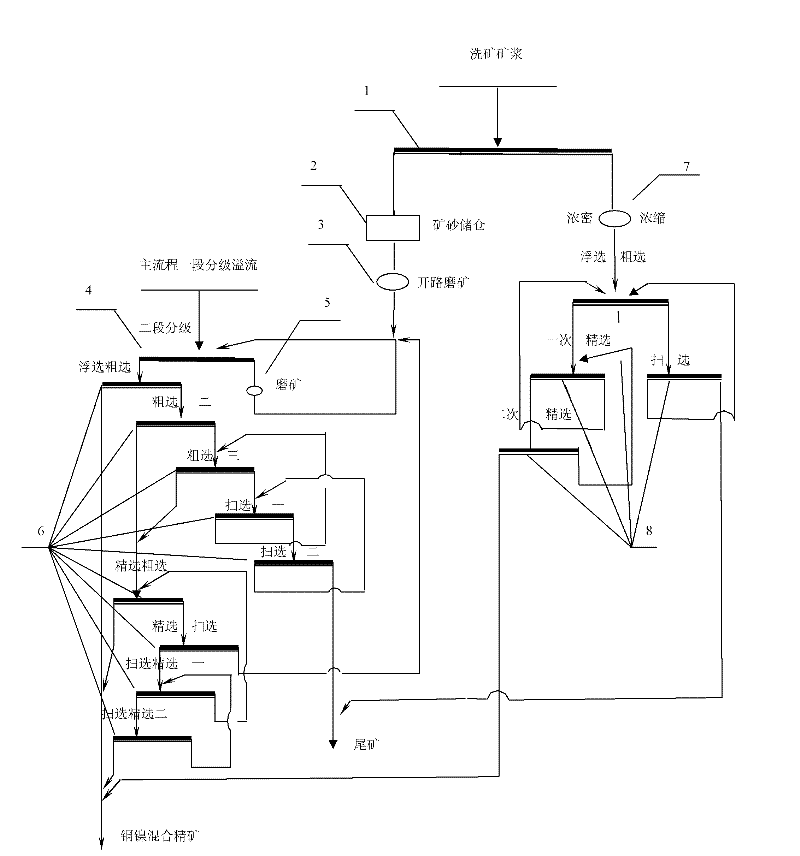

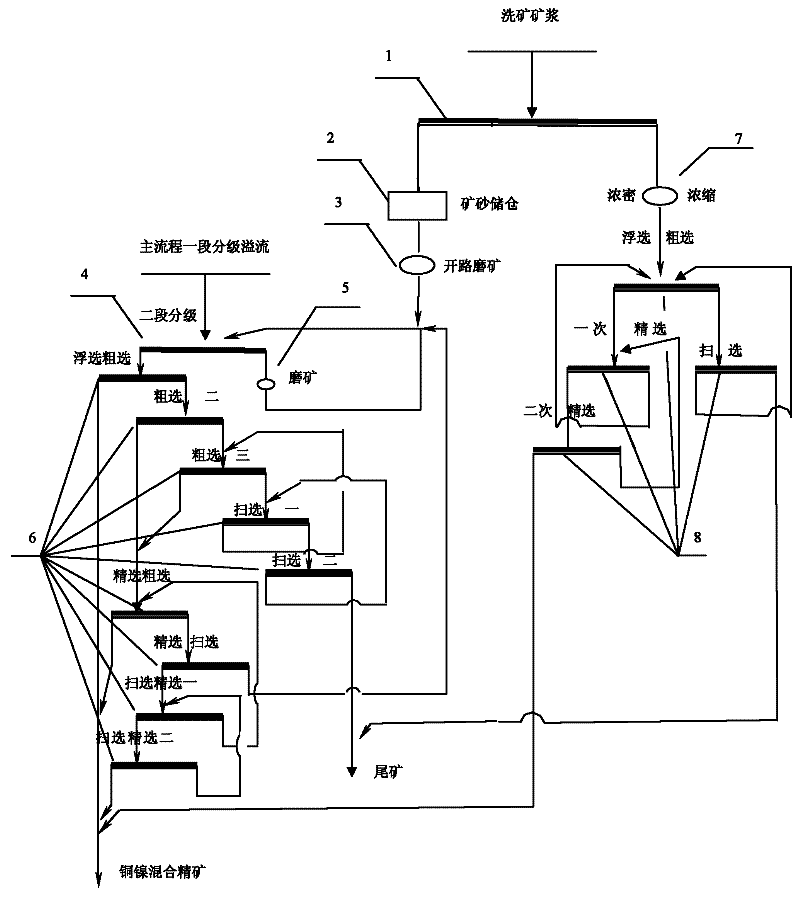

Ore-dressing method for recovering nickel from ore-washing slurry of copper-nickel sulfide ore

ActiveCN102225356AAdvanced technologyGuaranteed operationFlotationWet separationMaceralHigh concentration

The invention provides an ore-dressing method for recovering nickel from ore-washing slurry of copper-nickel sulfide ore. The method comprises the following steps: performing a gravity concentration process on the ore-washing slurry; storing and dewatering the ore sand of the gravity concentrate; performing an open-circuit grinding process; performing a main program check screening process; performing a closed-circuit grinding process on unqualified grains; adding drugs in qualified grains and then performing a flotation process, wherein after performing the processes of coarse selecting, scavenging and finely selecting, the nickel concentrate grade is 6%-8%, the copper grade is 1%-1.6%, the grade of nickel in tailings is less than or equal to 0.2%, and the grade of copper in tailings is less than or equal to 0.04%; and then concentrating and dewatering the gravity concentrate tailings by using a concentrating machine; performing a slurry flotation process; adding a dispersing agent after adjusting the slurry with high concentration; and adding an ore-dressing reagent in stage adding manner, wherein the nickel concentrate grade is 4%-7% and the copper grade is 0.8%-1.5%. The ore-dressing method has the advantages of low cost, high production efficiency and high comprehensive recovery rate of valuable metal. The ore-dressing method is an ideal ore-dressing method for recoveringnickel from ore-washing slurry of copper-nickel ore.

Owner:JILIN JIEN NICKEL IND

Process for preparing magnesium sulfate monohydrate by using water-containing magnesium sulfate heptahydrate

ActiveCN102583459ASolve the problem of easy cakingContinuous stable operationMagnesium sulfatesFree waterMagnesium sulphate heptahydrate

The invention discloses a process for preparing magnesium sulfate monohydrate by using water-containing magnesium sulfate heptahydrate, comprising the following steps of: (1) wet material feeding: delivering water-containing magnesium sulfate heptahydrate into a drying chamber of a spin flash dryer; (2) hot air delivery: heating the air to 220-320 DEG C, pressurizing by using a draught fan, and delivering the air into the spin flash dryer; (3) drying process: remaining a wet material to be dried in the drying chamber of the spin flash dryer for 2-6s to obtain finished magnesium sulfate monohydrate containing free water less than or equal to 3wt%; and (4) discharging and tail gas treatment and exhaust: delivering the dried material into a discharging device, carrying out cyclone dust removal and water film dust removal, then collecting the dried magnesium sulfate monohydrate, and exhausting tail gas. The process for preparing the magnesium sulfate monohydrate by using the water-containing magnesium sulfate heptahydrate, provided by the invention, has the advantages of easiness in controlling the drying temperature, short process flow, strong adaptability, continuous, stable and reliable drying process and good drying effect.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

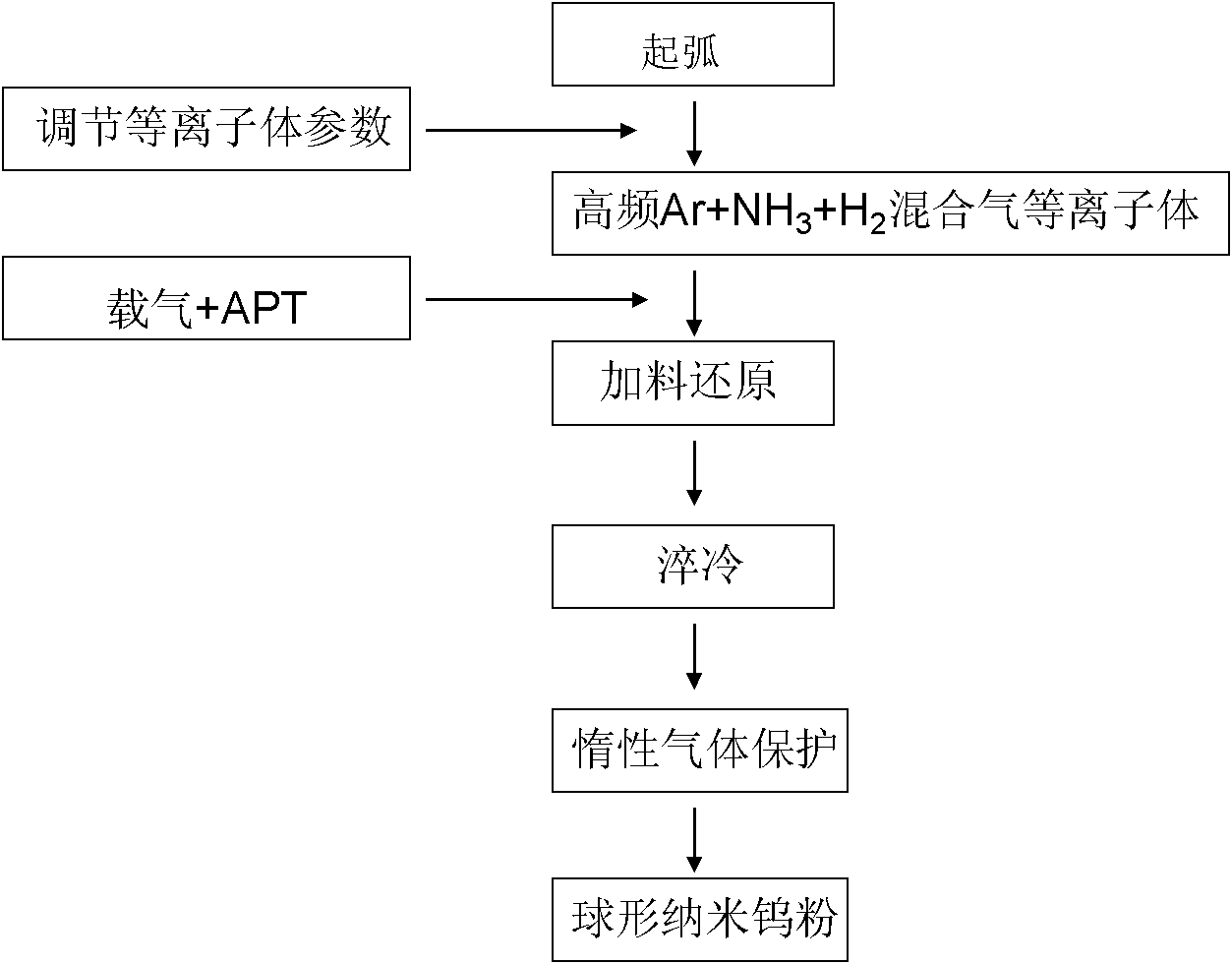

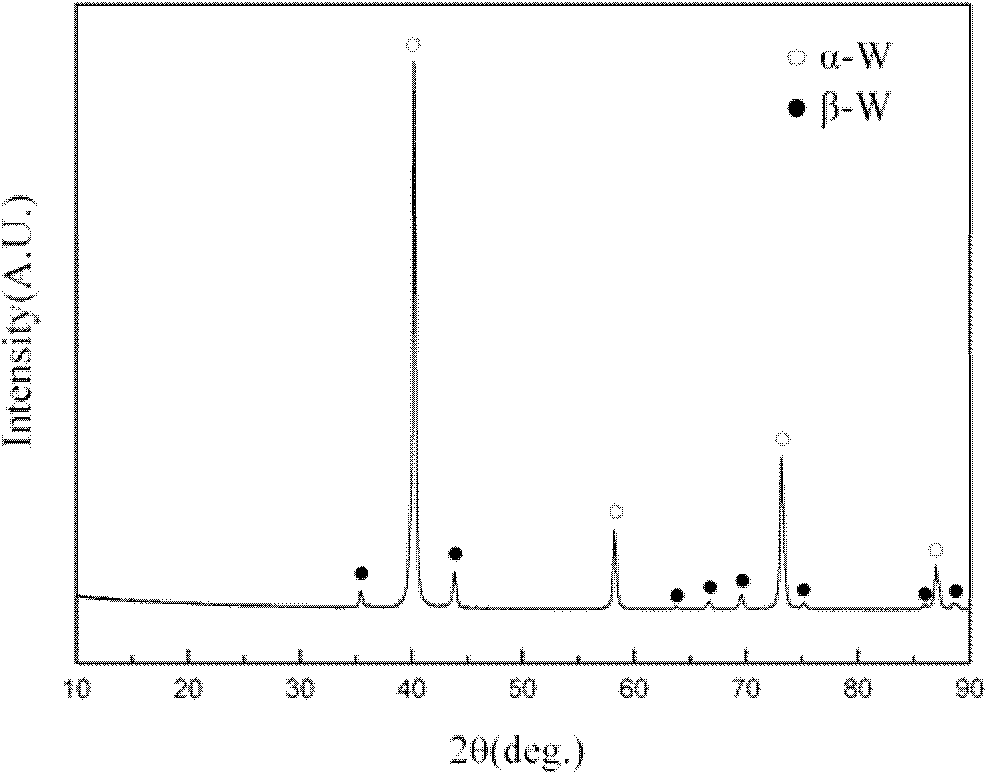

Method for preparing spherical nano tungsten powder

The invention discloses a method for preparing the spherical nano tungsten powder by using high frequency Ar+NH3+H2 mixed gas plasma to reduce ammonium paratungstate (APT) directly. In a high frequency plasma device, central gas and side gas uses Ar, carrier gas uses NH3and H2, and stably and continuously operating high frequency Ar+NH3+H2 mixed gas plasma is built. Material APT is added into the plasma by the drive of the carrier gas through a feeder and is further reduced to metal tungsten under the atmosphere of high reactivity high frequency Ar+NH3+H2 mixed gas plasma, and the metal tungsten is subjected to subsequent cooling and collection to obtain the spherical nano tungsten powder. The frequency Ar+NH3+H2 mixed gas plasma has the advantages that arc cylinders are long and thick, the cylinders are full, exhaust plume has no gap, problems of defects in arc cylinder contraction and exhaust plume and short reaction time of ordinary high frequency Ar+ H2 plasma are overcome, dwell time of materials in plasma arcs is prolonged, an ATP reduction process is strengthened, and the spherical nano tungsten powder is obtained. The spherical nano tungsten powder can be used in fields of electric vacuum cathode materials, thermal spraying and powder metallurgy.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

