Patents

Literature

57results about How to "Increase Separation Throughput" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

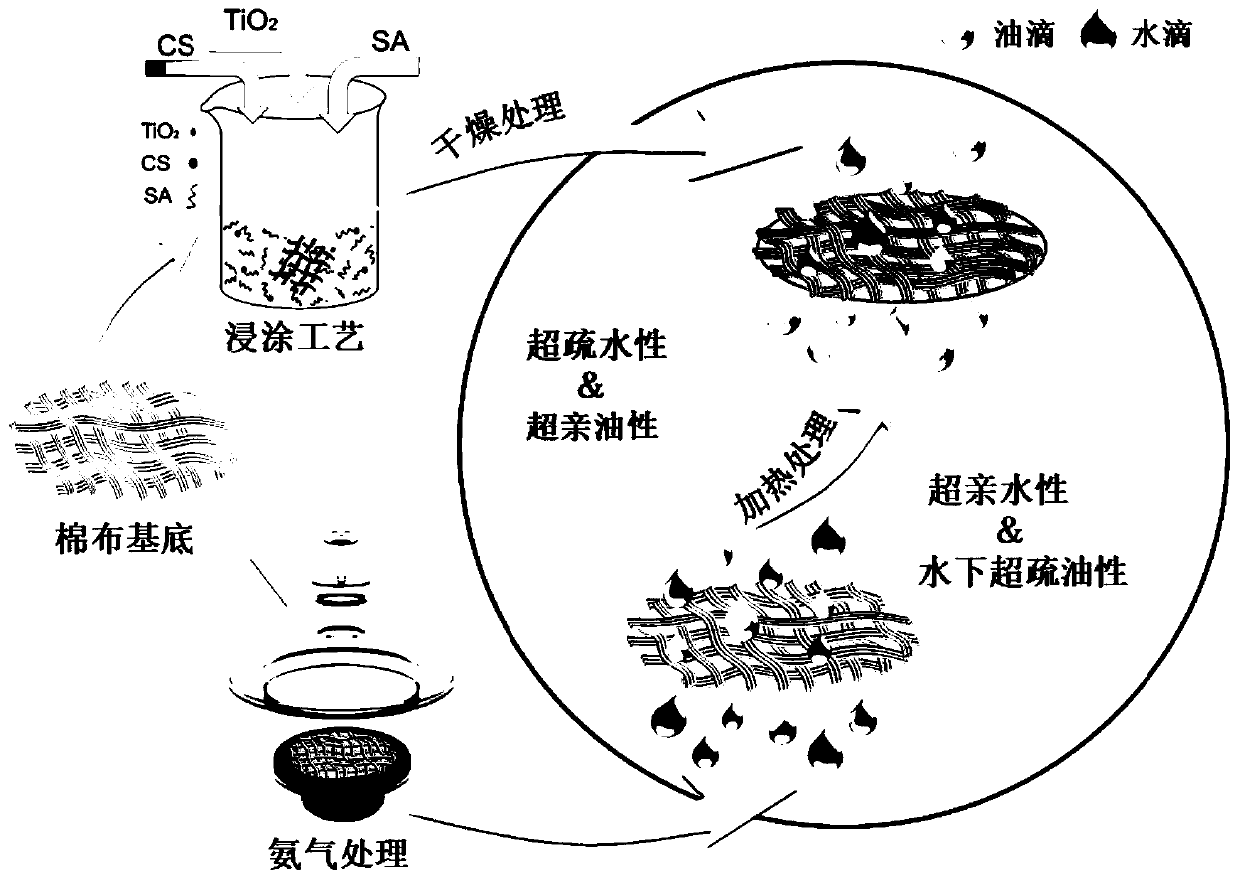

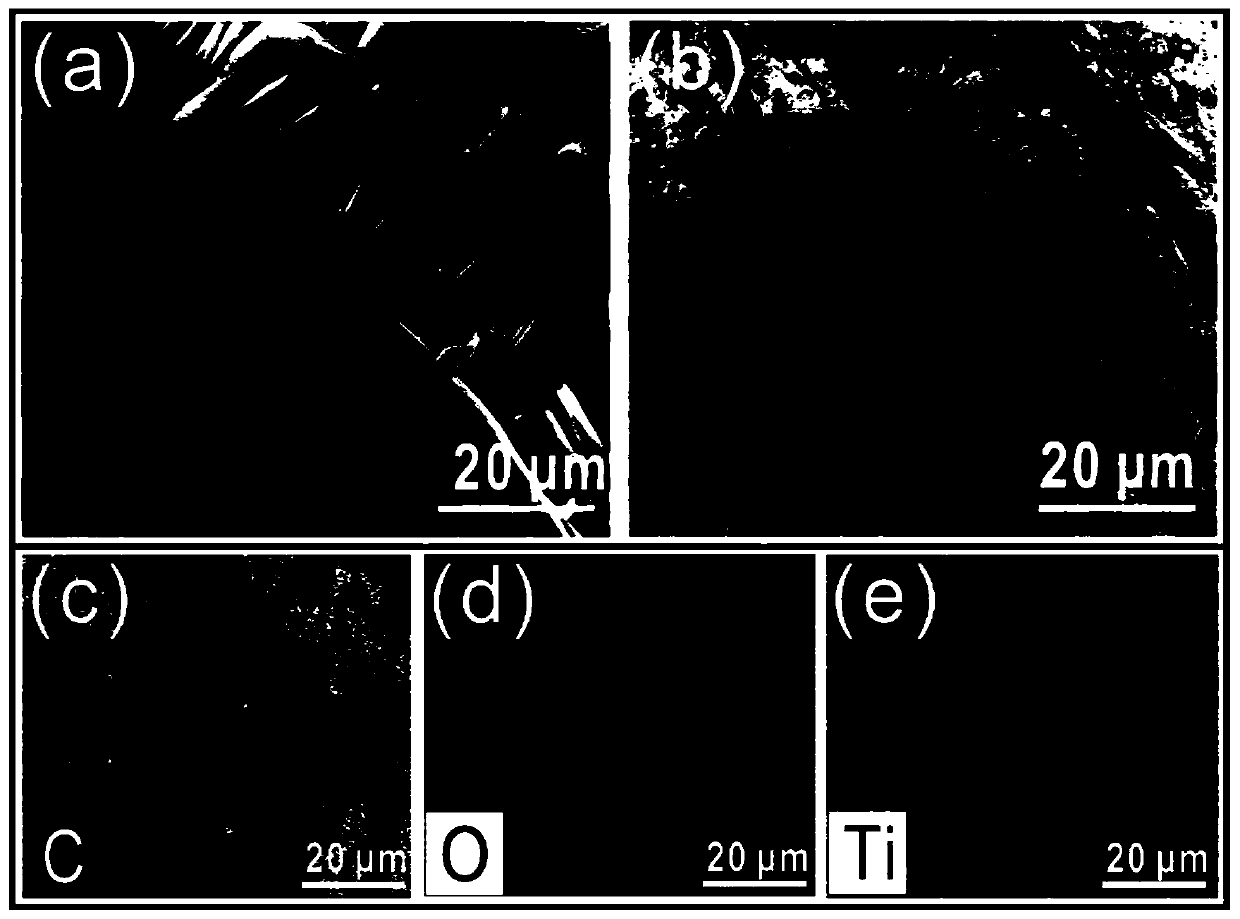

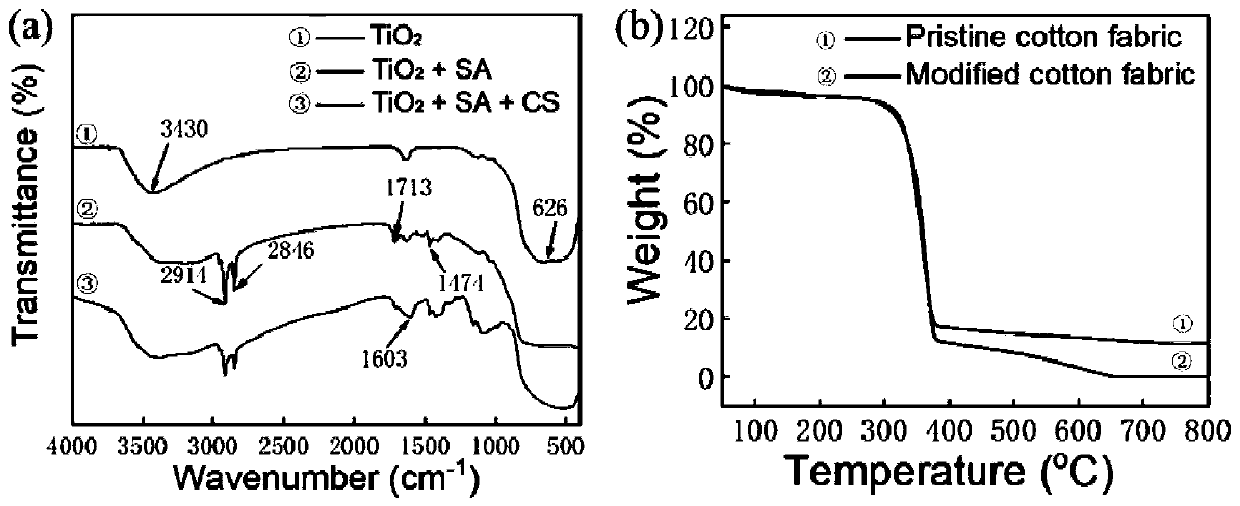

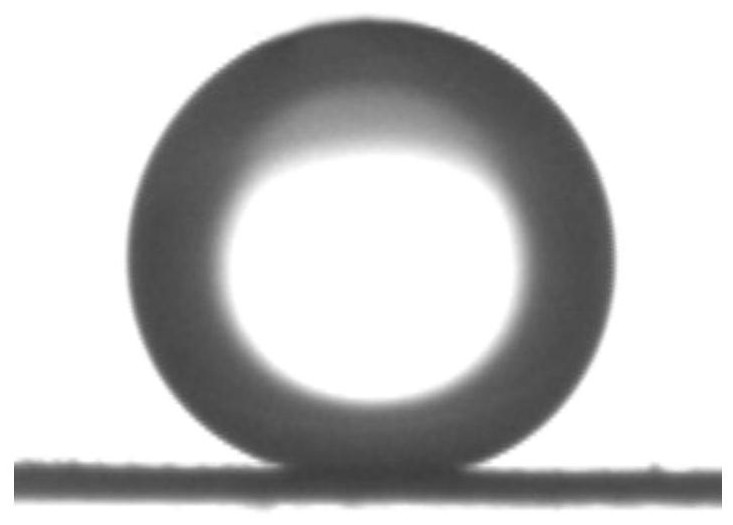

PH-responsive super-hydrophobic coating material as well as preparation method and application thereof

ActiveCN110734655ASuperhydrophobicImprove performanceCoatingsNon-miscible liquid separationActive agentOil phase

The invention provides a pH-responsive super-hydrophobic coating material as well as a preparation method and application thereof. The preparation method comprises the steps that: reacting stearic acid and nano titanium dioxide to obtain a stearic acid / nano titanium dioxide compound, reacting the stearic acid / nano titanium dioxide compound with chitosan to obtain the pH-responsive super-hydrophobic coating material, wherein the mass ratio of the nano titanium dioxide to the chitosan is 6-9: 1. The coating material provided by the invention not only can be converted into a super-hydrophilic state from a super-hydrophobic state under ammonia treatment, but also can recover the super-hydrophobicity again after heating treatment; and in addition, by utilizing the pH response mechanism of the coating material, continuous separation of oil / water / oil phases can be realized, and stable emulsion separation of different surfactants can also be realized.

