Patents

Literature

62results about How to "Won't cause clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

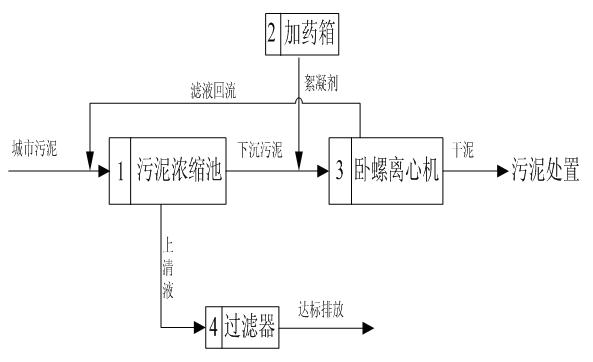

Integrated treatment method for thickening, drying and purifying municipal sludge

InactiveCN102167490AReduce dosageRealize synchronous processingSludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeWastewater

The invention discloses an integrated treatment method for thickening, drying and purifying municipal sludge. The method comprises the steps as follows: the municipal sludge is concentrated in a sludge concentrating pool, and the concentrated submerged sludge is transported into a decanter centrifuge; a polyacrylamide cationic flocculating agent in a medicine adding box is added into the decanter centrifuge, wherein 2-3g of polyacrylamide is added into each kilogram of the submerged dried sludge, and solid particles in the submerged sludge are bonded together to form a plurality of particle groups, so that solid is separated from liquid to form a supernate and a mud cake; the mud cake is transported into a sludge treating place by a shaftless screw conveyer, and the supernate is transported to a sludge concentrating pool through a clear liquor pipeline by a water pump in a reflowing way; the supernate in the sludge concentrating pool is transported to the bottom of a filter by an overflowing groove through a pipeline; and the solid is separated from the liquid due to the centrifugal precipitation principle of the decanter centrifuge, the sludge with different charging concentrations is treated by less flocculating agent, and the physical filtering function and the physical absorbing function of the filler are abundantly acted, so that the municipal sludge and the wastewater produced by the municipal sludge can be synchronously treated.

Owner:JIANGSU HENGLIANG CENTRIFUGE MFG

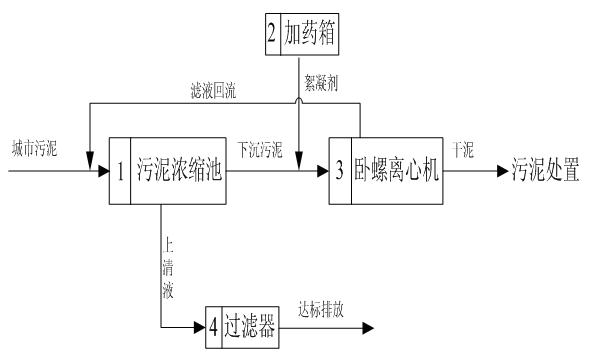

Edible ink for ink-jet printing on surface of eggshell and preparation method thereof

The invention discloses edible ink for ink-jet printing on the surface of an eggshell, which comprises the following components in percentage by weight: 3-6% of edible pigment, 0.01-0.5% of hydroxypropyl cellulose, 0-20% of propanediol, 0.0001-0.1% of ink lubricant, 0.0001-0.05% of dispersant and the balance of water. The preparation method comprises the following steps: preparing 0.1-5wt% of hydroxypropyl cellulose water solution; preparing the ink lubricant having a polydimethylsiloxane-silicon dioxide ratio of (8.5:1.5)-(9:1); preparing an emulsion from the ink lubricant, the dispersant and the water; and preparing the product from the edible pigment, the propanediol, the hydroxypropyl cellulose water solution and the emulsion. Compared with the prior art, the ink disclosed by the invention is safe to eat and highly applicable to various ink-jet printers, and has the advantages of excellent visibility, water resistance, stability and the like for an eggshell.

Owner:天津天康源生物技术有限公司

Rancidity-prone waste biogas utilization method based on in-subarea inoculation and quick start

The invention belongs to the technical field of solid waste pollution control, and relates to a method for making biogas from waste, which comprises the following steps: (1) pretreating the waste; (2) feeding the waste into a waste loading area for hydrolysis and acidification; (3) feeding the material subjected to hydrolysis and acidification in step (2) into a microbial inoculum loading area, and performing biogas production reaction under the effect of the microbial inoculum; (4) flowing out the material treated in step (3) from the microbial inoculum loading area, and returning to the waste loading area for further hydrolysis and acidification; and (5) repeating the cycle from step (2) to step (4) multiple times until the conversion of the waste into biogas is maximized. The invention overcomes the disadvantages of high rancidity possibility, long gas production start time, low gas production yield and gas production rate and the like of the waste conventional biogas utilization system, can greatly accelerate the gas production process of the rancidity-prone waste with a small amount of microbial inoculum, increases the gas production yield of the waste, lowers the amounts of leavings and waste liquids, and decreases the volume of a reactor and the operating cost.

Owner:TONGJI UNIV

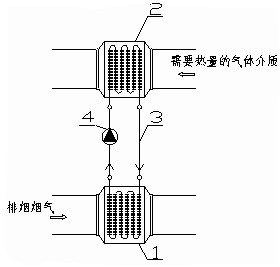

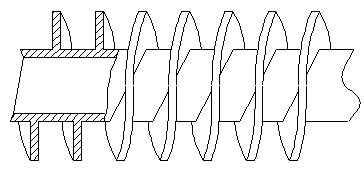

Device for recovering and utilizing waste heat generated by smoke discharging in split type heating medium circulating way

InactiveCN102384680AImprove thermal stabilityNo pollution in the processCombustion processIndirect heat exchangersCirculator pumpProcess engineering

The invention discloses a device for recovering and utilizing waste heat generated by smoke discharging in a split type heating medium circulating way, which comprises a heat absorbing and exchanging device, a heat releasing and exchanging device, and a connection pipeline and a circulation pump filled with heating medium heat conduction liquid, and is characterized in that low-temperature heat conduction oil is adopted as the heating medium heat conduction liquid, is used for absorbing the waste heat of the smoke in an exit flue, is delivered to the heat releasing and exchanging device through the connection pipeline after absorbing the waste heat, and is delivered to gas media needing the waste heat by the heat releasing and exchanging device, thereby recovering and utilizing the waste heat; and the heat absorbing and exchanging device and the heat releasing and exchanging device are tube type heat exchangers adopting oval tube H-shaped fin heat pipes. Heat conduction oil is used as the heating media to replace water, so that the device is applicable to cold regions, the temperature of which ranges from minus 30 DEG C to minus 50 DEG C, is not solidified when equipment is stopped for overhaul, and does not need to be heated additionally; and by adopting the tube type heat exchanger adopting the oval tube H-shaped fin heat pipe, the flow resistance at a smoke or gas side is small, the energy consumption is low, and the self-deashing effect is better, thereby preventing a smoke channel from being blocked.

Owner:上海和衡能源科技发展有限公司

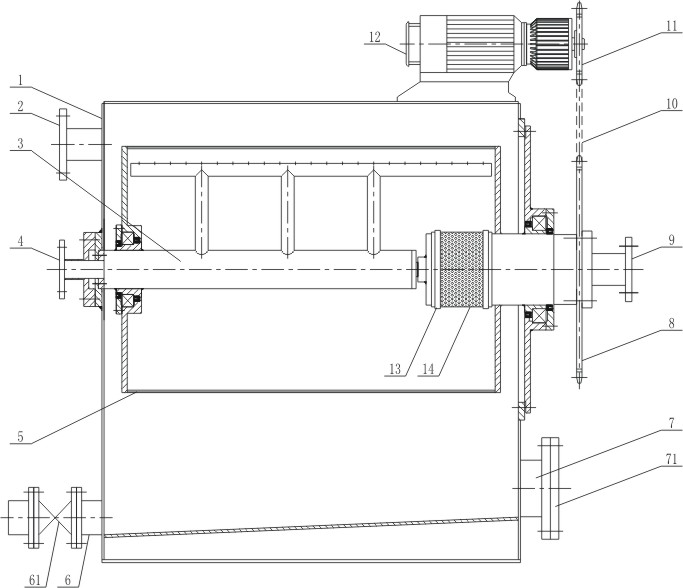

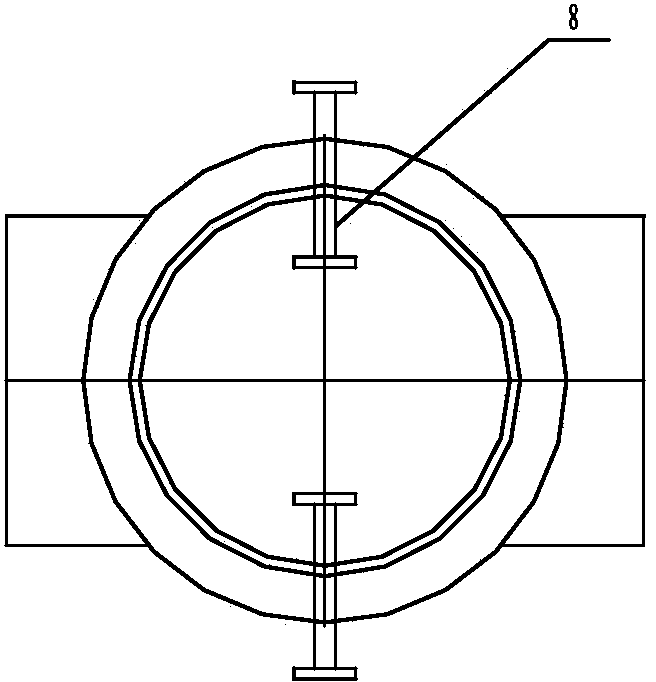

Fine filter device of high pressure back-flush rotary filter drum

InactiveCN102657969AGood technical effectHigh filtration precisionStationary filtering element filtersDouble filtrationHigh pressure

The invention discloses a fine filter device of a high pressure back-flush rotary filter drum. The fine filter device comprises a shell, a filter drum, a sewage inlet pipe, a sewage discharge pipe, a back-flush water inlet pipe, a water outlet pipe and a high pressure fixed spray pipe, wherein the high pressure fixed spray pipe is arranged in the filter drum; one end of the water outlet pipe is connected with a water inlet with a filter screen; the end with the filter screen of the water inlet with the filter screen is positioned in the filter drum; one end of the filter drum is connected with the high pressure fixed spray pipe through a first bearing, and the other end of the filter drum is connected with the water inlet with the filter screen; one end of the water inlet with the filter screen is arranged on the shell through a second bearing, and the other end of the water inlet with the filter screen is connected with the high pressure fixed spray pipe through a third bearing; the top of the shell is provided with a motor; an output shaft of the motor is provided with a driving chain wheel; a driven chain wheel is arranged at a connecting end of the filter drum with the water outlet pipe; and the driving chain wheel is connected with the driven chain wheel through a chain. Double filtration is formed through the filter screen on the filter drum and the water inlet with the filter screen, so that the filtration accuracy of water is improved.

Owner:WISDRI WUHAN WIS IND FURNACE

A kind of wet chemical preparation method of ceramic separation membrane

ActiveCN102258945AIncrease Separation ThroughputNarrow pore size distributionSemi-permeable membranesNitrateMicrometer

The invention relates to a wet chemical preparation method for a ceramic separation membrane. The method provided by the invention comprises the following steps: adding aluminum oxide particles with the particle size of 30-70 micrometers and an aqueous solution which is prepared by dissolving aluminum nitrate, titanium alkoxide and lanthanum nitrate or yttrium nitrate in advance into a sufficientquantity of ammonia water; adjusting the pH value to 8-10; after fully reacting at 65-90 DEG C, precipitating, washing, aging and drying; presintering at 500-800 DEG C to obtain the aluminum oxide particles coated with nano oxides; after mixing the aluminum oxide particles coated with the nano oxides and an organic molding assistant, kneading to form plastic pug; extruding to form a green body ofa support body; sintering the green body for 0.5-5 hours at 1450-1700 DEG C to form the support body; and coating a membrane and sintering to obtain a ceramic separation membrane product. The preparation method provided by the invention has the advantages that a nano material is utilized to coat Al2O3 powder, thus spherical particles with high sintering activity is obtained, a molding formula andprocess in production procedures can be simplified and the complicated courses of drying the green body and turning over the green body can be avoided.

Owner:SANDA FILM SCI & TECH XIAMEN

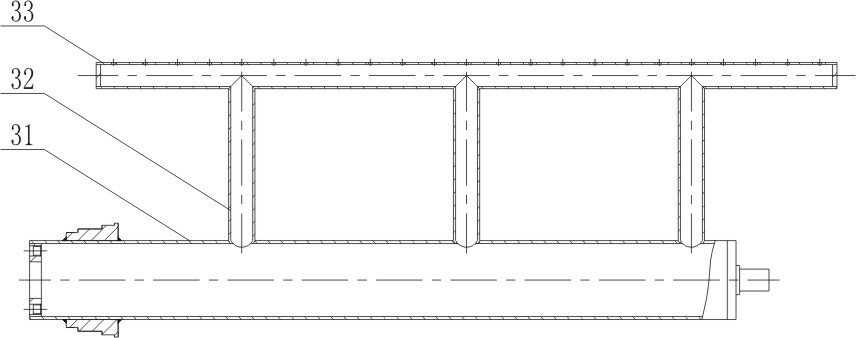

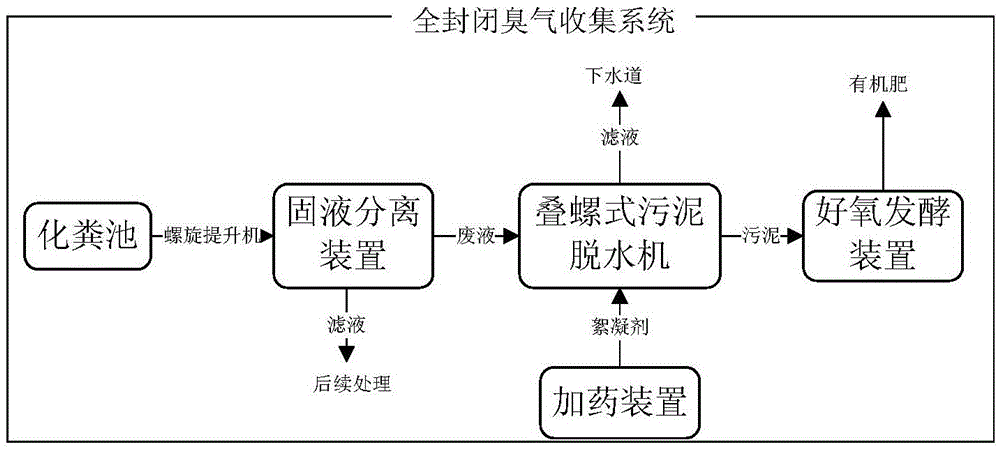

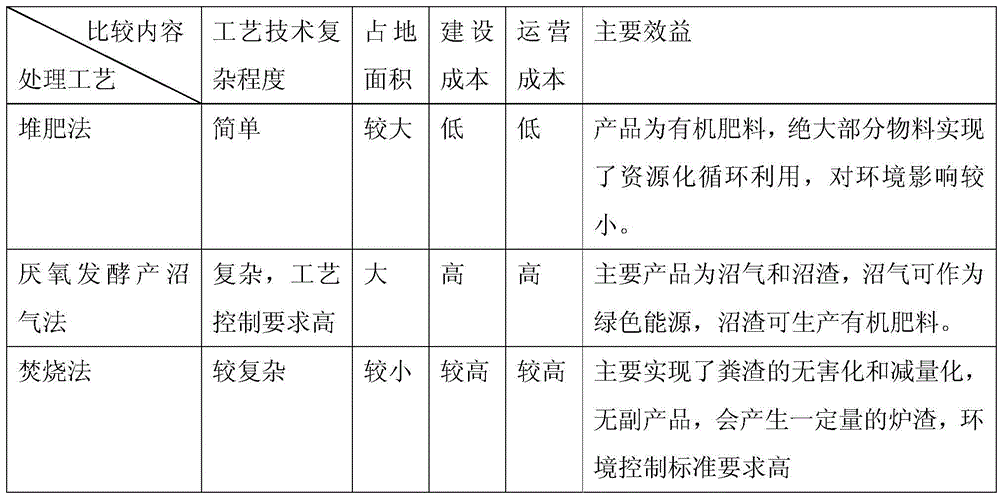

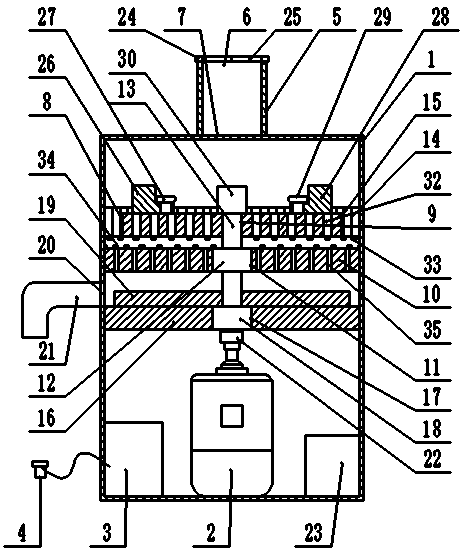

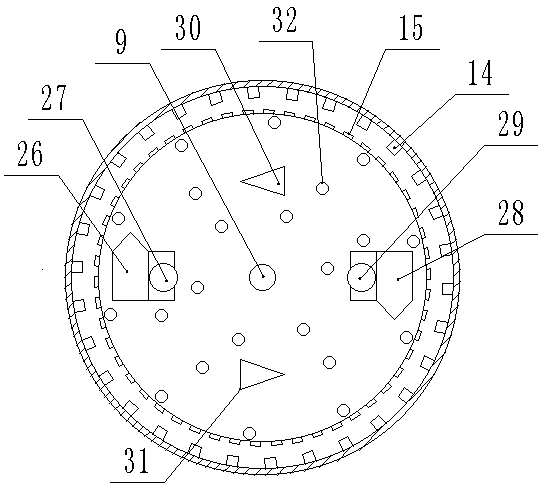

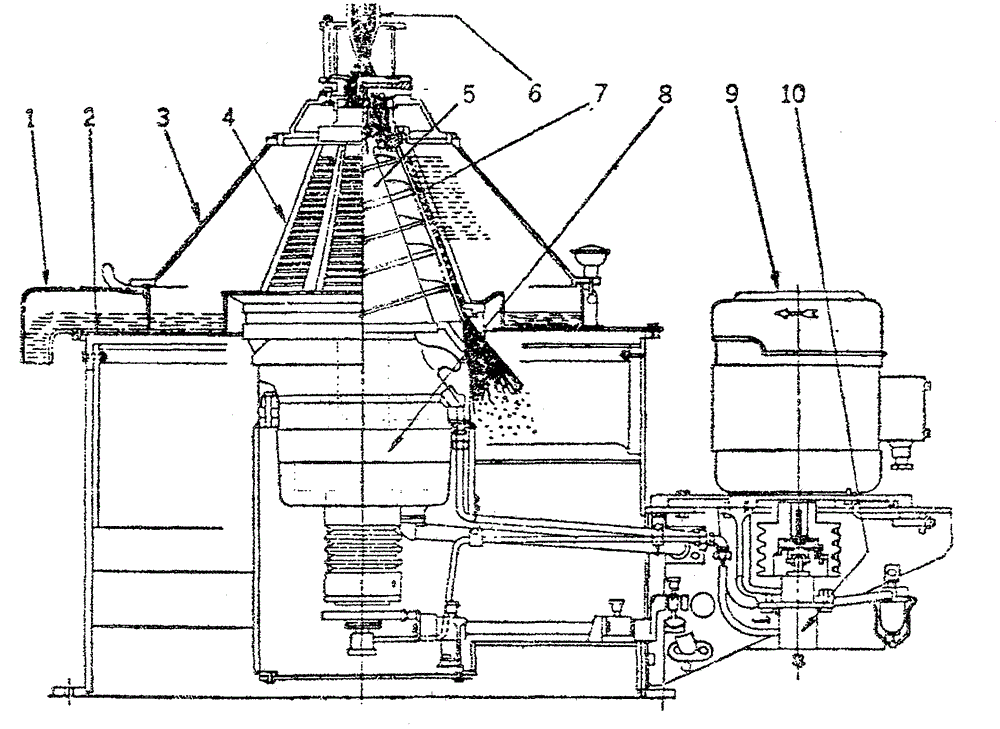

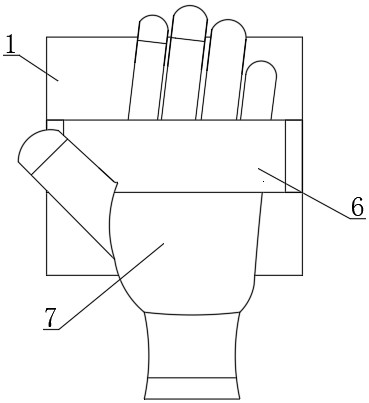

Night-soil on-site treatment system and treatment method thereof

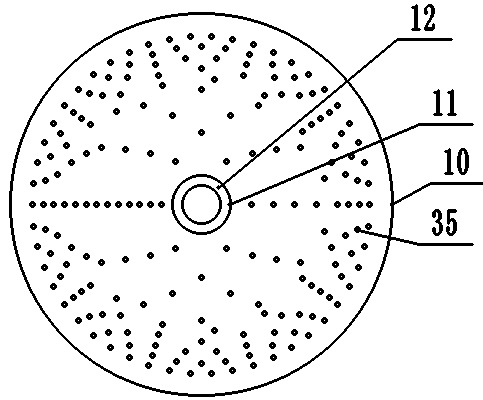

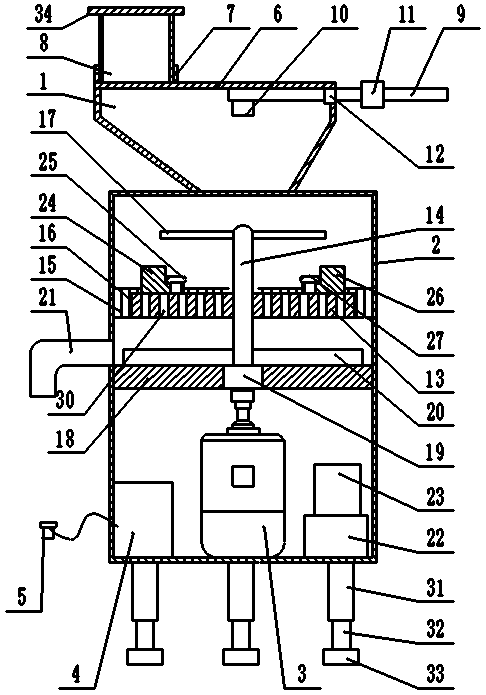

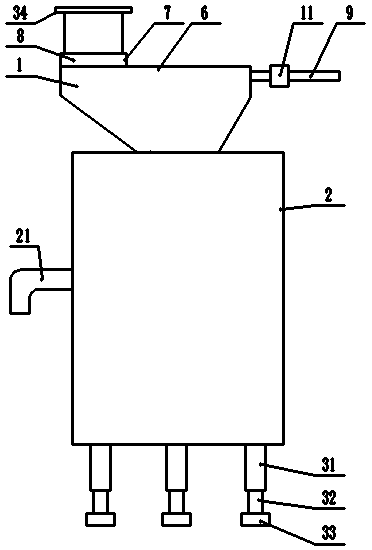

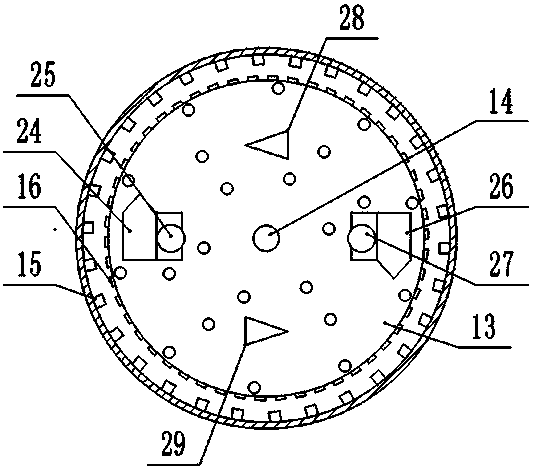

InactiveCN105541062ASave cleaning workWon't cause cloggingSludge treatment by de-watering/drying/thickeningSludge processingSites treatmentEngineering

The invention provides a night-soil on-site treatment system. The night-soil on-site treatment system comprises a screw elevator, a solid-liquid separating device, an overlap-spiral type sludge dewatering machine, a chemicals dosing plant and an aerobic fermentation device; wherein the screw elevator, the solid-liquid separating device, the overlap-spiral type sludge dewatering machine and the aerobic fermentation device are connected in sequence, and the chemicals dosing plant and the overlap-spiral type sludge dewatering machine are connected. According to the night-soil on-site treatment system and a treatment method thereof, urban night-soil is separated by a new night-soil pumping mode and working procedures such as solid-liquid separation, screw press dewatering, small dynamic aerobic fermentation, chunks of waste are transported to a refuse transfer station as household refuse, wastewater is transported to a sewage treatment plant via a sewer for treatment, and sludge is subjected to harmless treatment on site, all pollutants are well treated, meanwhile refuse reclamation can be performed to produce an organic fertilizer, the recycling use of resources is realized, and aims of harmlessness, reclamation and reduction of the treatment of the urban night-soil are truly achieved.