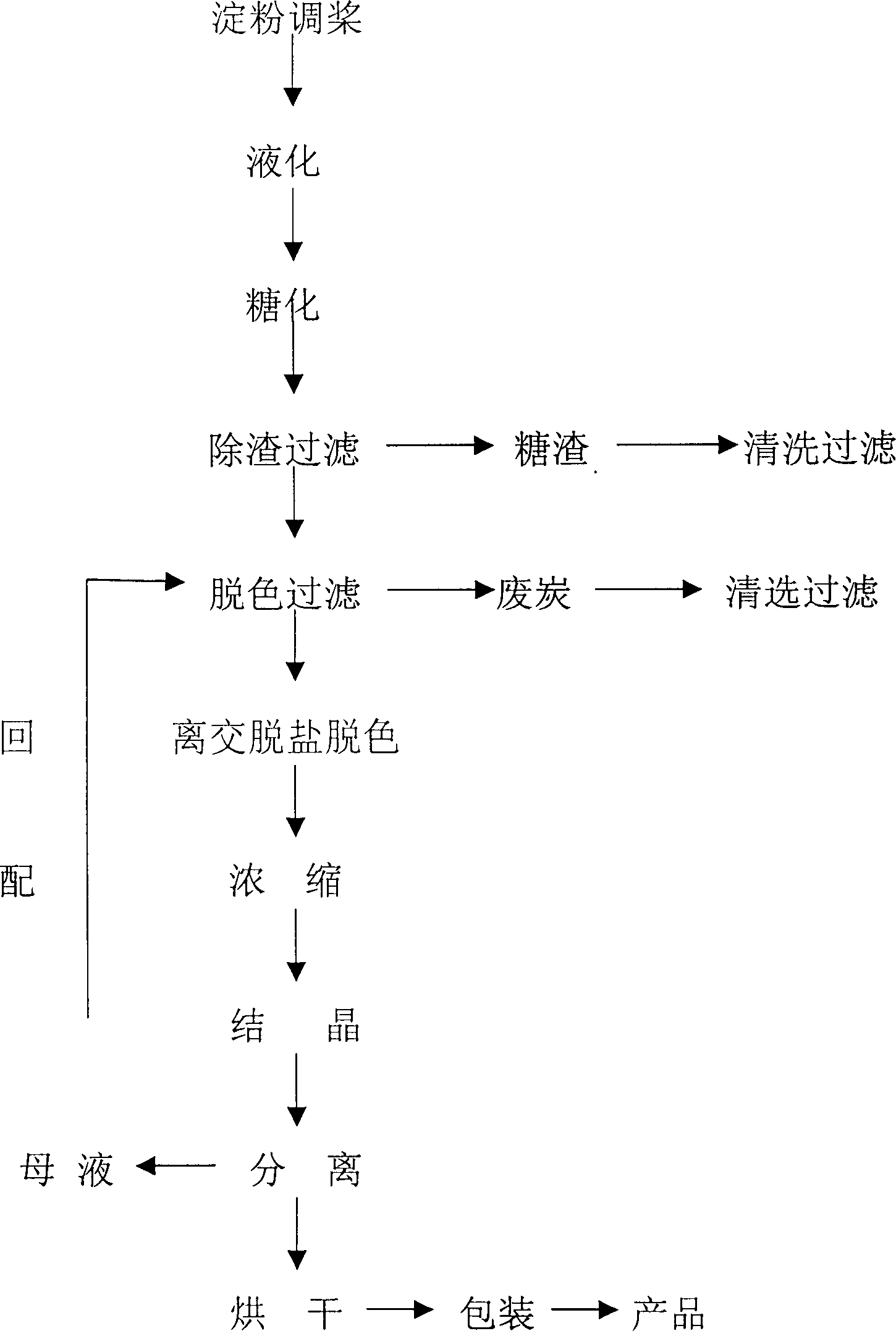

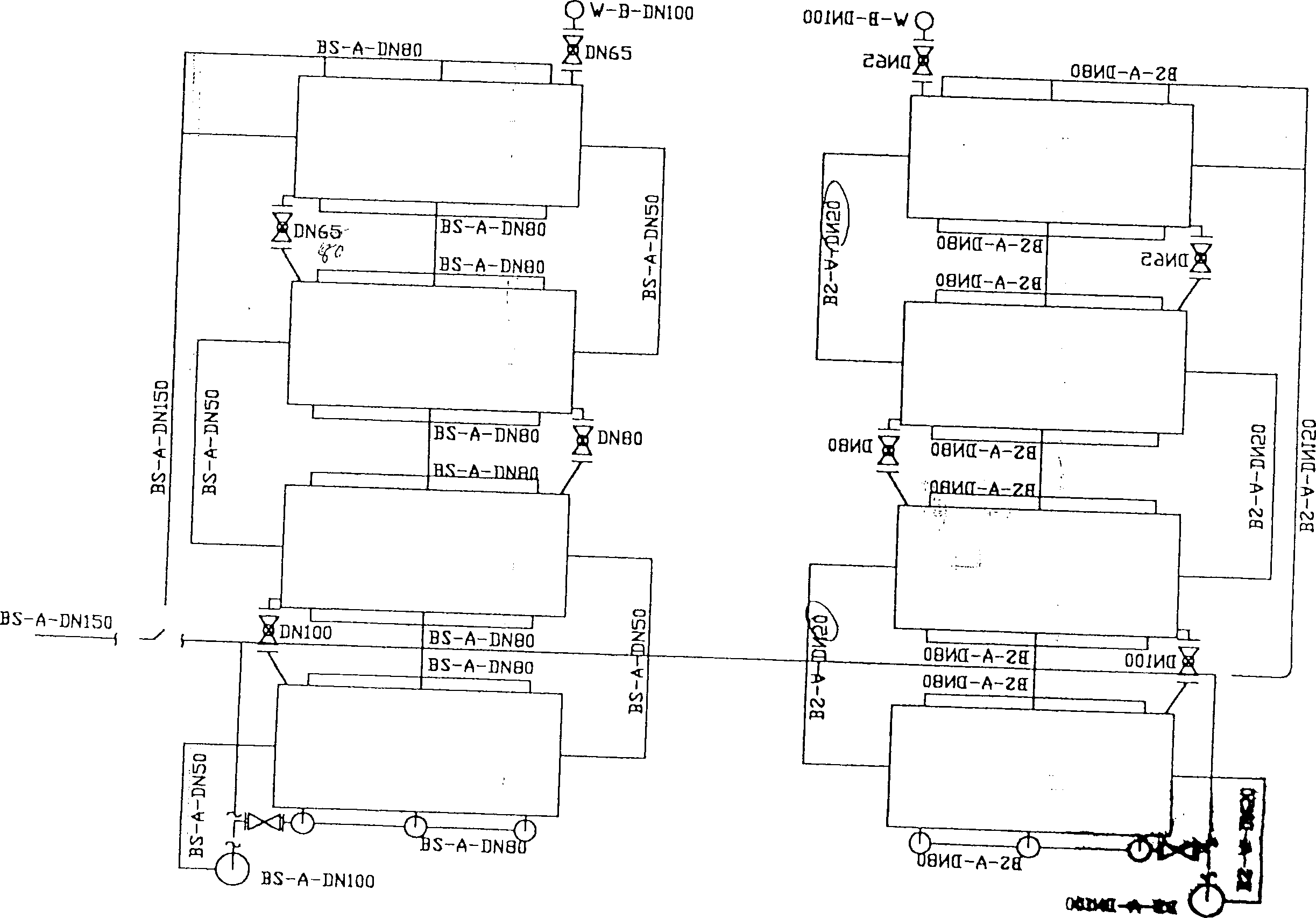

Ion exchange technology in preparing glucose

InactiveCN1390845ALow regeneration costExtended recovery periodMonosaccharidesGlucose productionIon exchangeIon

An ion exchange process for preparing glycose features that multiple cationic resin columns are parallelly connected into a group, multiple anionic resin columns are parallelly connected into a group, and both groups are connected via buffer tank and pump. Its advantages are regeneration of any resin column without stopping production, low cost for regeneration and saving resin by 30%.

Owner:XIWANG GROUP

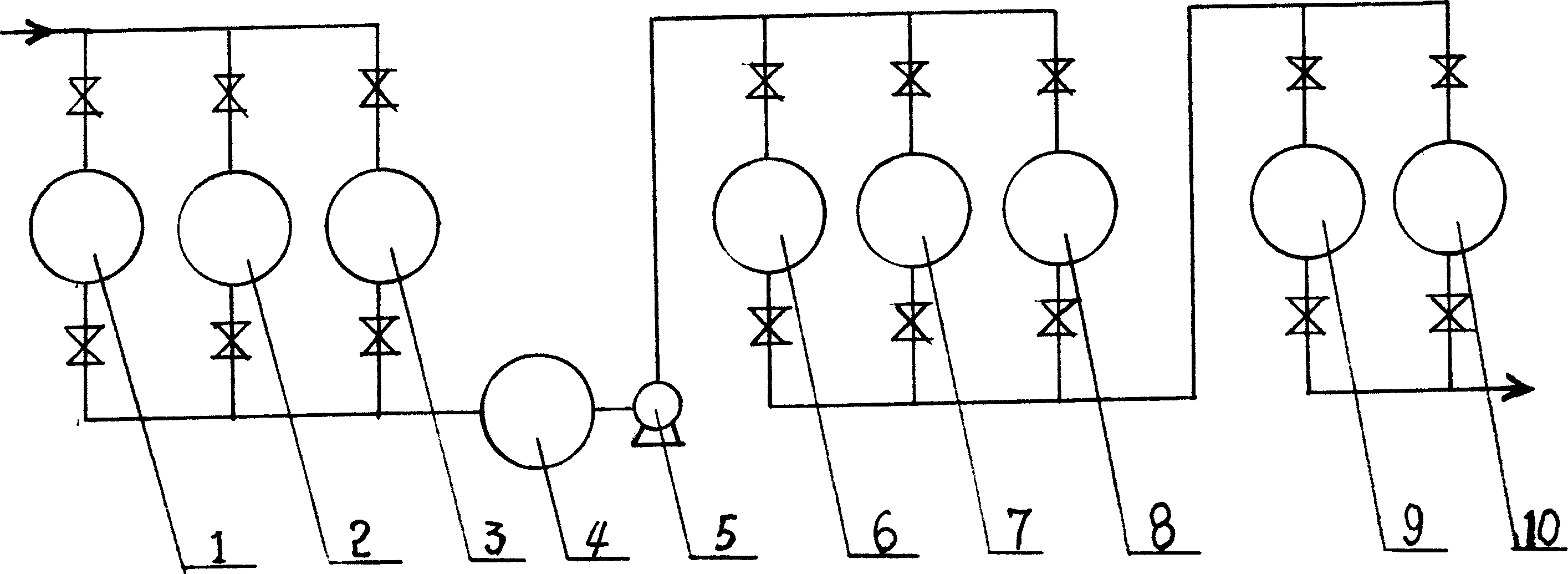

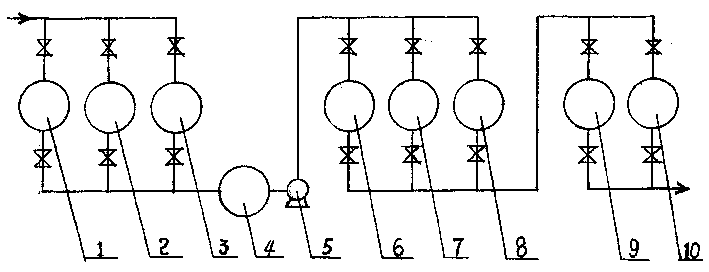

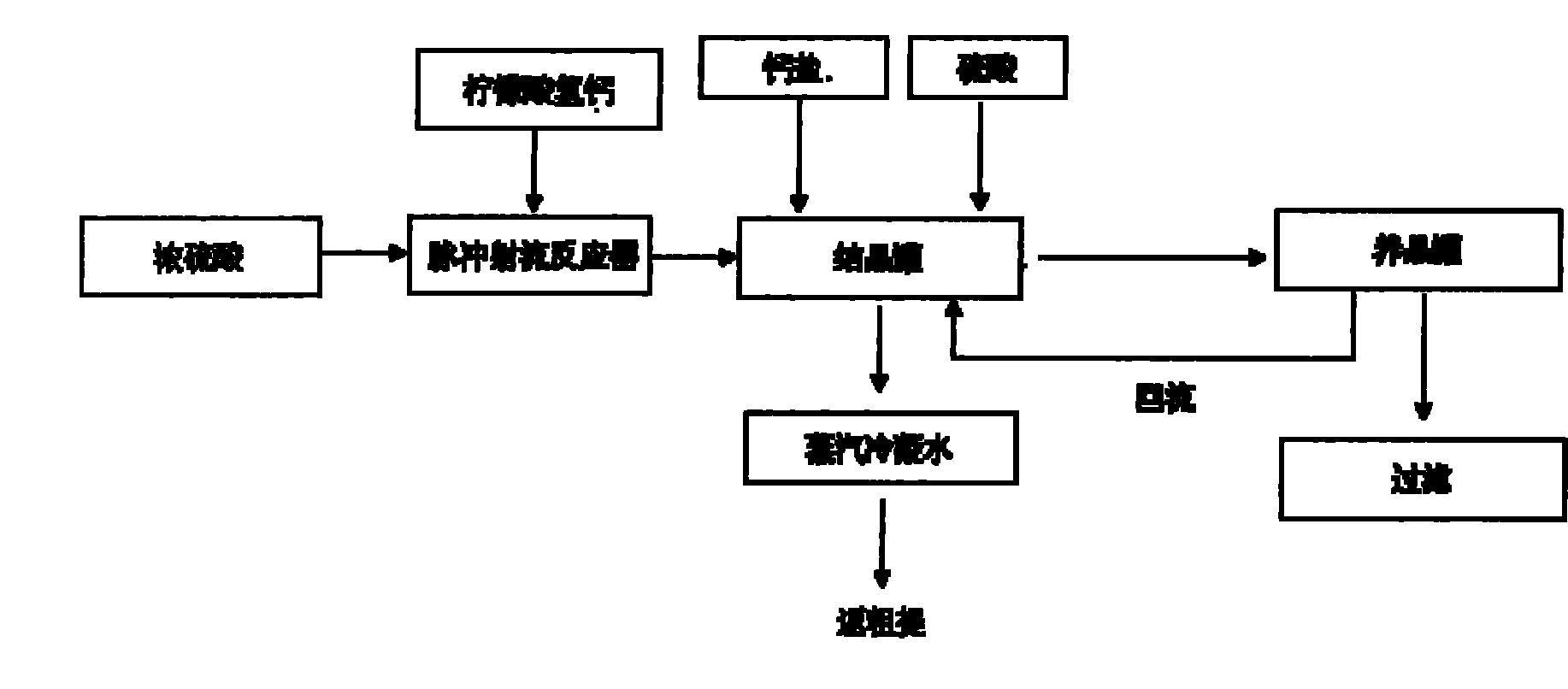

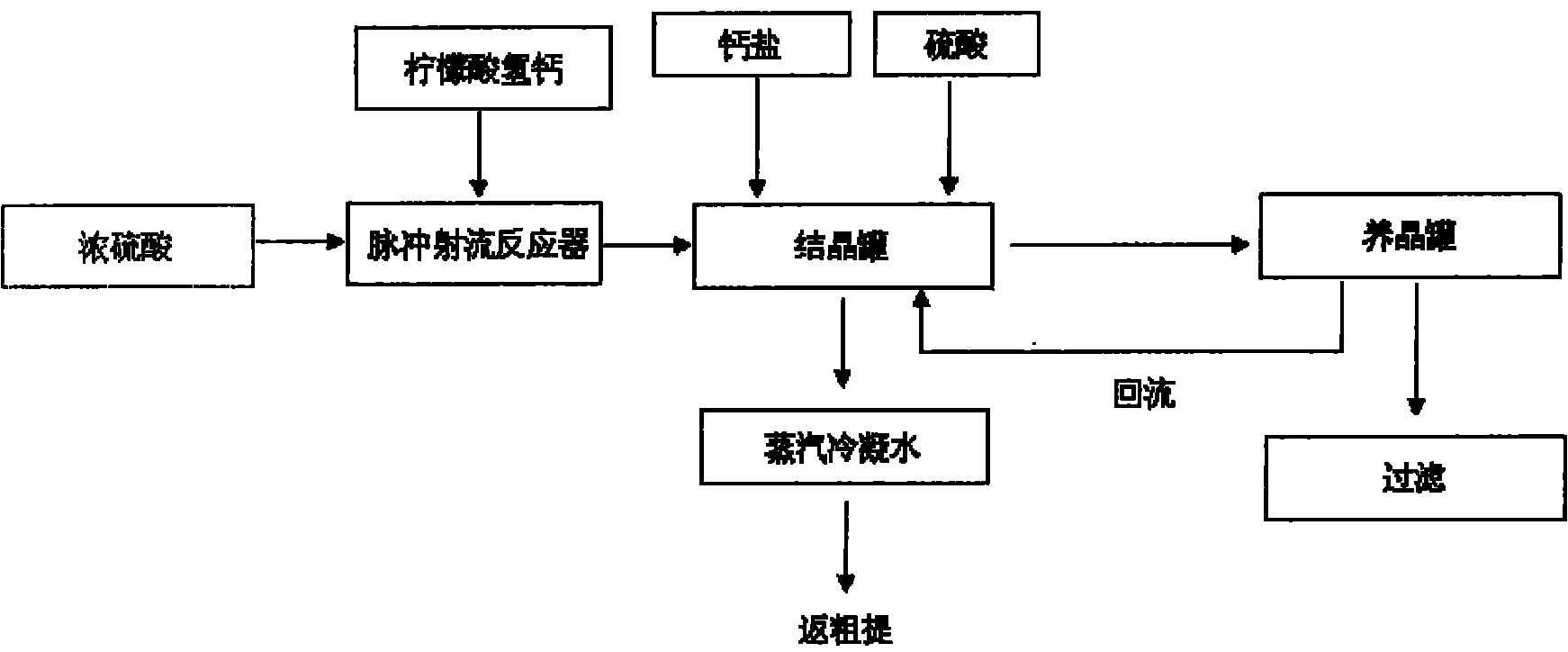

Continuous acidolysis process for calcium hydrogen citrate

ActiveCN102060691AHigh degree of automationContinuous stable operationPreparation from carboxylic acid saltsCarboxylic compound separation/purificationMagmaCITRATE ESTER

The invention relates to a continuous acidolysis process for calcium hydrogen citrate. The process mainly the following steps of: 1, respectively feeding calcium hydrogen citrate and concentrated sulfuric acid into a pulse jet reactor through pipelines for finishing an instantaneous acidolysis reaction in the reactor; 2, performing fine adjustment on the pH value of reaction solution in a crystallizer and finishing a crystallization process; and 3, finishing coarse-fine granule grading of the magma liquid in a maturing tank, and making the magma liquid enter a filtering process to finish solid-liquid separation. The process has the advantages of thorough reagent reaction, high automation degree, high acidity of acidolysis liquid, good crystal form of byproducts such as calcium sulphate, controllable granularity and the like.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