Owner:QILU UNIV OF TECH

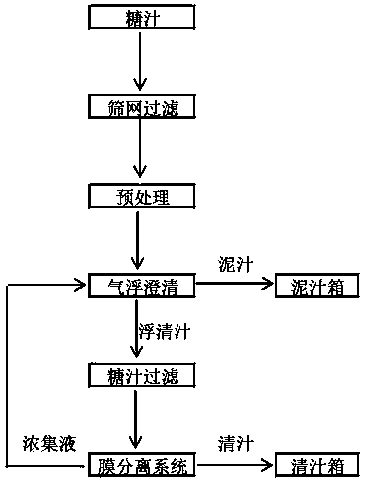

Syrup clarification method

The invention relates to a syrup clarification method, belonging to the technical field of syrup clarification of the sugar industry. The syrup clarification method is used for clarifying the syrup by use of a syrup air flotation clarification and membrane separation coupling technology and comprises major processes of treating in a syrup air flotation clarification pretreatment system, a syrup air flotation clarification system and a syrup membrane separation system, and specifically comprises the following steps: performing air flotation clarification pretreatment on the syrup first, namely filtering the syrup with a filter screen, adding lime and phosphoric acid to adjust the pH value, and performing primary heating treatment; after the treatment, treating the syrup in the air flotation clarification system, and removing the non-sugar components of the network in the syrup; treating the syrup obtained by the air flotation clarification with a syrup filtering system; and clarifying in the efficient syrup membrane separation system to obtain clear syrup of which the clarification quality is not lower than that of the traditional sugar production technology to finish the syrup clarification process. The process provided by the invention mainly adopts the air flotation clarification and membrane separation coupling technology; the method is simple and advanced, the retention time of the syrup is short, the sucrose loss is little, the clarification is stable and controllable, the clarification efficiency is high, and the method is an effective measure of a sugar refinery for realizing energy-saving and clean production and implementing sustainable development and has a relatively good application prospect.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

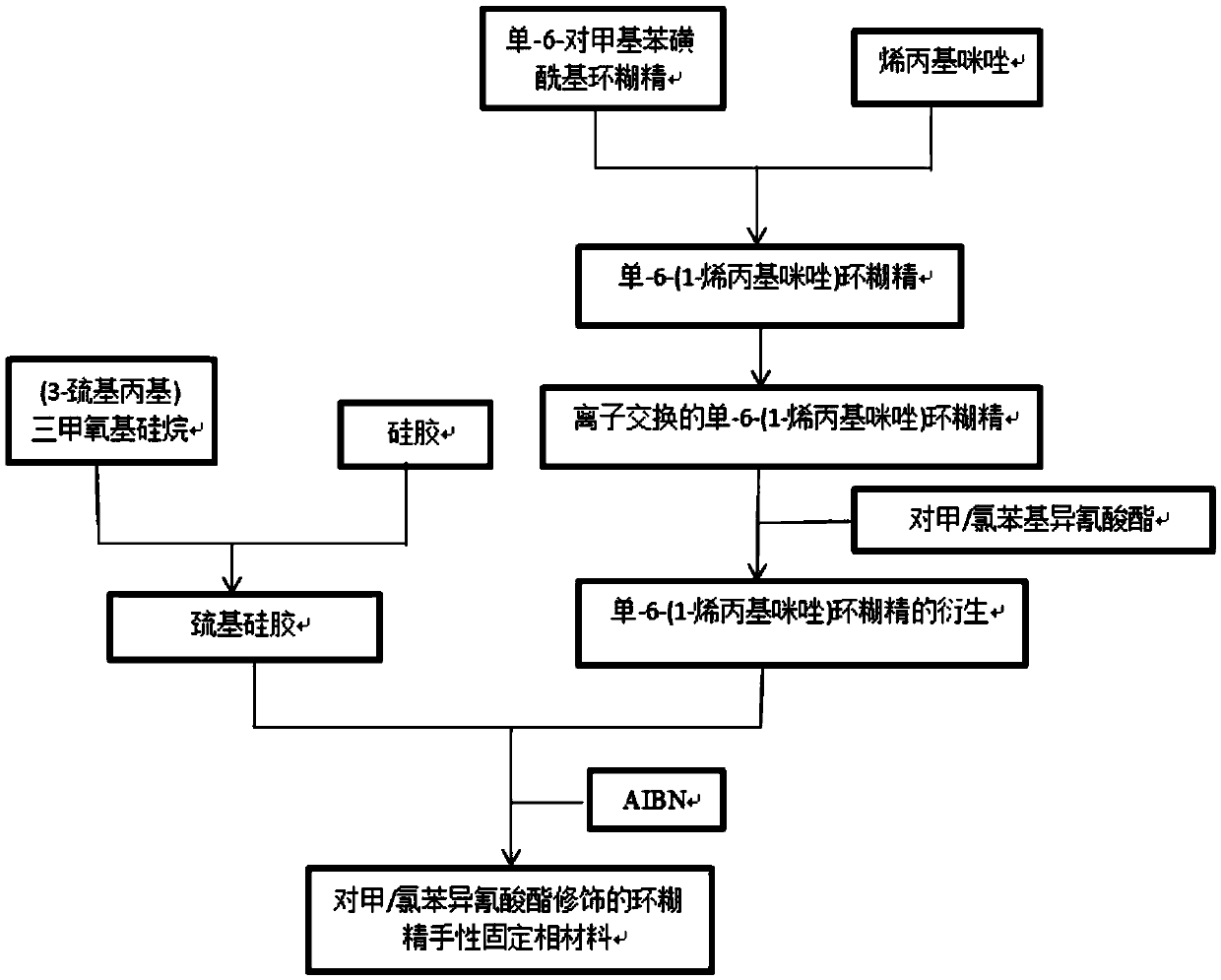

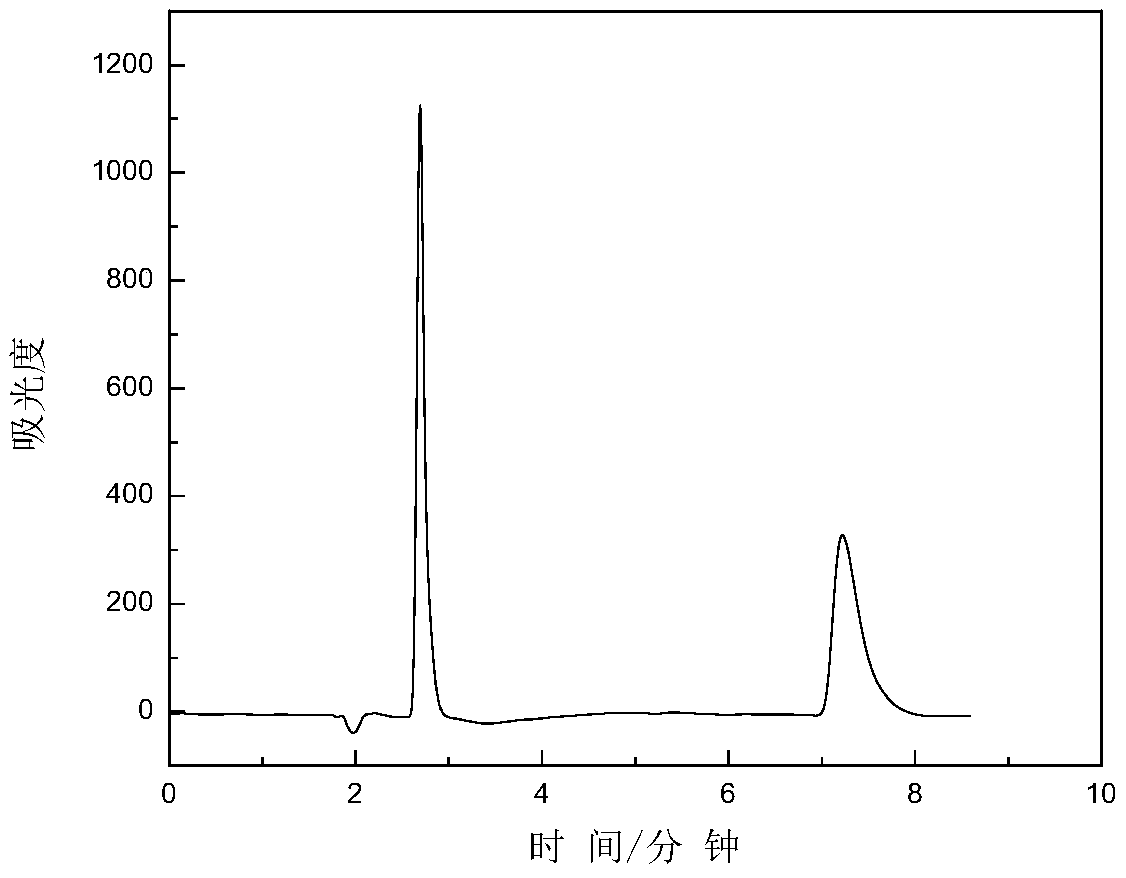

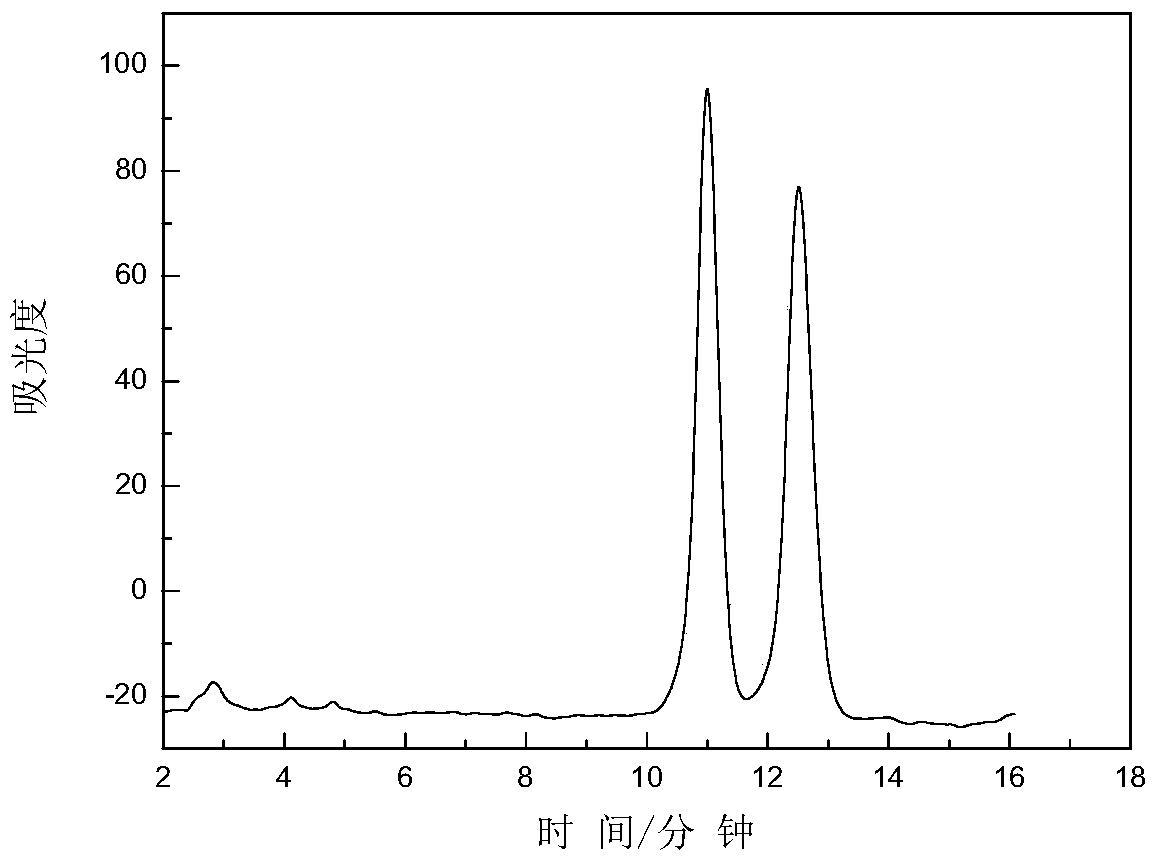

Preparation of p-tolyl/4-chlorophenyl isocyanate-modified cationic cyclodextrin chiral resolution material through click chemistry and application of chiral resolution material

InactiveCN105498735AImprove performanceReduce loading difficultyOther chemical processesSolid sorbent liquid separationCyclodextrinClick chemistry

The invention discloses a method for preparing a p-tolyl / 4-chlorophenyl isocyanate-modified cationic cyclodextrin chiral resolution material through click chemistry. According to the method, 4-chlorophenyl isocyanate and p-tolyl isocyanate groups are introduced for function derivation of allylimidazole cyclodextrin, then mercapto-alkene click reaction is carried out to realize controllable bridging of allylimidazole cyclodextrin and mercapto-modified silica gel, and a hydrophobic modified cyclodextrin monomolecular layer is constructed on the surface of porous silica gel through thioether bonds, so the novel cyclodextrin chiral resolution material with definite structure and a plurality of action sites is prepared. The p-tolyl / 4-chlorophenyl isocyanate-modified cationic cyclodextrin chiral resolution material can be applied to chiral separation of compounds in a reversed-phase chromatographic mode and shows excellent resolution capability to medicines of different classes, e.g., isoxazolines, flavanones, bendrofluazide and 4-chromanol. The mercapto-alkene click reaction provided by the invention provides a highly-universal effective approach for preparation of a controllable chiral resolution material with stable structure.