Owner:SHENZHEN LONGJISHUN IND DEV

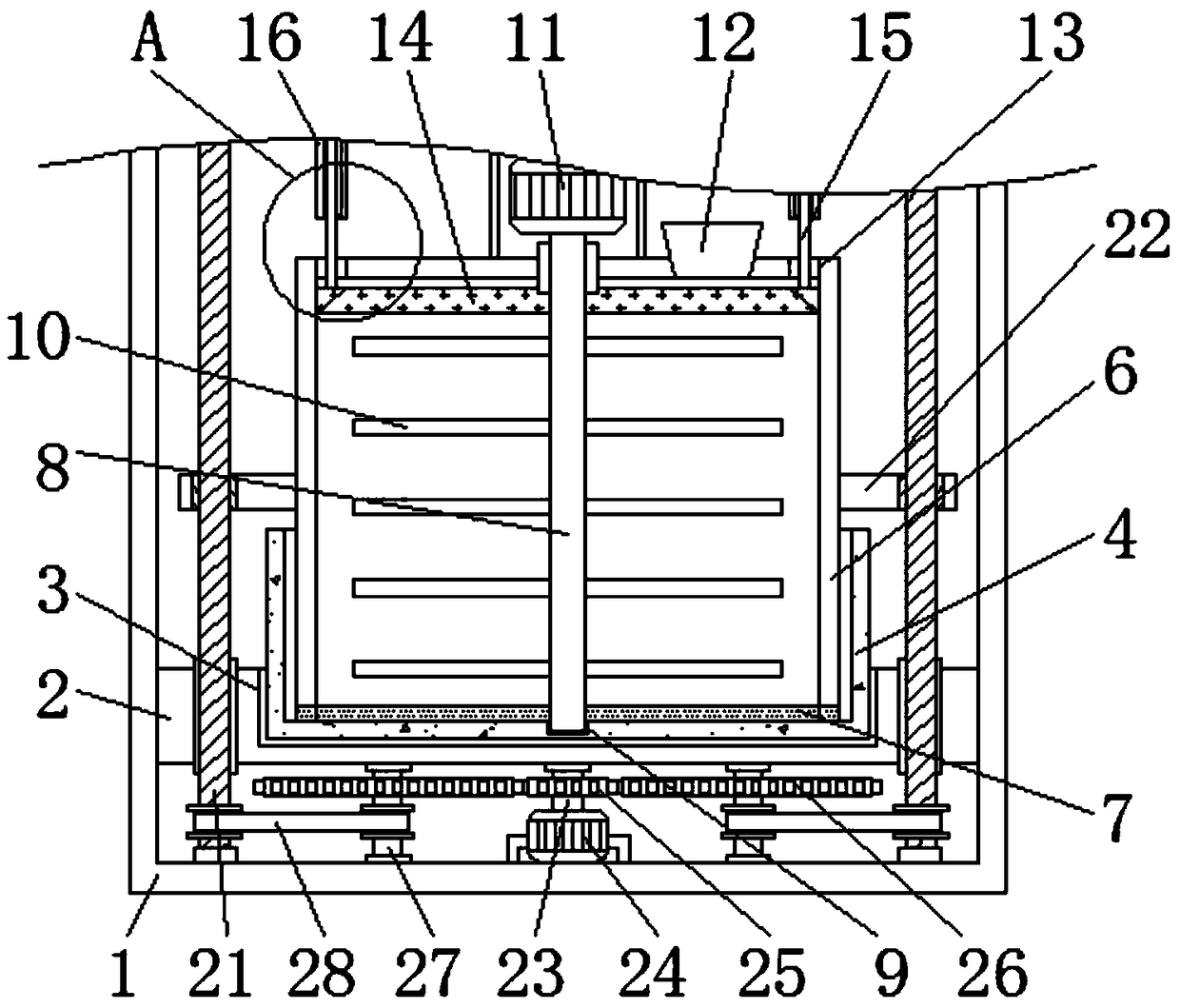

Device for treating food wastes

The invention discloses a device for treating food wastes. The device comprises a machine enclosure, a grinding device, a drainage device, an alternating current (AC) motor, a controller and a switch,wherein a feed barrel, formed into a whole together with the machine enclosure, is arranged at the center of the upper end of the machine enclosure; a feeding hole is formed in the upper end of the feed barrel, and a blanking hole passing through the interior of the machine enclosure is formed in the bottom end of the feed barrel; the machine enclosure is internally provided with the grinding device and the drainage device; the AC motor is arranged in the machine enclosure and under a drainage plate; a rotating end of the AC motor is connected with a rotating shaft by means of a coupler; thecontroller and a rotating speed sensor are arranged in the machine enclosure and at one side of the AC motor; the rotating speed sensor is used for detecting the rotating speed of the AC motor. The device for treating the food wastes has the beneficial effects of being simple in structure and high in practicality.

Owner:龚卫珍

Intelligent garbage treatment environmental protection device

The invention discloses an intelligent garbage treatment environmental protection device. The intelligent garbage treatment environmental protection device comprises a feed sloping hopper, a machine case, a driving motor, a controller, a switch button, a crushing and grinding device, a drainage device and a water supply device. The feed sloping hopper is fixed to the machine case. A hopper plate is fixed to the upper end of the feed sloping hopper. A threaded connecting tube is fixed to the hopper plate. A feed tube is arranged on the threaded connecting tube. The water supply device is composed of a spray pipe, a solenoid valve and a spray head jointly. The crushing and grinding device is composed of a grinding cutter head, a rotary shaft, a grinding tooth ring, cutter head grinding teeth, a knife fan and a knocking device jointly. The drainage device is composed of a drainage plate, a bearing, a drainage impeller and a drainage pipe jointly. The rotary shaft penetrates through the bearing and is connected with the driving motor. The controller, a Hall sensor and an overload protector are arranged in the machine case. Adjustable supporting devices are arranged at the bottom end ofthe machine case. The intelligent garbage treatment environmental protection device has the beneficial effects of being simple in structure and high in practicality.