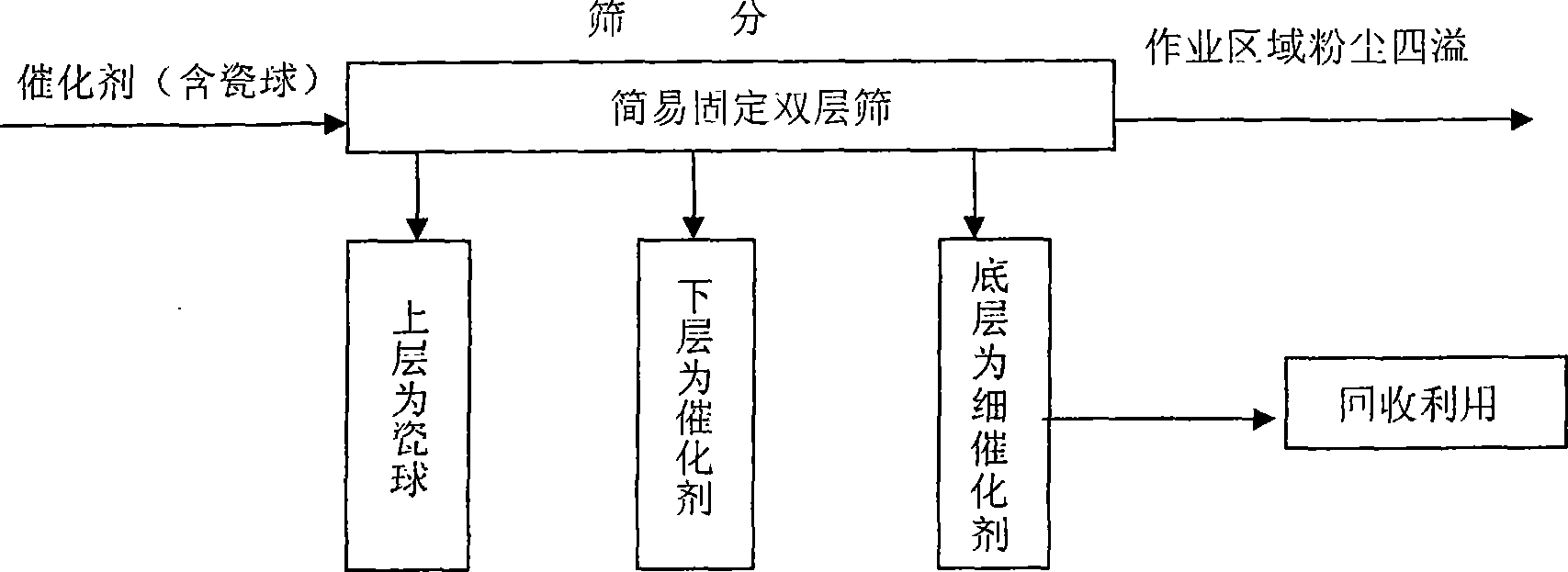

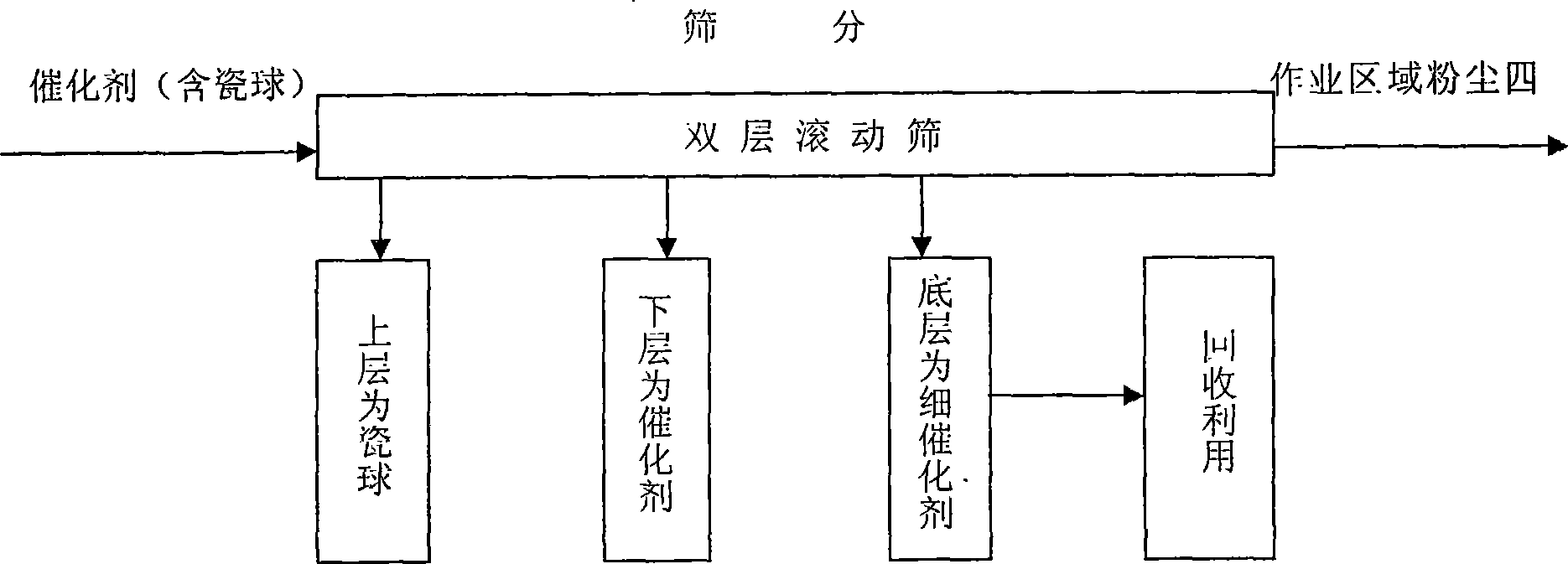

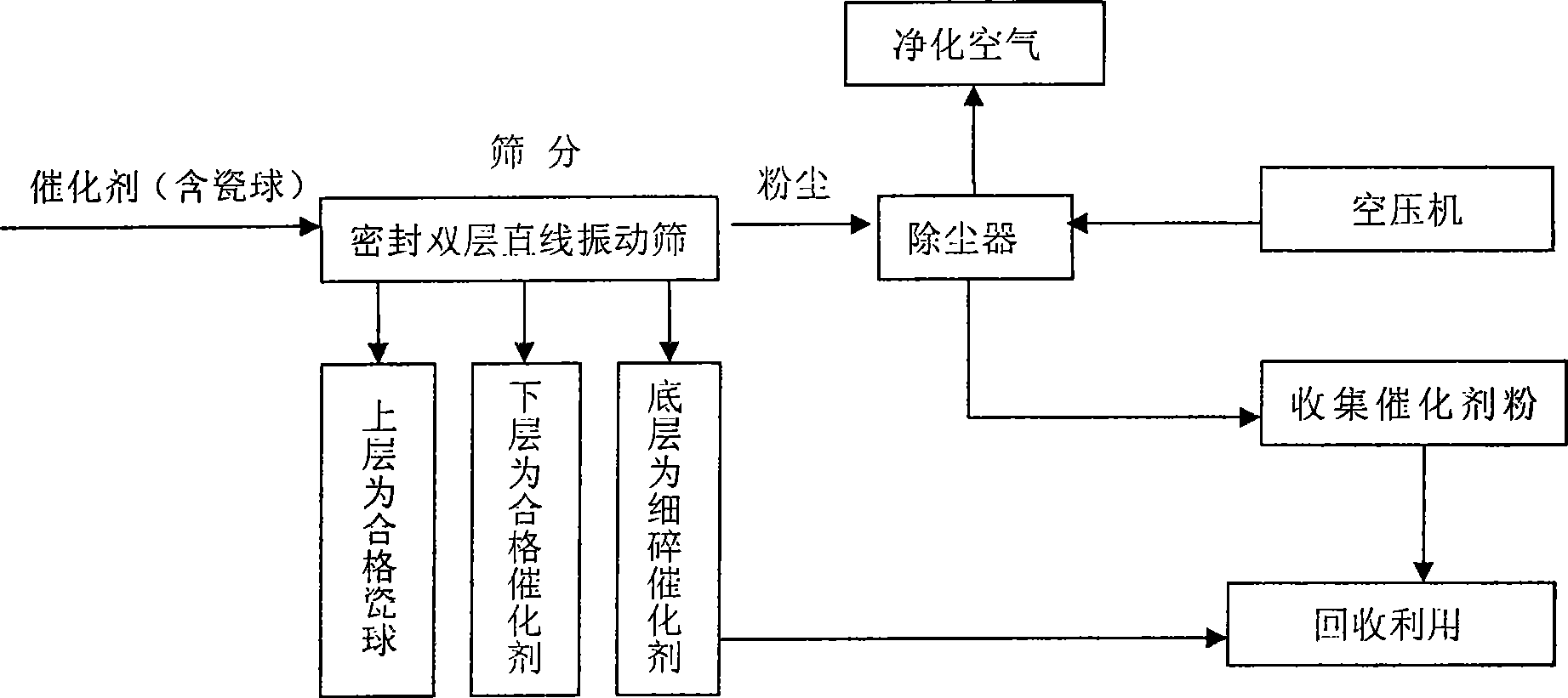

Catalyst screening method during preparation of sulphuric acid

InactiveCN101391755AReduce energy consumptionImprove efficiencySulfur-trioxide/sulfuric-acidWorking environmentEconomic benefits

The invention discloses a sulfuric acid catalyst screening method, which comprises: the catalyst is placed in a sealed double-layer linear mechanical vibrating screen to be screened level by level and the dusts generated during screening are filtered by a dust catcher; the screened thin catalyst grains and the catalyst dusts collected by the dust catcher are bagged respectively for later recycling. The application of the method can dramatically enhance the work environment and the dust density of the screening work zone is less than 3mg / m<3>, thus effectively protecting the health of workers. The improvement of environment can reduce the investment cost and the total screening cost can be saved by 5 to 10 percent, thus enhancing the economic benefit. The screening time can be dramatically shortened so as to obtain more time for the starting of sulfuric acid apparatus and guarantee smooth completion of the manufacturing task, thus having positive practical meaning and high popularization and application value.

Owner:云南云天化股份有限公司三环分公司 +1

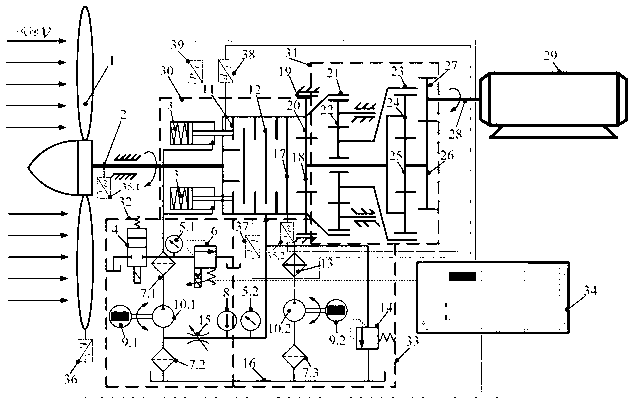

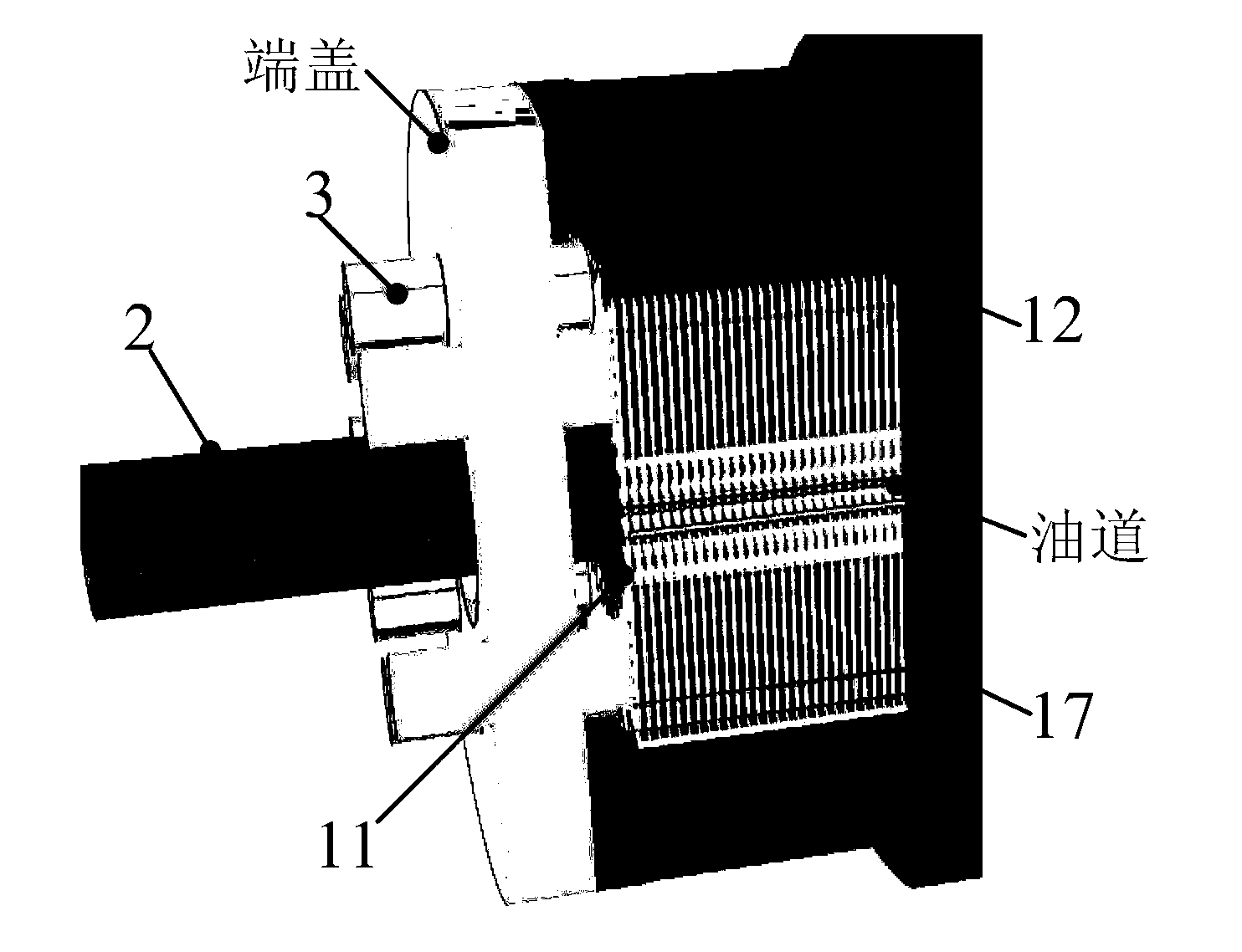

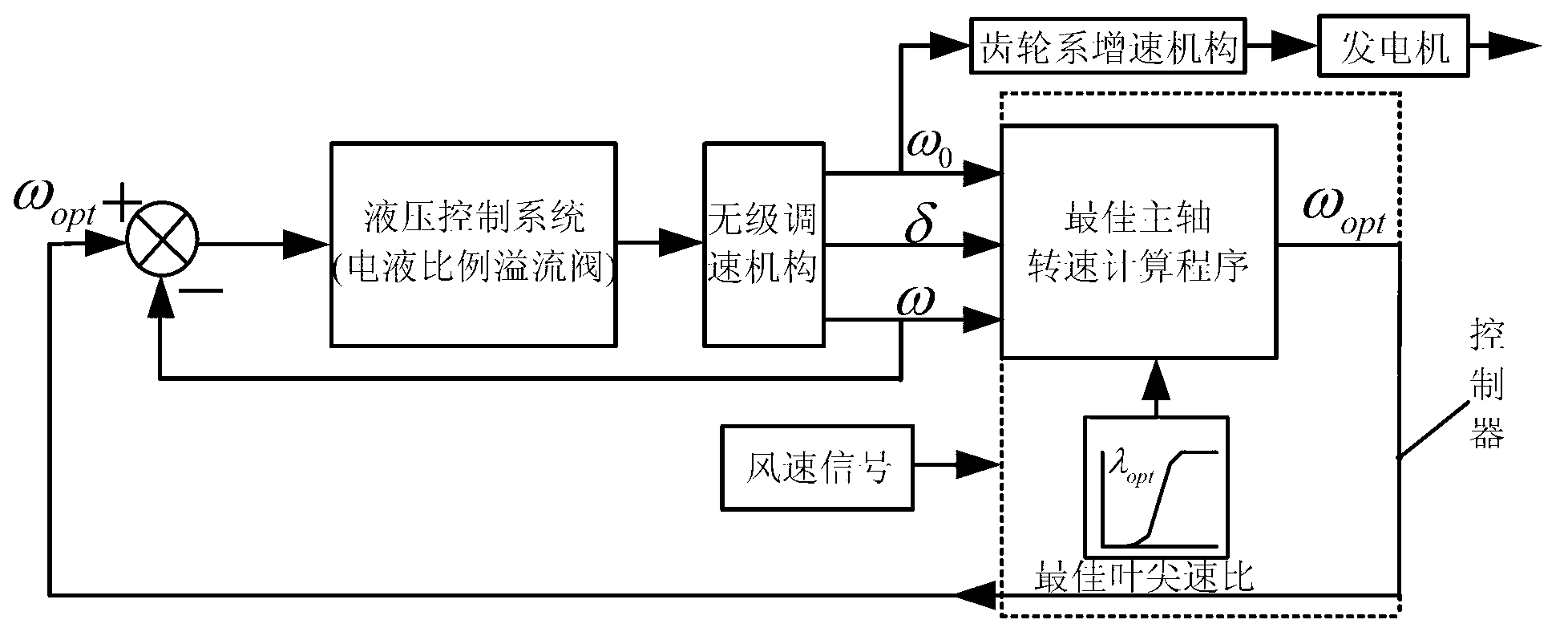

Stepless speed-up type wind power generation system

InactiveCN103233862AImprove stabilityIncrease powerWind motor controlWind motor combinationsThree levelPower grid

An embodiment of the invention discloses a stepless speed-up type wind power generation system. A wind wheel is connected with a stepless speed regulating mechanism through a spindle, the stepless speed regulating mechanism is connected with a three-level differential planet gear speed-up mechanism through a first-stage planet carrier of the three-level differential planet gear speed-up mechanism, the three-level differential planet gear speed-up mechanism is connected with a generator through a high-speed shaft, input energy of the wind wheel is wind energy, output kinetic energy of the wind wheel is input into the spindle, output kinetic energy of the spindle is input to the stepless speed regulating mechanism, the stepless speed regulating mechanism can control and change an input rotating speed continuously in a stepless mode, stabilizes an output rotating speed and outputs the speed to the follow-up three-level differential planet gear speed-up mechanism, the three-level differential planet gear speed-up mechanism transmits input power to the high-speed shaft through speed-up transmission with a certain transmission ratio, the rotating speed of the high-speed shaft is the same as the rotating speed of the generator so as to output the kinetic energy into the generator, and the generator converts the energy input by the high-speed shaft into electric energy and sends the electric energy to a power grid.