Owner:TIANJIN UNIV

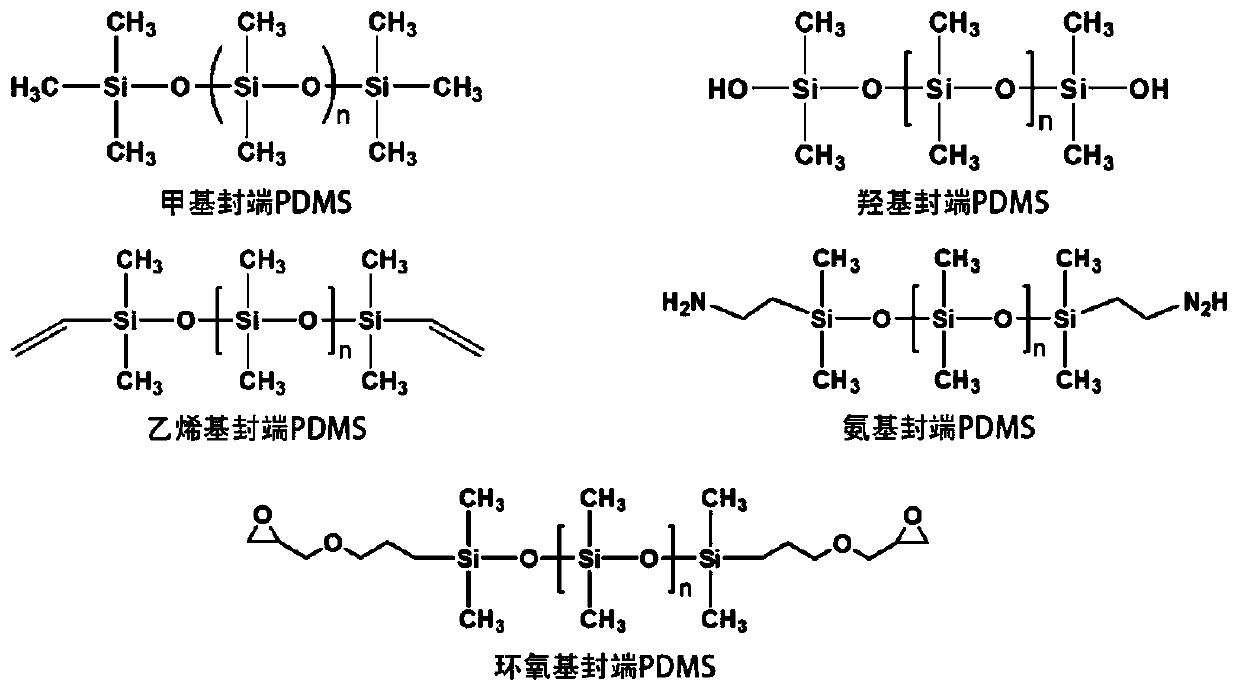

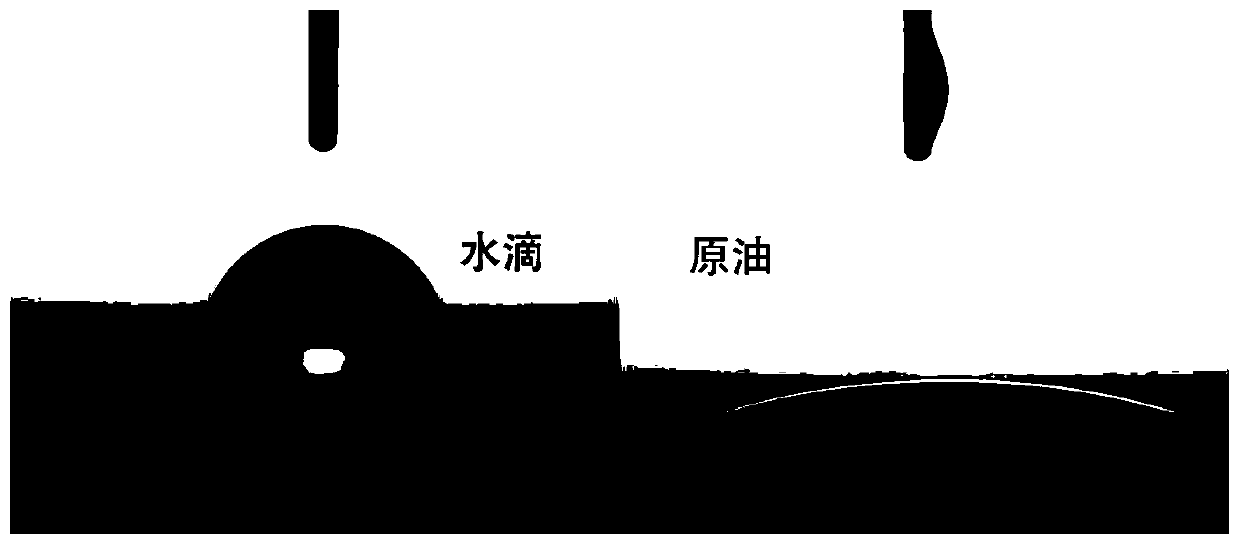

Preparation method of linear polydimethylsilane (PDMS) modified oil-water separation film, and oil-water separation film prepared through preparation method

ActiveCN109806780AImprove antifouling performanceIncrease Separation ThroughputSemi-permeable membranesNon-miscible liquid separationChemistryDimethylsilane

The invention discloses a preparation method of a linear polydimethylsilane (PDMS) modified oil-water separation film, and the oil-water separation film prepared through the preparation method. The preparation method comprises the following steps: a porous substrate is cleaned, surface organic impurities are removed, surface hydroxylation treatment is conducted, the porous substrate is immersed inlinear PDMS liquid to be subjected to a surface flexible polymer brush-type liquid layer grafting reaction, cleaning is conducted to remove excess PDMS, and drying is conducted to obtain the PDMS modified oil-water separation film. According to the preparation method, raw materials are non-toxic and environmentally friendly, the preparation process is simple, relying on expensive equipment is notneeded, and the overall low cost; through simple flexible chain single molecular layer decoration, the appearance shape of a base material is not affected; and the prepared oil-water separation material has the good anti-fouling property, can reduce adhesion of organic matter and oil on the surface, and can effectively separate a crude oil-water mixture with the high viscosity, and the separationspeed of the oil-water separation material is twice or above that of the same material modified by the cross-linking PDMS and an ordinary alkane molecular brush.

Owner:SUN YAT SEN UNIV

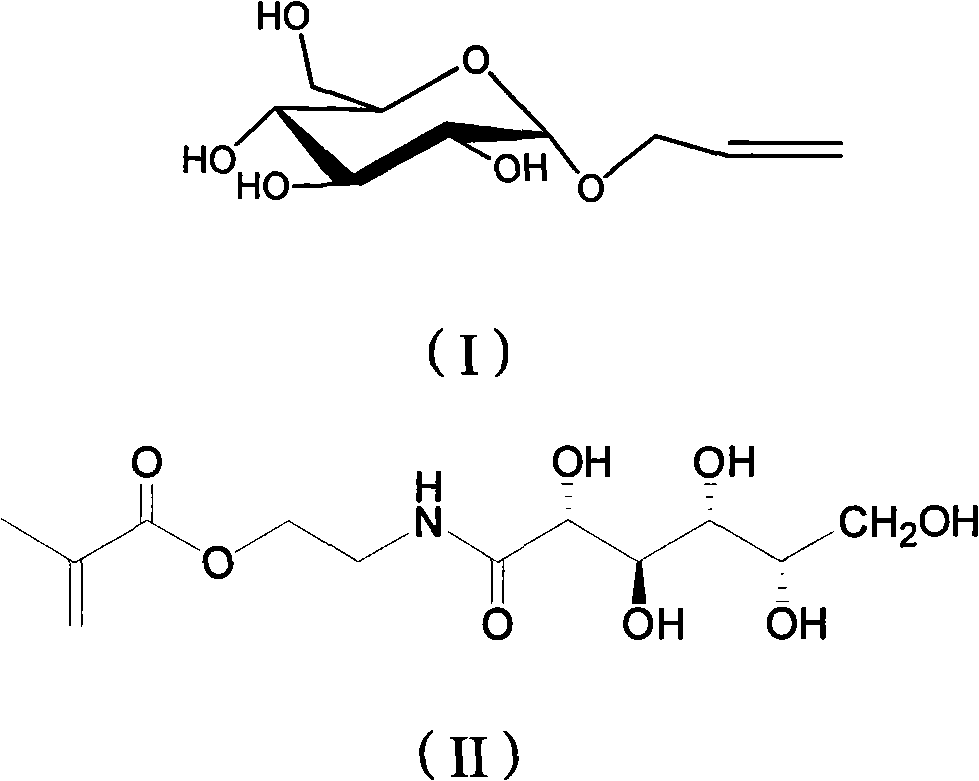

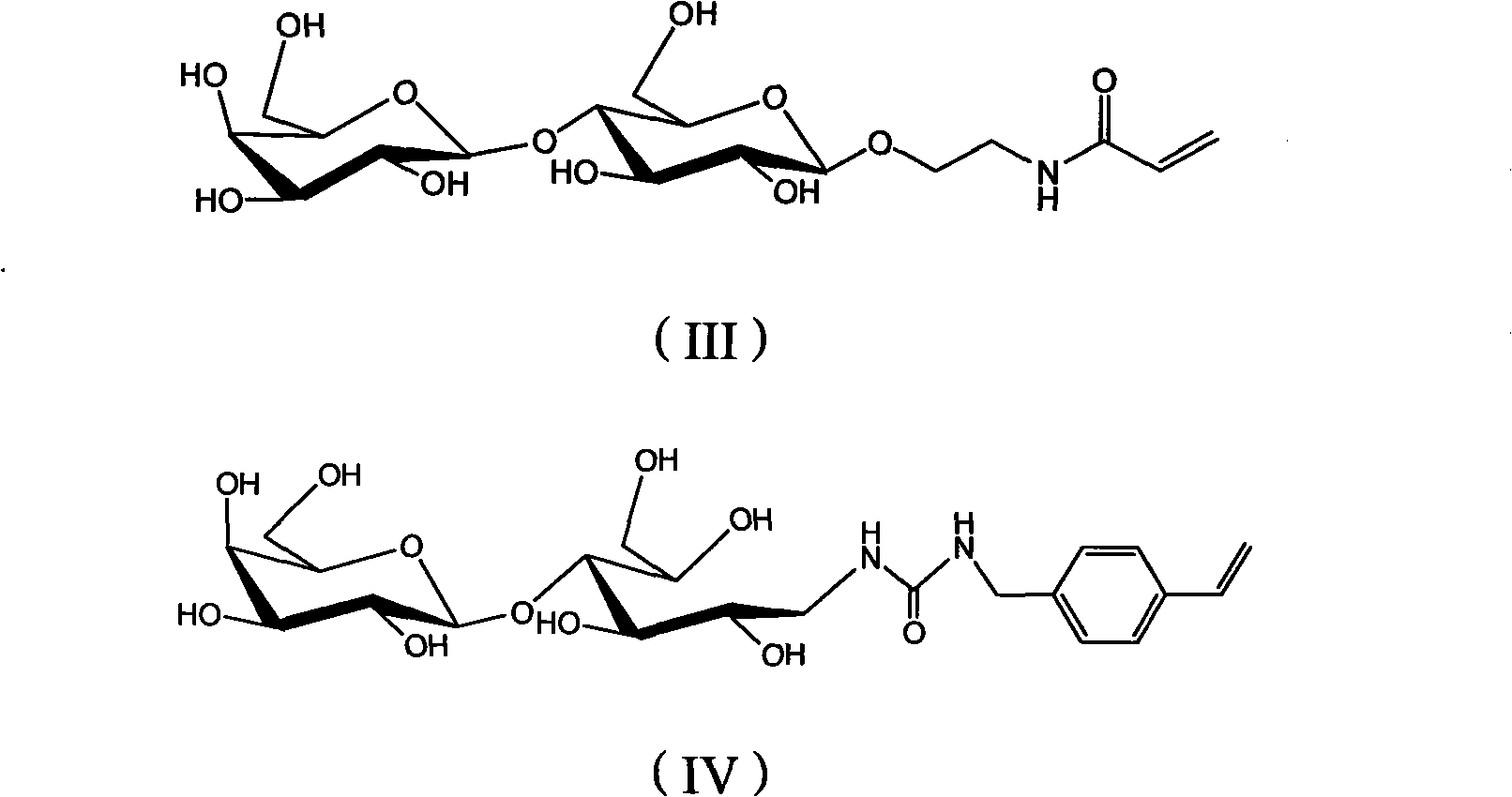

Sugar-containing polymer compound film with blocked pore and preparation thereof

InactiveCN101301590AImprove mechanical propertiesFix stability issuesSemi-permeable membranesPolymer scienceIn situ polymerization

The present invention discloses a production method of sugar-containing polymer hole-blocking compound membrane and the application in permeation vaporization and dehydration of organic solvent. The said method comprises the following steps: mixing sugar-contained monomer, comonomer, cross linker, evocating agent and solvent to formulate polymerized solution; performing in-situ polymerization by adopting photo-initiation or thermal initiation mode after the polypropylene microporous membrane is immersed in polymerization solution for a special time; getting sugar-contained polymer hole-blocking compound membrane after cleaning and drying. The sugar-containing polymer hole-blocking compound membrane prepared by the invention can be used for organic solvent dehydration, has advantages of high separation factor, large separation flux, good mechanical properties, good chemical stability and thermostability, and has utility value in separation and purification of organic solvent.