Owner:凌中良

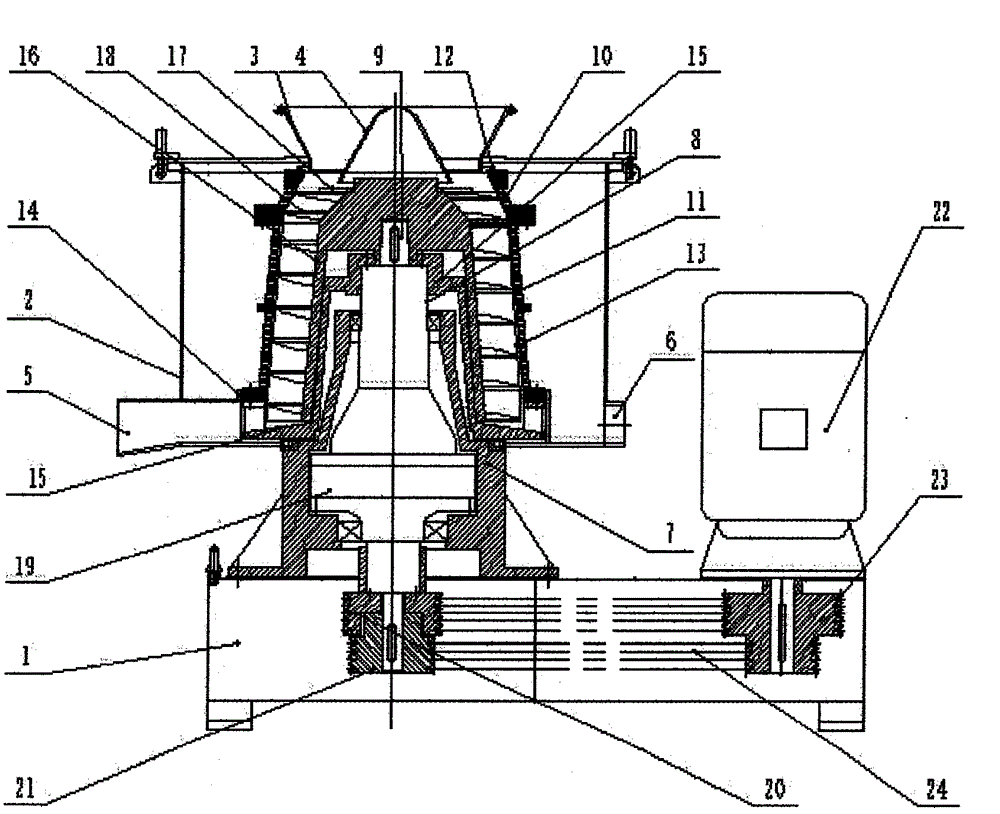

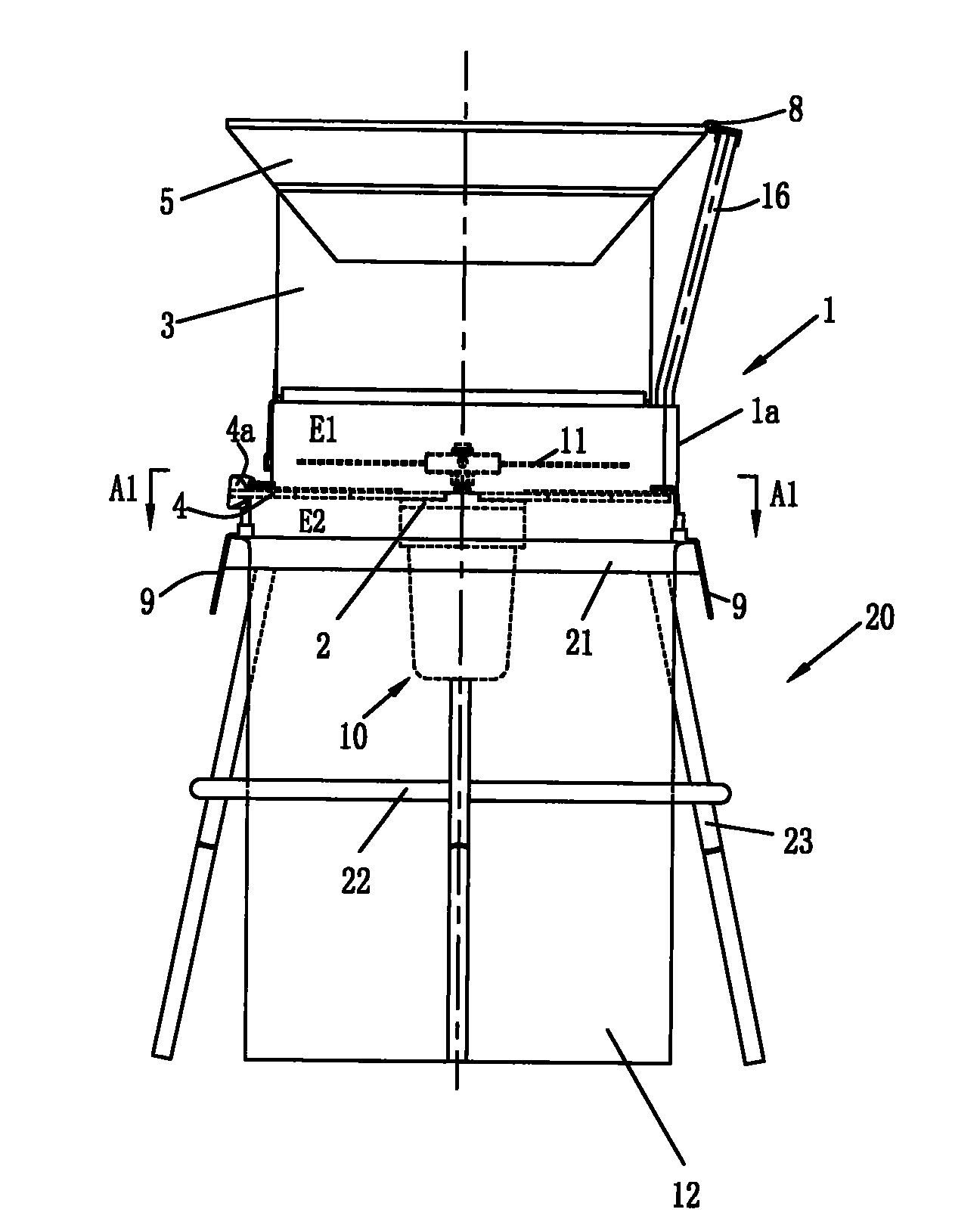

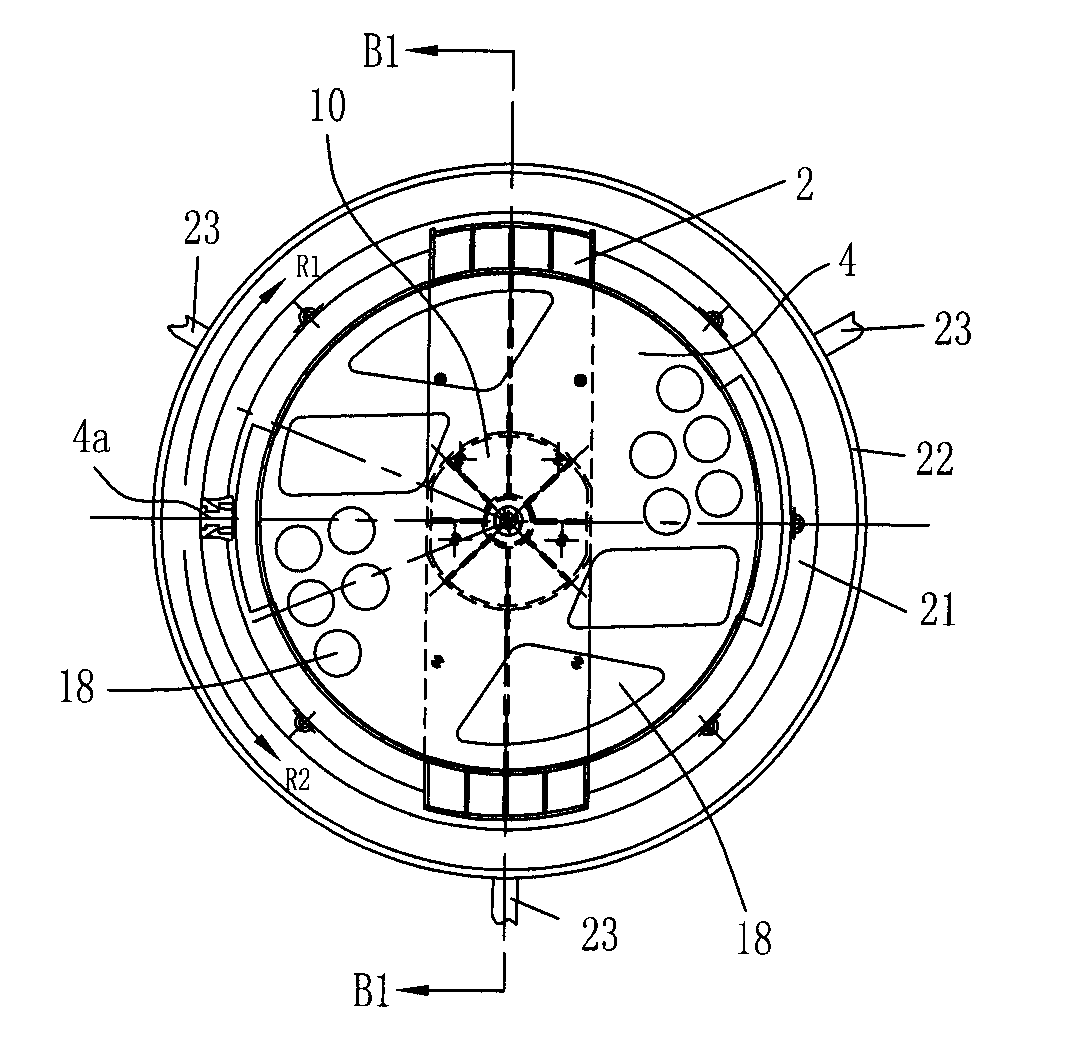

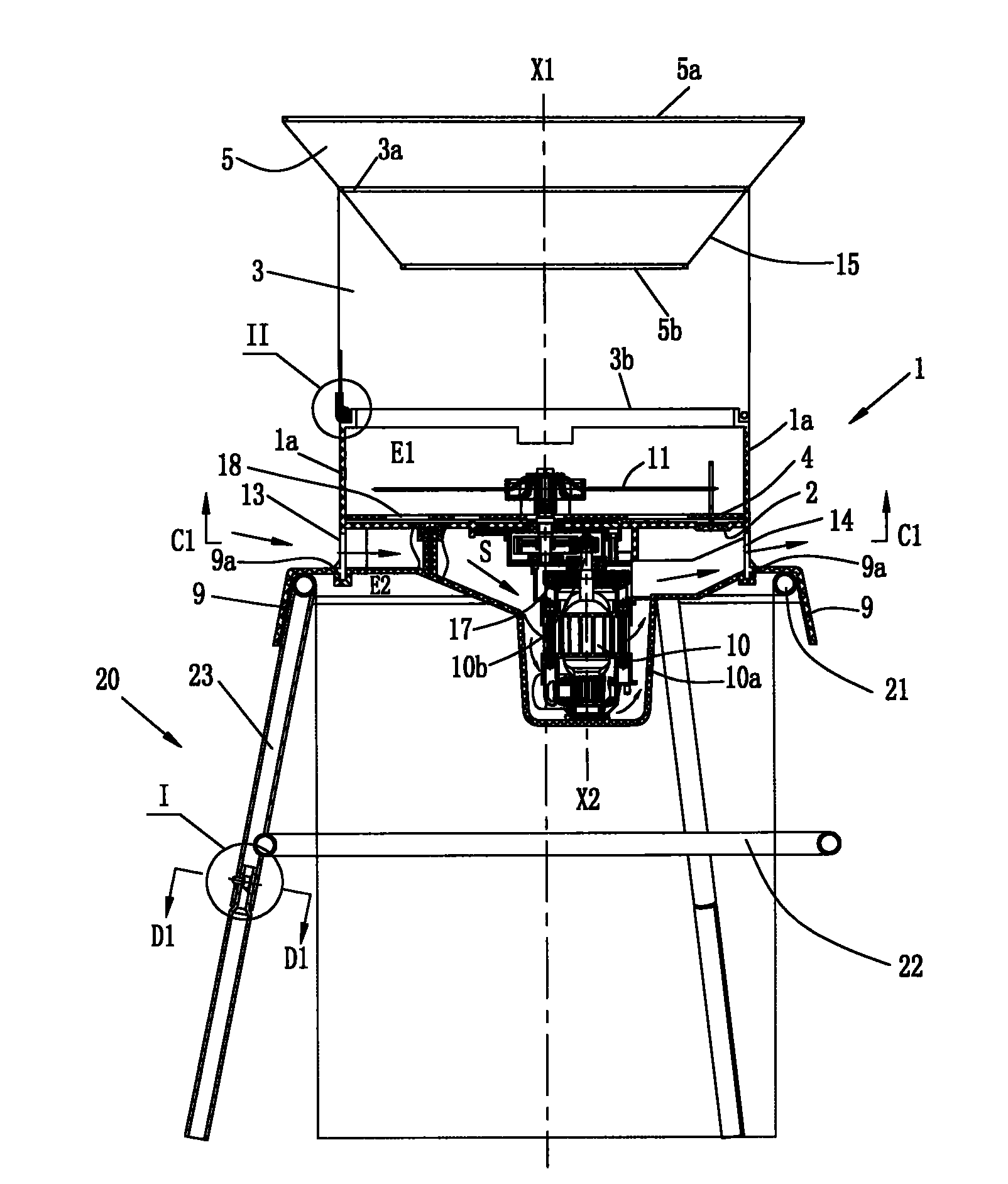

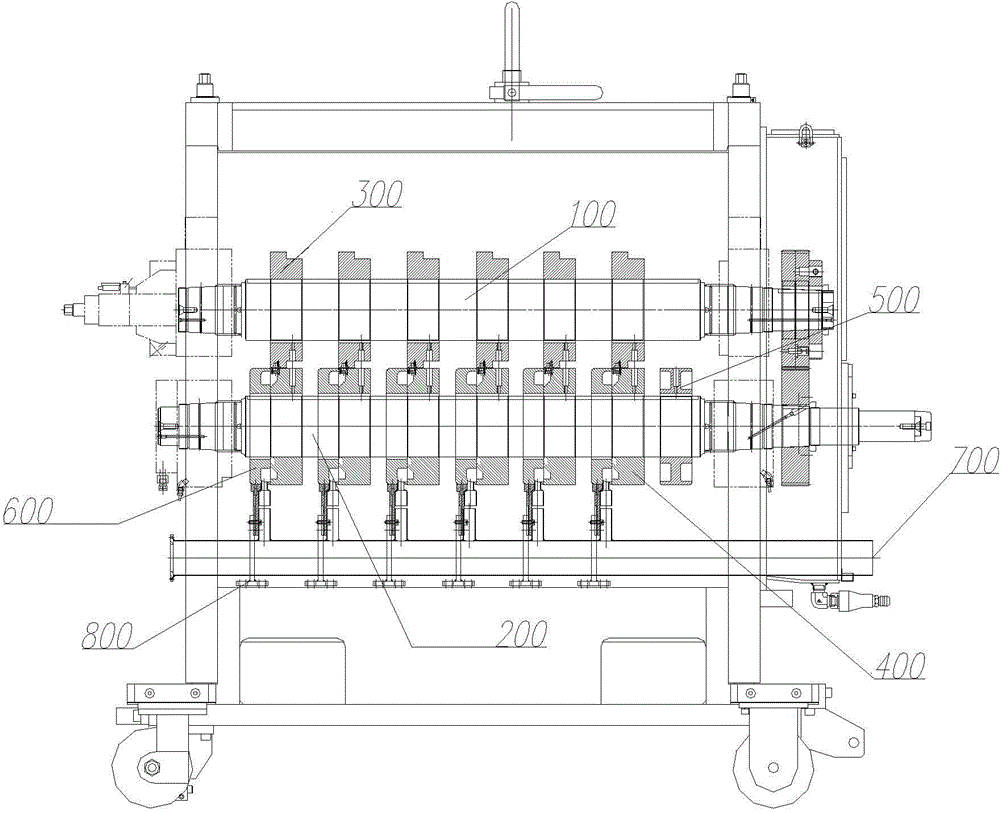

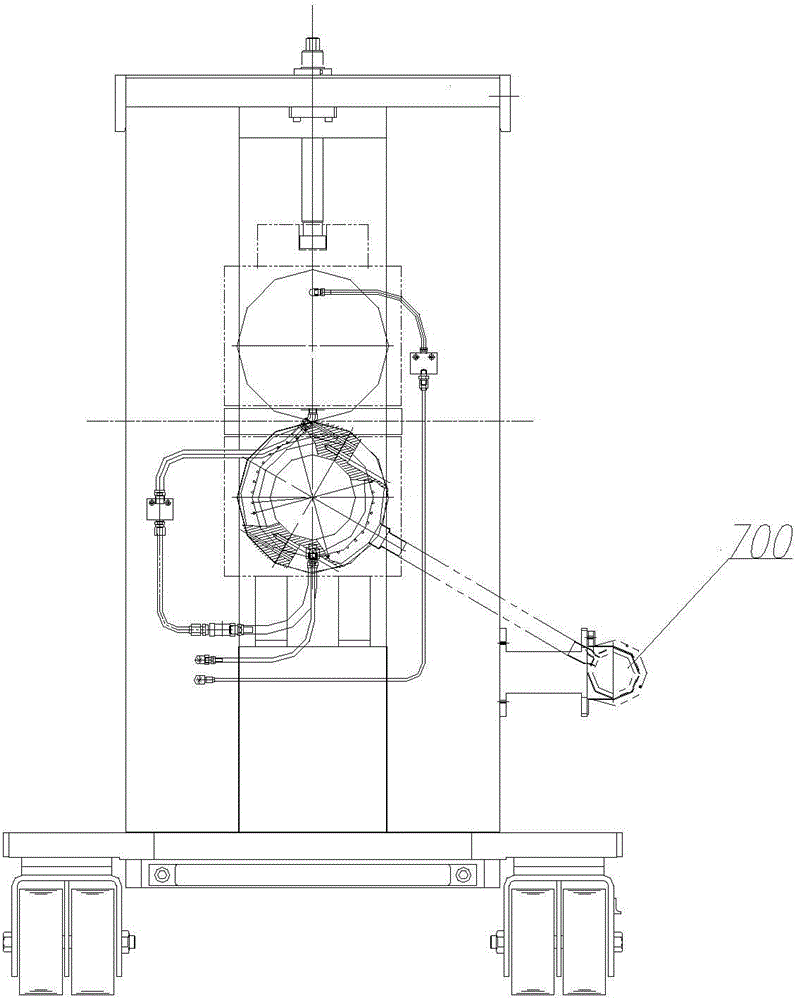

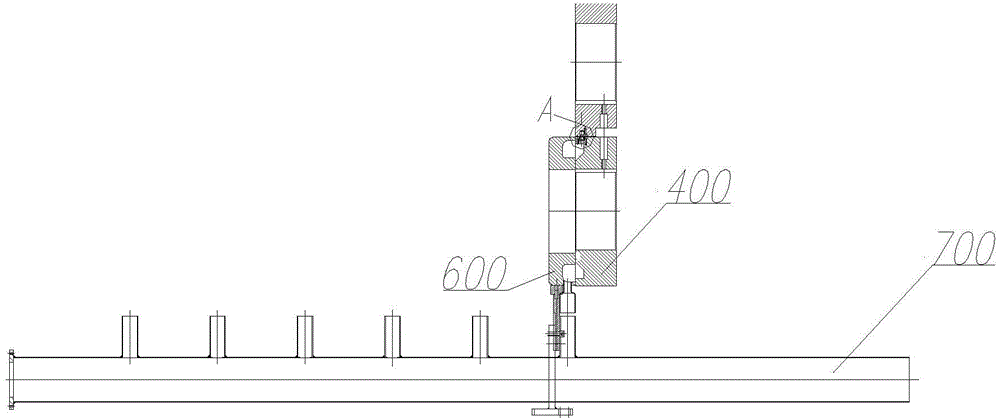

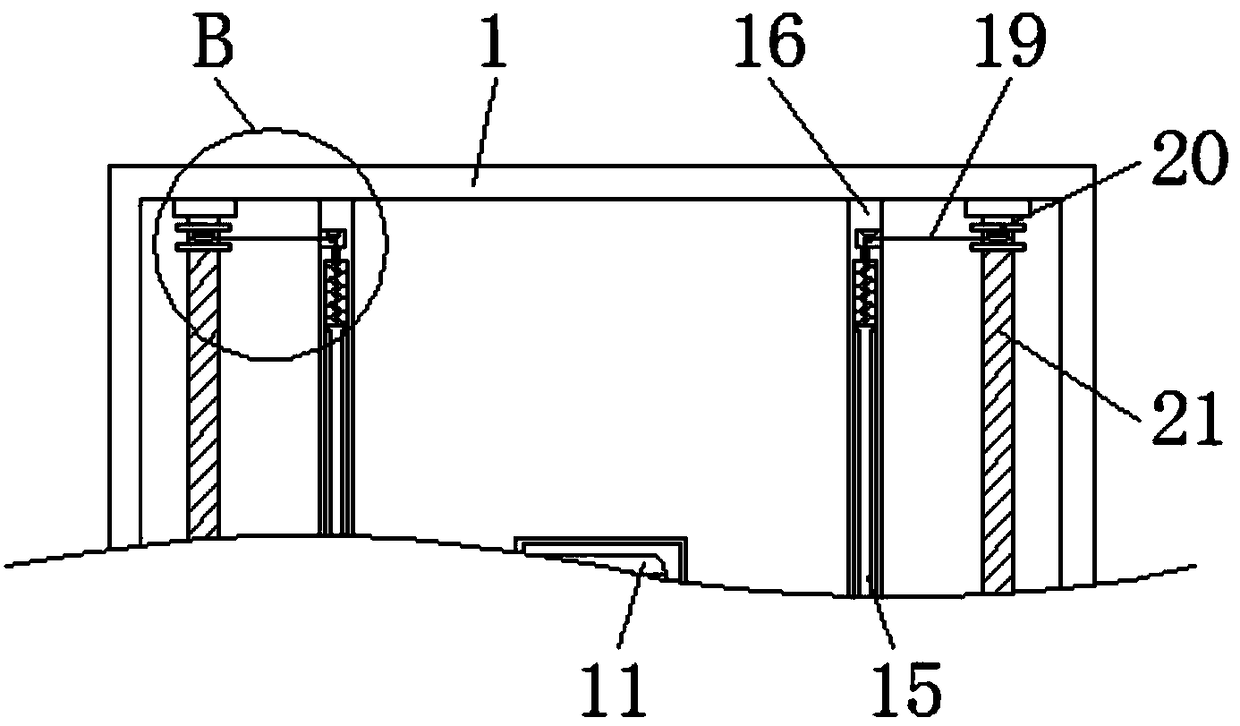

Improved vertical type spiral discharge filtering centrifuge

InactiveCN106179779AUnbreakableCrushing continuous automaticRotary centrifugesSpiral bladeEngineering

The invention discloses an improved vertical type spiral discharge filtering centrifuge. The improved vertical type spiral discharge filtering centrifuge comprises a centrifuge base, a shell, an inner guide conical barrel, an outer guide conical barrel, an upper drum, a lower drum, an upper drum filter screen, a lower drum filter screen, a spiral conveyor, a material accelerating disc, a spiral blade, a differential mechanism and the like. A poor-liquidity or solid breakable solid-liquid mixture enters the material accelerating disc from the inner guide conical barrel and the outer guide conical barrel and enters a centrifugal dehydration cavity after acceleration. Materials are not liable to be blocked and not liable to be broken by the spiral blade. In order to prevent the materials from spattering and overflowing from the top of the upper drum, the material accelerating disc shall be a distance lower than the top end of the upper drum. In order to prevent the materials being attaching to the upper drum filter screen in a self-locking mode, the half cone angle of the inner wall of the upper drum shall be larger than the frictional angle of the materials and the upper drum filter screen. After the materials enter the centrifuge, liquid is discharged from the drums and liquid discharge holes of the filter screens through centrifugal force, solids are pushed into solid discharge holes of the drums by the spiral blade through rotation speed difference generated by the differential mechanism and discharged from a solid discharge pipe on the side lower portion of the shell through centrifugal force, and automatic and continuous dehydration separation is achieved.

Owner:莫珉珉 +1

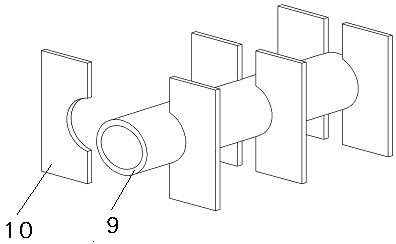

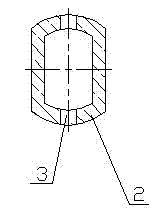

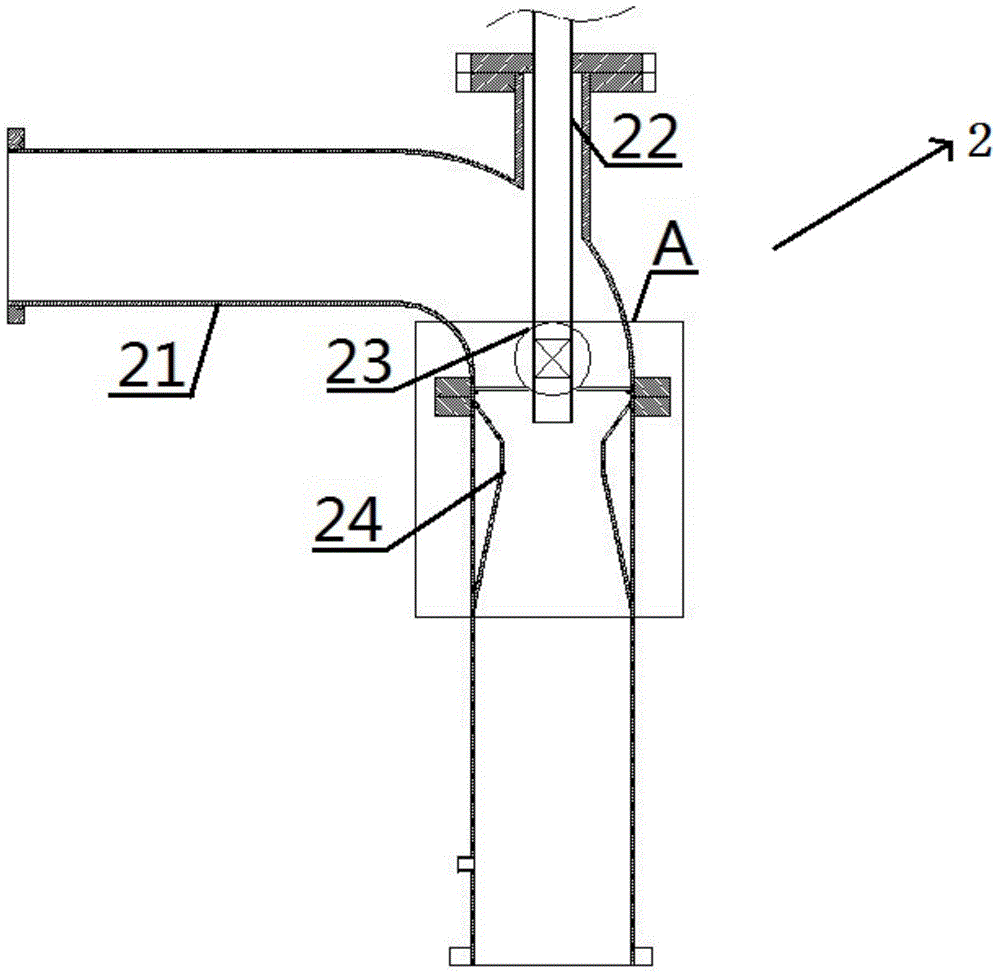

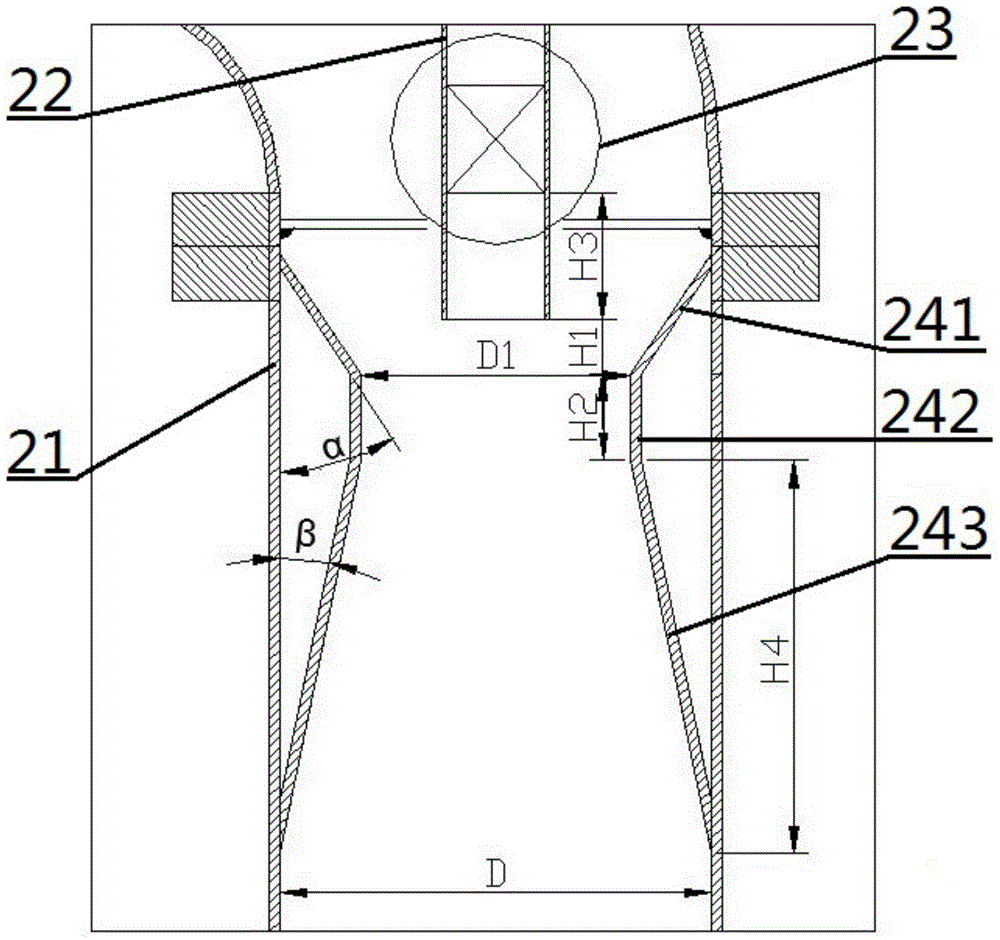

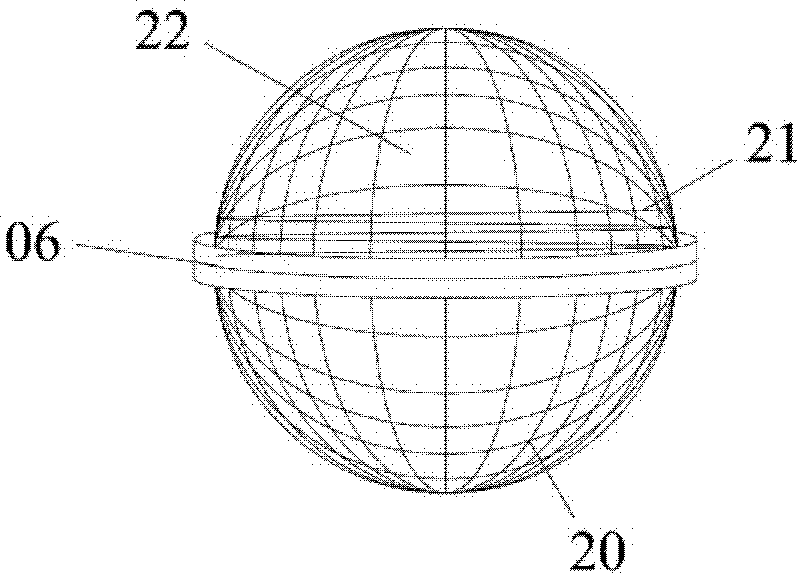

Multi-functional upper expanding device for producing antimony trioxide

ActiveCN103508490APromote aggregationWon't cause cloggingAntimony compoundsEngineeringAntimony trioxide

A multi-functional upper expanding device for producing antimony trioxide comprises an inlet pipe, an abdomen pipe, and an air exhausting pipe, wherein the inlet pipe, the abdomen pipe and the air exhausting pipe are orderly connected and communicate with each other; the inner diameter of the abdomen pipe is larger than those of the inlet pipe and the air exhausting pipe; the inlet end of the inlet pipe is arranged on the outlet end of the antimony trioxide reaction chamber, and the outlet end of the air exhausting pipe is connected to the inlet end of the antimony trioxide crystallization device. The multi-functional upper expanding device can adjust the particle size of antimony trioxide product at will, effectively controls the antimony trioxide product quality, timely recycles the agglomerated oxides generated during the antimony trioxide production process, and improves economic and technical indexes such as product yield, and the like.

