Hydrogenation method for producing hydrogen peroxide and device adopting hydrogenation method

A technology for producing hydrogen peroxide and hydrogenation reaction, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve complex operation control, Occupy a lot of land, equipment investment and other problems, to achieve the effect of reducing the system volume, area reduction, saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

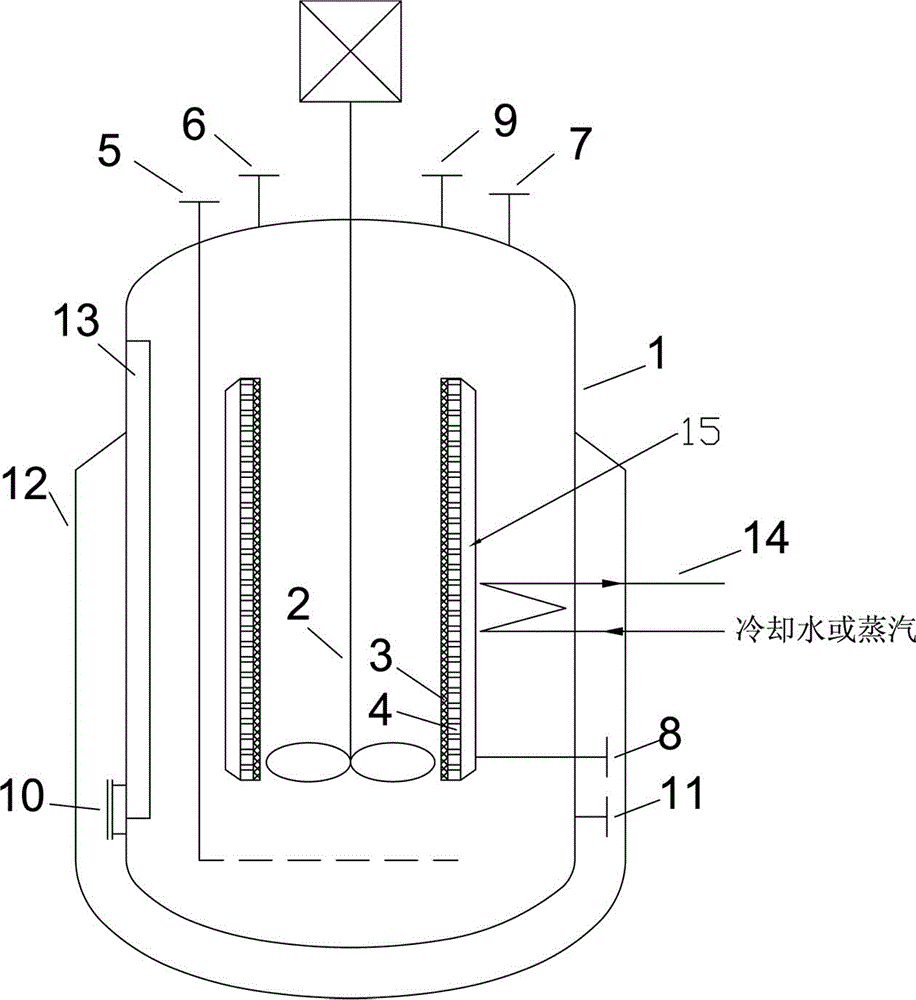

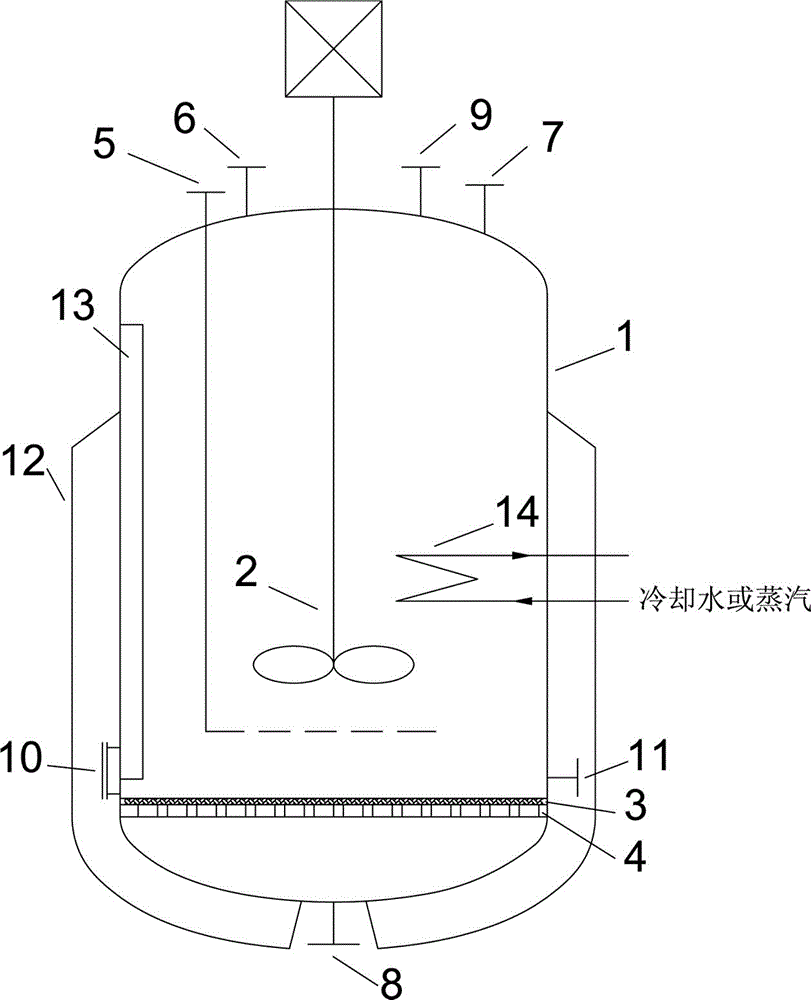

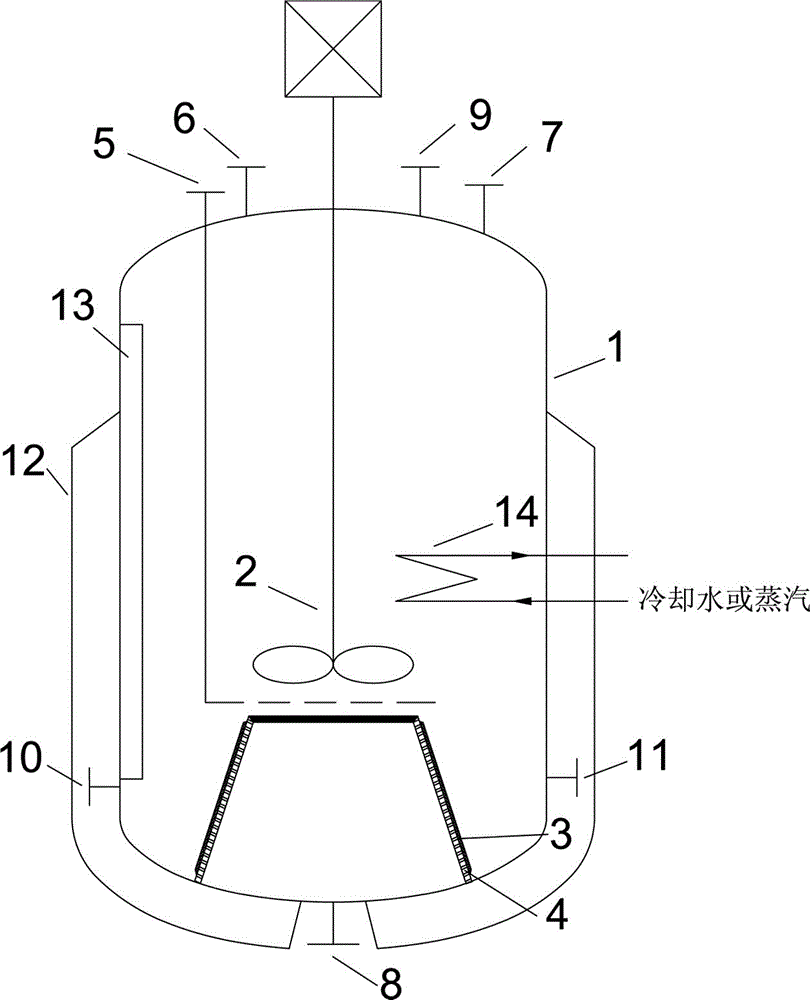

[0053] use figure 2 The structure of the reactor shown: the reactor shell is composed of upper and lower elliptical heads and a cylindrical straight cylinder in the middle, with a height-to-diameter ratio of 1.0, and a push-type impeller. The ratio of the impeller diameter to the reactor diameter is 1 / 3. The filter material in the filter element is a layer of stainless steel mat-type wire mesh with a warp mesh of 165 mesh and a weft mesh of 1100, in which the diameter of the weft is 0.045 mm and the diameter of the warp is 0.071 mm. The wire mesh is fixed on a stainless steel perforated plate, and the perforated plate is fixed between the reactor cylinder and the lower head by a flange. The speed of the stirrer is 200 rpm.

[0054] Add 12 kg of palladium-supported catalyst into the reactor from the catalyst feed pipe 9, and the particle size distribution of the catalyst is 50-100 microns. Hydrogen 43 Nm 3 / h Enter the hydrogenation reactor through the inlet pipe 5, and establis...

Embodiment 2

[0056] According to the same conditions as in Example 1, except that 0.018 kg of catalyst with a particle size distribution of 20-45 microns was added to the reactor, the filtration flux was reduced by 30% compared with Example 1. After 240 hours of continuous operation, the filtration flux remained stable.

Embodiment 3

[0058] According to the same conditions as in Example 2, only 0.13 kg of catalyst with a particle size distribution of 20-45 microns was added to the reactor. After 2 hours of operation, the filtration flux dropped significantly and the reaction was forced to stop.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com