Owner:ZHEJIANG UNIV

Oil-water separation filtering structure and production method thereof

InactiveCN109692502AEasy to operateMaterials are readily availableNon-miscible liquid separationBis(trimethylsilyl)amineOil water

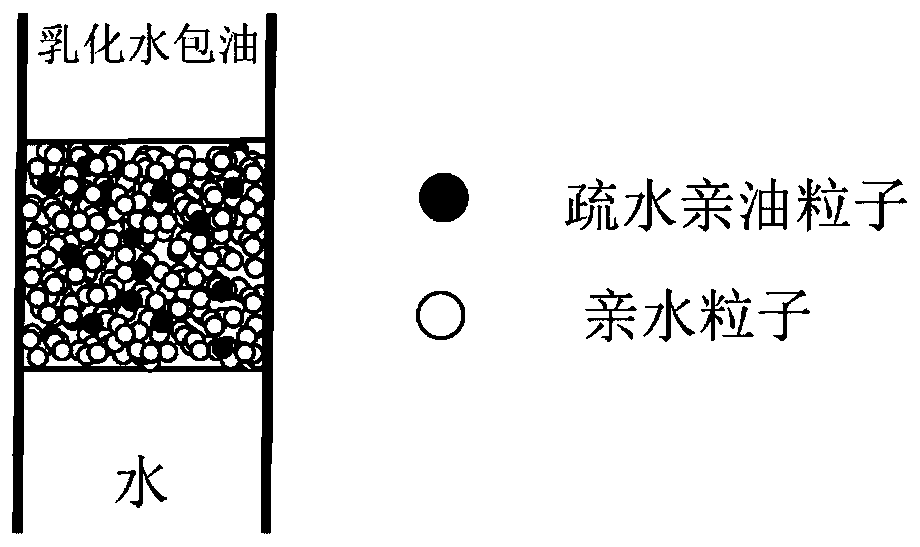

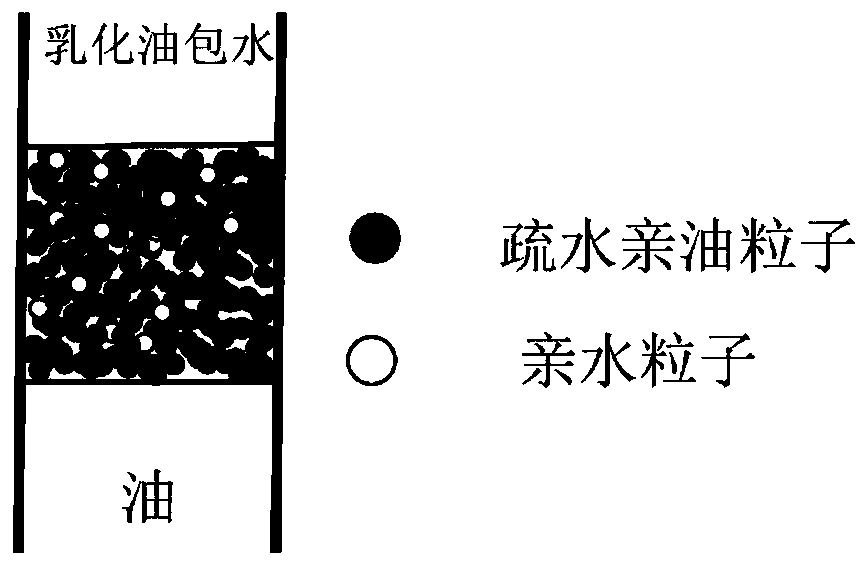

The invention discloses an oil-water separation filtering structure and a production method thereof. The oil-water separation filtering structure comprises a filter device main body, the filter devicemain body is provided with a filtering channel, the filtering channel is provided with a perforated support plate, the perforated support plate of the filtering channel is filled with an oil-water separation medium layer, and the oil-water separation medium layer is a mixture of hydrophilic particles and hydrophobic particles; the hydrophilic particles are one or more of silica, sands, ore and attapulgite; and the hydrophobic particles are one or more of hexamethyldisilazane modified silica, sands, ores and attapulgite. The oil-water separation filtering structure has the advantages of simpleproduction process, environmentally-friendly raw materials, low cost and good recycling efficiency, and allows the separation efficiency of emulsified water in oil to reach up to 99.99% and the oil content in the water separated from the emulsified water in oil to be as low as 5 ppm.

Owner:SOUTH CHINA UNIV OF TECH

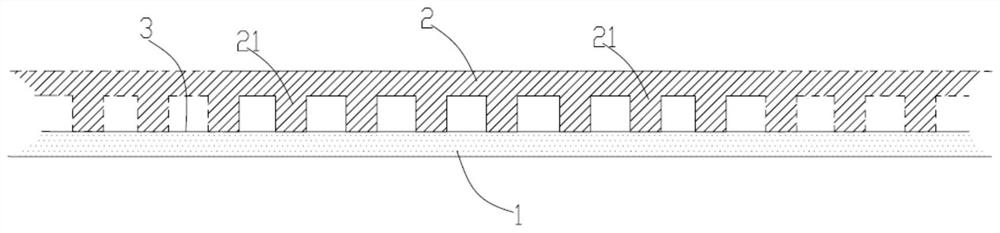

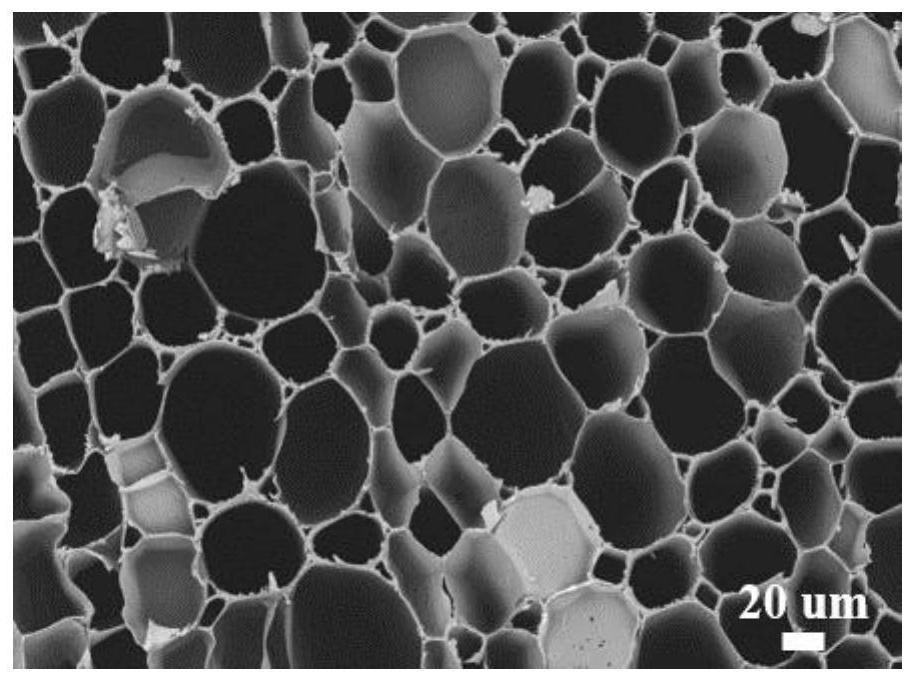

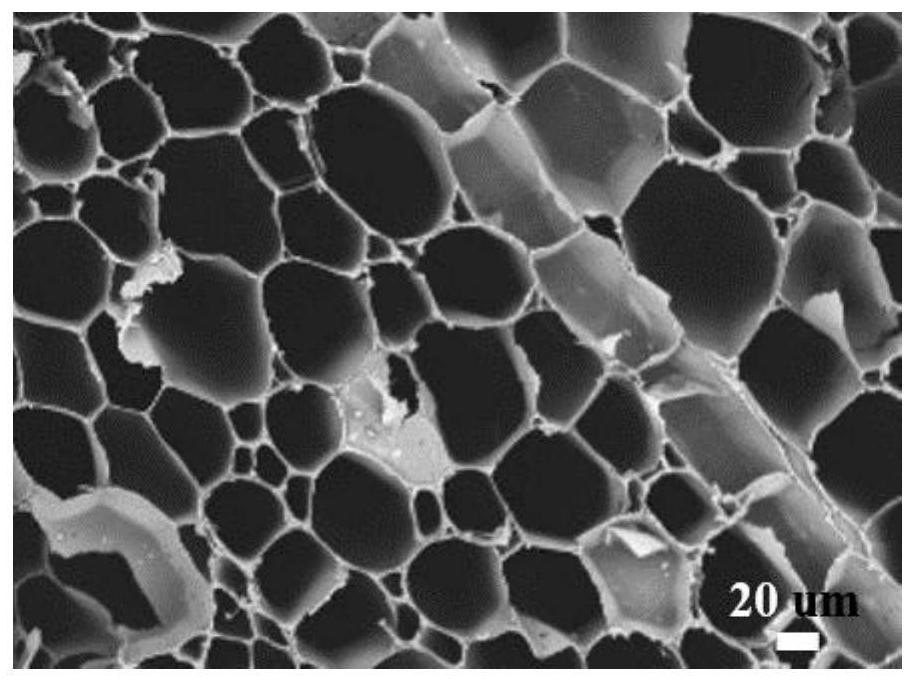

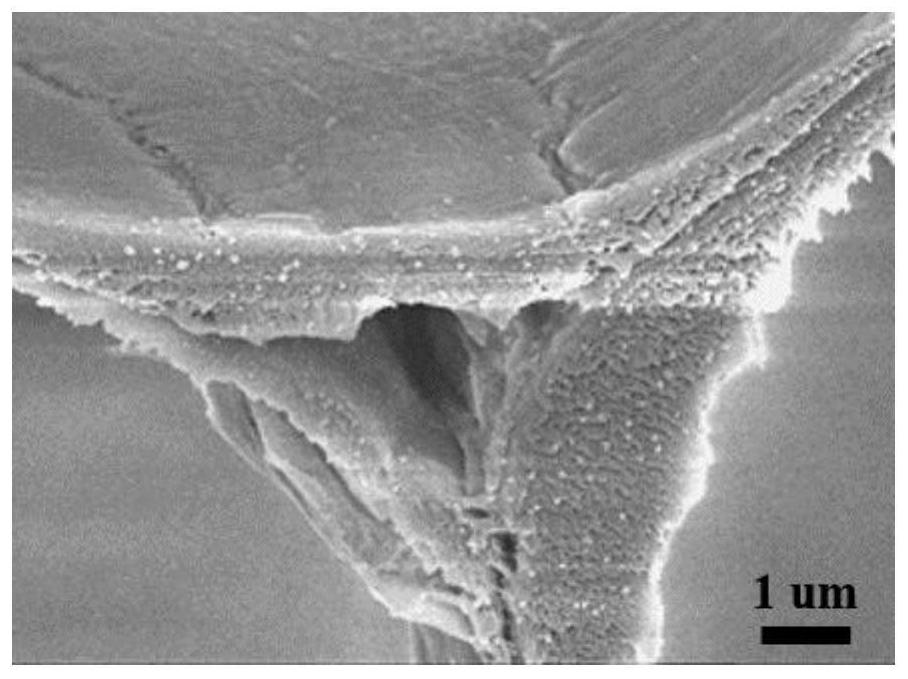

A kind of wet chemical preparation method of ceramic separation membrane

ActiveCN102258945AIncrease Separation ThroughputNarrow pore size distributionSemi-permeable membranesNitrateMicrometer

The invention relates to a wet chemical preparation method for a ceramic separation membrane. The method provided by the invention comprises the following steps: adding aluminum oxide particles with the particle size of 30-70 micrometers and an aqueous solution which is prepared by dissolving aluminum nitrate, titanium alkoxide and lanthanum nitrate or yttrium nitrate in advance into a sufficientquantity of ammonia water; adjusting the pH value to 8-10; after fully reacting at 65-90 DEG C, precipitating, washing, aging and drying; presintering at 500-800 DEG C to obtain the aluminum oxide particles coated with nano oxides; after mixing the aluminum oxide particles coated with the nano oxides and an organic molding assistant, kneading to form plastic pug; extruding to form a green body ofa support body; sintering the green body for 0.5-5 hours at 1450-1700 DEG C to form the support body; and coating a membrane and sintering to obtain a ceramic separation membrane product. The preparation method provided by the invention has the advantages that a nano material is utilized to coat Al2O3 powder, thus spherical particles with high sintering activity is obtained, a molding formula andprocess in production procedures can be simplified and the complicated courses of drying the green body and turning over the green body can be avoided.