Owner:湖南黄金股份有限公司 +1

Wet chemical preparation method for ceramic separation membrane

ActiveCN102258945BIncrease Separation ThroughputNarrow pore size distributionSemi-permeable membranesNitrateMicrometer

Owner:SANDA FILM SCI & TECH XIAMEN

Gardening crusher

ActiveCN101940970AProtect healthReduce healthCooling/ventillation arrangementGrain treatmentsCooling effectWorking environment

The invention discloses a gardening crusher. The gardening crusher comprises a body provided with peripheral side walls, wherein a supporting plate is arranged in the body; garbage accommodating space is formed above the supporting plate; dust exhaust space is formed below a partition plate; a cutting mechanism used for crushing garbage is arranged in the accommodating space; a motor used for driving the cutting mechanism is arranged below the supporting plate; an air channel used for cooling the motor at least comprises an air inlet and an air outlet; and the air channel is separated from the accommodating space and the dust exhaust space. The motor cooling air channel is arranged in such a way that the working environment full of dust can be effectively improved, a cooling effect of themotor can be ensured and the service life of the motor can be prolonged effectively.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

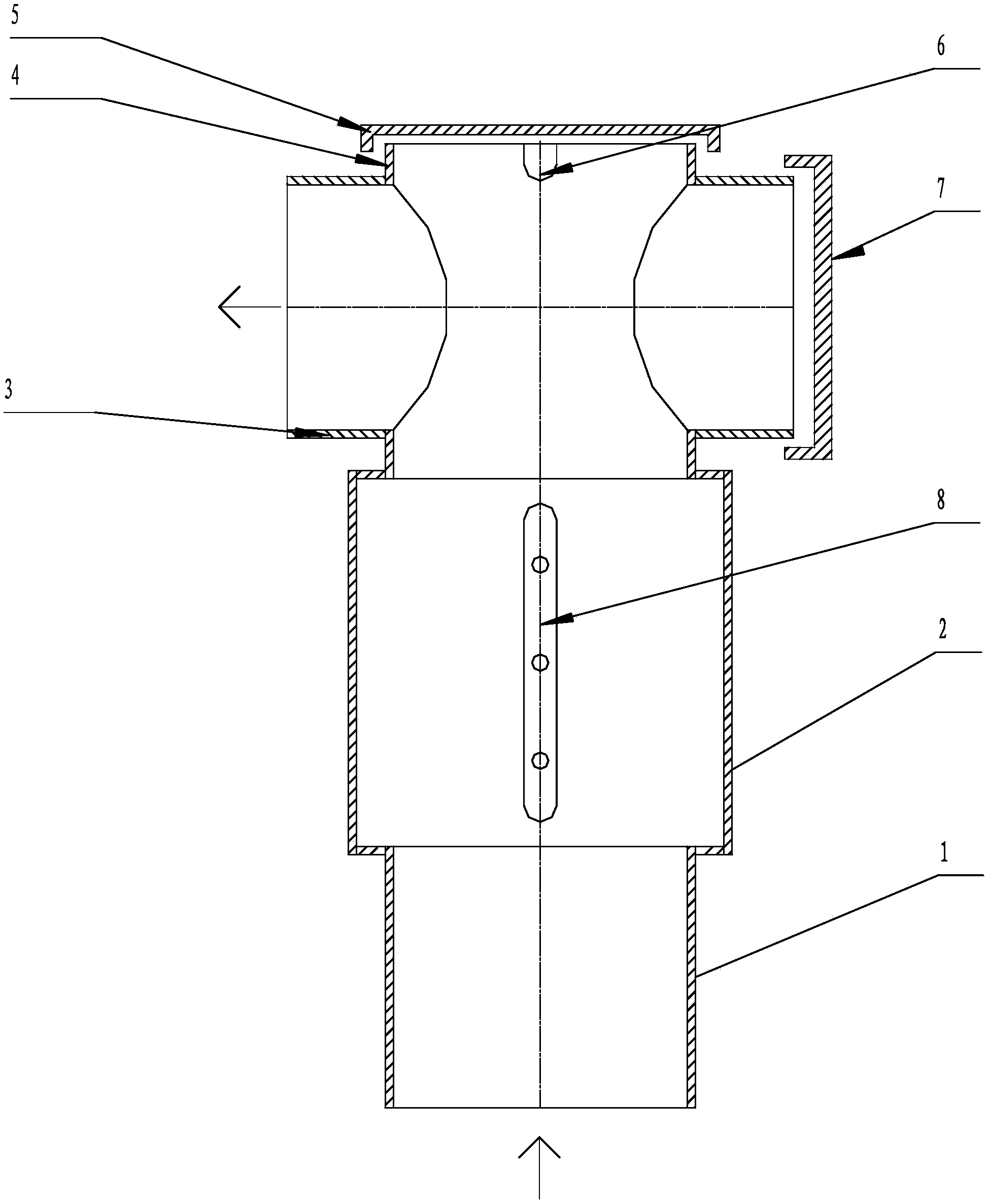

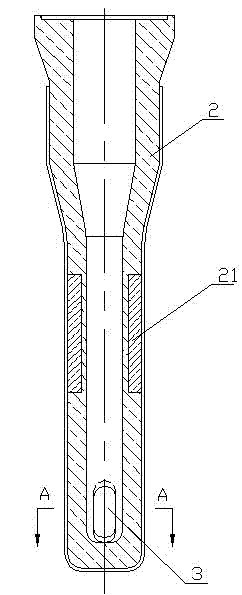

Submersed nozzle for slab continuous casting

InactiveCN103192041AUniform temperaturePromote meltingMelt-holding vesselsConventional castingMolten steel

The invention relates to the field of molten steel continuous casting, in particular to a submersed nozzle for slab continuous casting. A pair of discharge holes (3) are eccentrically formed in the two sides of a central line at the bottom of a nozzle body respectively; one discharge hole is close to the inner wall on one side at the bottom of the nozzle body; and the other discharge hole is close to the inner wall on the other side of a diagonal line at the bottom of the nozzle body. According to the submersed nozzle, the pair of eccentric discharge holes can form a mixing flow field in a crystallizer in the casting process, so that a good effect of reducing subsurface inclusions and air bubbles can be obtained, a flowing dead zone is removed at the same time, the molten steel temperature is uniform, and casting powder is conveniently molten and uniformly flows into the crystallizer, thereby improving the slab surface quality; and compared with electromagnetic mixing equipment, the investment cost can be greatly reduced, the slab continuous casting operation is also easily carried out on the conventional casting machine at the same time, the crystallizer of the continuous casting machine does not need to be complicatedly improved, the improvement and usage costs are very low, the energy is saved, the environment is protected, and the value in popularization and application is wide.

Owner:BAOSHAN IRON & STEEL CO LTD

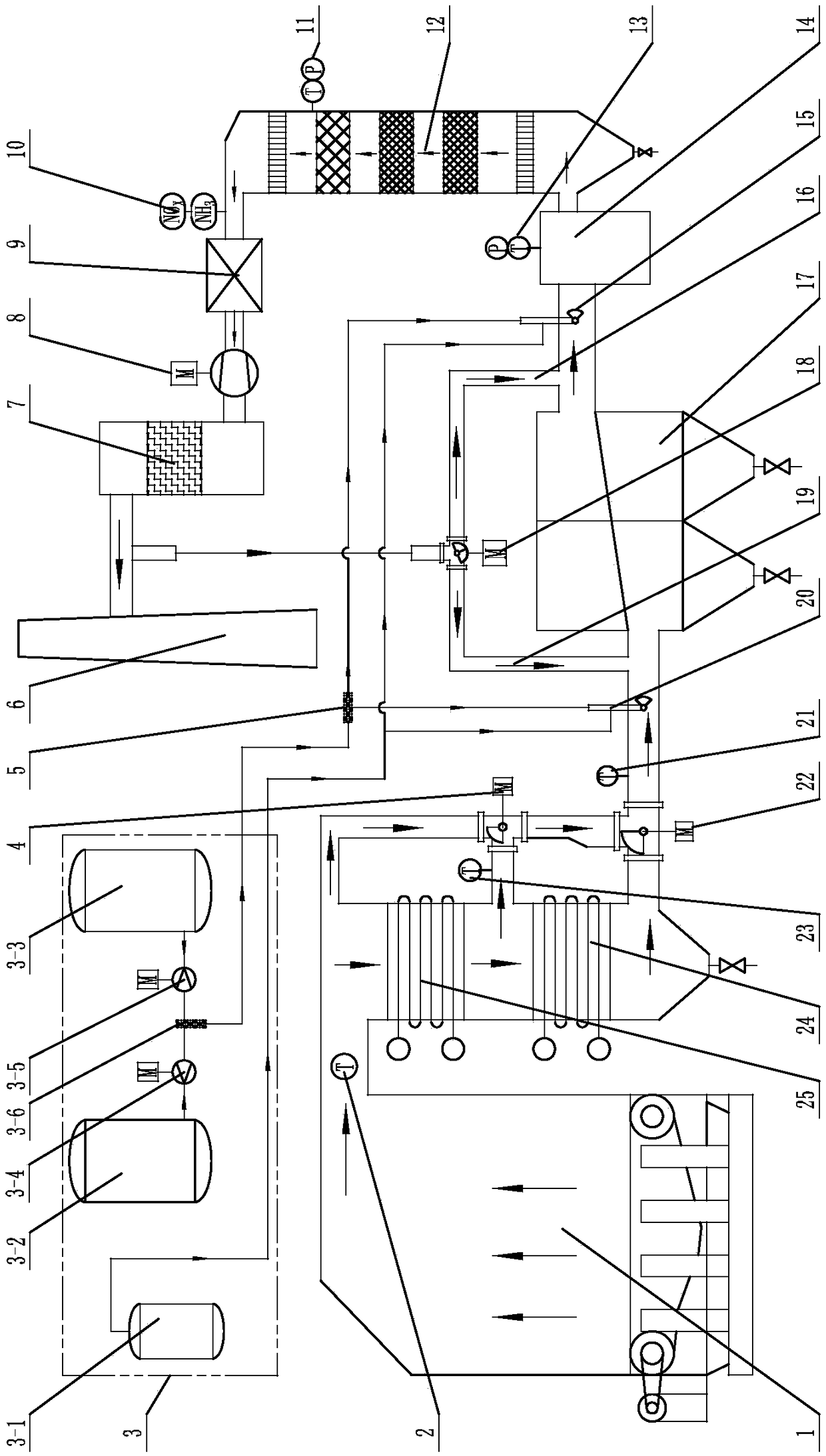

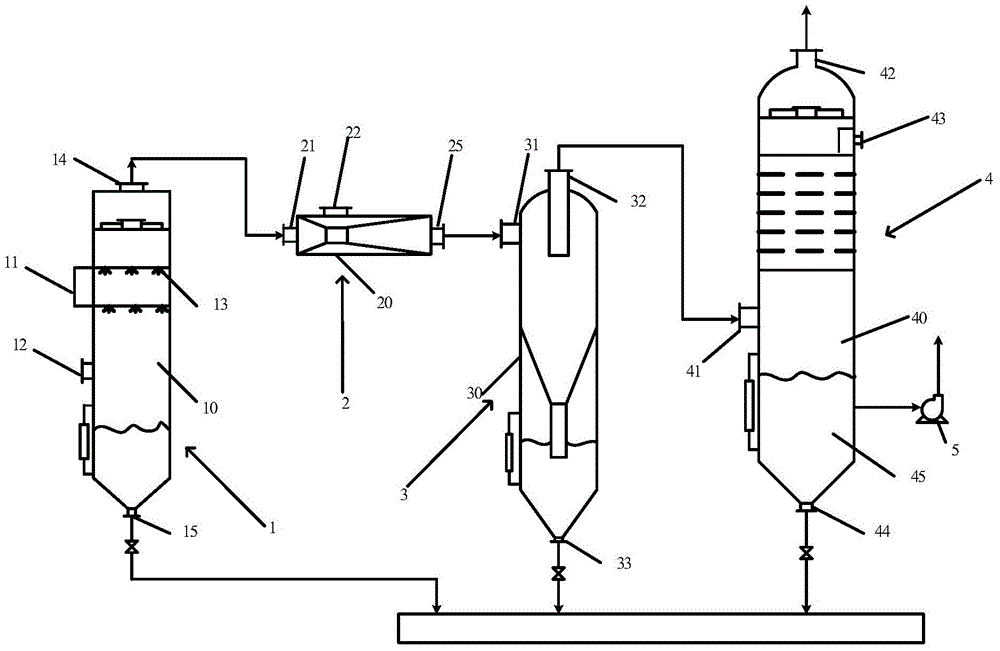

Super-clean treatment process system for flue gas

PendingCN108654374ADoes not affect operationReduce resistanceGas treatmentDispersed particle filtrationProcess systemsFlue gas

The invention discloses a super-clean treatment process system for flue gas, relates to the field of super-clean emission treatment of flue gas from industrial boilers and kilns and solves the problems that performance of the existing SCR denitration system is greatly affected by load fluctuation, resistance is higher, dust removal efficiency of a pre-dedusting device is low, and secondary dust removal equipment needs to be added in front of an induced draft fan to realize super-clean emission. The super-clean treatment process system comprises a smoke temperature regulating system, a dust remover, an SCR reactor, a waste heat recovery system, an induced draft fan and super-clean desulfurization dust removal equipment which are sequentially connected from front to back, one end of a reducing agent system is communicated with an inlet of the dust remover, the other end of the reducing agent system is communicated with an inlet of a disturber, the disturber is arranged at an inlet of theSCR reactor, a first thermocouple is arranged at an inlet of a high-temperature heat exchange surface, a second thermocouple is arranged at an outlet of the high-temperature heat exchange surface, and a third thermocouple is mounted between an outlet of a medium-temperature three-way valve and the dust remover. The process system is used for realizing super-clean flue gas emission denitration treatment of first dust removal and later smoke removal treatment.

Owner:宁波国电龙高科环境工程技术有限公司

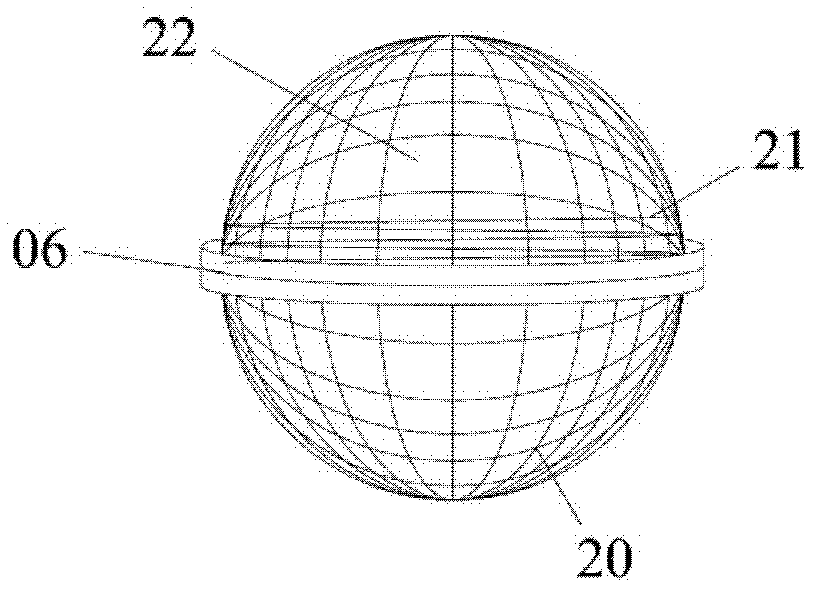

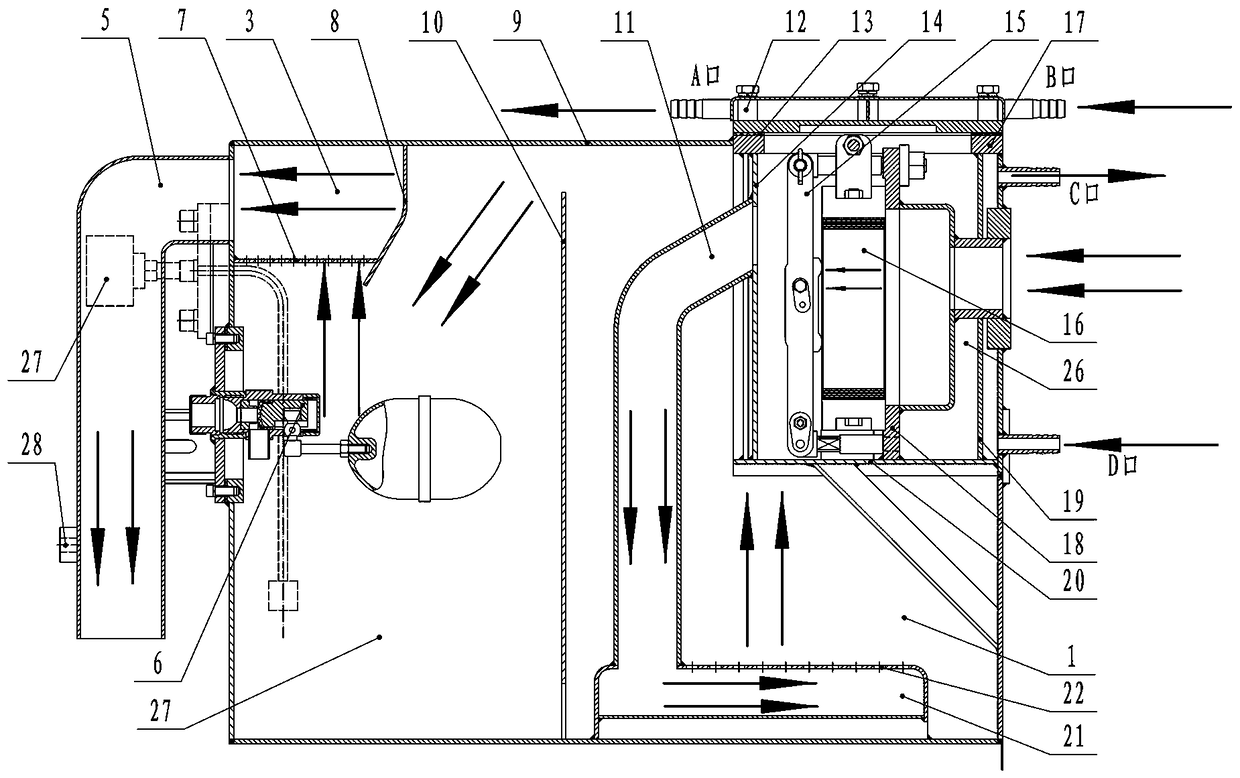

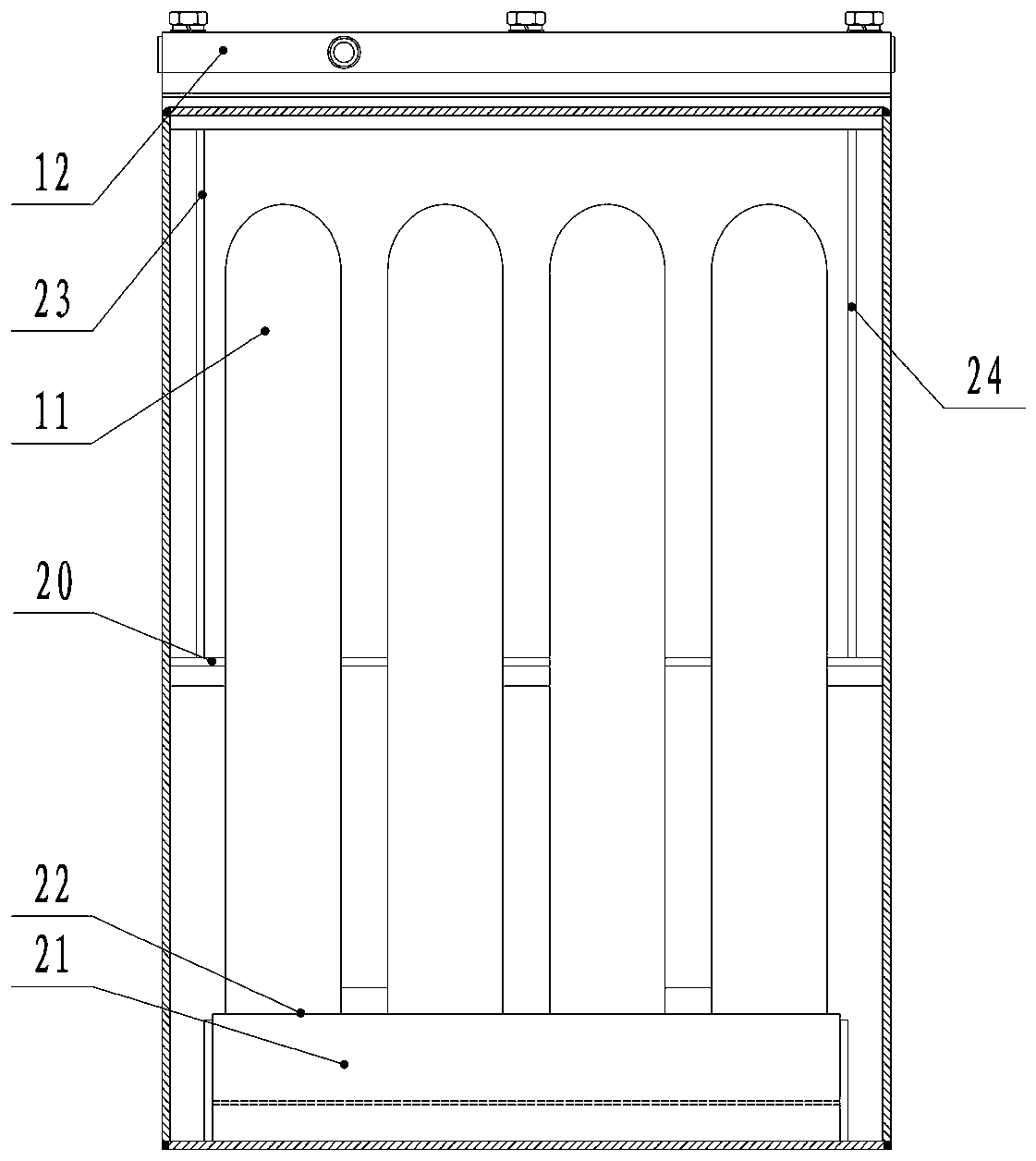

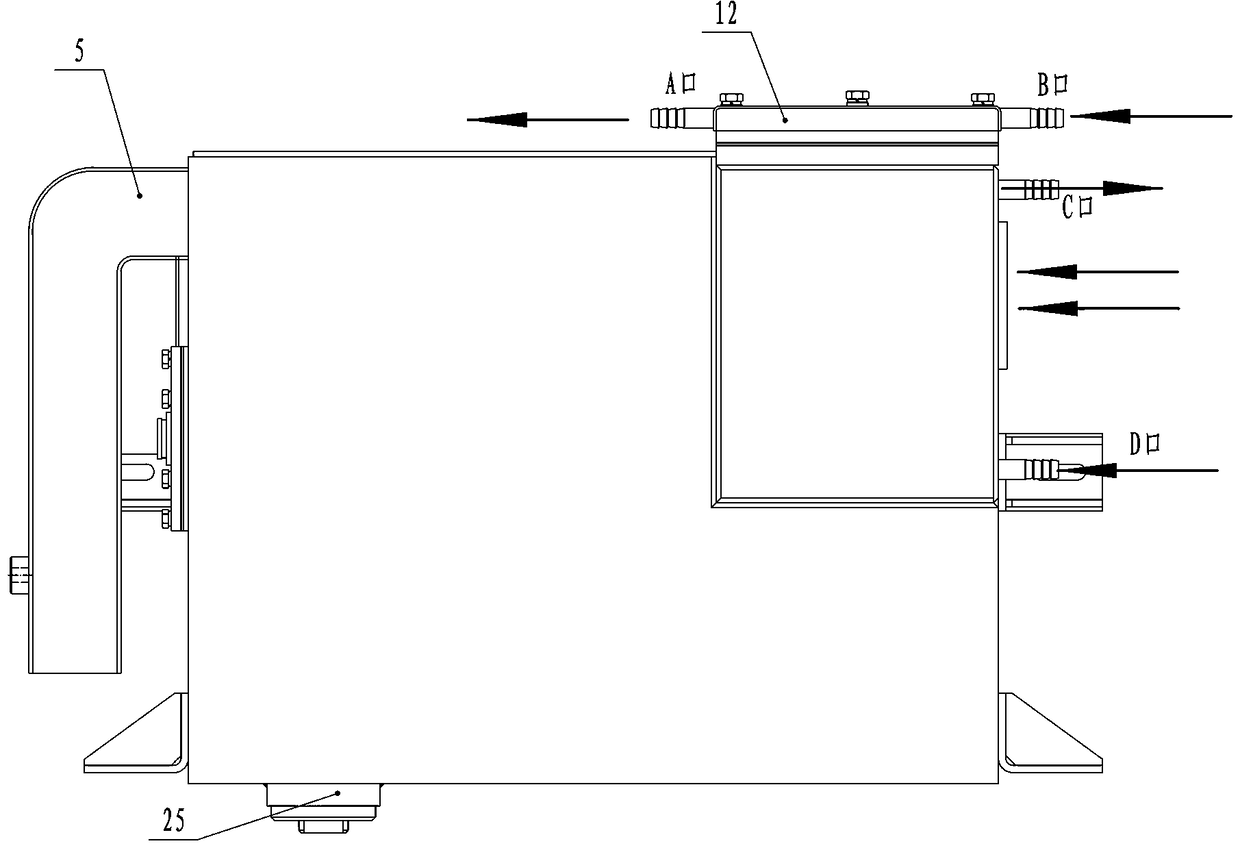

Exhaust gas treatment device for composite explosion-proof diesel engine

ActiveCN108999678ASimple designLow costExhaust apparatusSilencing apparatusUltrasound attenuationFlame arrester