Owner:ZHEJIANG UNIV

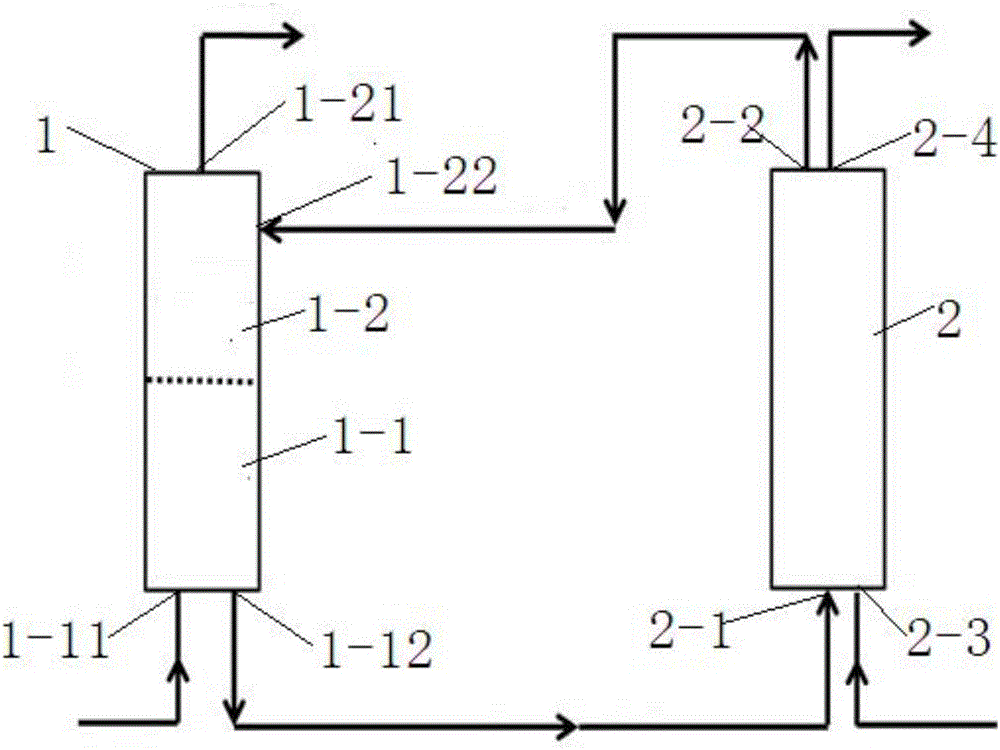

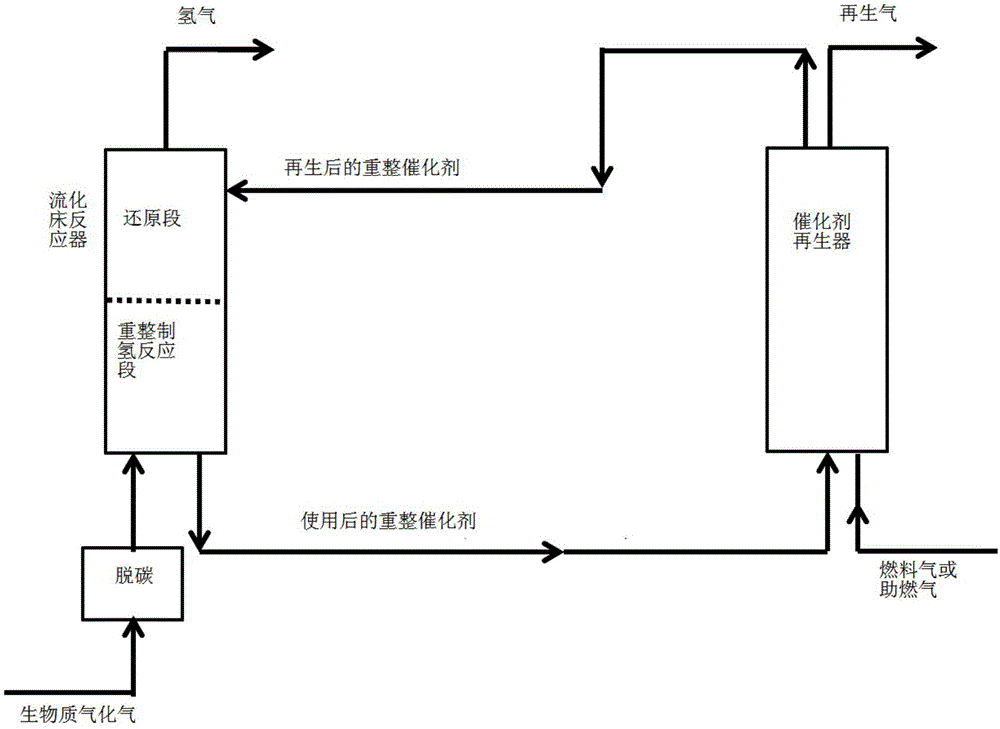

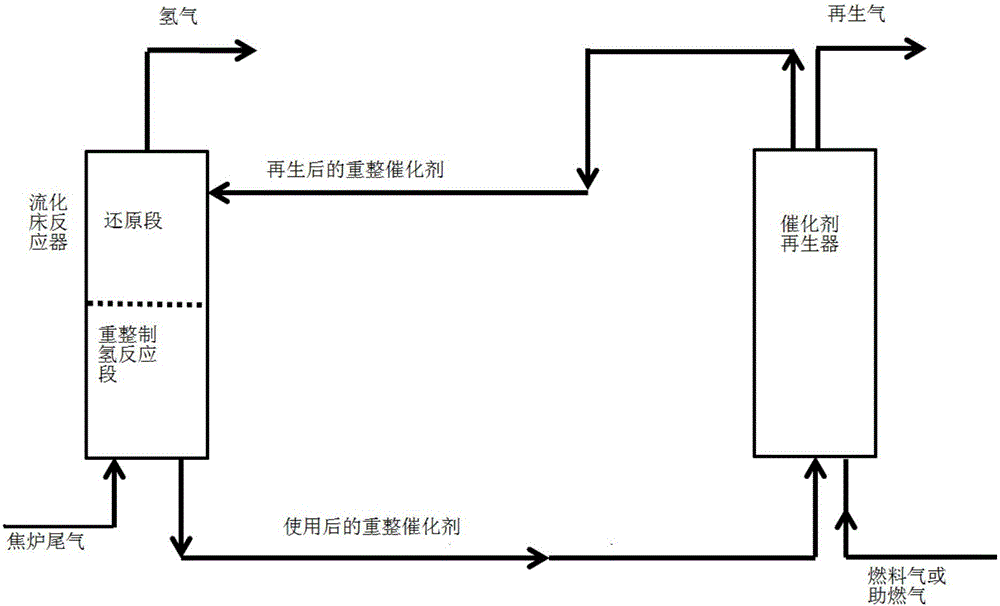

Process for hydrogen production by adsorption catalysis of crude synthetic gas and device thereof

ActiveCN106629600AEliminate desulfurizationOmit separabilityHydrogenHydrogen/synthetic gas productionCombustionWater vapor

The invention discloses a process for hydrogen production by adsorption catalysis of crude synthetic gas and a device thereof. The process comprises the following steps: 1) mixing water vapor and the crude synthetic gas according to a water-carbon mol ratio of 2 to 6, adding a reduced reforming catalyst with an adsorption function, and carrying out a reforming hydrogen-producing reaction in a fluidized state; 2) oxidizing the reforming catalyst after a high-temperature combustion reaction so as to remove carbon deposit and sulfur-containing components on the reforming catalyst, and heating the reforming catalyst so as to release CO2 and realize regeneration; and 3) subjecting the regenerated reforming catalyst to in-situ reduction at 400 to 900 DEG C, subjecting the reduced reforming catalyst to circulating production of hydrogen, i.e., a product. According to the invention, the crude synthetic gas containing coal tar and sulfur can be further converted into hydrogen, so sulfur removal and coal tar separation of the crude synthetic gas are saved, and the selection range of hydrogen-producing raw gases is greatly broadened; through in-situ reduction of the reforming catalyst, a reduction procedure is not needed to be additionally arranged; and the device provided by the invention saves the use of auxiliary equipment like a degassing tank and a reduction reactor, so procedures are greatly simplified.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

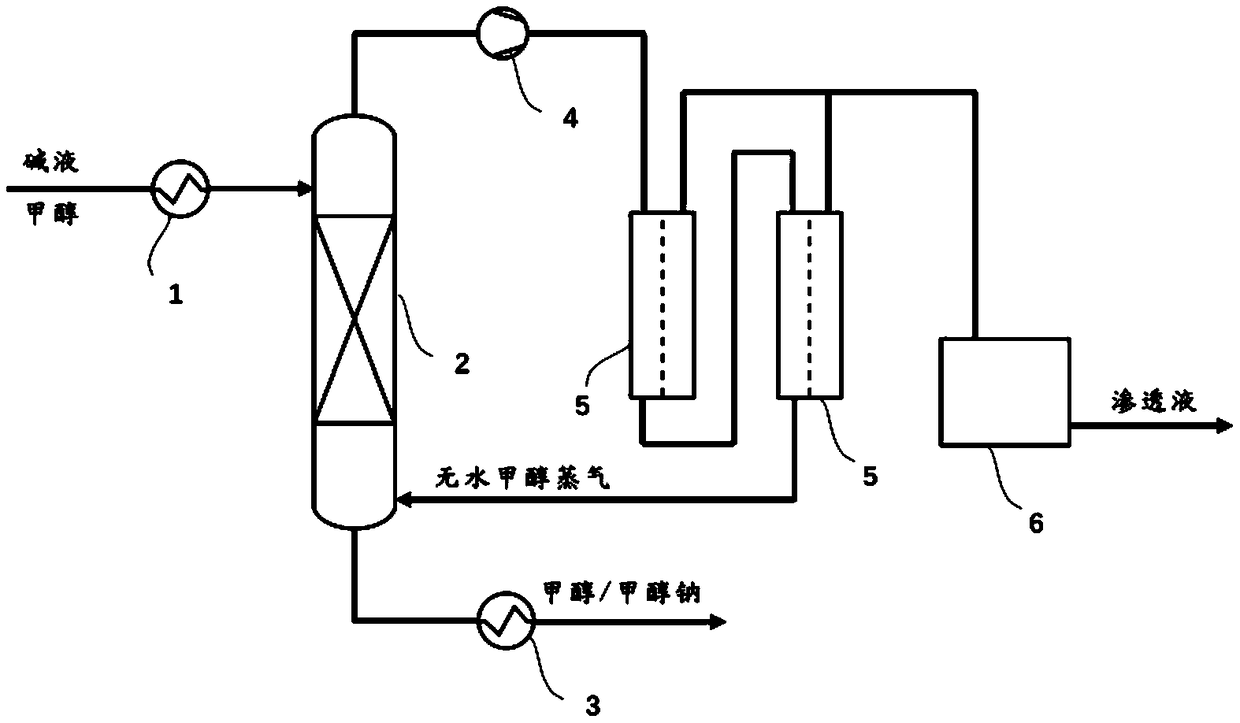

Method and device for preparing sodium methoxide by coupling steam permeation and alkaline process

PendingCN108863719AGreat operating flexibilityReduce energy consumptionPreparation of metal alcoholatesHydroxy compound separation/purificationChemistrySodium methoxide

The invention provides a method and a device for preparing sodium methoxide by coupling steam permeation and alkaline process. The method is characterized in that the produced methanol-water mixture in the alkaline type sodium methoxide production process is separated by a steam permeation membrane separation device and a technique, and the separated high-purity methanol is directly used for the production of the sodium methoxide. The device and the method have the advantages that the steam permeation membrane separation is used for the steam recycling of sodium methoxide, so that the traditional rectification methanol recycling tower is replaced; compared with the prior art, the anhydrous methanol can be completely recycled and reutilized, so as to ensure the stable and continuous runningof the reaction process; the operation elasticity is improved, the energy consumption is decreased, and the running cost, land occupation area and investment cost are reduced; the operation of the whole set of device is simple and convenient, and the running is stable.

Owner:HYMATER CO LTD

Deep evaporating method for phenol hydroxylated liquid detarring tower

InactiveCN102805954AEasy to separateContinuous stable operationOrganic chemistryOrganic compound preparationReboilerSoft water

The invention discloses a deep evaporating method for a phenol hydroxylated liquid detarring tower, which comprises the following steps of: (1) feeding at a lateral line liquid phase material inlet in a rectifying tower, and pumping the tower bottoms in the rectifying tower into a bottom reboiler and a double-shaft stirring reboiler by a bottom material outlet through a circulating pump; (2) after heating the materials entering from the tower into the double-shaft stirring reboiler, changing the volatile components into steam and then distilling the steam entering the rectifying tower by a lateral line gas phase material inlet through a pipeline, changing a top gas phase of the rectifying tower into condensate after heat exchange with a condenser and soft water, and extracting part of condensate from a material extracting port on a side wall of the tower top; and (3) changing the soft water in the condenser into steam after the soft water exchanges heat with the top gas phase of the rectifying tower, and then enabling the soft water to enter a steam drum through a pipe, and conveying the steam in the steam drum to other low pressure steam users when the steam pressure reaches the set pressure. According to the method, the stability of the product quality and the running reliability of the devices are improved.