Owner:SANDA FILM SCI & TECH XIAMEN

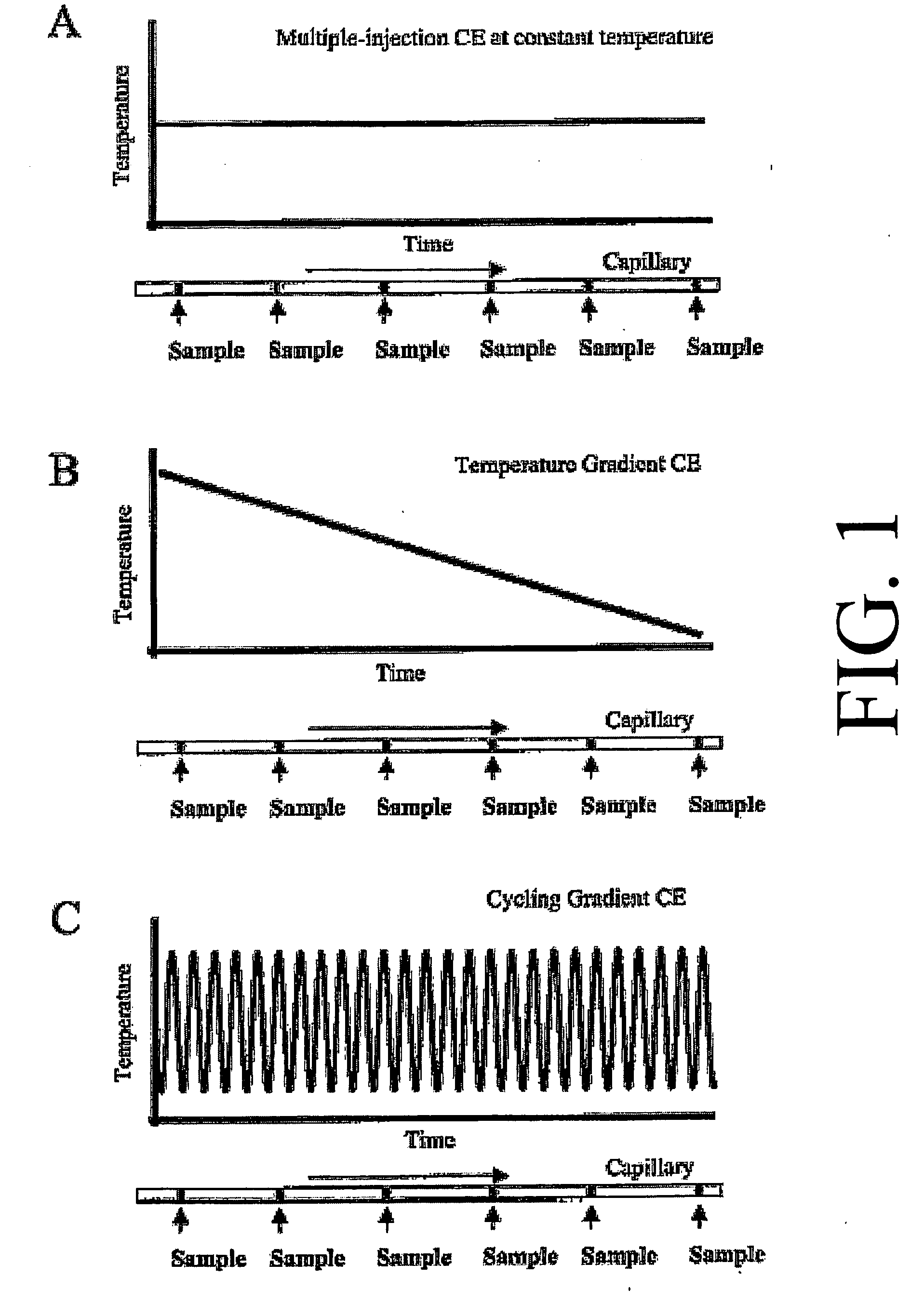

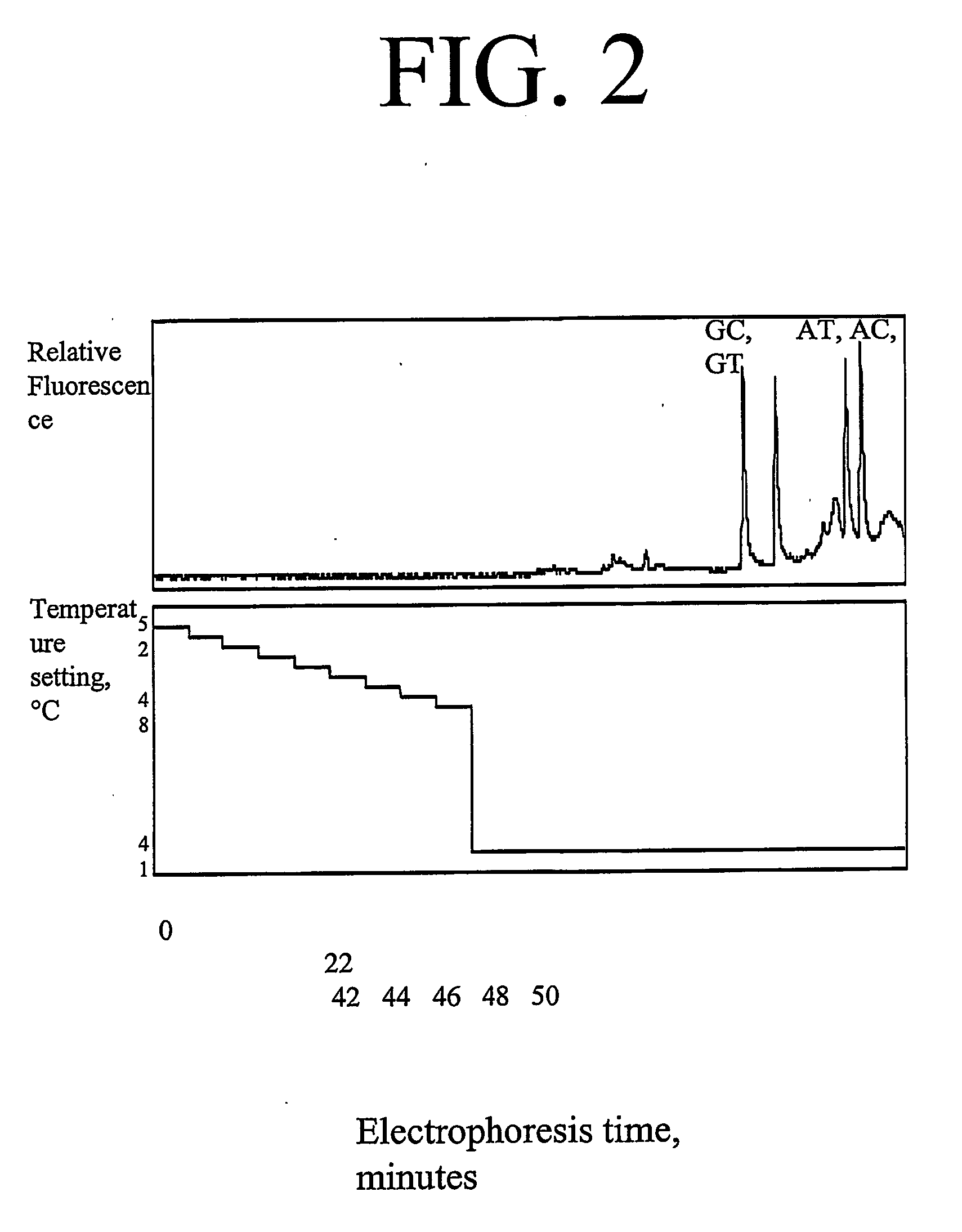

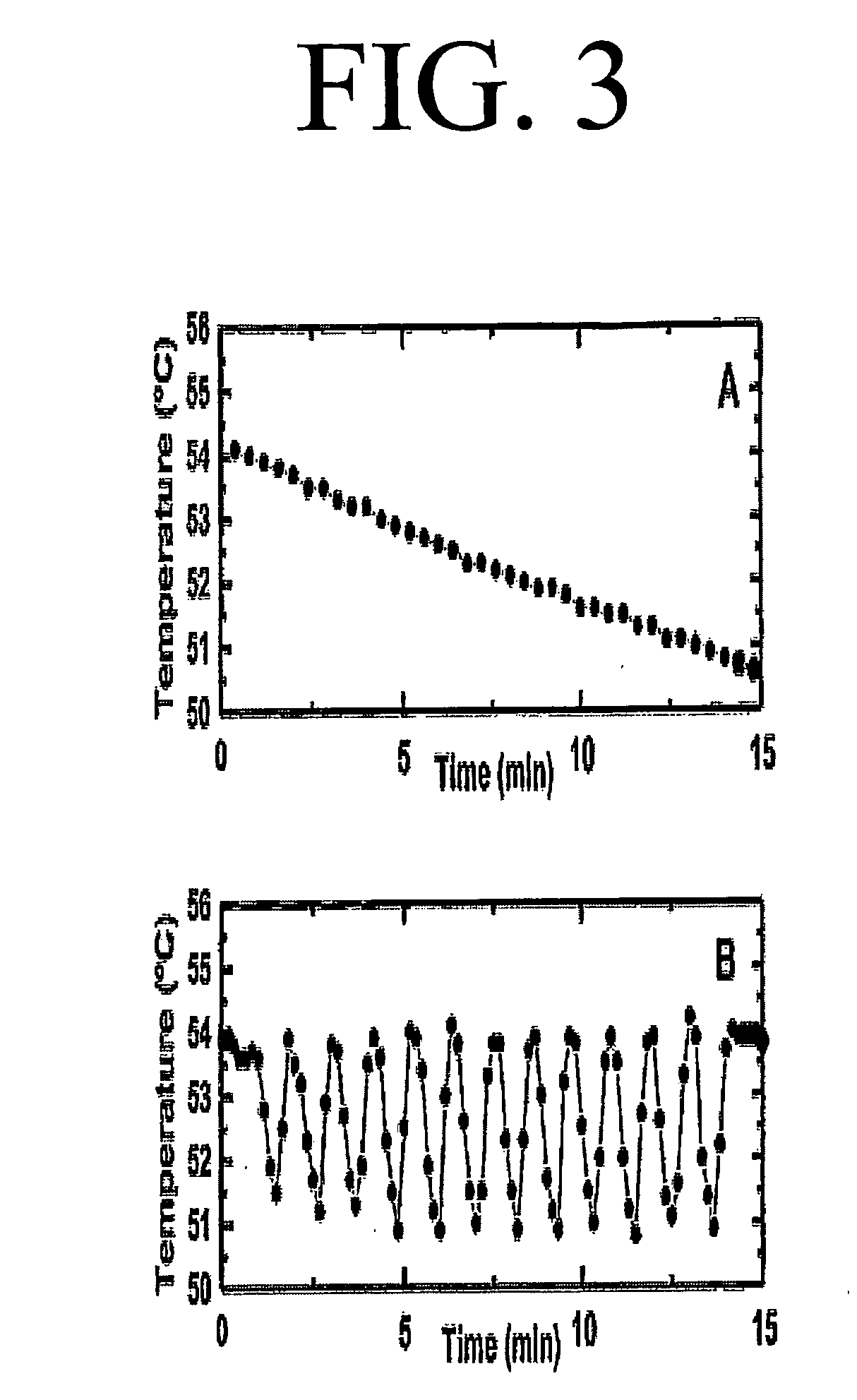

Oscillating temperature capillary electrophoresis and uses therefor

InactiveUS20070117096A1Increase Separation ThroughputEfficient separationElectrolysis componentsMicrobiological testing/measurementAllele frequencyBiology

Methods for separating biomolecules using oscillating temperature electrophoresis are disclosed. Uses for such methods are also disclosed including high throughput screening, estimation of allele frequencies, identification of polymorphisms, and separation of DNA molecules.