The invention belongs to the technical field of downhole explosion-proof diesel engines in coal mines, and provides an exhaust gas treatment device for with a good treatment effect for a composite explosion-proof diesel engine. The exhaust gas treatment device comprises a box body, a partition plate is arranged in the box body, the box body is partitioned into a water washing chamber and a floating ball chamber by the partition plate, and a gap for allowing tail gas to pass is reserved between the upper portion of the partition plate and the box body; a flame arrester chamber located in the box body is arranged on one side of the water washing chamber, a water sleeve is arranged between the flame arrester chamber and the box body, the water washing chamber is internally provided with a built-in exhaust cylinder and a sound attenuation cavity, one end of the exhaust cylinder communicates with an exhaust opening of the flame arrester chamber, and the other end of the exhaust cylinder communicates with the sound attenuation cavity; the floating ball chamber is internally provided with a water level control valve and a water level sensor, and a second sound attenuation plate and a water baffle are fixed to the upper portion of the floating ball chamber, wherein a plurality of through holes are formed in the surface of the second sound attenuation plate; the bottom of the water baffle is located on the lower portion of the second sound attenuation plate; and an exhaust chamber is formed by the second sound attenuation plate, the water baffle and the box body. The exhaust gas treatment device can be widely applied to the field of the downhole explosion-proof diesel engines in the coal mines.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

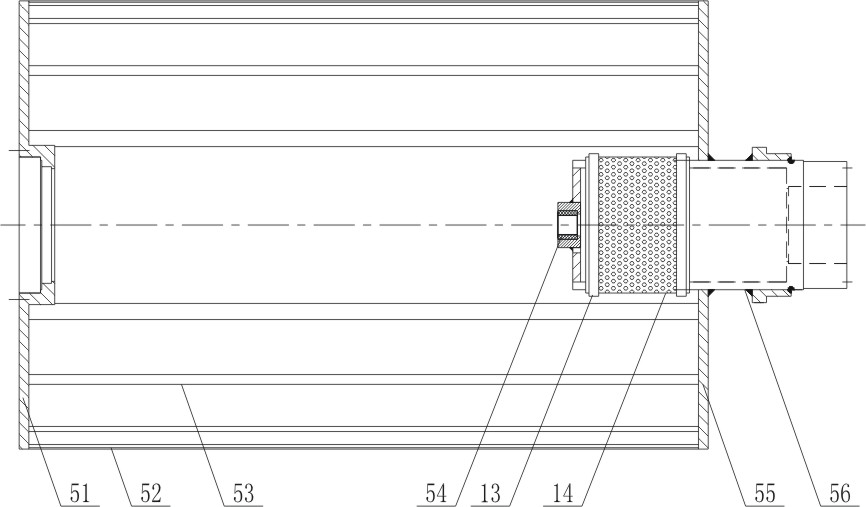

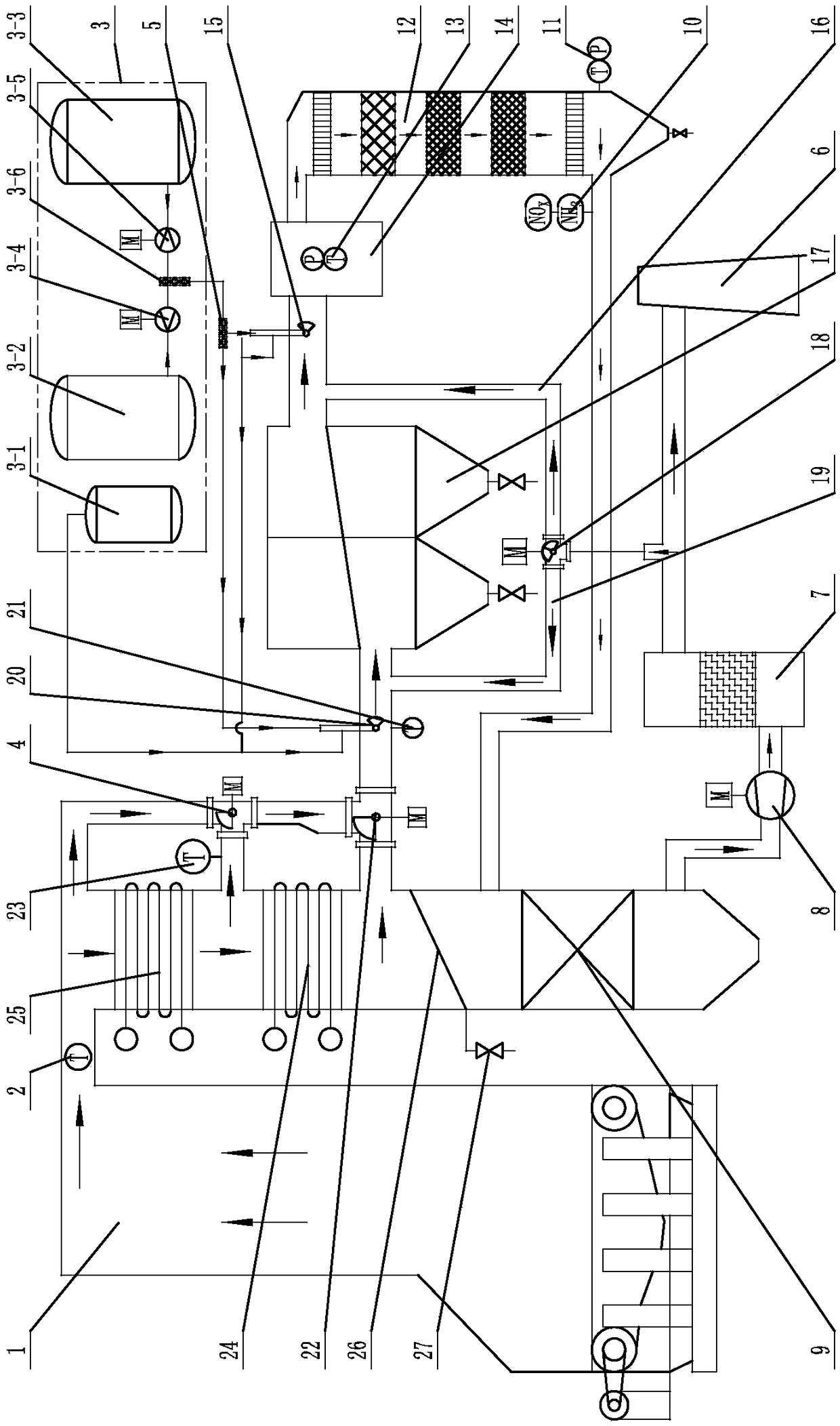

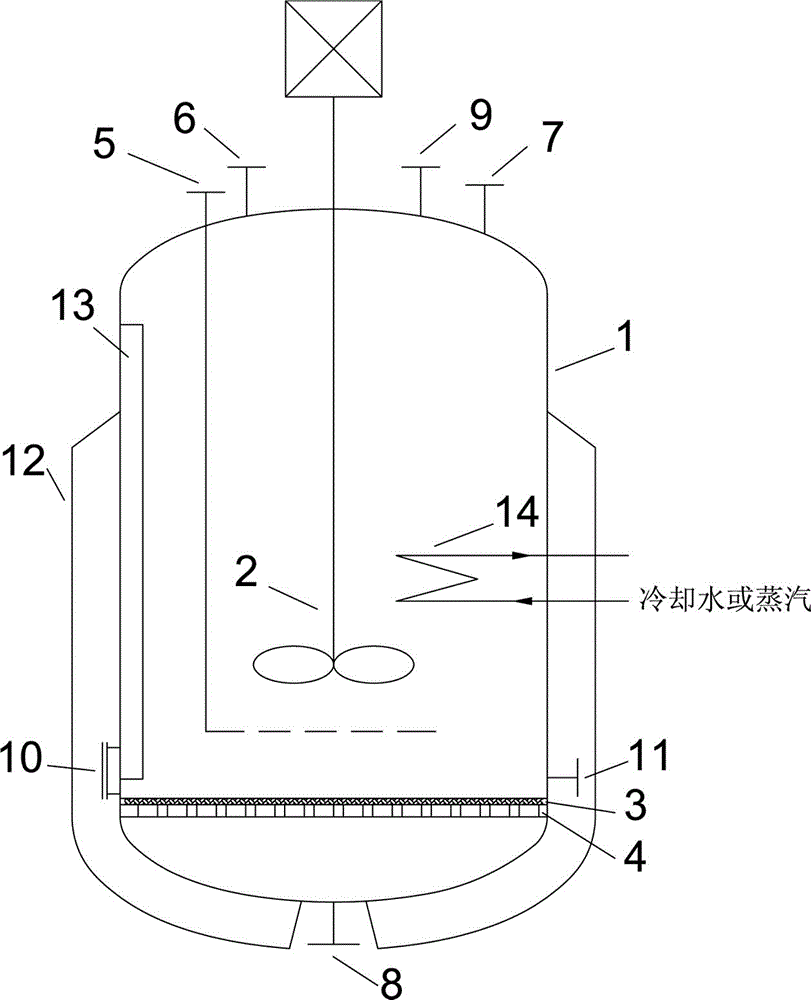

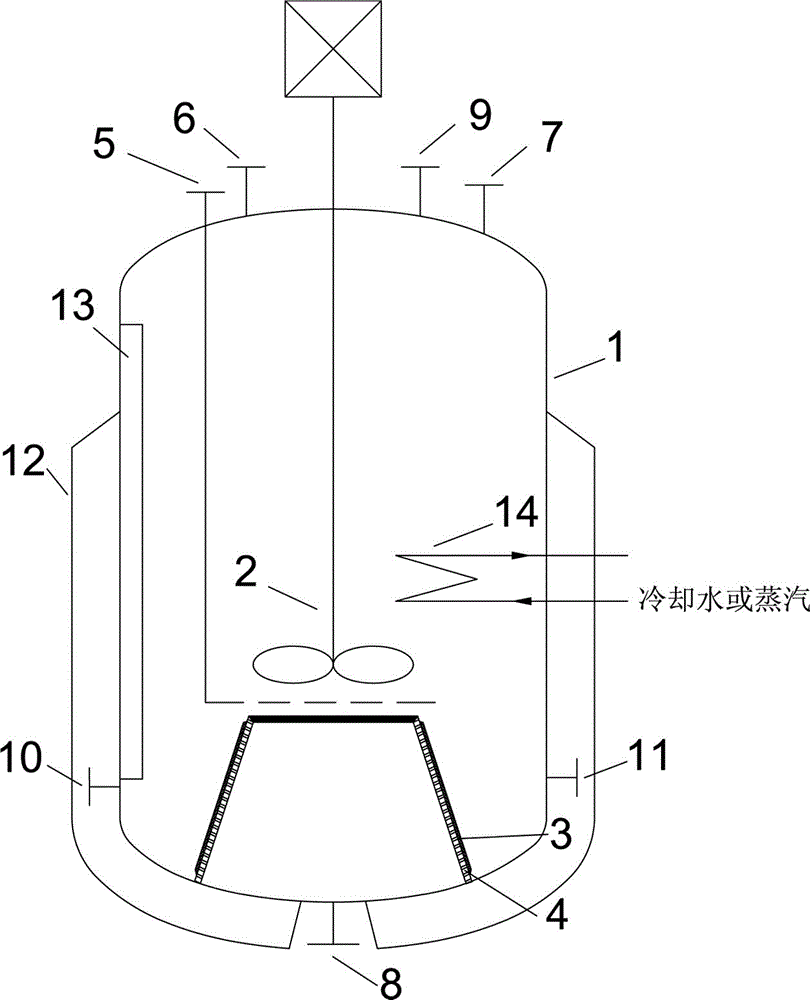

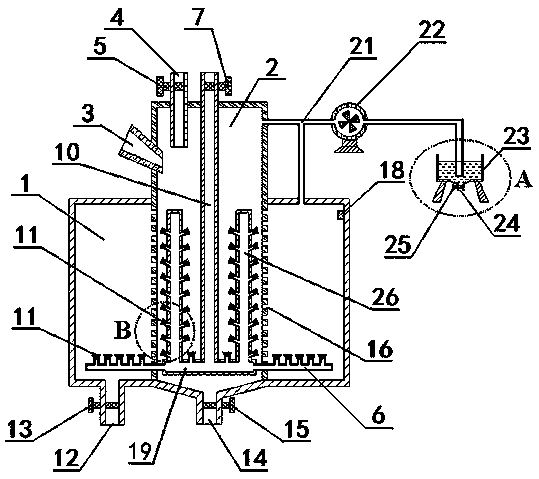

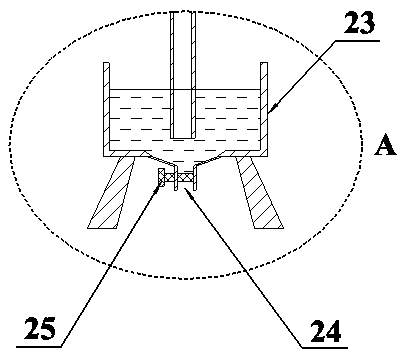

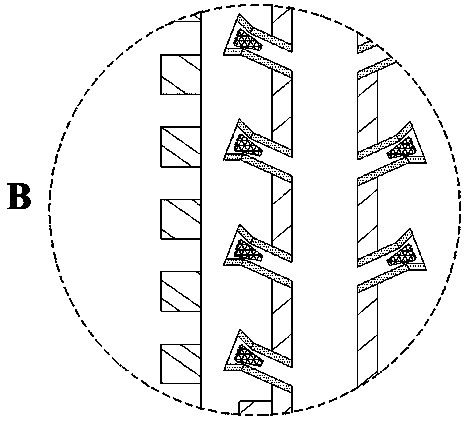

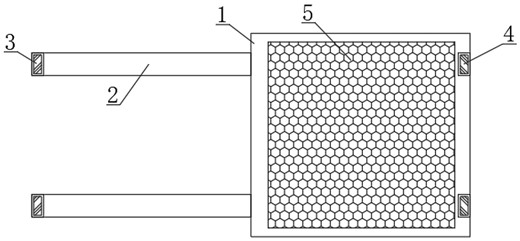

Hydrogenation method for producing hydrogen peroxide and device adopting hydrogenation method

InactiveCN104150447AWon't clogWon't cause cloggingPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesYarnPtru catalyst

The invention discloses a hydrogenation method for producing hydrogen peroxide and a device adopting the hydrogenation method. The hydrogenation method comprises the following steps: adding hydrogen-containing gas, and a working solution prepared by dissolving alkylanthraquinone in an organic solvent into a reactor in which a stirrer and a filtering element are arranged; in a stirring state, sufficiently contacting and reacting the working solution, the hydrogen-containing gas and a powdery catalyst to obtain hydrogenated slurry liquid; filtering the obtained hydrogenated slurry liquid by a filtering element to obtain hydrogenated clear liquid; continuously draining the hydrogenated clear liquid out of the reactor, wherein in the filtering element, a filtering material with a filtering function is selected from filter cloth or a metal mesh; the diameter of the thinnest yarn in yarns of the filter cloth or the metal mesh is not greater than the diameter of more than 99wt% of particles in the powdery catalyst. The hydrogenation method provided by the invention integrates reaction, gas-liquid separation and liquid-solid separation and has large filtering flux; backwashing is not required during the liquid-solid separation; the hydrogenation method has the advantages of being simple operation, small in occupied area, low in investment, easy to popularize and the like; by the hydrogenation method, continuous smooth operation can be achieved.

Owner:河北都邦石化工程设计有限公司

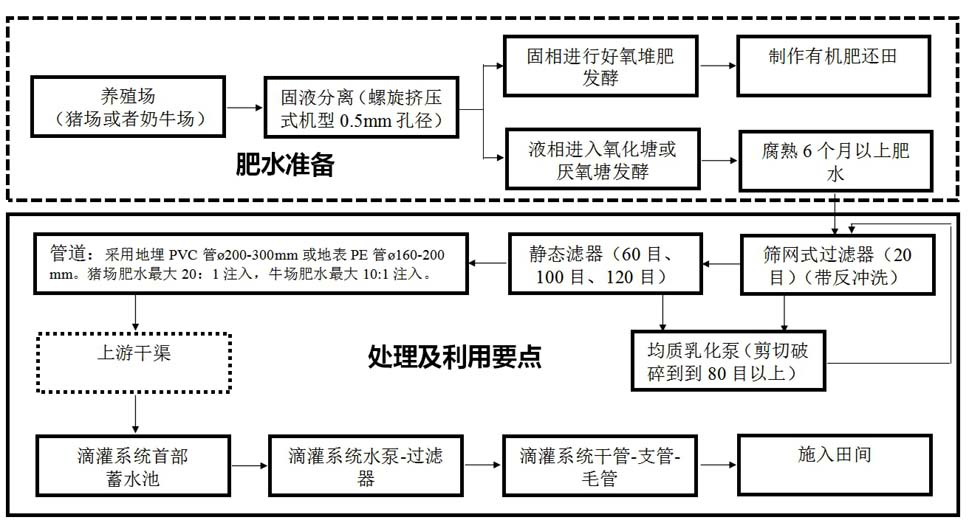

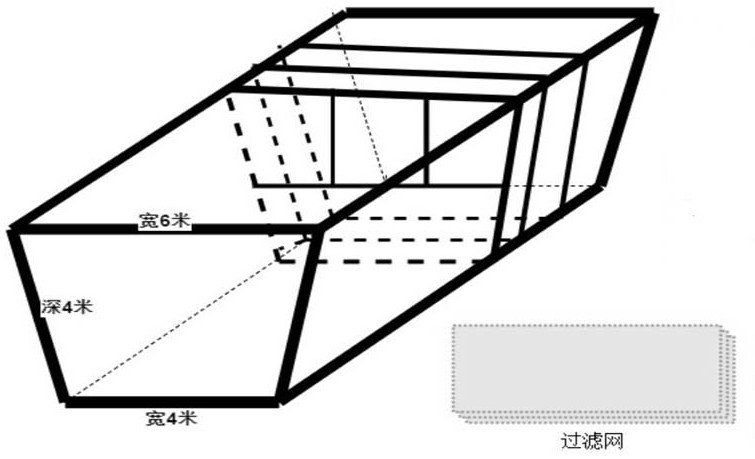

Method for applying farm fertilizer water to drip irrigation system

ActiveCN112042350AIncrease capture rateWon't cause cloggingFertilising methodsCultivating equipmentsSoil scienceAgricultural engineering

The invention provides a method for applying farm fertilizer water to a drip irrigation system. Drip irrigation cultivation agronomic measures are combined, the reverse anti-blocking thought of filtration+emulsification+filtration is adopted, large-particle-size suspended solids are sheared and crushed while being filtered, and the problem that the drip irrigation system is blocked due to the factthat the particle size of the culture fertilizer water suspended solids is too large in particle size is solved. According to the method, crop drip irrigation cultivation agronomic measures are closely combined and fully utilized, the fertilizer water utilization period is long, the fertilization cost is saved, fertilizer water can be continuously matched at the flow rate of 10-200 m<3> / h according to different water flows of drip irrigation head and branch (bucket and trunk) canals, the method is suitable for large and medium-sized farms, and fertilizer water utilization can be completed within a short time. The method is simple in process, higher in nutrient content in fertilizer water compared with a filtering type process, and beneficial to improving soil fertility and crop yield andquality.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Graded purification device and graded purification method for dusty gas

ActiveCN104667683AReduce washing and purification loadImprove washing efficiencyCombination devicesSyngasPurification methods

The invention discloses a graded purification device and graded purification method for dusty gas. The graded purification device comprises a spray tower, a venturi scrubber, a separator and a foam scrubber connected orderly. In the graded purification method, the graded purification device is used. The method comprises the following steps: orderly introducing to-be-treated gas into the spray tower, scrubbing, further scrubbing through the venturi scrubber, separating through the separator, and finally, scrubbing in the foam scrubber. Water temperature in the spray tower is 10-200 DEG C, lower than the temperature of the to-be-treated gas, 0.001-10L of water is used for per cubic meter of the to-be-treated gas; water temperature in the venture scrubber is 10-200 DEG C, lower than the gas temperature, and 0.001-10L of water is used for per cubic meter of primarily treated gas; and water temperature in the foam scrubber is 0-200 DEG C, lower than the gas temperature. Removal rate of ultrafine particles by adopting the purification method provided by the invention is 95% or more, and the content of fine ash in clean synthetic gas is 1.0mg / Nm<3> or less.