Owner:TIANJIN UNIV

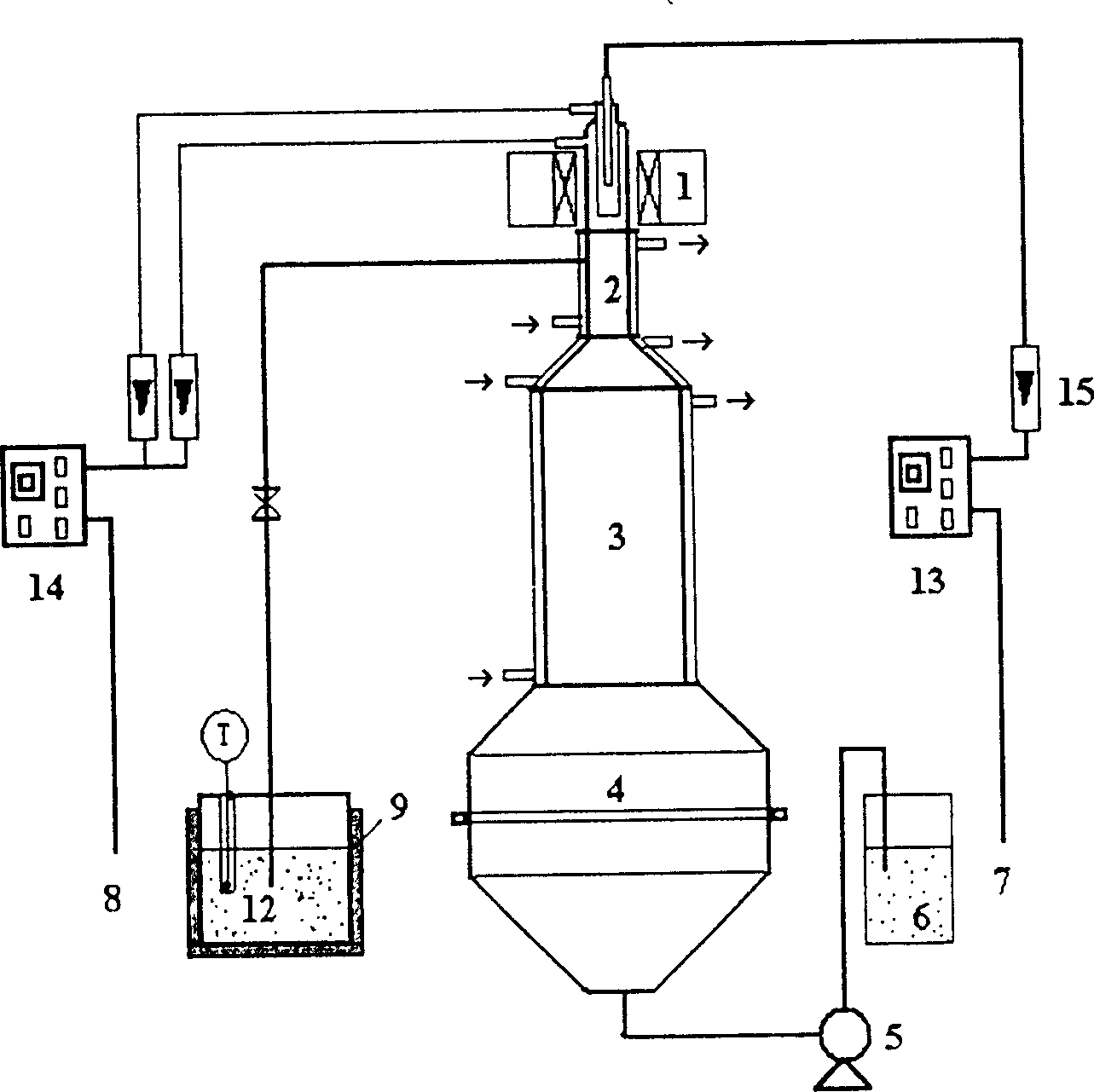

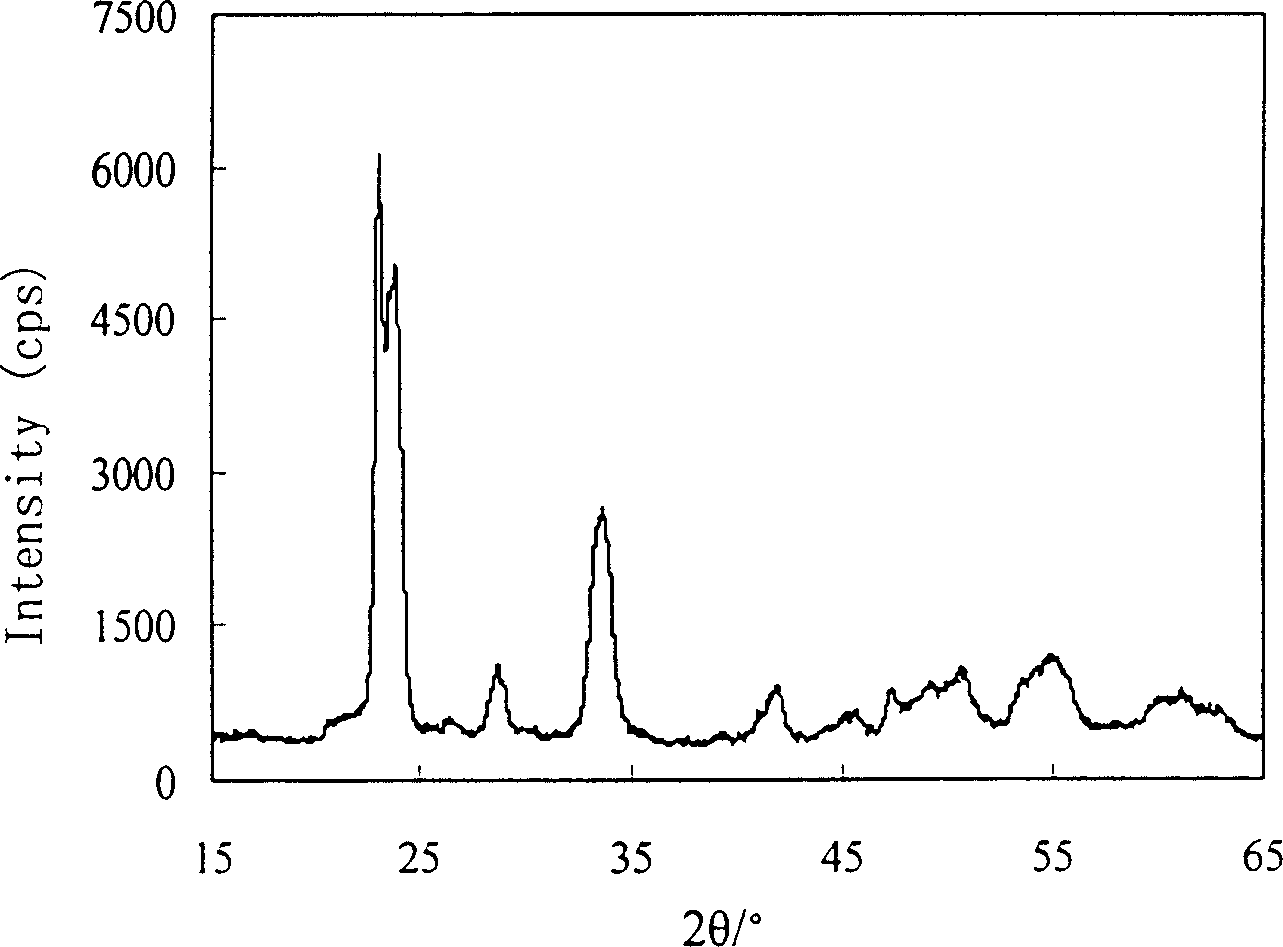

Preparation method of nanometer tungsten trioxide crystallite

InactiveCN1830813AShort processContinuous stable operationTungsten oxides/hydroxidesFrom chemically reactive gasesChemistryCrystallite

Owner:TAIYUAN UNIV OF TECH

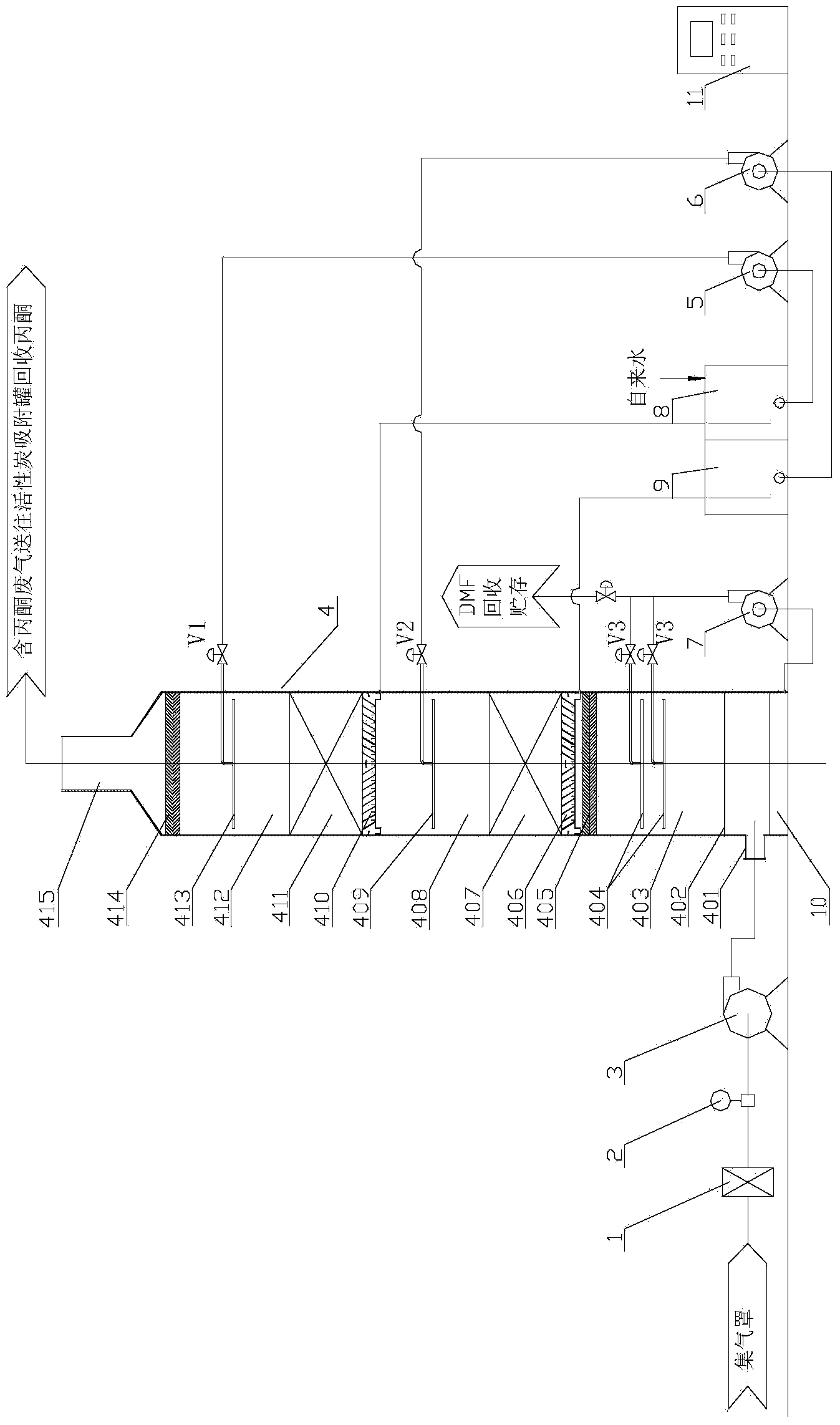

DMF (dimethyl formamide) waste gas water-washing recycling device and method for manufacturing of copper-clad plates

InactiveCN104248904AImprove absorption rateImprove absorption efficiencyDispersed particle filtrationSheet steelSprayer

The invention relates to a DMF (dimethyl formamide) waste gas water-washing recycling device for manufacturing of copper-clad plates. The device comprises a filter, a flow meter, a fan, a water-washing tower, a multi-stage circulating water pump, multiple circulating liquid storage tanks and a control system, wherein the filter is connected with the flow meter; the flow meter is connected with the fan; the fan is connected with the water-washing tower; the water-washing tower comprises a wind inlet, a wind-equalizing pore plate, multiple sprayers, a tower plate and a waste gas outlet; the multiple circulating liquid storage tanks are connected with the tower plate; the multiple circulating liquid storage tanks are also connected with the multiple sprayers through the multi-stage circulating water pump; a groove is formed around the outer edge of the tower plate; a circular opening is formed in the middle of the tower plate; the diameter of the circular opening is smaller than that of the inner edge of the groove; multiple rows of flow-guiding inclined plates are supported on the upper end surface of the tower plate; multiple steel plates for fixing the flow-guiding inclined plates are arranged on the upper end surfaces of the flow-guiding inclined plates. The DMF waste gas water-washing recycling device for manufacturing of copper-clad plates makes airflow distribution more uniform, reduces resistance of the tower plate, and adopts multi-stage independent circulating absorption, with the DMF absorbing rate reaching up to 98.5%.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

Technology for continuously producing cesium rubidium alum and aluminum potassium sulfate

InactiveCN105366701AHigh yieldContinuous stable operationChemical industryAluminium sulfatesCentrifugationPhysical chemistry

A technology for continuously producing cesium rubidium alum and aluminum potassium sulfate comprises the following steps: (1) performing single / multiple effect vacuum cooling crystallization on a mother solution containing cesium, rubidium, potassium and aluminium, so as to obtain a cesium rubidium alum crystal slurry; (2) performing centrifugation separation, so as to obtain crude cesium rubidium alum and a mother liquid; (3) performing thermal dissolving, recrystallization and centrifugation separation on crude cesium rubidium alum, so as to obtain the cesium rubidium alum product; (4) performing multi-effect forced circulating refrigeration crystallization on the mother liquid with the aluminum potassium sulfate content of 6 wt% or more according to a forward flow, so as to obtain a aluminum potassium sulfate crystal slurry; and (5) performing centrifugation separation and drying, so as to obtain the aluminum potassium sulfate product. The technology realized continuous large-batch production, the product quality is stable, yield is high, the purity of obtained cesium rubidium alum is 95% or more, and the purity of aluminum potassium sulfate is 97% or more. The solid concentration of each-stage crystallizer is easy to control. Cold energy can be fully utilized, and the energy-saving synergic effect can be reached. The technology effectively prevents large-area obstruction of pipes and obstruction of equipment. Equipment structure is simple, operation and maintenance are convenient, automatic control is easy to realize, and large-scale industrial production can be realized.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Nesting device used in nesting process for high-vacuum multilayer heat-insulating LNG tank for ship

ActiveCN104896301AContinuous smooth operationNo risk of scratchingPressure vesselsEngineeringTractor

The invention discloses a nesting device used in a nesting process for a highly-vacuum multilayer heat-insulating LNG tank for a ship and relates to the field of manufacturing the highly-vacuum multilayer heat-insulating LNG tank for the ship. The nesting device comprises a self-powered tractor which comprises a chassis, two traveling speed reducers, two traveling motors, a flange half shaft, a coupler and a rotating motor, two driving wheels and two driven wheels are mounted on the lower portion of the chassis, a shaft of each driving wheel is connected with an output shaft of one traveling speed reducer, and an input shaft of each traveling speed reducer is connected with one traveling motor. The tractor can draw an inner container to be in horizontal linear motion on a rail, so that nesting and horizontal axial positioning of the inner container and an outer shell are facilitated; the tractor also can drive the inner container to rotate, so that peripheral positioning of the inner container and the outer shell can be assisted during nesting; the nesting device is continuous and stable in operation in the process of nesting, scratching risk is avoided, and low-temperature performance of the highly-vacuum multilayer heat-insulating LNG tank which is produced finally is unaffected.

Owner:HEAVY EQUIP ENG CO LTD OF WUCHANG SHIPBUILDING IND

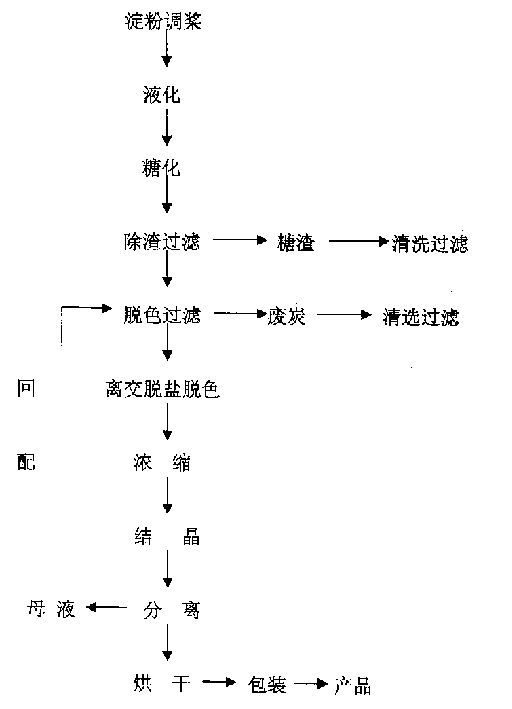

Crystallization process for glucose production

InactiveCN1398989AShorten the production cycleLess investmentGlucose productionGlucose productionD-Glucose

A crystallization process for glucose production features several horizontal crystallizers connected serially for continuous feeding, continuous crystallization and continuous discharging. The stable continuous operation of the crystallization process is maintained by controlling the material inlet temperature, discharging temperature and other several main parameters. Compared with the traditional crystallization process, the present invention has the advantages of low investment in equipment, high production efficiency, continuous stable operation of crystallization process, high product quality and high yield of crystallized glucose.