Owner:THE NORWEGIAN RADIUM HOSPITAL RES FOUND

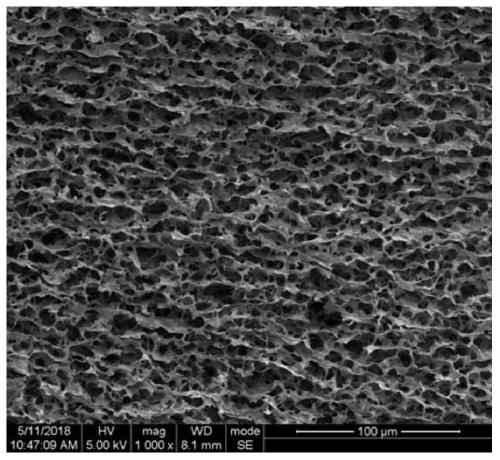

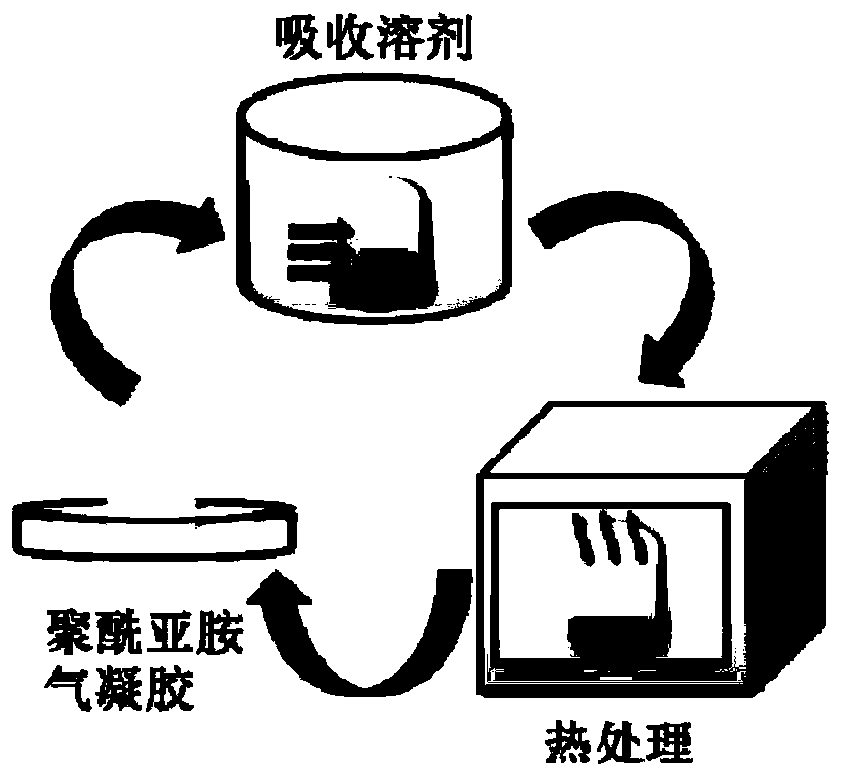

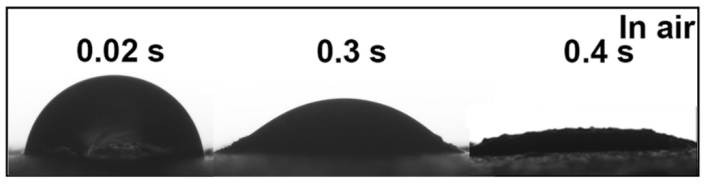

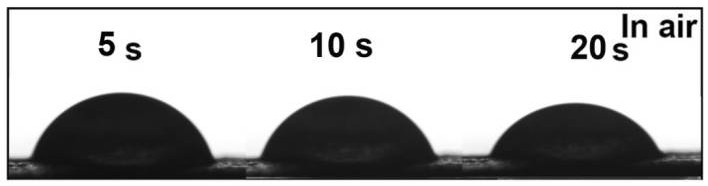

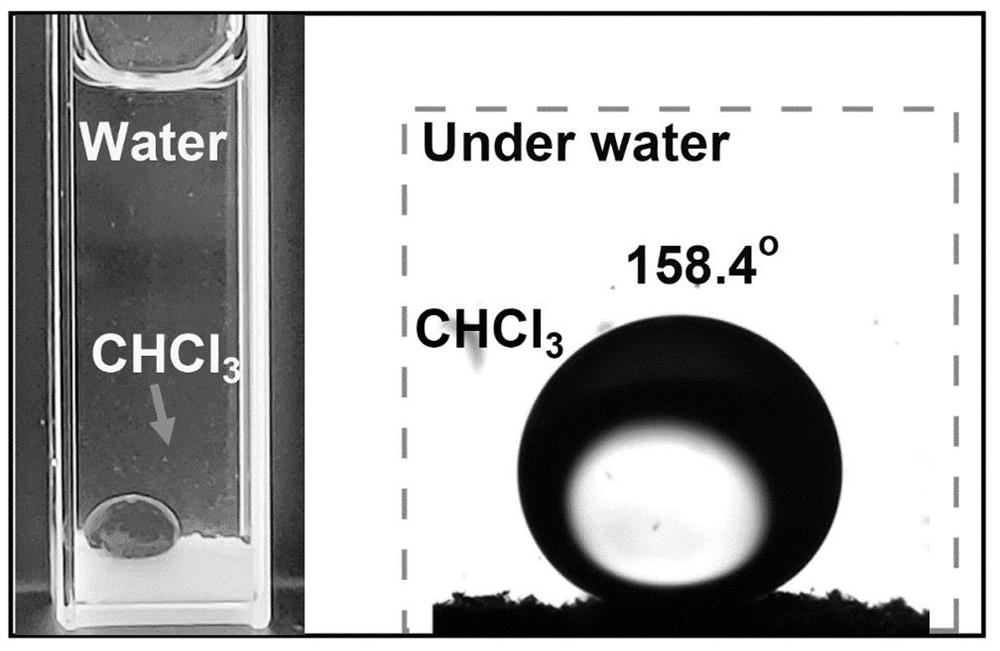

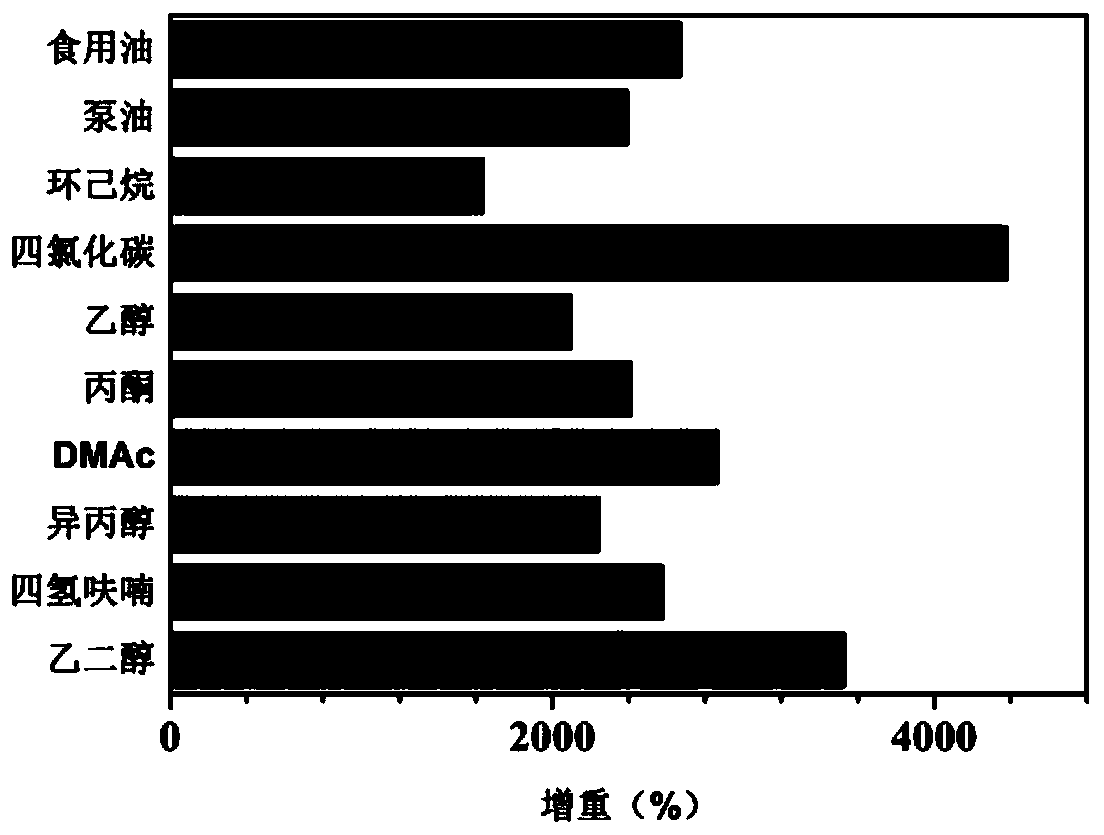

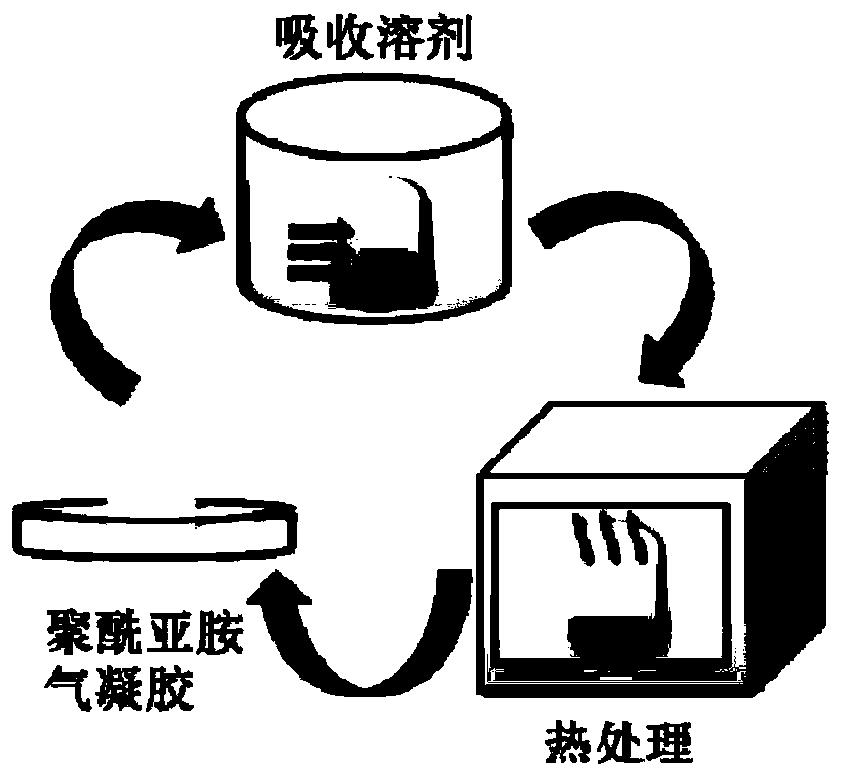

Intrinsic hydrophobic polyimide aerogel, preparation method and application thereof

ActiveCN109929134AHighly hydrophobicAchieve separationOther chemical processesLiquid separationSupercritical dryingHigh rate

Relating to the technical field of preparation of three-dimensional porous materials and application thereof in oil-water separation materials, the invention discloses an intrinsic hydrophobic polyimide aerogel, a preparation method and application thereof. The preparation method of the polyimide aerogel introduces 2-(4-)-5-aminobenzimidazole containing a benzimidazole structure as diamine, the prepared polyimide aerogel has high hydrophobicity, can realize separation of water-in-oil emulsion and oil-water separation in harsh environments, also has high separation flux and can be recycled repeatedly. The preparation method is simple, avoids the solvent replacement process and supercritical drying in traditional polyimide aerogel preparation, at the same time, the preparation process is green and environment-friendly and short in time, and the prepared polyimide aerogel can achieve high efficiency and high rate oil-water separation under multiple extreme conditions.