Owner:EAST CHINA UNIV OF SCI & TECH +1

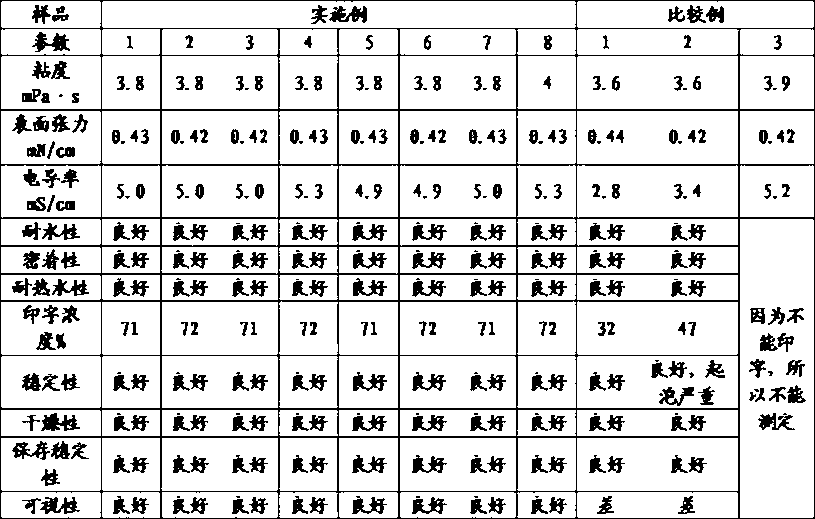

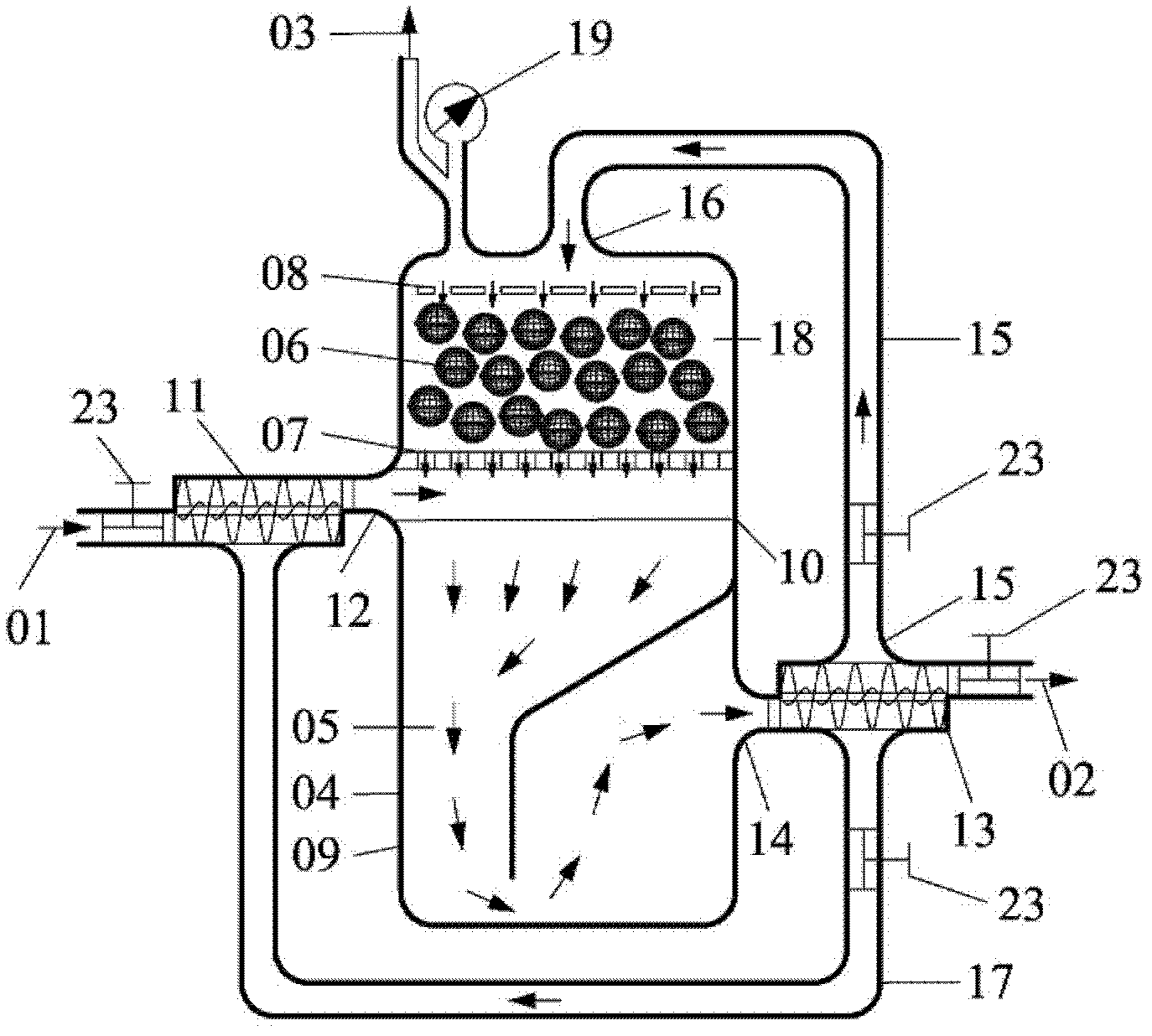

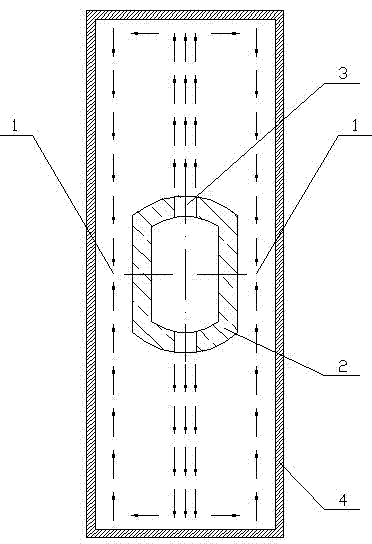

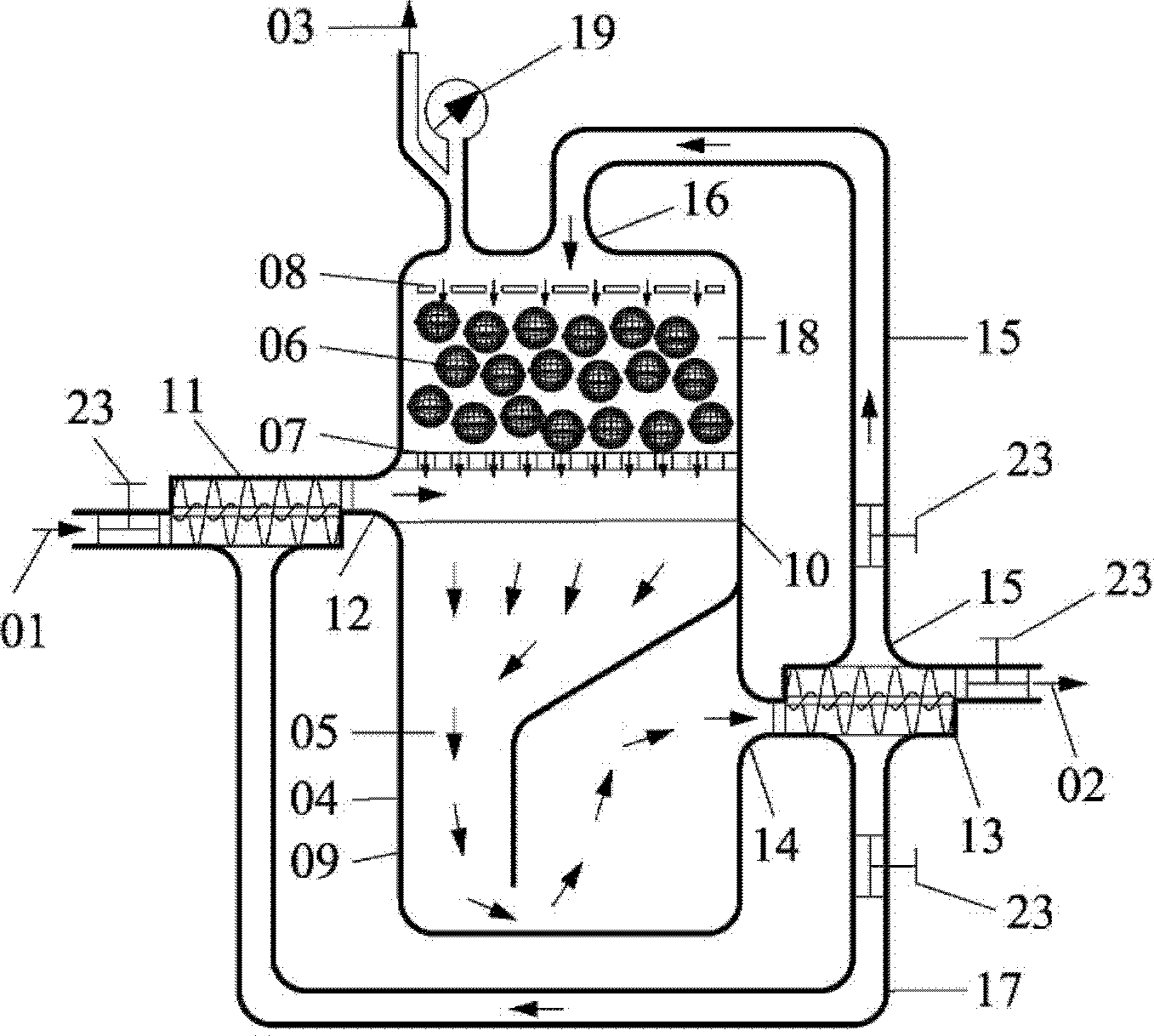

Rancidity-prone waste biogas utilization method based on in-subarea inoculation and quick start

ActiveCN102492728BStable biogas productionWon't cause cloggingWaste based fuelFermentationLiquid wasteProduction rate

The invention belongs to the technical field of solid waste pollution control, and relates to a method for making biogas from waste, which comprises the following steps: (1) pretreating the waste; (2) feeding the waste into a waste loading area for hydrolysis and acidification; (3) feeding the material subjected to hydrolysis and acidification in step (2) into a microbial inoculum loading area, and performing biogas production reaction under the effect of the microbial inoculum; (4) flowing out the material treated in step (3) from the microbial inoculum loading area, and returning to the waste loading area for further hydrolysis and acidification; and (5) repeating the cycle from step (2) to step (4) multiple times until the conversion of the waste into biogas is maximized. The invention overcomes the disadvantages of high rancidity possibility, long gas production start time, low gas production yield and gas production rate and the like of the waste conventional biogas utilization system, can greatly accelerate the gas production process of the rancidity-prone waste with a small amount of microbial inoculum, increases the gas production yield of the waste, lowers the amounts of leavings and waste liquids, and decreases the volume of a reactor and the operating cost.

Owner:TONGJI UNIV

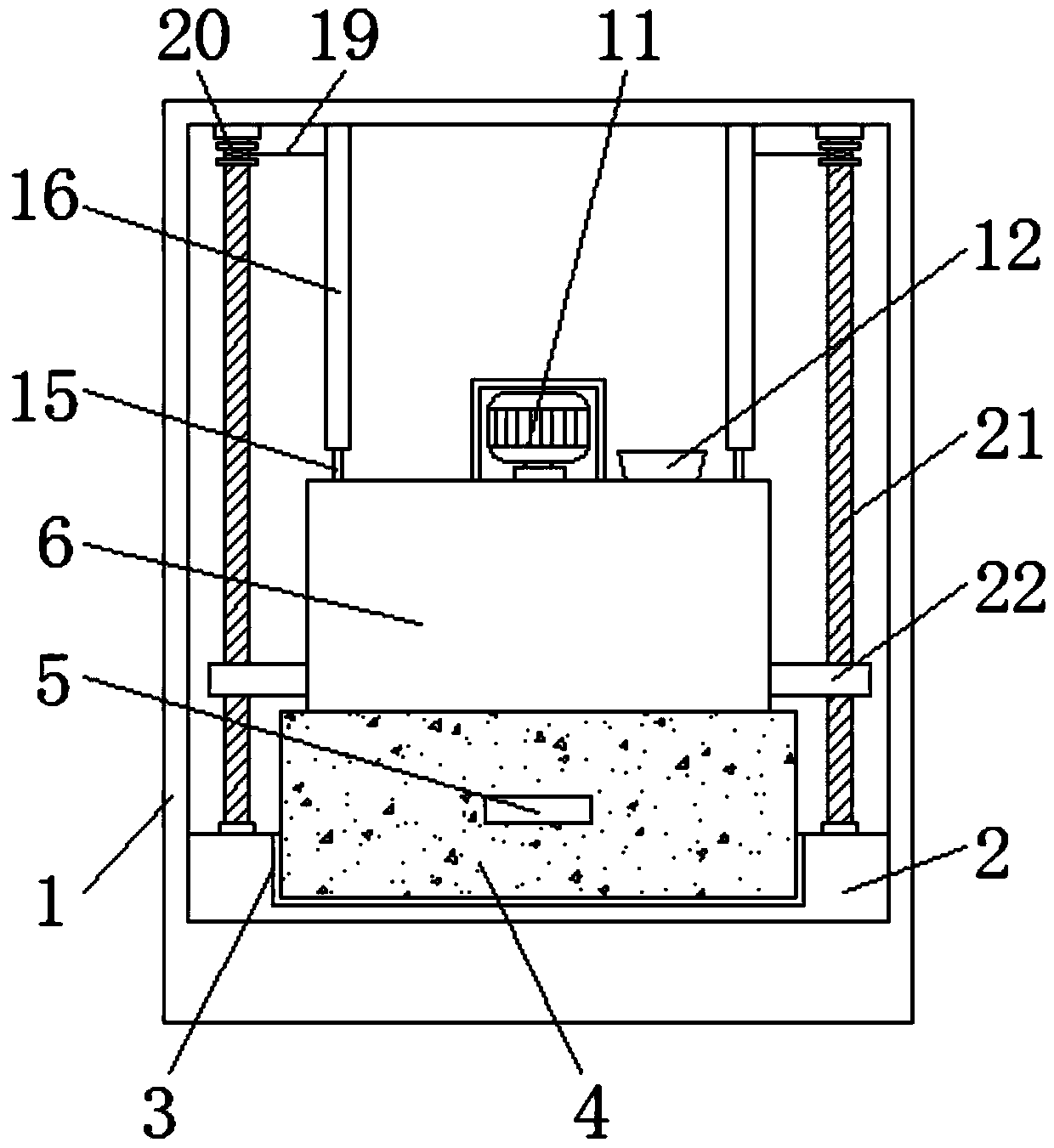

Sewage treatment dry powder wet agent adding device free of dust leakage and thorough in dispersion

PendingCN109966972ACreate troubleDisperse thoroughlyTransportation and packagingMixer accessoriesPulp and paper industrySewage treatment

The invention discloses a sewage treatment dry powder wet agent adding device free of dust leakage and thorough in dispersion, and belongs to a mixer in the technical field of water treatment. The device is mainly formed by an agent dissolving tank, a liquid storage cavity, an air stirring device and an exhaust device and is characterized in that 1, an agent powder dispersing link and a pump conveying link are separated through the agent dissolving tank and the liquid storage cavity; 2, multi-center pneumatic stirring is utilized or combined with mechanical stirring; 3, negative pressure is formed in the agent dissolving tank. Compared with the prior art, the device has the advantages that 1, pump blocking is avoided by designing the agent dissolving tank and the liquid storage cavity; 2,by means of multi-center pneumatic stirring or combination of multi-center pneumatic stirring and mechanical stirring, agent powder and water are dispersed thoroughly; 3, by means of the negative pressure of the agent dissolving tank, the dry agent powder which is not wet by spraying cannot flutter out of an agent adding chute opening, and inconvenient influence on an operator is avoided.

Owner:李成义

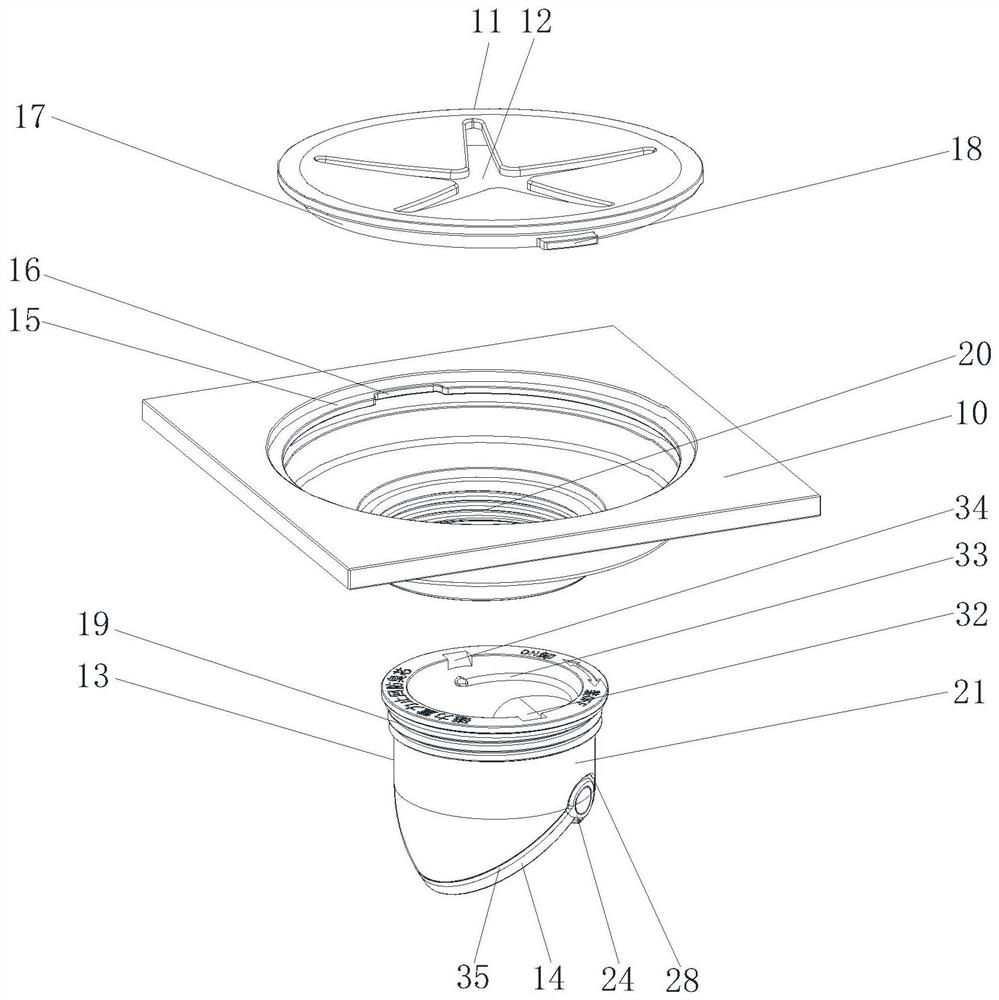

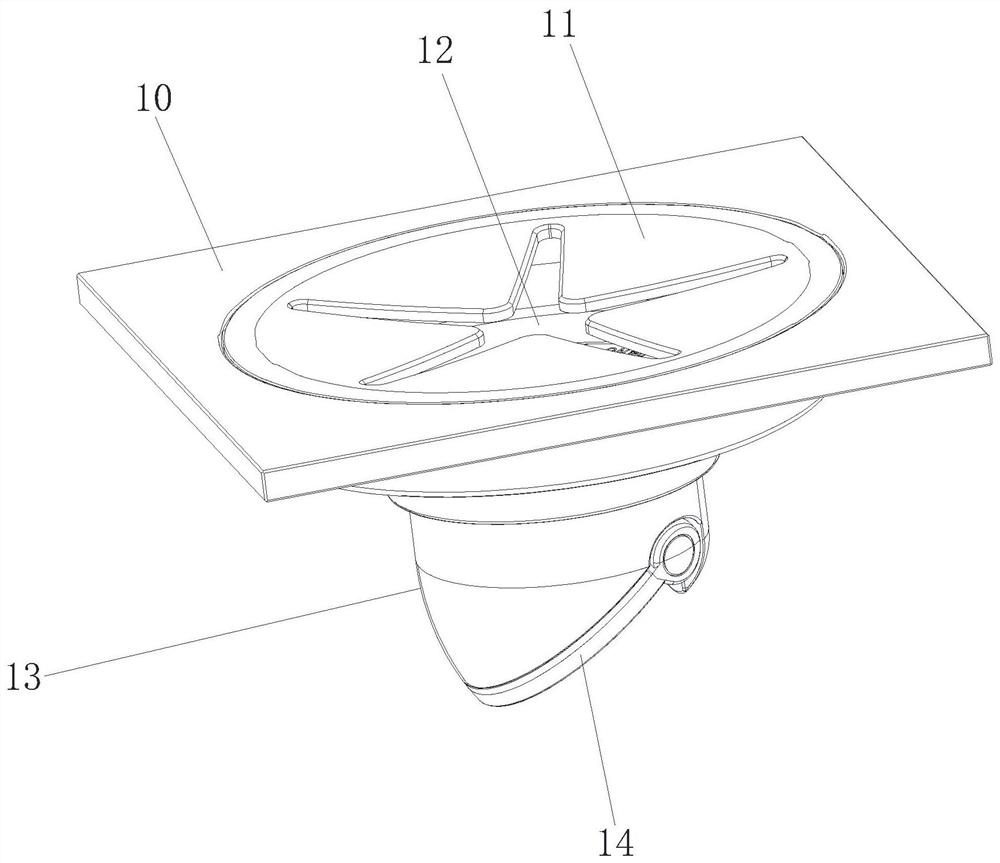

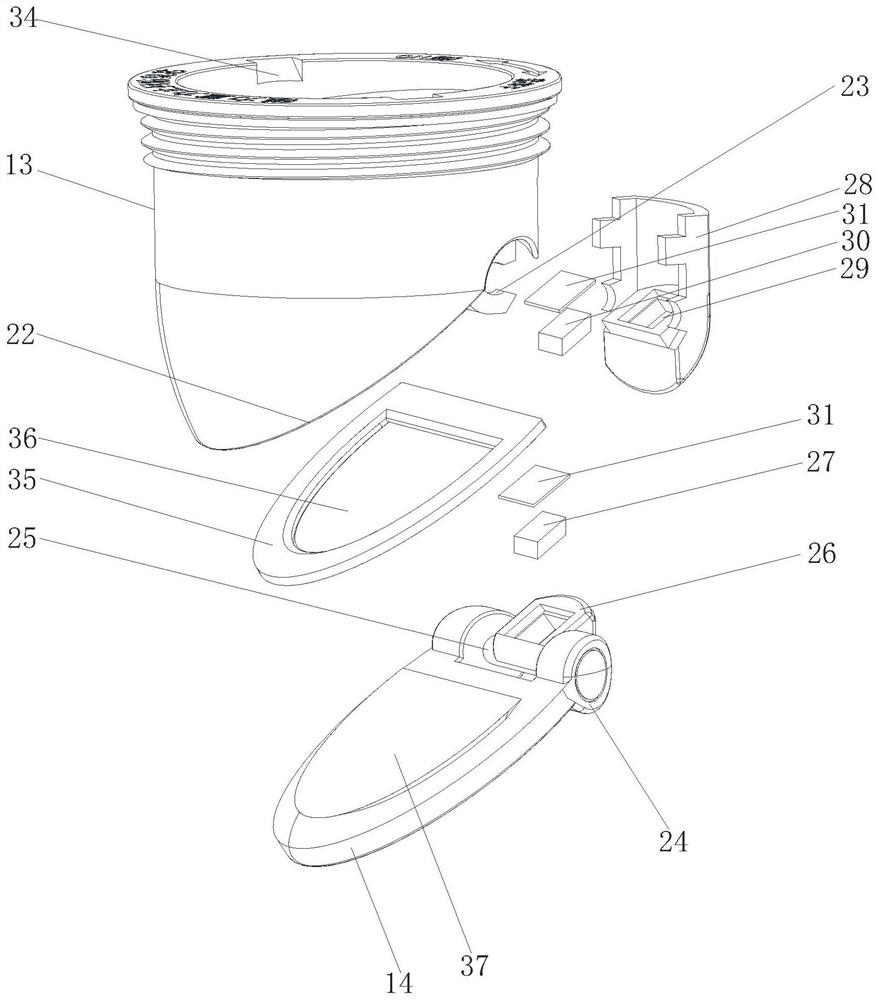

Self-cleaning and cleaning-free odor-resistant floor drain

PendingCN113417350AWith self-cleaning functionWith anti-odor and anti-insect functionSewerage structuresEnvironmental engineeringMechanical engineering

The invention discloses a self-cleaning and cleaning-free odor-resistant floor drain. The self-cleaning and cleaning-free odor-resistant floor drain comprises a floor drain seat, a face plate covers the floor drain seat, a water inlet hole is formed in the face plate, the face plate is concave in an arc shape, a direct drainage floor drain core is detachably and tightly installed on the floor drain seat, and a valve type sealing plate is installed on the direct drainage floor drain core in a hinged mode. The self-cleaning and cleaning-free odor-resistant floor drain is scientific and reasonable in structure, a filter screen does not need to be arranged, due to the fact that the face plate is in the arc-shaped concave shape, the water inlet holes communicate, the shapes of the water inlet holes are not limited, in the drainage process, impurities such as hair can be directly discharged into the direct drainage floor drain core through water washing, then the impurities can be discharged through the direct drainage floor drain core by opening the valve type sealing plate, hair hanging is avoided, blocking is avoided, the self-cleaning function is achieved, the cleaning-free effect is achieved, the valve type sealing plate recovers the closed state after discharging is completed, and the odor-resistant and insect-resistant effects are achieved.