Owner:XIWANG GROUP

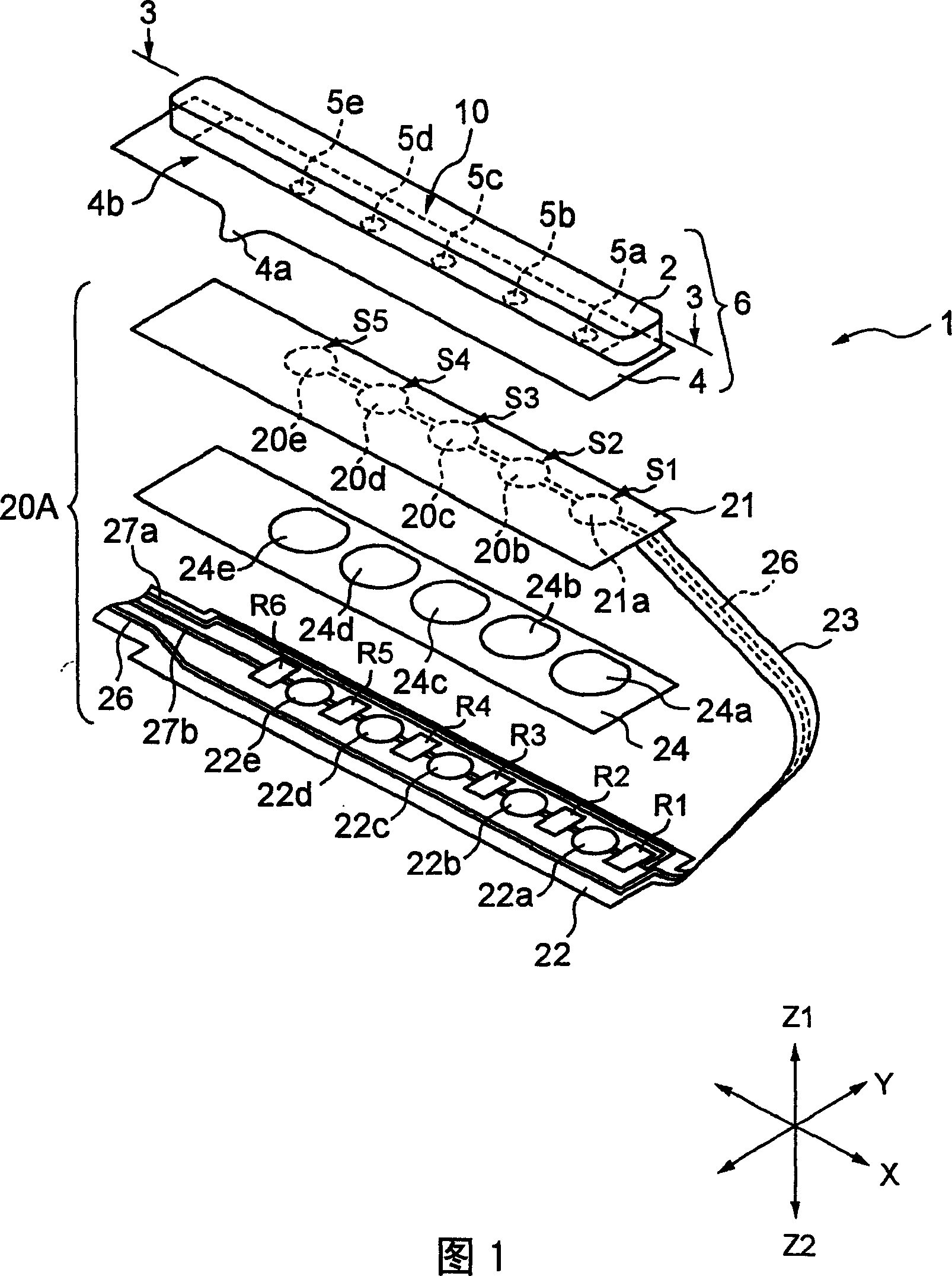

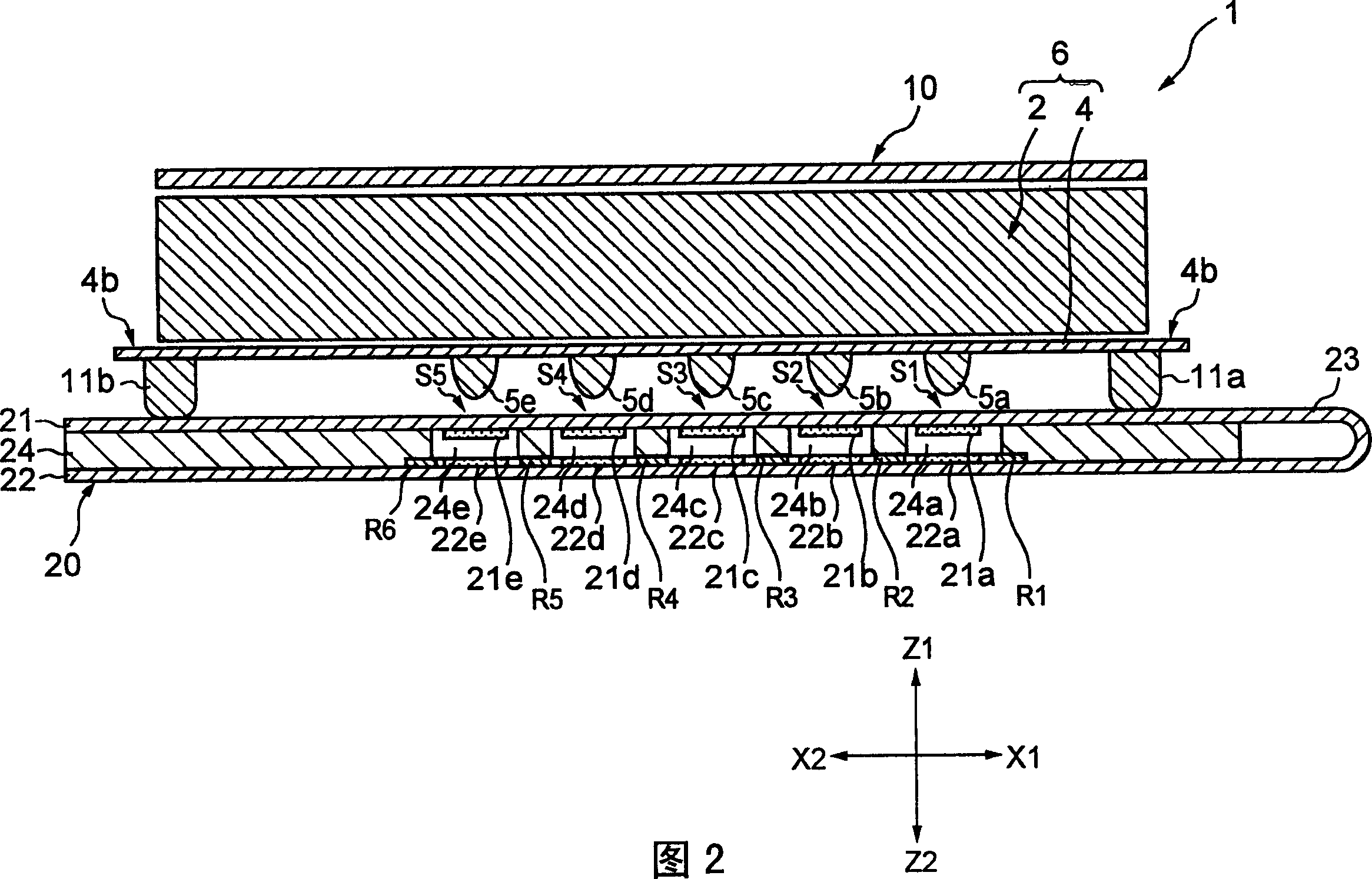

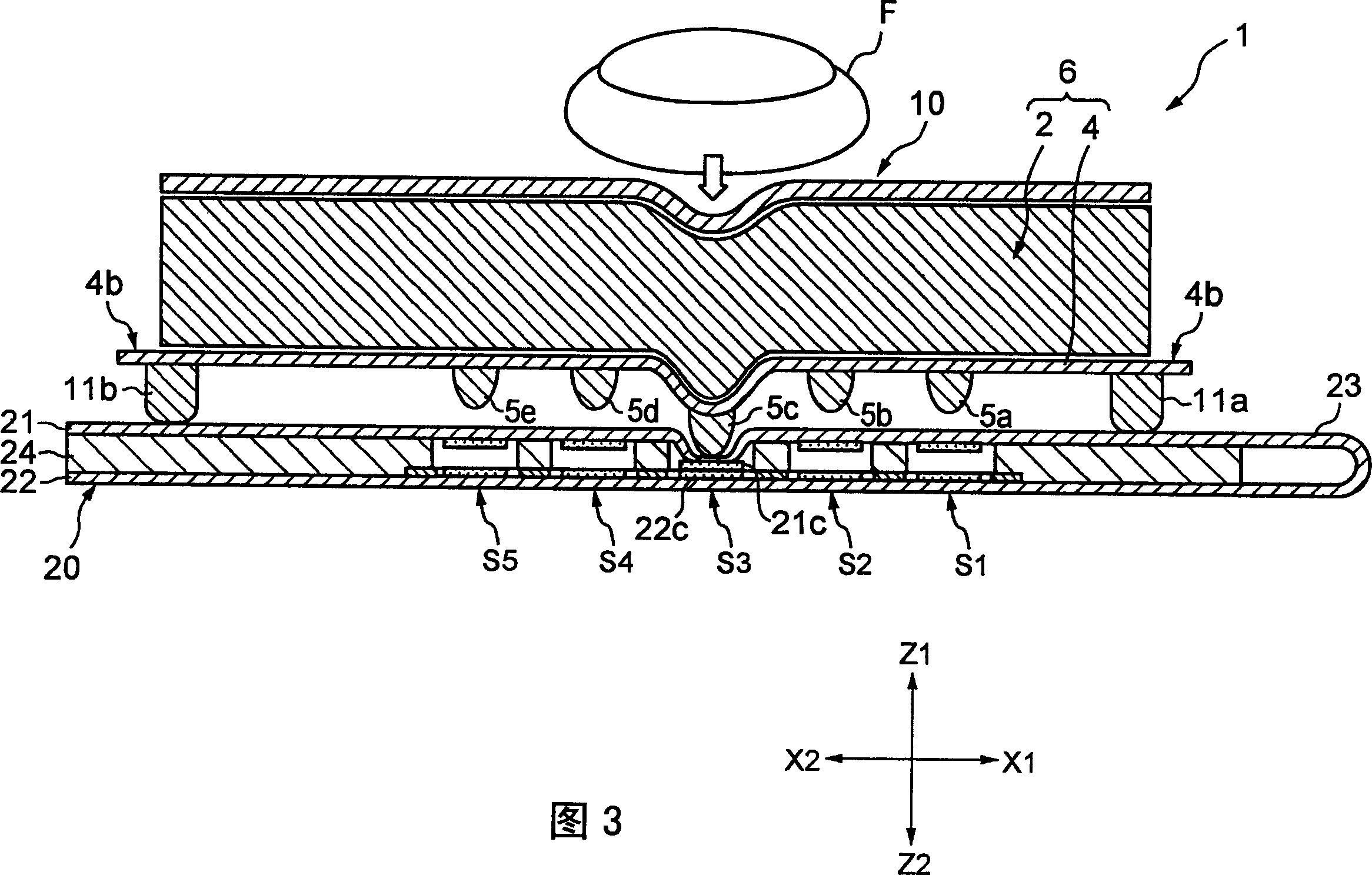

Operation device

InactiveCN1595553AReliable inputEasy to operateControlling membersResisitors with sliding contactCompanion animalLow friction

Provided is an operation device capable of being mounted on a small electronic apparatus and allowing various kinds of operations. A film-like reinforcing member 4 formed of PET or the like is fixed to the undersurface of an elastic member 2 formed of silicone rubber, and a detection means 20A is fixed to its lower part. An operation surface 10 formed of a resin layer having low friction resistance is formed on a surface of the elastic member 2. When the operation surface 10 corresponding to switch parts S1-S5 is pressed, the elastic member 2 and the reinforcing member 4 are locally deformed, and projections 5a-5e turn on the switch parts S1-S5 provided for the detection means 20A. Since the output voltage of an extraction pattern 26 is different on the basis of ON states of the switch parts S1-S5, which switch part is operated can be detected from the output voltage.

Owner:ALPS ALPINE CO LTD

Cement clinker sintering technology and its equipment

InactiveCN1830867AReduce the impact of firingRealize fast burning and rapid coolingClinker productionIt equipmentCombustor

A technology for calcining cement clinker includes metering, adding water, stirring, calcining and cooling. Its apparatus features that a pre-heating and baking chamber at the outlet of feeder is communicated with the draught fan via air drought pipe and the cooling chamber via hot air mixing burner, the cooling chamber is communicated with combustion chamber via sealing pipe, and the combustion chamber is communicated with hot air mixing burner via hot air pipe.

Owner:缪建通

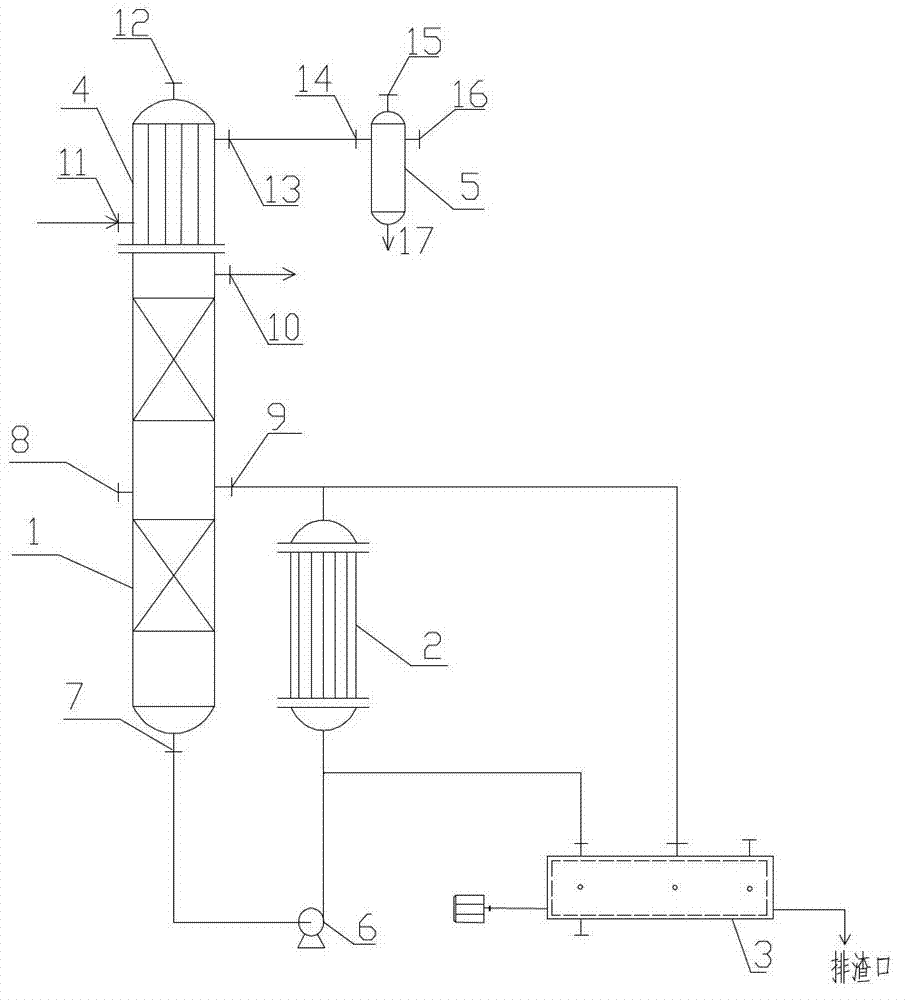

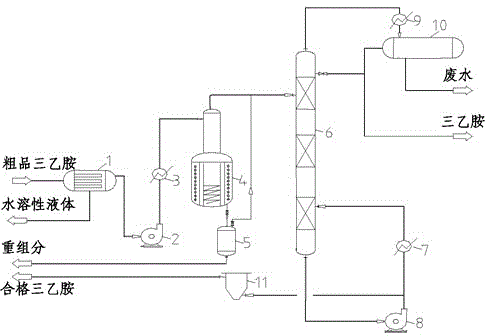

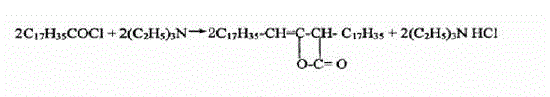

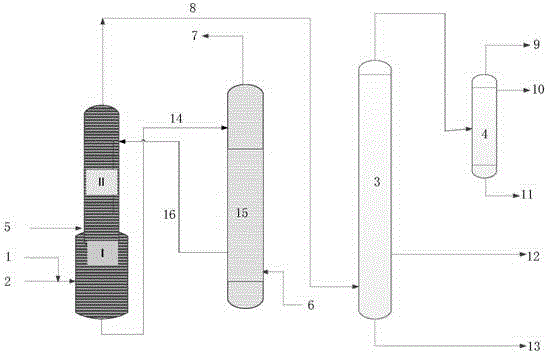

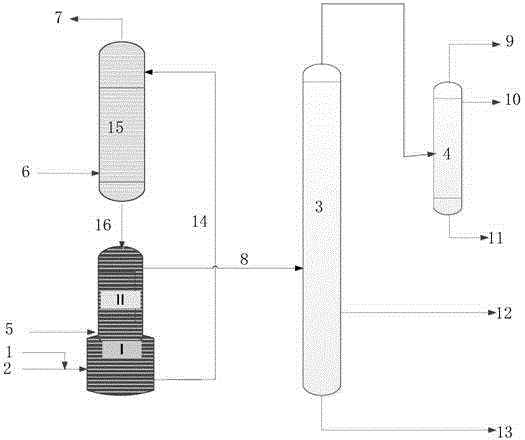

Method for recycling crude product triethylamine in AKD (alkyl ketene dimer) production

InactiveCN104478734AContinuous stable operationImprove evaporation efficiencyAmino compound purification/separationGas phaseEvaporation

The invention relates to a method for recycling a crude product triethylamine in AKD (alkyl ketene dimer) production. The method comprises steps as follows: a, the crude product triethylamine is subjected to crude separation by a decanter; b, the crude product triethylamine enters the top of an evaporator after preheated by a preheater, heavy components enter a revaporizer, residual triethylamine is continuously evaporated in the revaporizer, and the heavy components are discharged from a tower bottom; c, light components continuously enters a rectifying tower after evaporation, and trace moisture in triethylamine is removed according to the azeotropic distillation principle; and d, trace solid particles in the crude product triethylamine evaporation process are removed by a filter arranged at the tower bottom. The crude product triethylamine in the AKD production process is treated and reused in AKD production, waste water and waste residue emission pollution is avoided, gas-phase feeding is adopted, steam consumption is reduced, further, triethylamine recycling rate is high, the production cost of an AKD product is reduced, and more remarkable economic benefits are achieved.