Owner:SICHUAN UNIV

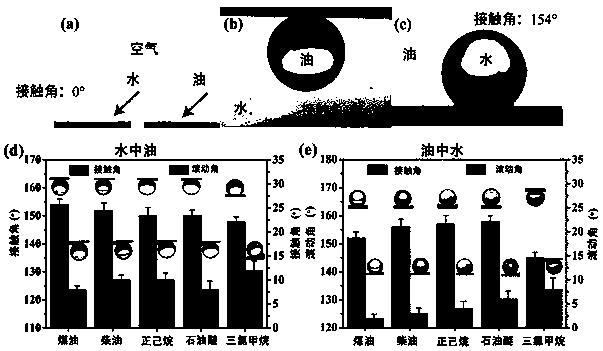

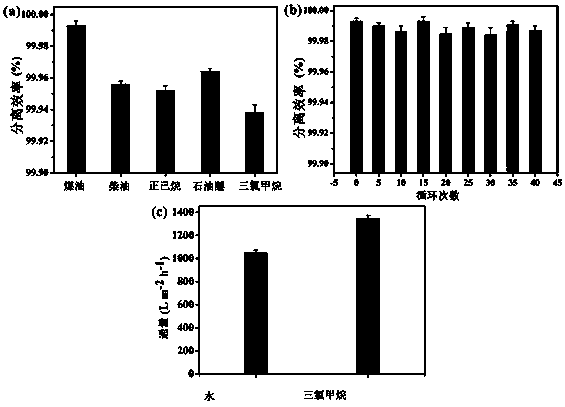

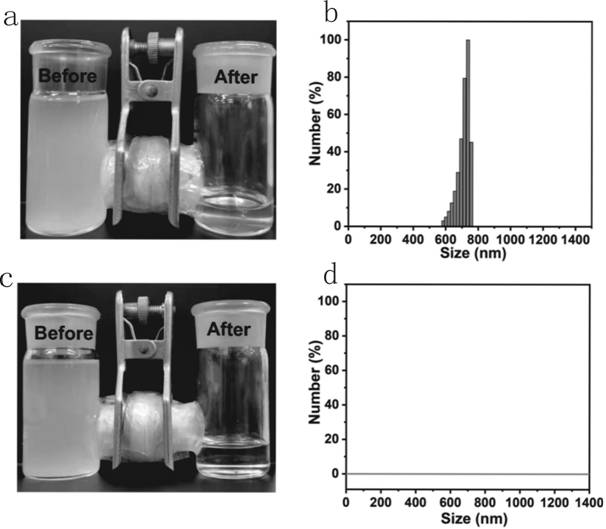

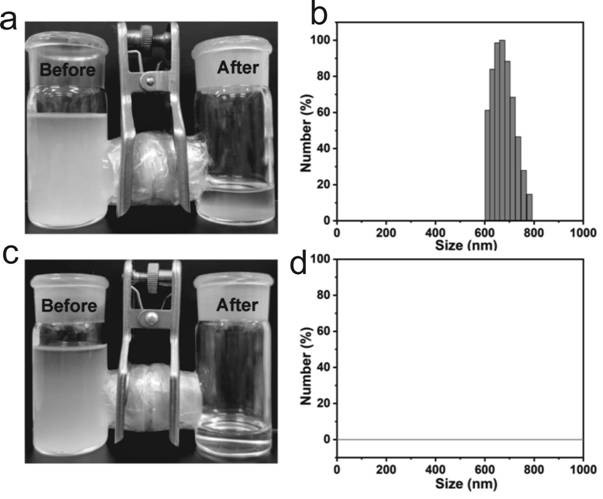

Preparation and application of underwater super-oleophobic and under-oil hydrophilic emulsion separation functional fibers

ActiveCN112095337AUnderwater super oleophobicHydrophilic under oilLiquid repellent fibresAnimal fibresFiberPolymer science

The invention discloses emulsion separation functional fibers. The functional fibers are prepared by taking skin collagen fibers as a base material and regulating and controlling the surface wettability of the skin collagen fibers by loading metal ions on the skin collagen fibers. The emulsion separation functional fibers have special wetting performance of underwater super-oleophobicity and under-oil hydrophilicity, can separate water-in-oil emulsion and oil-in-water emulsion, have double separation performance, and are high in separation efficiency, large in separation flux, good in stability and reusable.

Owner:SICHUAN UNIV

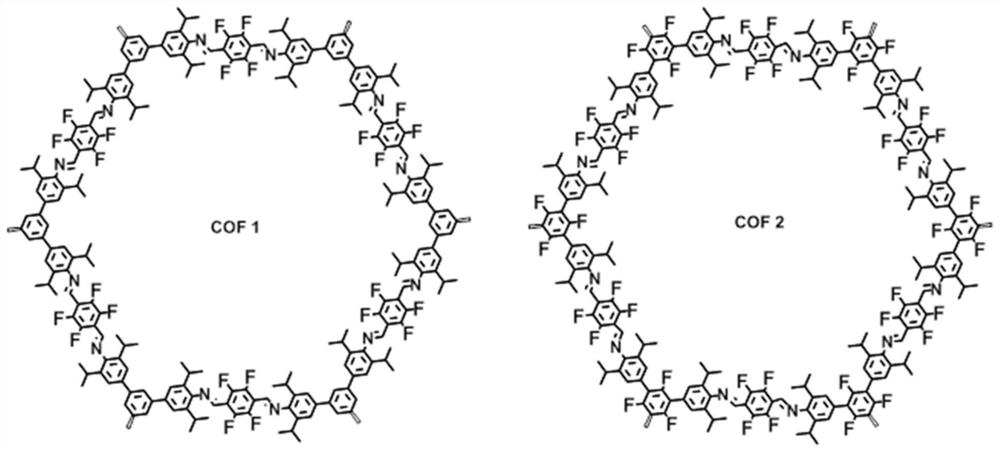

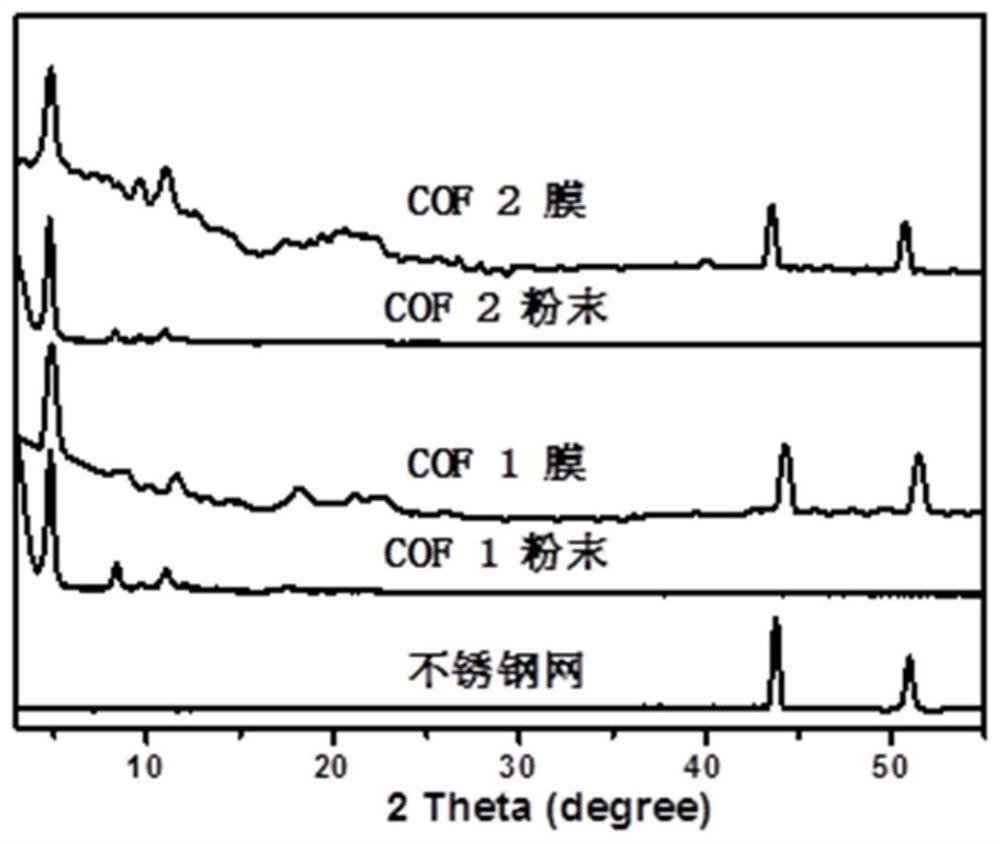

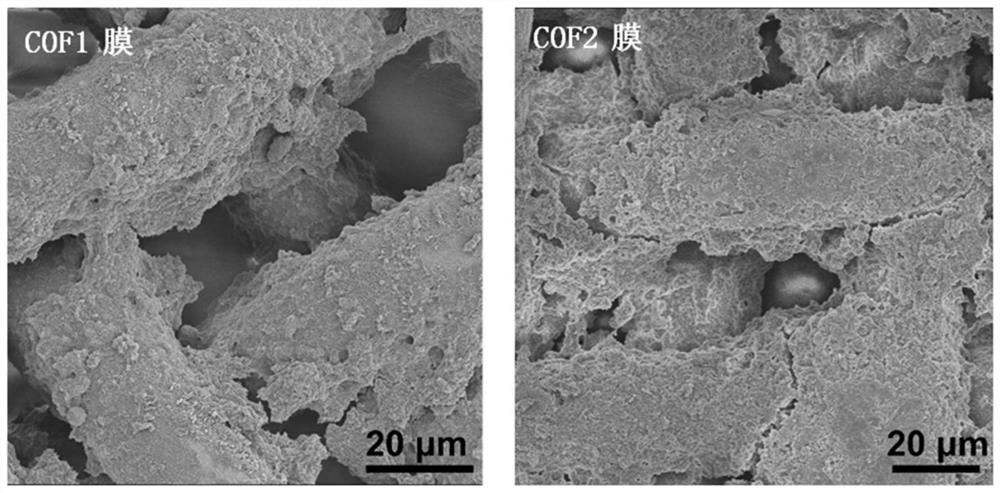

High-flux oil-water separation COF membrane as well as preparation method and application thereof

PendingCN112934008AAdjust hydrophobicityImprove applicabilitySemi-permeable membranesMembranesTriethoxysilaneHigh flux

The invention relates to a high-flux oil-water separation COF membrane and a preparation method and application thereof.The preparation method comprises the following steps: (1) placing cleaned stainless steel mesh in a 3-aminopropyltriethoxysilane solution for a reaction to prepare an amino-modified stainless steel mesh; (2) putting the amino-modified stainless steel mesh in a linear bidentate dialdehyde solution for a reaction to prepare an aldehyde-modified stainless steel mesh. and 3) placing the aldehyde modified stainless steel mesh in a COF mother solution, adopting a secondary growth method to obtain a super-hydrophobic COF membrane supported by the stainless steel mesh, and performing post-treatment to obtain the high-flux oil-water separation COF membrane. Compared with the prior art, the prepared super-hydrophobic COF membrane shows high flux and separation efficiency in the oil-water separation process, has high water pressure tolerance and self-cleaning capacity, solves the problem that an existing hydrophobic COF membrane is tedious in synthesis process, and has wide development prospects.