Owner:TAIZHOU NIXI SANITARY WARE CO LTD

Novel middle waste absorbing punching roller

InactiveCN104875233AFall will notReduce processing stepsMetal working apparatusPunchingPulp and paper industry

The invention discloses a novel middle waste absorbing punching roller. The novel middle waste absorbing punching roller comprises an upper punching roller body, a lower punching roller body and a waste outlet. The upper punching roller body and the lower punching roller body are hollow rollers. The waste outlet is communicated with the lower punching roller body. The upper punching roller body and the lower punching roller body are provided with an upper punching die and a lower punching die respectively, and the upper punching die and the lower punching die are meshed with each other. The novel middle waste absorbing punching roller has the advantages of being high in speed and precision and low in noise, the working efficiency can be improved, and the comprehensive cost can be lowered.

Owner:上海伯奈尔印刷包装机械有限公司

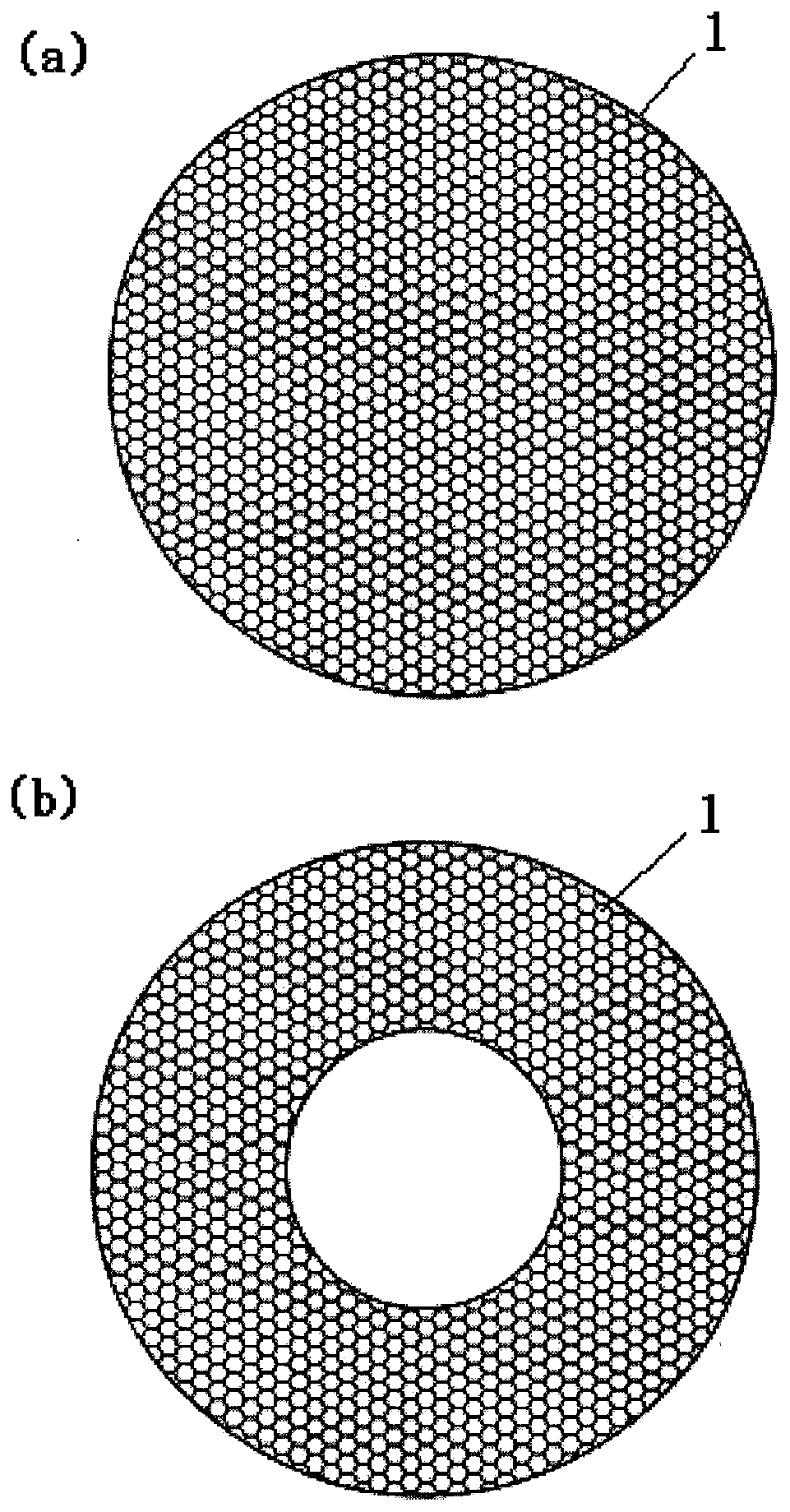

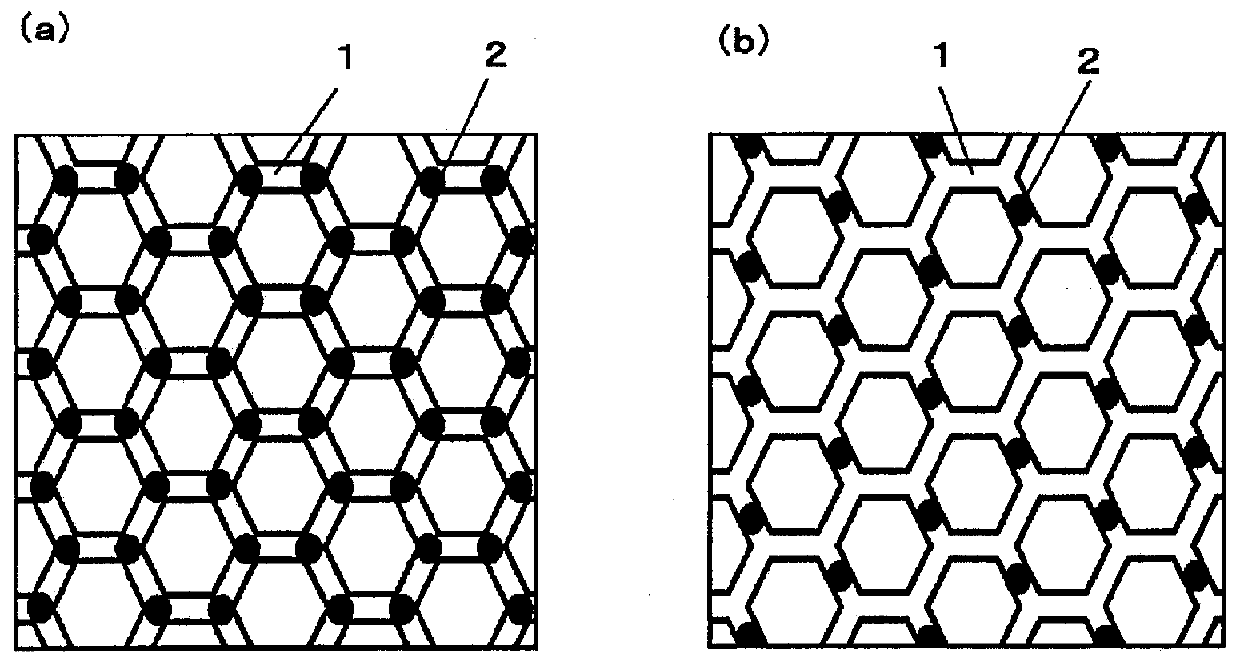

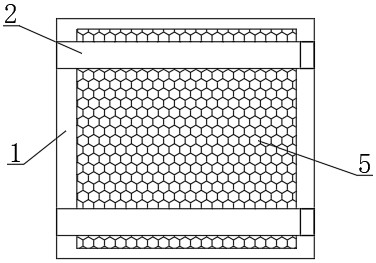

Grindstone

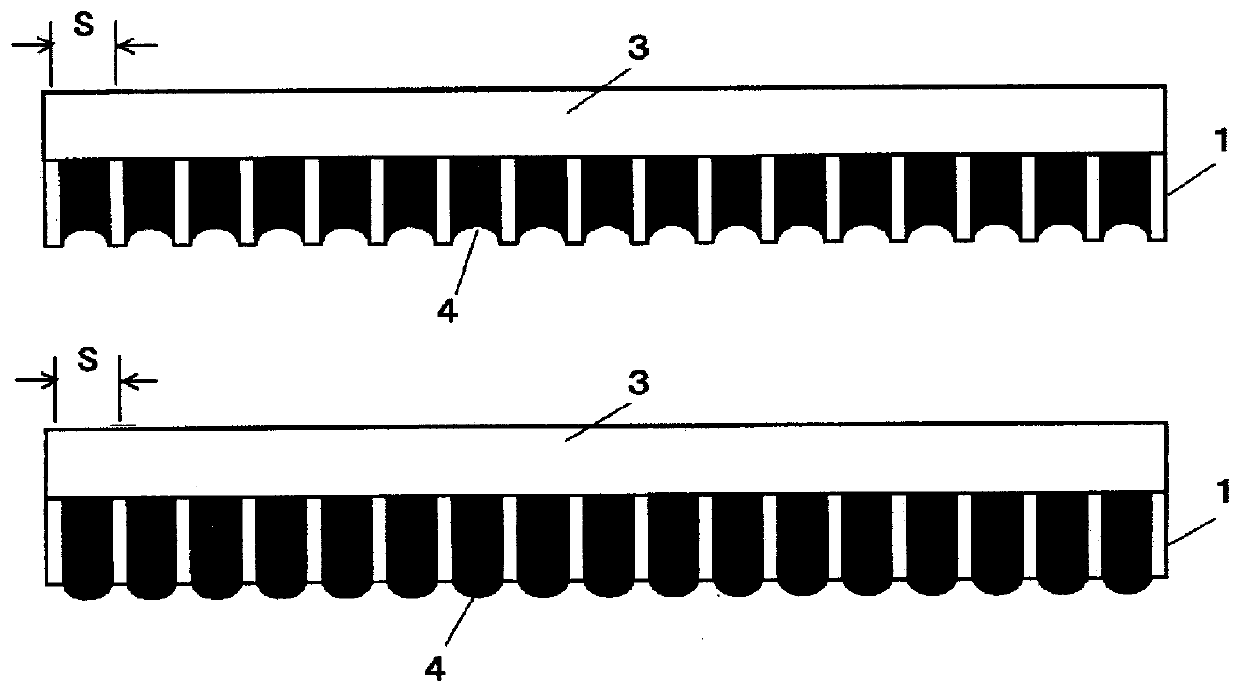

PendingCN109890563ANo air hammerReduce touch pointsBonded abrasive wheelsGrinding/polishing apparatusElastomerSuperfinishing

The purpose of the invention is to provide a grindstone such that grinding, polishing, and super-fine polishing can be achieved using the same grindstone and without causing clogging when used continuously. The invention provides a grindstone having a grinding / polishing part which is for working a workpiece and which has a honeycomb structure comprising polygonal columns arranged without any gap therebetween, wherein the grindstone is provided with grinding columns, each comprising abrasive grains (5) and a binding material (6), having an axis L in the depth direction of a surface to be ground / polished, and disposed at an intersection or on a wall part of the honeycomb structure. A porous elastomer disposed inside the honeycomb, thereby enabling super-fine polishing.

Owner:NANO TEM

Silver fine particles and processes and equipment for the production thereof

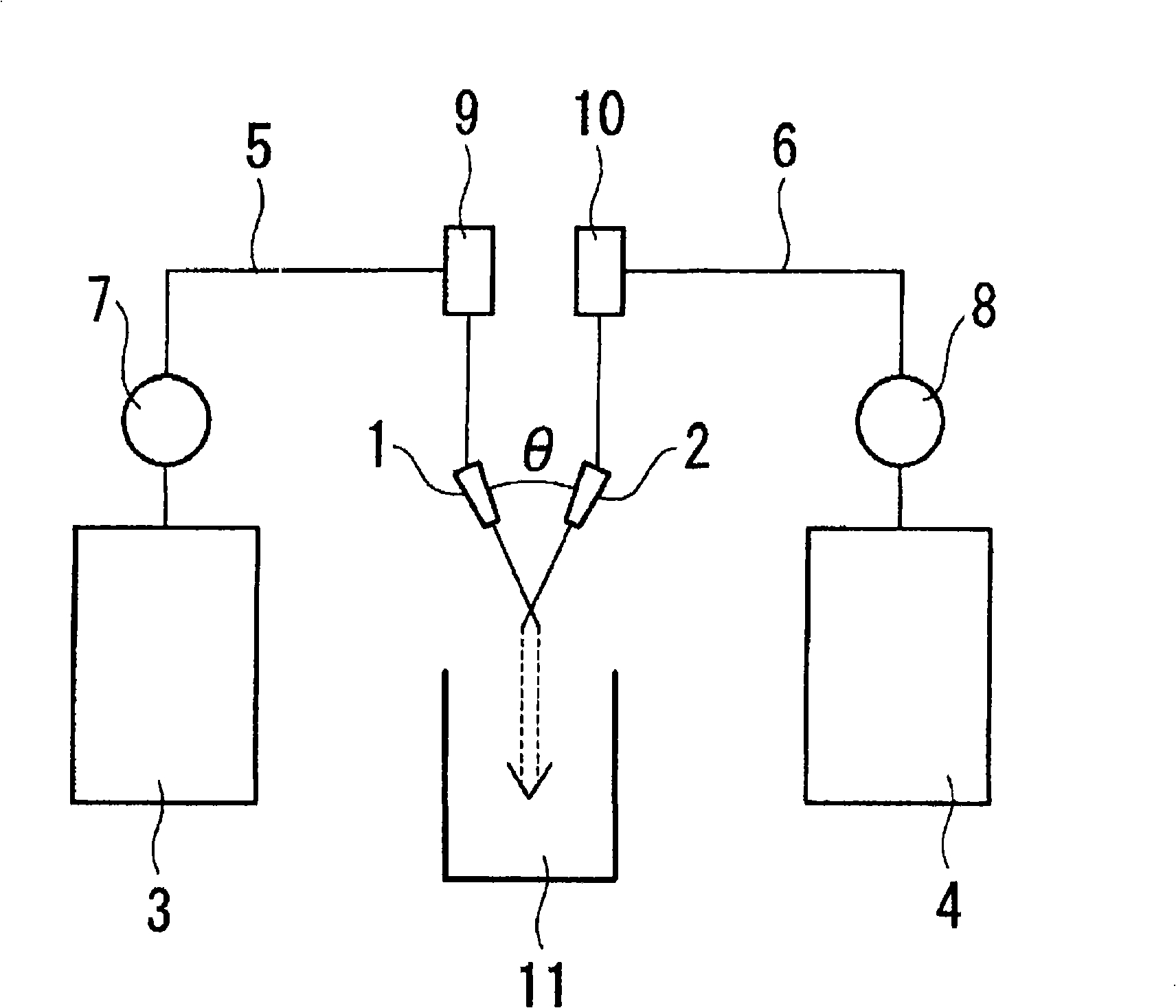

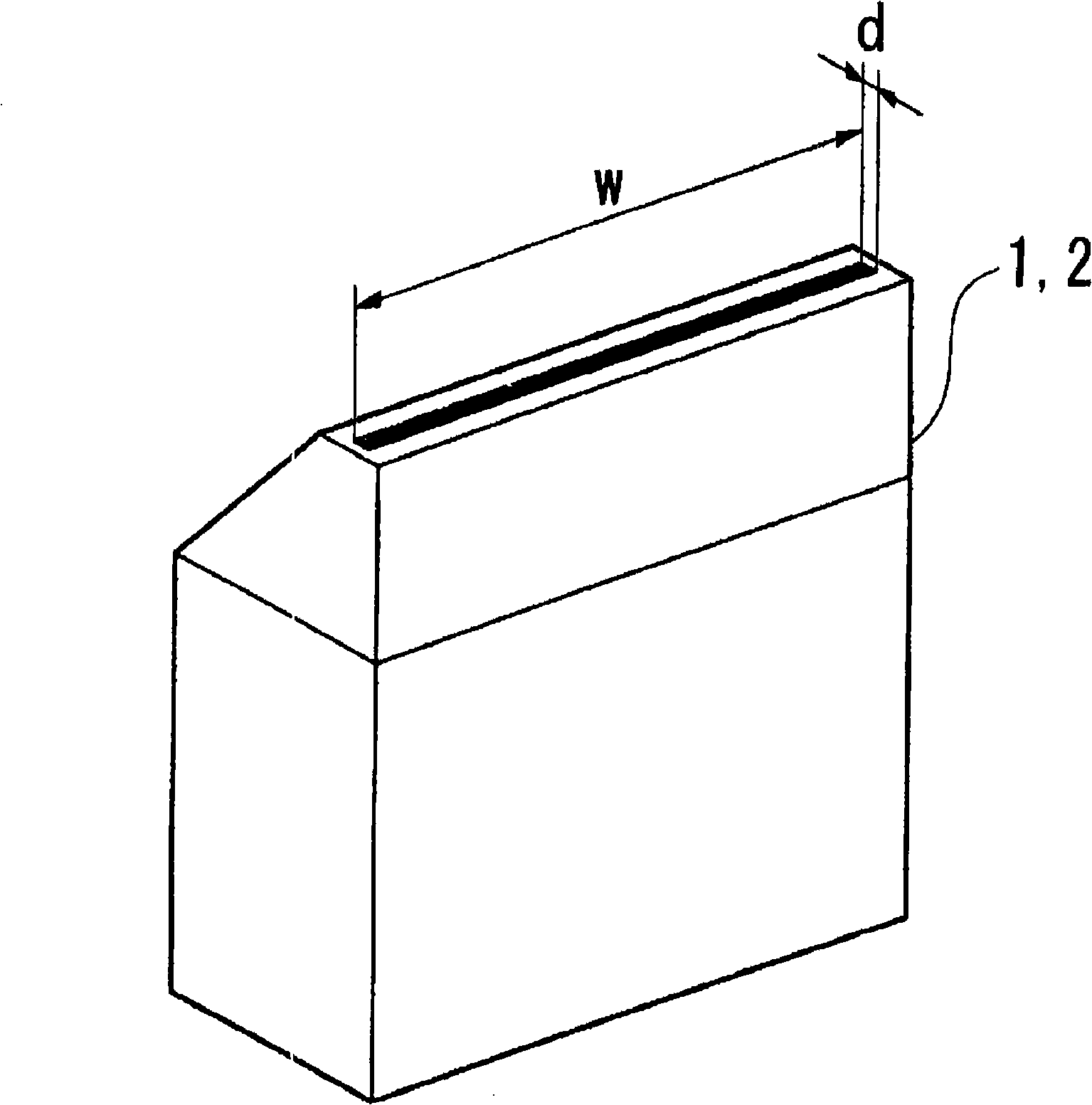

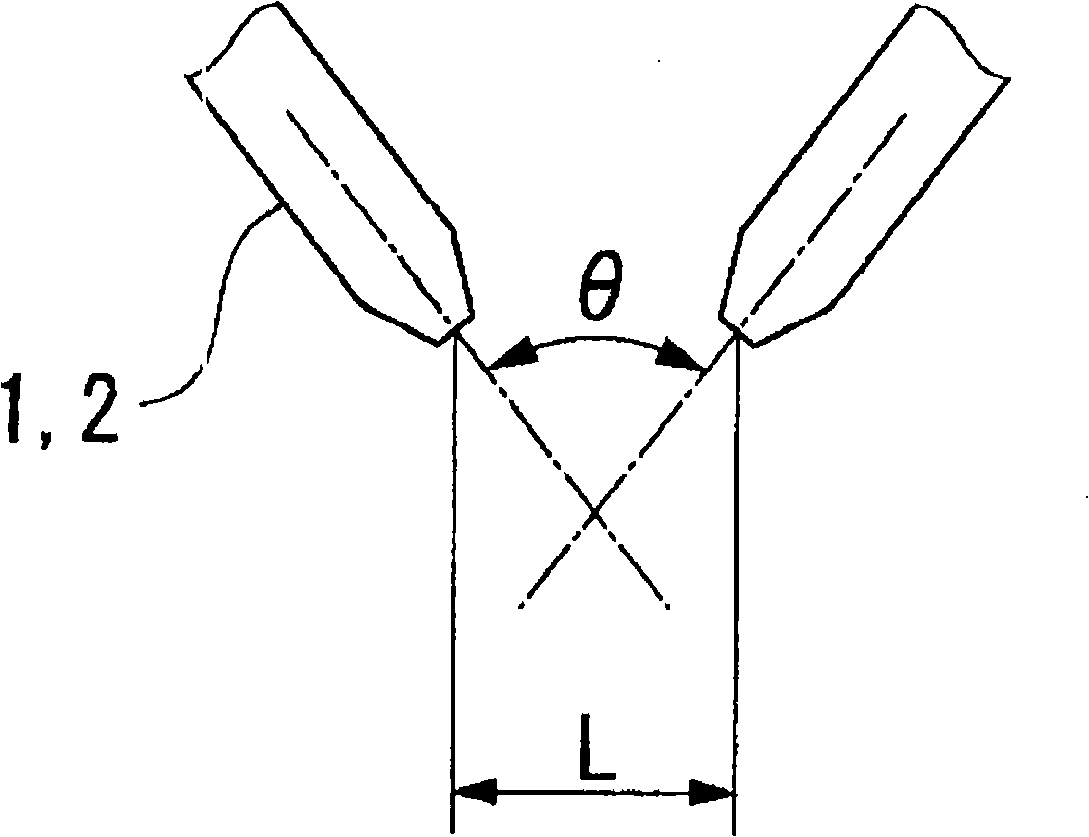

InactiveCN101495257AUniform particle sizeAvoid mixingMetal-working apparatusThin material handlingFree formMicroparticle