Owner:甘肃银光聚银化工有限公司

Processing method by shale oil through catalytic cracking

ActiveCN105586080AShort processNo hydrogen consumptionTreatment with plural serial stages onlyHydrogen atmosphereColloid

The invention provides a processing method by shale oil through catalytic cracking. The method is characterized in that a moving-bed reactor is divided into an adsorption zone and a cracking zone, under non-hydrogen atmosphere, shale oil is introduced into the adsorption zone of the moving-bed reactor with low temperature, impurity such as a basic nitride, colloid and heavy metal can be absorbed and removed, and then the shale oil is introduced into the cracking zone of the moving-bed reactor and is contacted with a regeneration agent with high temperature and high activity for performing a catalytic cracking reaction. The invention provides the method for producing a lightweight product by the shale oil through direct catalytic cracking, and has the advantages of high shale oil conversion capability, low dry gas and coke, and high liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

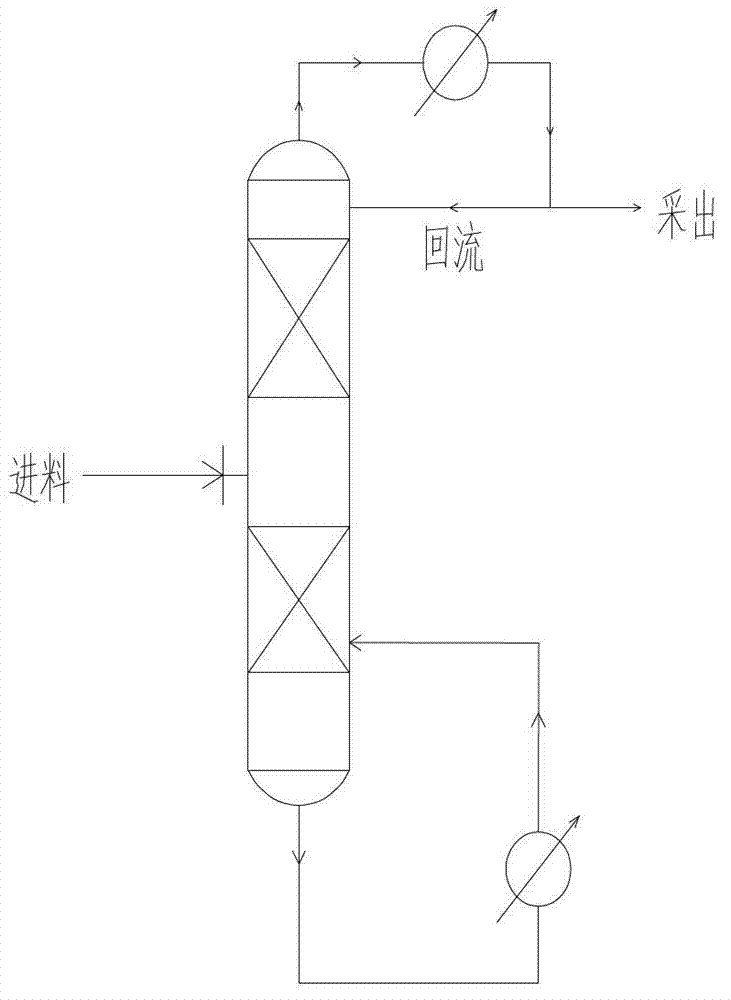

Continuous low-energy consumption acetonitrile refining process

ActiveCN102516119AGuarantee continuous and stable operationContinuous stable operationCarboxylic acid nitrile purification/separationChemical treatmentEconomic benefits

The invention relates to a continuous low-energy consumption acetonitrile refining process which comprises the following steps of: continuously refining crude acetonitrile in a decyanation tower, a chemical treatment kettle, a drying tower, a finished product tower and a tail gas absorbing tower and removing impurities to obtain a qualified acetonitrile product. The chemical treatment kettle comprises three same kettles which are connected with one another in parallel; the three kettles respectively run through process control to accept feeding, reacting and discharging and circularly operate, so that the whole chemical treatment kettle continuously feeds and discharges and continuously refines acetonitrile; and the drying tower and the finished product tower are used for heat integration. Compared with the prior art, the continuous low-energy consumption acetonitrile refining process has the advantages of continuous and stable operation, reduced production energy consumption, reduced operation expense, improved economic benefit and the like.

Owner:WISON ENG

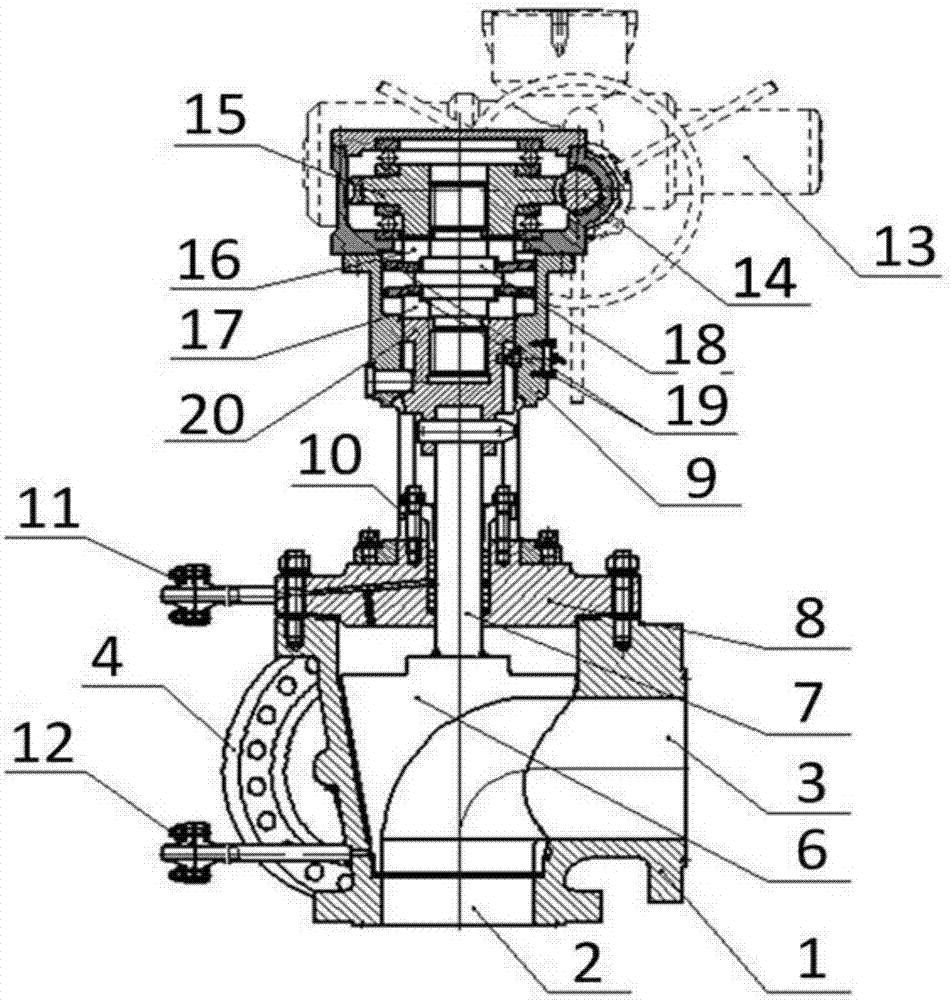

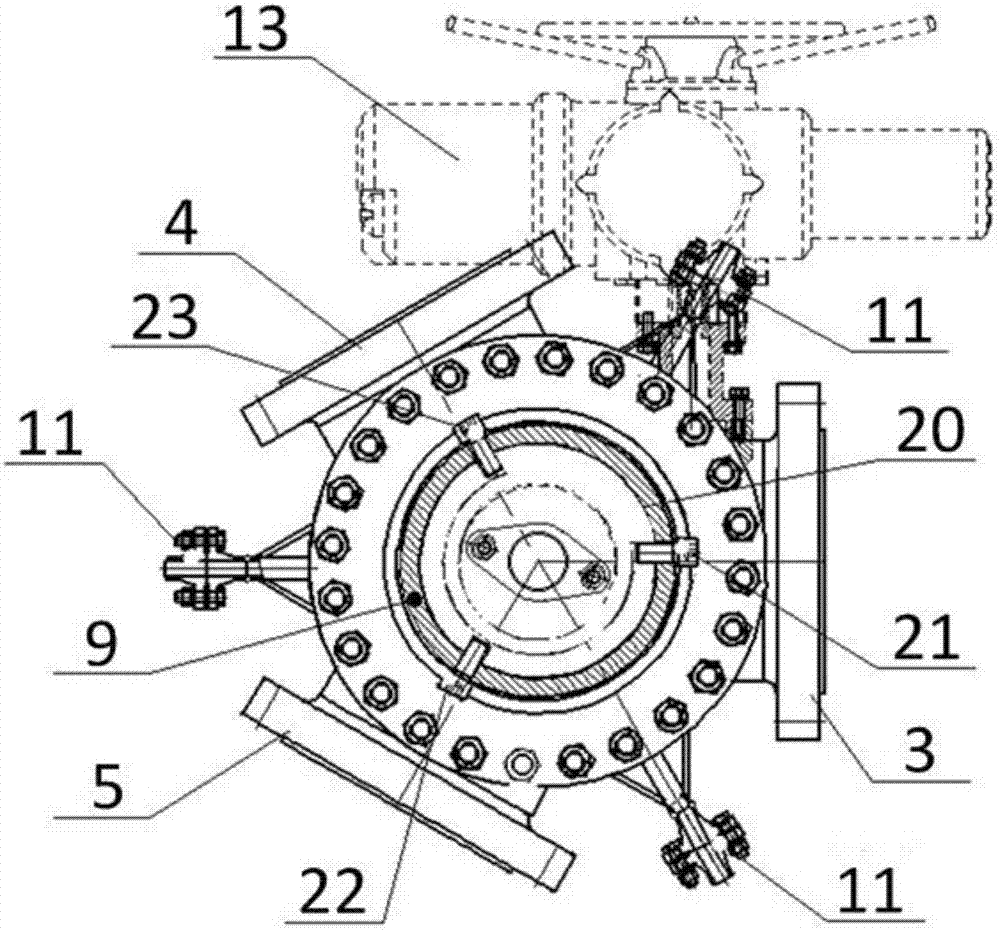

Electric four-way plug valve

InactiveCN107956901AContinuous stable operationSimple structureMultiple way valvesEngineeringHeating furnace

The invention relates to an electric four-way plug valve. The technical scheme includes that the electric four-way plug valve comprises a valve, a main feed inlet, a side feed outlet I, a side feed outlet II, a bypass outlet, a plug, a valve stem, a valve bonnet, a support, a packing gland, packing box blowing devices, a valve cavity blowing device, an electric head, a worm, a worm gear, an upperfriction disc, a lower friction disc, a transmission lead screw, a disc spring and a connector. The electric four-way plug valve has the advantages that the electric four-way plug valve is positionedon a coke tower bottom oil inlet pipeline of a device and is used for switching the flow directions of raw oil, accordingly, the raw oil from a heating furnace can be assuredly timely switched from acoke tower filled with coke to another preheated coke tower to continue to be operated, the device can be continuously and stably operated, is easy to electrically control, low in steam consumption, simple in structure and convenient to operate, and the manufacturing cost and the production and operation costs of the device can be reduced to a great extent.

Owner:樊东升

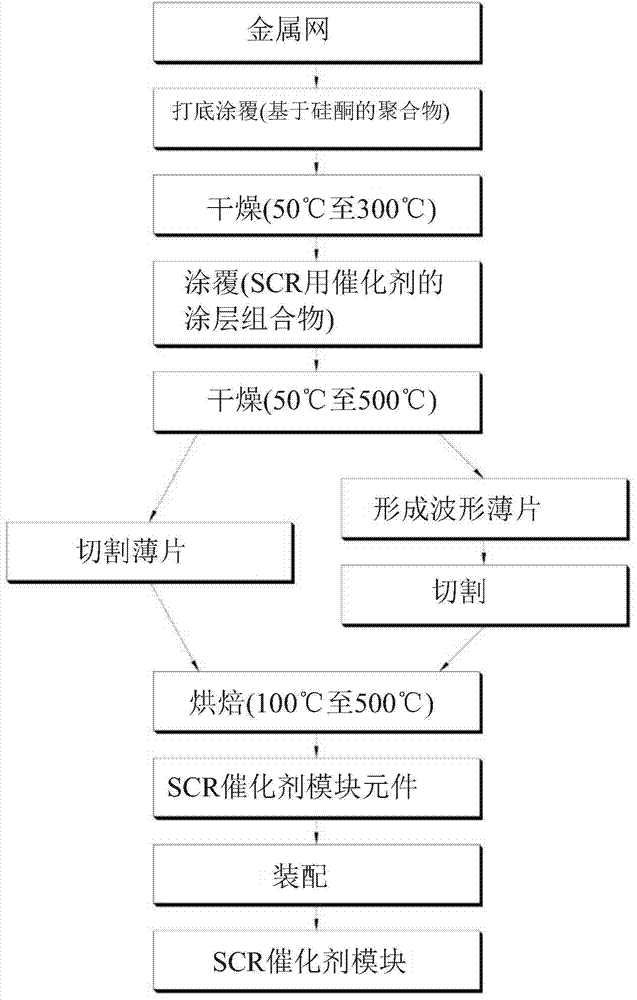

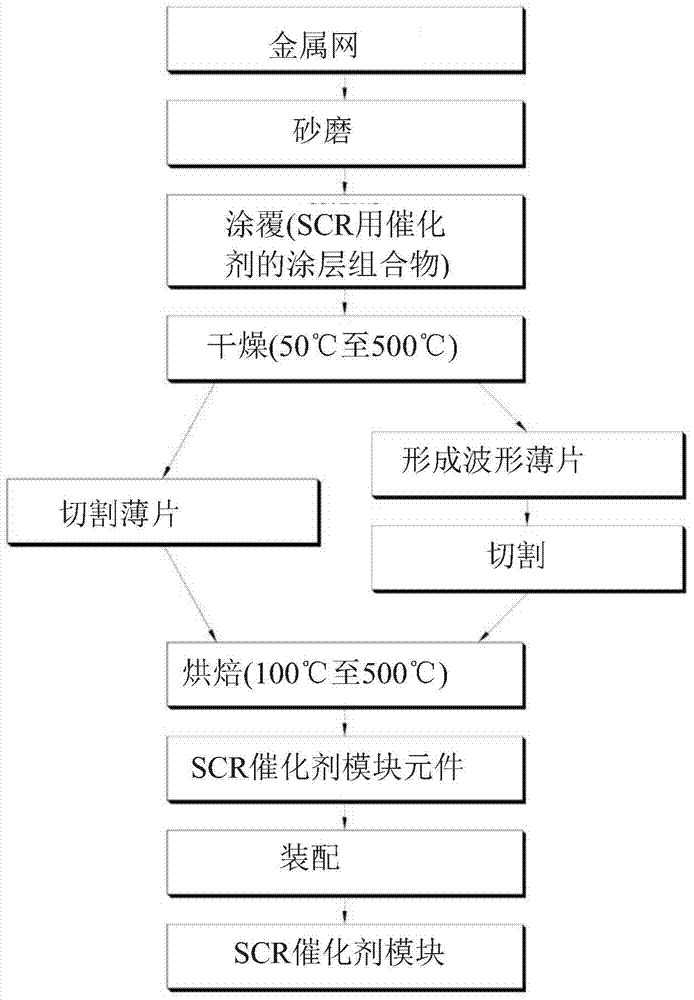

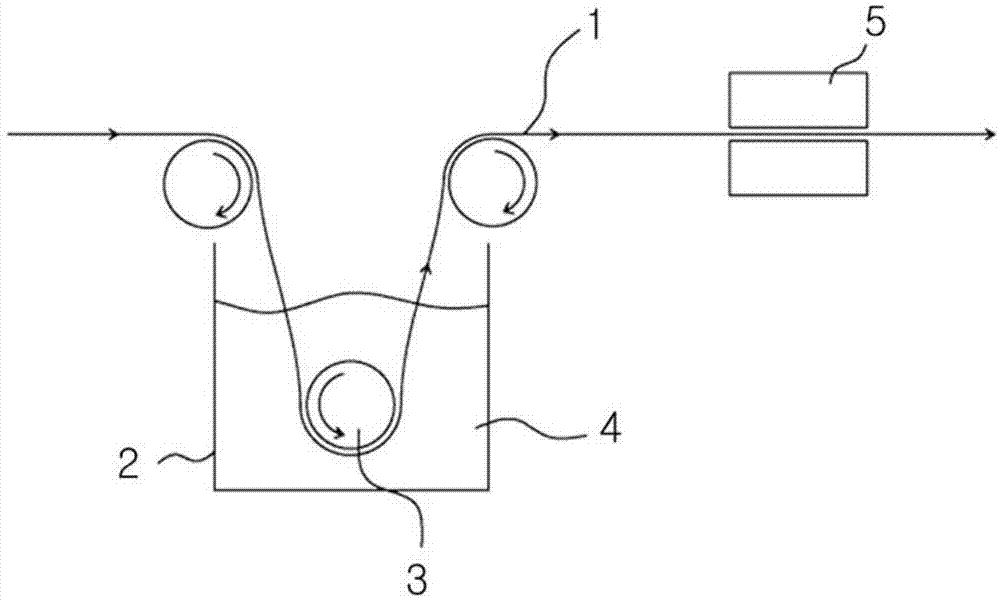

Catalyst module element for selective catalytic reduction, catalyst module using the element, and method for manufacturing the same

ActiveCN103769236AGood wear resistanceReduce crackingOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationContinuous operationChemistry

In a method of using a catalyst for selective catalytic reduction to remove nitrogen oxide included in flue gas, a catalyst module element and a catalyst module are provided which have excellent wear resistance, durability, thermal shock resistance and impact resistance, stable and continuous operation is provided by prevention of damage of a catalyst, and the fracture of the catalyst is caused by the flow velocity of the flue gas. A method for manufacturing the catalyst module element and the catalyst module are also provided. The catalyst module has excellent wear resistance, durability, thermal shock resistance and impact resistance, and damage of the catalyst is minimized, even if impact is applied to the flow velocity of the flue gas containing coal dust when the flue gas passes through a catalyst reactor, and thus shortening of life is suppressed, stable operation can be realized. The removal efficiency of the nitrogen oxide is excellent, and the manufacturing method is simple.

Owner:大英C&E

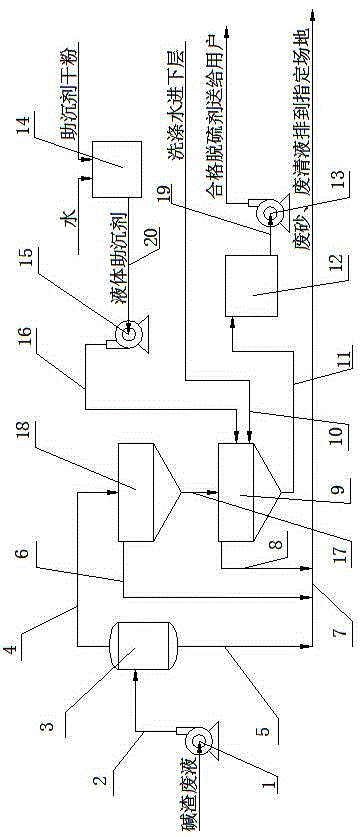

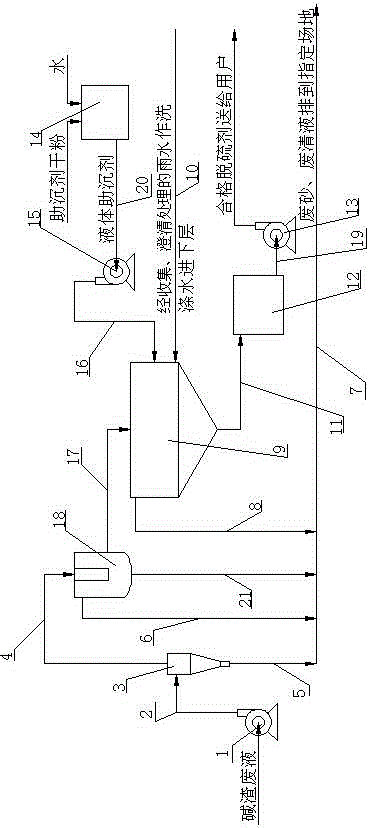

Preparation device and method for alkali residue liquid desulfurizing agent

ActiveCN104857831AAvoid loading and unloadingBlock deliveryDispersed particle separationFlue gasProcess engineering

The invention relates to a preparation device and method for a desulfurizing agent, in particular to a preparation device and method for an alkali residue liquid desulfurizing agent. The preparation device comprises an alkali residue conveying pump, wherein the alkali residue conveying pump is connected with a sand removal device through a first pipeline; the top end of the sand removal device is connected with a thickener through a second pipeline; the upper part of the thickener is connected with a main collection pipeline through a first overflow pipeline; the thickener is connected with a chlorine reducing bucket through a fifth pipeline; an assistant preparation tank is connected with a middle layer of the chlorine reducing bucket; a washing water pipeline is connected with a lower layer of the chlorine reducing bucket; the bottom of the chlorine reducing bucket is connected with a finished product buffer bucket through a sixth pipeline; an upper layer of the chlorine reducing bucket is connected with the main collection pipeline through a second overflow pipeline. The preparation method comprises the following steps: performing gravitational sand settling, thickening and settling and chlorine reduction by washing, performing settling and thickening, discharging the liquid desulfurizing agent from the bottom of the chlorine reducing bucket, and enabling the liquid desulfurizing agent to enter the buffer bucket for storage. Compared with the prior art, the application of high-energy equipment such as a pressure filter, a centrifuge and the like is avoided, mechanical solid-liquid separation of waste alkali residue liquid is avoided, and the flue gas desulfurization effect is effectively improved.

Owner:TANGSHAN SANYOU CHEM IND

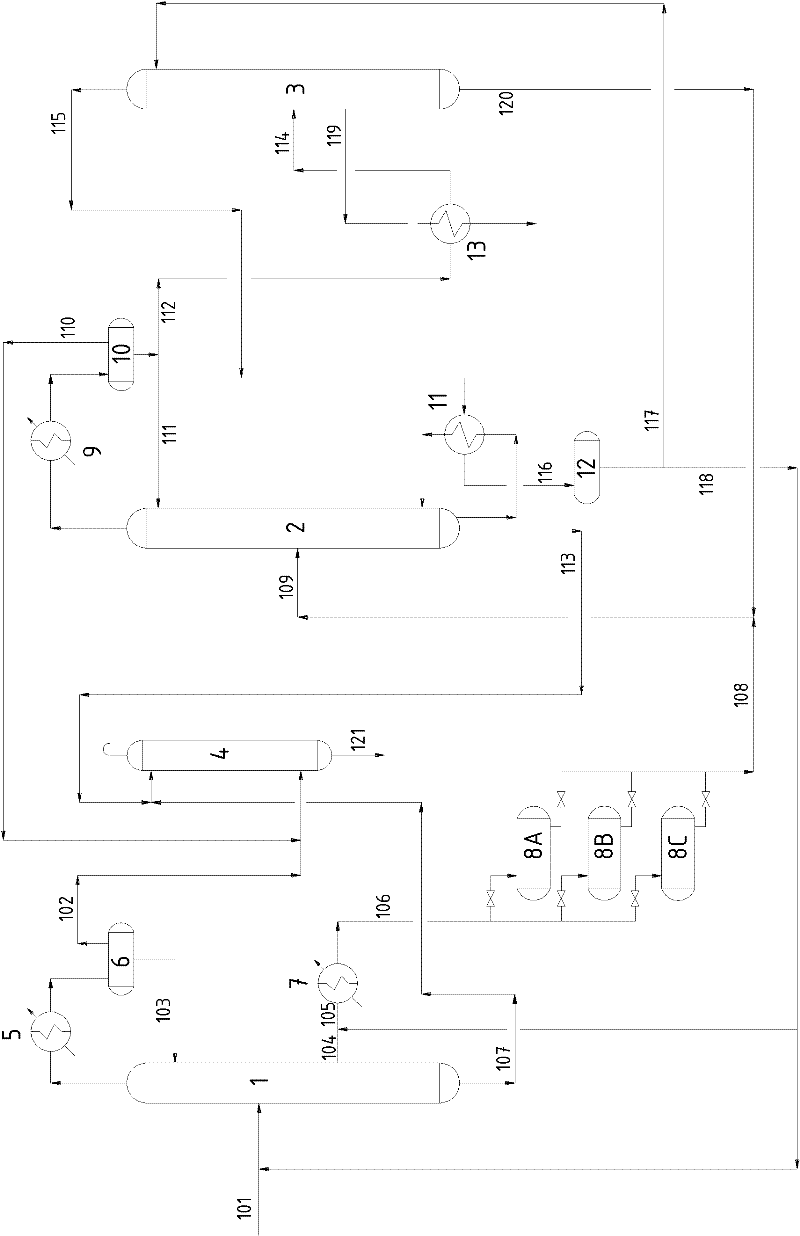

Process for producing (meth)acrolein or (meth)acrylic acid

InactiveCN1697798AAvoid stopContinuous stable operationOrganic compound preparationOrganic chemistry methodsMeth-Decomposition

There is provided a process for producing (meth)acrolein or (meth)acrylic acid which is capable of avoiding stoppage of operation of a plant for production thereof as a whole due to failure of an oxidation reaction step in the process and ensuring a continuous stable operation of the plant, and is excellent in economical aspects. The process for producing (meth)acrolein or (meth)acrylic acid according to the present invention sequentially comprises an oxidation reaction step of subjecting a raw gas to gas-phase catalytic oxidation; a reaction gas cooling step of cooling the resultant reaction gas; a low-boiling fraction separation step of separating low-boiling components from the reaction product; a purification step of separating and removing high-boiling components from the reaction product; and a high-boiling fraction decomposition step of decomposing high-boiling components contained in a bottom liquid obtained from the purification step, said oxidation reaction step comprising a plurality of oxidation reaction steps which are disposed in parallel with each other and operated at the same time.

Owner:MITSUBISHI CHEM CORP

Blue alga cake tubular pyrohydrolysis dewatering method and device

InactiveCN102303942AShorten spin timeSettling fastSludge treatment by de-watering/drying/thickeningEngineeringEnergy recovery

The invention provides a blue alga cake tubular pyrohydrolysis dewatering method and a blue alga cake tubular pyrohydrolysis dewatering device. The device provided by the invention consists of a feeding system, a modifying system, a dewatering system, a heat exchange system and a purifying system. The method comprises: filling the pretreated blue alga cake raw material with a water content of about 80 percent by using raw material tank, heating the raw material by low-pressure steam directly, performing pyrohydrolysis under a medium-temperature condition, fully recovering and using residual energy in a hydrolysis process, adding treated clay, increasing the specific gravity of the mixture and obtaining a liquid-solid mixture; making the water content in the treated material obtained after liquid-solid separation adjustable, and reducing the water content to 40 to 60 percent from the 80 percent in the originally treated blue alga cake. Compared with the prior art, the device has the advantages that: the structure is simple, the operation is continuous and smooth; the hydrolysis temperature of algae is 110 to 150 DEG C; the reaction time is 10 to 20 minutes; the alga treatment is economic; reduction and innocent treatment can be realized quickly and effectively; and large-scale treatment can be carried out easily. Therefore, the invention provides a new approach for the treatment, disposal and recycling of blue algae and the recovery of energy from the equipment.

Owner:安徽合协生态环境科技有限公司

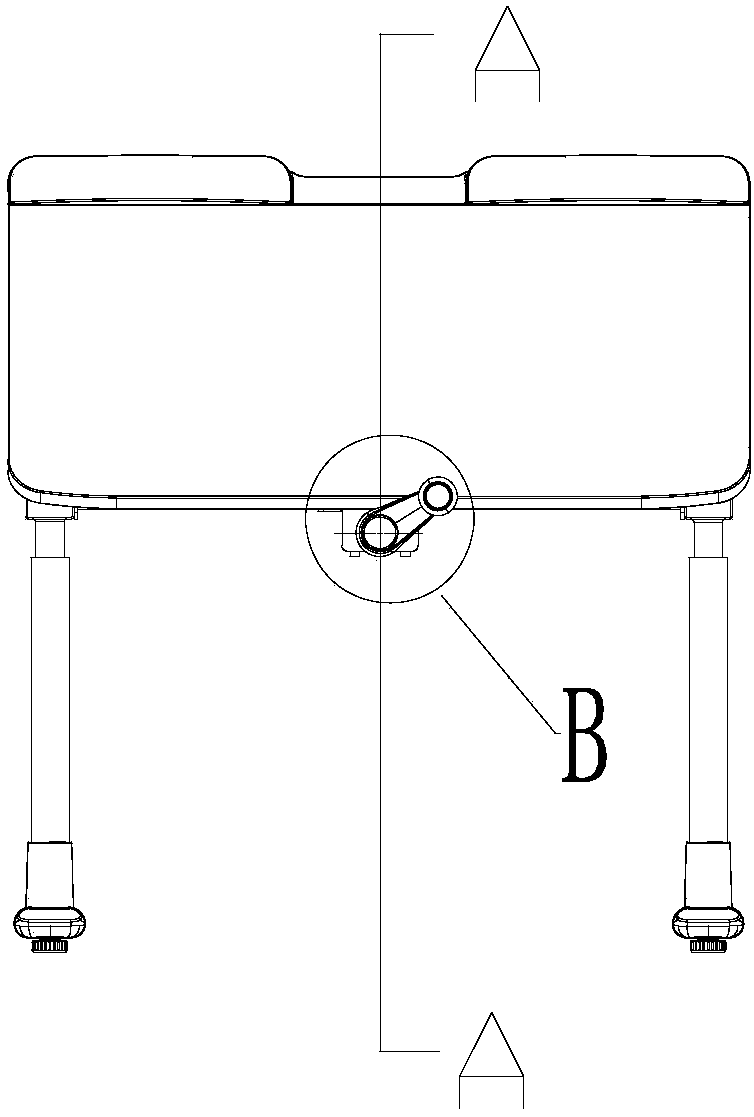

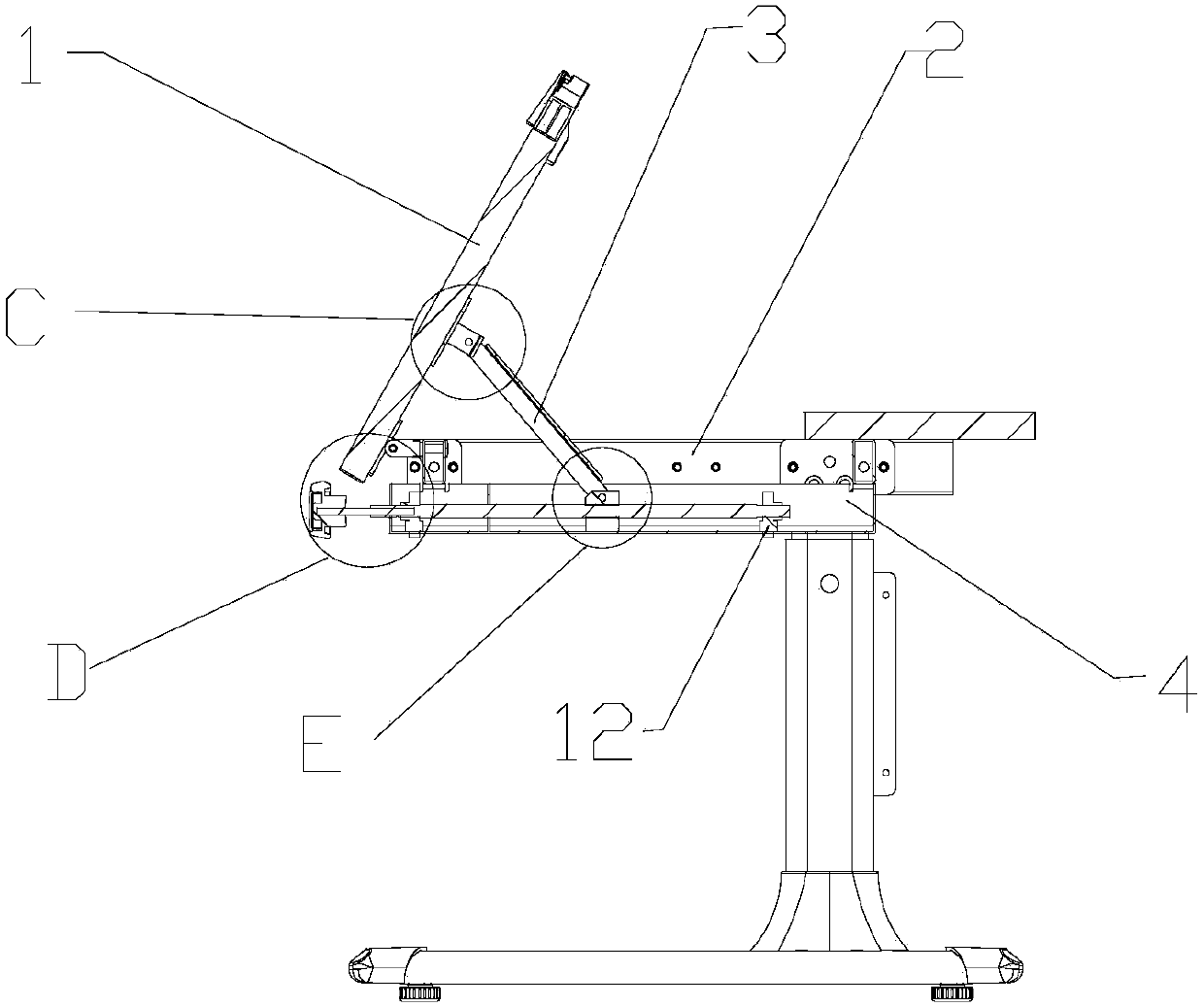

Regulating mechanism realizing continuous and wide-range adjustment on dip angle of table board and learning table

PendingCN107692513ASimple structureLabor-saving operationDrawing desksFeetRolling-element bearingCrank

The invention provides a regulating mechanism realizing continuous and wide-range adjustment on the dip angle of a table board and a learning table using the regulating mechanism. The regulating mechanism comprises a connecting part, a trapezoidal screw, a first rolling bearing with a box, a second rolling bearing with a box, a trapezoidal nut slider and a hand crank, wherein the upper end of theconnecting part is hinged to the back side of the table board, and the lower end of the connecting part is hinged to the trapezoidal nut slider; a first end of the trapezoidal screw and the first rolling bearing with the box are in transition fit, and the part, close to the second end, of the trapezoidal screw and the second rolling bearing with the box are in transition fit; the first rolling bearing with the box and the second rolling bearing with the box are fixedly connected with a table board fixing rack; and the hand crank is arranged in the second end of the trapezoidal screw. For the regulating mechanism and the learning table, the trapezoidal screw and the trapezoidal nut slider are in screwing match, a self-locking effect is achieved, the self-locking is steady and reliable, theadditional locking and unlocking components and parts are not needed, the learning table with the design is simple in structure, and easy and labor-saving to operate, more important, the dip angle adjustment is smooth and steady, as well as continuous, and the range is large. The adjustment on the dip angle of the table board can reach 90 degrees, and continuous adjustment within 0-90 degrees canbe realized.

Owner:ZHEJIANG ANJI CHILD CARE FURNITURE CO LTD

Hydrogenation method for producing hydrogen peroxide and device adopting hydrogenation method

InactiveCN104150447AWon't clogWon't cause cloggingPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesYarnPtru catalyst

The invention discloses a hydrogenation method for producing hydrogen peroxide and a device adopting the hydrogenation method. The hydrogenation method comprises the following steps: adding hydrogen-containing gas, and a working solution prepared by dissolving alkylanthraquinone in an organic solvent into a reactor in which a stirrer and a filtering element are arranged; in a stirring state, sufficiently contacting and reacting the working solution, the hydrogen-containing gas and a powdery catalyst to obtain hydrogenated slurry liquid; filtering the obtained hydrogenated slurry liquid by a filtering element to obtain hydrogenated clear liquid; continuously draining the hydrogenated clear liquid out of the reactor, wherein in the filtering element, a filtering material with a filtering function is selected from filter cloth or a metal mesh; the diameter of the thinnest yarn in yarns of the filter cloth or the metal mesh is not greater than the diameter of more than 99wt% of particles in the powdery catalyst. The hydrogenation method provided by the invention integrates reaction, gas-liquid separation and liquid-solid separation and has large filtering flux; backwashing is not required during the liquid-solid separation; the hydrogenation method has the advantages of being simple operation, small in occupied area, low in investment, easy to popularize and the like; by the hydrogenation method, continuous smooth operation can be achieved.

Owner:河北都邦石化工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com