A process for production of silver fine particles which is characterized by making an aqueous silver ammine complex solution and a reducing agent solution meet each other in an open space to reduce the silver ammine complex and deposit silver fine particles, either in which the meeting is conducted by (i) a method of spraying an aqueous silver ammine complex solution and a reducing agent solution through nozzles or (ii) a method of ejecting an aqueous silver ammine complex solution and a reducing agent solution from obliquely downward nozzles opposite to each other to thereby produce silver fine particles which are free form coarse particles having particle sizes of 5[mu]m or above and have a mean particle size of primary particles of 0.08 to 1.0[mu]m and crystallite sizes of 20 to 150nm or in which an aqueous silver ammine complex solution having a silver concentration of 20 to 180g / L and an organic reducing agent solution having a reducing agent concentration of about 0.6 to about 1.4 times the silver concentration by reaction equivalent are used to thereby stably produce silver fine particles having a mean particle size of primary particles of 0.05 to 1.0[mu]m and crystallite sizes of 20 to 150nm.

Owner:MITSUBISHI MATERIALS CORP

Food-processing device

The invention discloses a food processing apparatus including a support frame, a rotating electric machine, a second rotating shaft and a servo motor, wherein a horizontal plate is fixed inside the support frame, a handle is fixed on the outer wall of the contain box, an agitating shaft is installed inside the agitating shell, the upper end of the stirring shaft penetrates the top of the stirringshell and is mutually connected with a rotating electric machine, the top of the stirring shell is respectively provided with a feeding port and a through hole, the upper end surface of the cleaning plate is fixed with the lower end of the sleeve rod, the upper end of the sleeve is internally fixed with a pulley, one end of the traction wire is fixed to the upper end of the sleeve rod, the upper end and the lower end of the first rotary shaft are respectively installed on the top and the bottom of the support frame, the upper end of the second rotary shaft is installed on the bottom of the horizontal plate, and the side of the first gear is provided with a second gear. The food processing device can avoid blockage at the bottom of the stirring shell, and can avoid adhesion of minced meat on the inner wall of the stirring shell.

Owner:上海雅沐食品有限公司

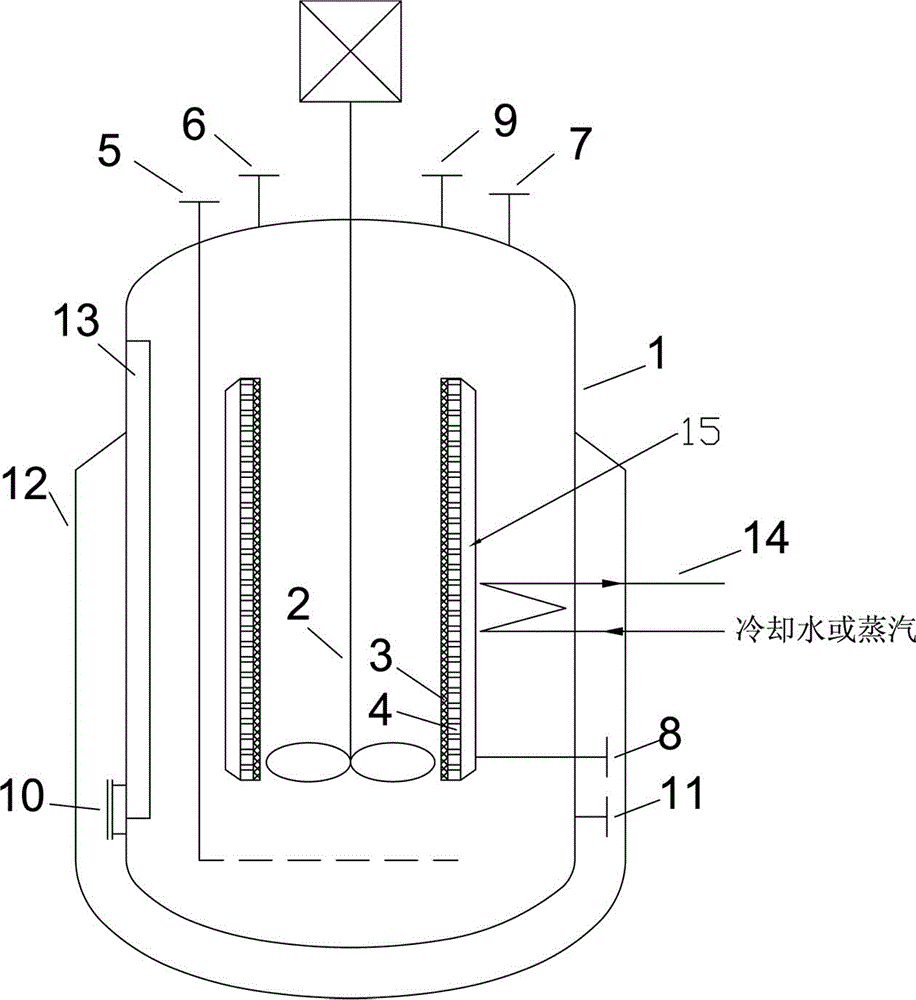

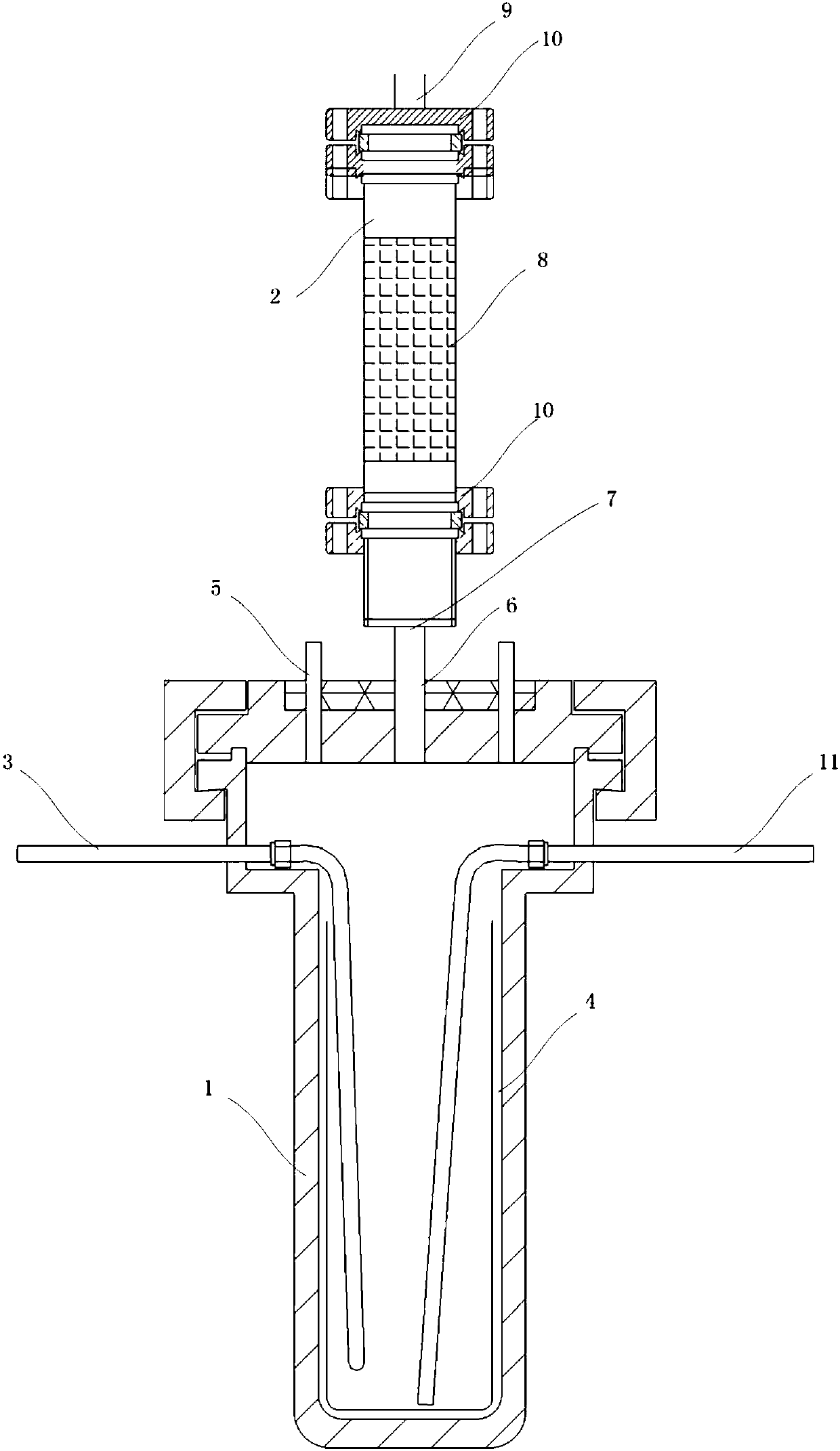

Reaction device for uranium fluorination reaction in molten salt system and operation method thereof

PendingCN110042434ADoes not cause condensationWon't cause cloggingNuclear energy generationRecycling and recovery technologiesPotassium fluorideAlloy

The invention discloses a reaction device for a uranium fluorination reaction in a molten salt system and an operation method thereof. The reaction device comprises a fluorination reactor, and is characterized in that the inner wall surface of the fluorination reactor is provided with a crucible lining with the thickness being 2-5 mm, wherein the crucible lining is a nickel metal crucible lining,a nickel-based alloy crucible lining, a ceramic crucible lining or a graphite crucible lining; a filter is arranged on a pipeline where a gas product outlet of the fluorination reactor is located; a filter filler in the filter is fluoride particles with the grain size being 2-6 mm, the fluoride particles are one or more of sodium fluoride particles, magnesium fluoride particles, barium fluoride particles and potassium fluoride particles; the filling diameter of the filter filler is 3-10 cm; and the ratio of the filling height of the filter filler to the filling diameter of the filter filler is3-10. The reaction device is able to resist double corrosion of high-temperature fluorine salt and fluorine gas without causing blockage of an outlet gas pipe and a valve of the reactor, and long-term safe operation of the reactor can be achieved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

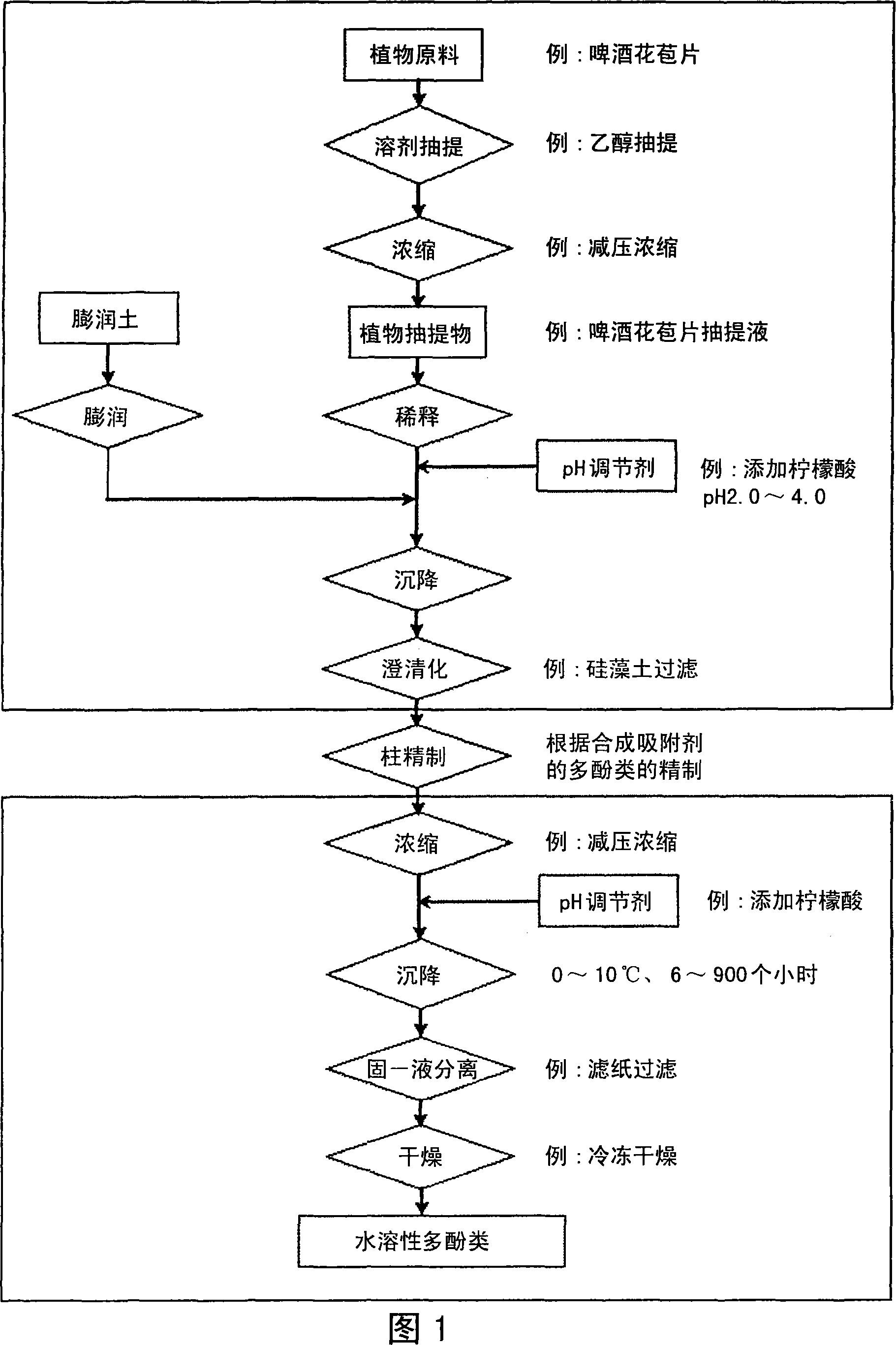

Method for preparation of plant extract

InactiveCN101155819AEfficient removalAvoid turbidityBy-product recoveryOrganic chemistryClay mineralsSodium Bentonite

It is intended to develop a technique for producing a water-soluble polyphenol at high purity and with high efficiency in a short time from hop bract or the like which is a by-product in the beer brewing. A method for preparation of a purified plant extract comprising steps of treating a plant extract with a clay mineral such as bentonite and removing any divalent cations from the resulting product; a method for producing a polyphenol comprising steps of passing the purified plant extract through a column to adsorb polyphenols onto the column and passing a solvent through the column to elute a water-soluble polyphenol from the column; and a method for producing a water-soluble hot bract polyphenol comprising steps of adding bentonite to a hop bract extract and allowing the resulting mixture to stand under acidic conditions, performing solid-liquid separation to produce a supernatant, purifying the supernatant through a column to give a polyphenol-containing fraction, cooling the fraction and allowing the cooled fraction to stand to cause the precipitation of water-insoluble ingredients and performing solid-liquid separation to give the desired water-soluble hop bract polyphenol.

Owner:ASAHI GRP HLDG LTD

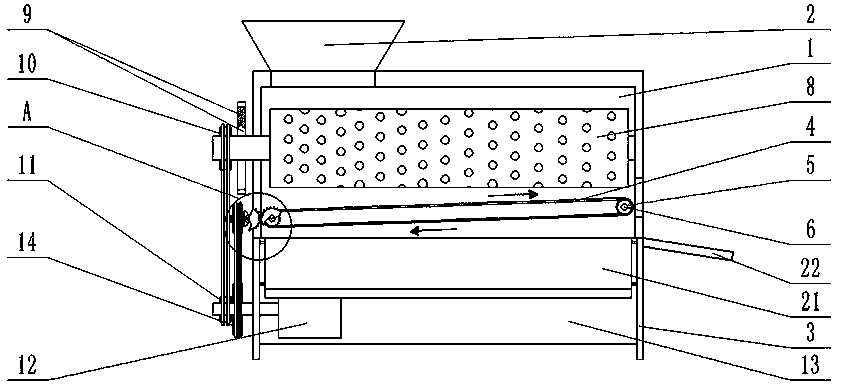

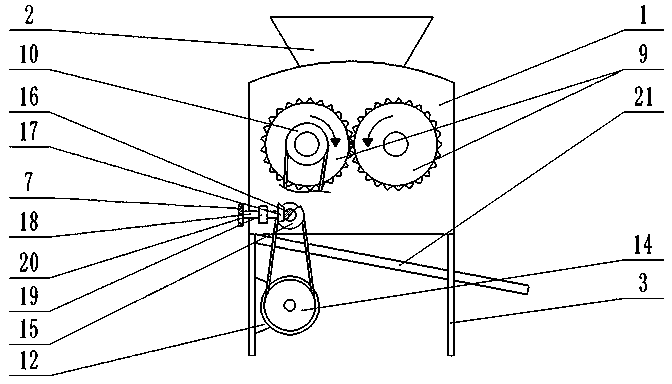

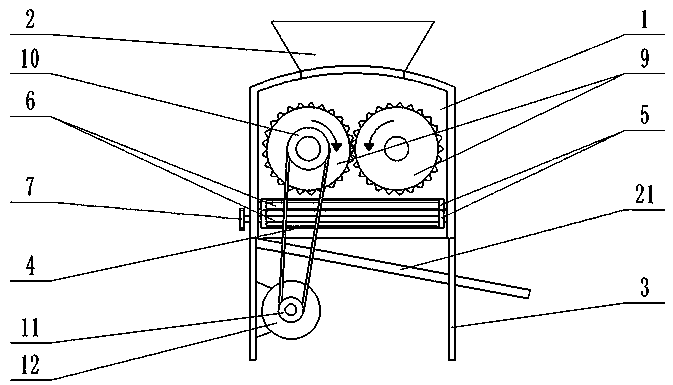

Corn thresher

InactiveCN110558058ASmooth and stable transportationStrong diameter adaptabilityThreshersBrickGear wheel

The invention discloses a corn thresher. The corn thresher comprises a threshing bin, a feeding hopper and supporting legs. The corn thresher is characterized in that the bottom of the threshing bin is open, the two ends of a net-shaped conveyor belt are supported through conveyor belt gear sets, one end of each conveyor belt rotary shaft penetrates through the threshing bin, second conveyor beltgears are installed at ends, the tail of one end of a threshing roll of a threshing roll set penetrates through the threshing bin, a threshing roll gear set is installed at the end, one threshing rollend of the threshing roll set is further sleeved with a first driven belt wheel, the output end of a motor is sleeved with a first driving belt wheel and further sleeved with a second driving belt wheel, a brick laying shaft is sleeved with a second driven belt wheel, an umbrella-type gear set is installed on the brick laying shaft and provided with a power shaft, a first conveyor belt gear is installed at one end of the power shaft, and the distance between the threshing roll set and the net-shaped conveyor belt is gradually decreased in the moving direction of corn con threshing.

Owner:王刚

Maintenance wiping method and maintenance wiping wet tissue for ink-jet printer nozzle

The invention discloses a maintenance wiping method and a maintenance wiping wet tissue for an ink-jet printer nozzle. The maintenance wiping wet tissue is composed of the following components including, by weight, 10% of NPGDA, 33% of TPGDA, 24% of HDDA, 23% of DPGDA and 10% of a surfactant. A using method of the maintenance wiping method for the ink-jet printer nozzle comprises the following steps that 1, materials are prepared, wherein foam and a wet tissue body are prepared; 2, the foam is taken up and placed flatly; and 3, the viscous force of a hook-and-loop fastener loop surface and a hook-and-loop fastener hook surface are overcome, a fixing band is uncovered, and one end of the fixing band is far away from the foam. The maintenance wiping method and the maintenance wiping wet tissue for the ink-jet printer nozzle has the beneficial effects that a traditional ink-jet printer nozzle maintenance wiping method is changed, the wiped nozzle is not damaged, head drying, head blockingand damage of the nozzle cannot be caused, the wiping effect is obvious, the service life of the nozzle is prolonged, the cost is saved, and the consumption is reduced; and due to the addition of thesurfactant, the sterilization effect is improved.

Owner:郑州奥诚电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com