Owner:SHANGHAI JIAO TONG UNIV

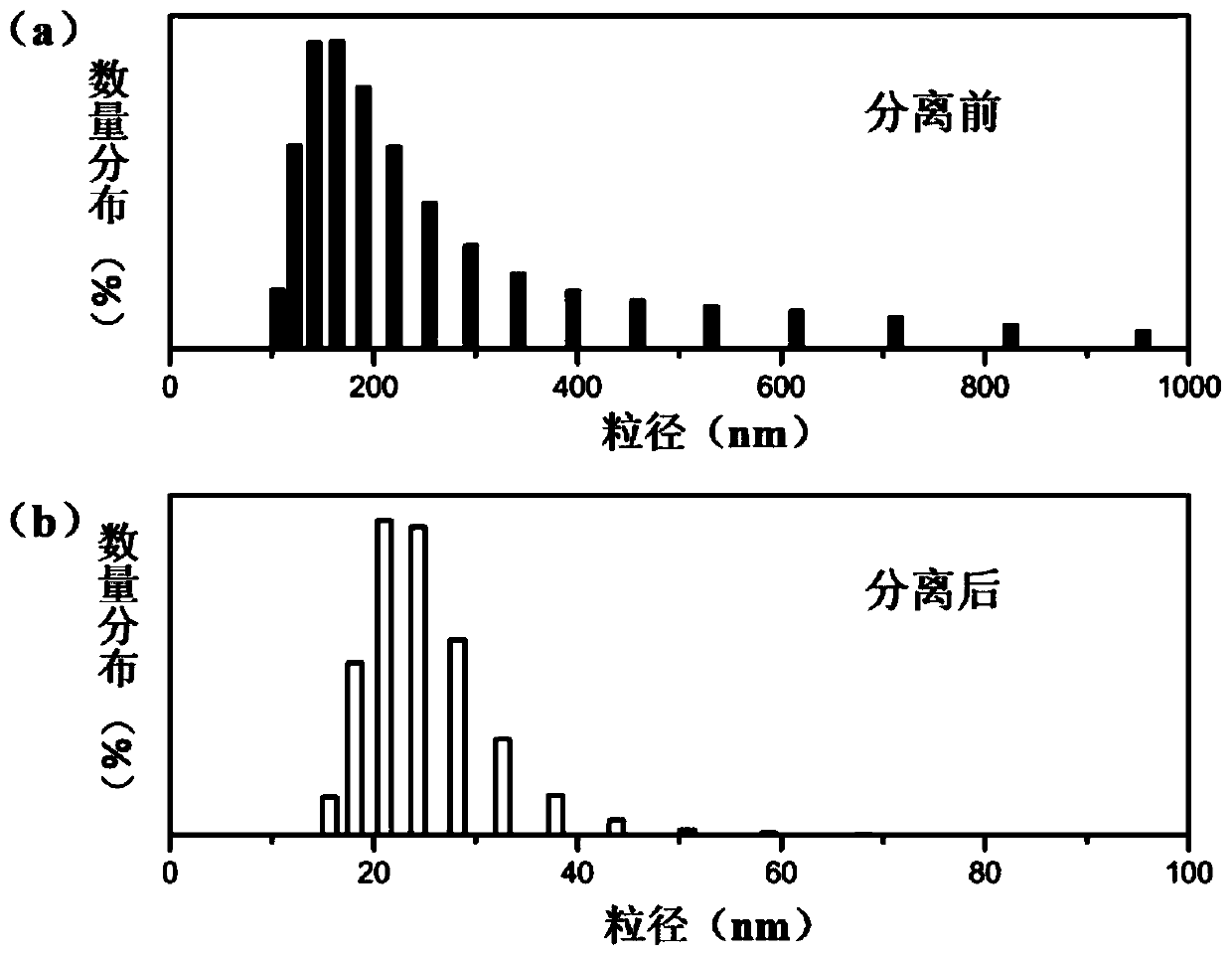

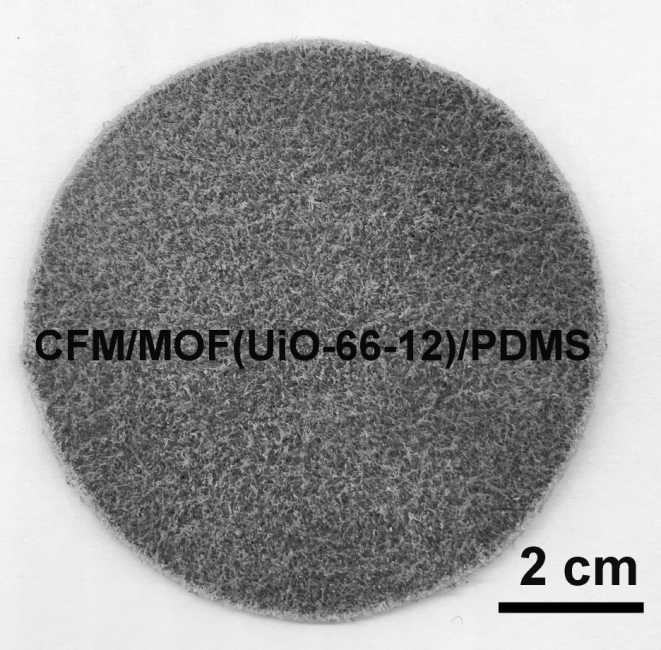

Preparation and application of high-throughput emulsion separation material

ActiveCN111058281AEffective regulationSignificant capillary effectSemi-permeable membranesAnimal fibresFiberActive agent

Owner:SICHUAN UNIV

Method for preparing oil-water separation membrane from waste cigarette filter tip and application in oil-water separation

InactiveCN109157868AIncrease Separation ThroughputImprove separation efficiencyNon-miscible liquid separationLipophilicityCigarette filter

The invention discloses a method for preparing an oil-water separation membrane from a waste cigarette filter tip. The method for preparing the oil-water separation membrane from the waste cigarette filter tip comprises the steps of dissolving the cleanly washed waste cigarette filter tip in a mixed solution of N, N-dimethyl formamide and acetone to prepare an electrostatic spinning fluid with concentration of 12-14 wt%; and using a cleanly washed stainless steel wire net as a receiver to prepare the oil-water separation membrane by using an electrostatic spinning technology. An experiment shows that the prepared oil-water separation membrane possesses special infiltrating property of super-hydrophilicity / underwater super-oleophobicity / super-lipophilicity / super-hydrophobicity under oil, can be used for separation of multiple oil-in-water emulsions and water-in-oil emulsions and has the advantages of high separating efficiency, high cycling stability and the like. In addition, the oil-water separation membrane also shows higher emulsion separation flux; and according to the characteristics, the prepared oil-water separation membrane can be widely applied to separation of oil-water mixtures.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation and application of durable high-flux emulsion separation membrane material

ActiveCN113244793APromote formationRealize demulsification separationSemi-permeable membranesNon-miscible liquid separationOrganic solventOil emulsion

The invention discloses preparation and application of a durable high-flux emulsion separation membrane material. Firstly, a metal organic framework (MOF) material is loaded on a leather collagen fiber membrane; then the leather collagen fiber membrane loaded with the MOF is soaked in a precursor solution for growing the MOF for standing reaction for secondary growth of the MOF, and the screening demulsification performance of the MOF loaded on the leather collagen fiber membrane is regulated and controlled by controlling secondary growth conditions; and then the MOF modified leather collagen fiber membrane is subjected to surface hydrophobic treatment by using a low-surface-energy substance, so that the durable high-flux emulsion separation membrane material is obtained. The durable high-flux emulsion separation membrane material provided by the invention can be used for high-flux separation of a water-in-oil emulsion stabilized by a compound surfactant, has excellent chemical stability such as organic solvent resistance, acid and alkali resistance, and ultraviolet resistance, and still has excellent separation performance on the water-in-oil emulsion after being worn.

Owner:SICHUAN UNIV

Wet chemical preparation method for ceramic separation membrane

ActiveCN102258945BIncrease Separation ThroughputNarrow pore size distributionSemi-permeable membranesNitrateMicrometer

Owner:SANDA FILM SCI & TECH XIAMEN

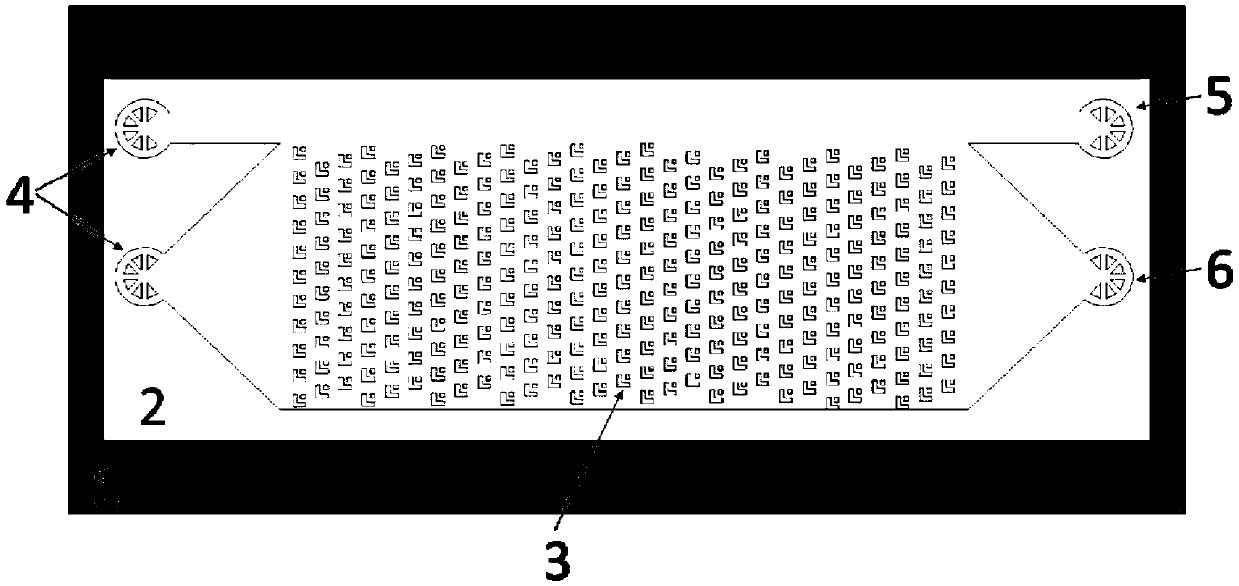

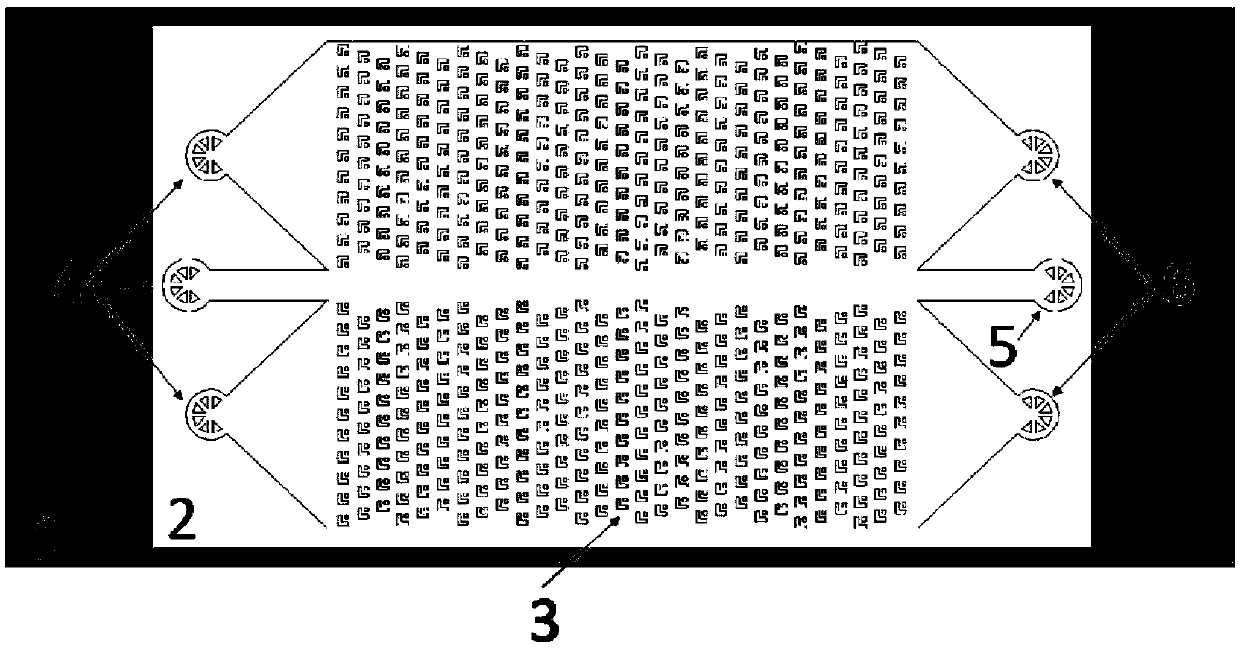

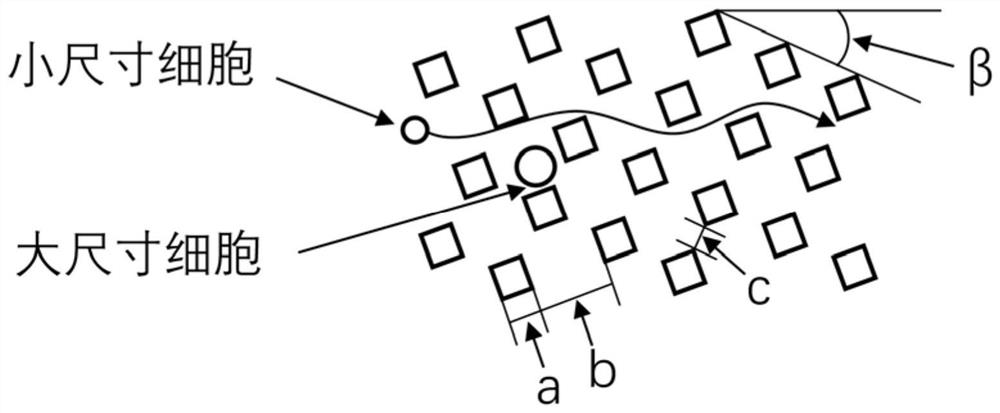

Lateral deviation micro column array chip and application thereof

ActiveCN108753572AReduce critical separation dimensionIncrease Separation ThroughputBioreactor/fermenter combinationsBiological substance pretreatmentsMicro columnEngineering

The invention discloses a lateral deviation micro column array chip and application thereof. The lateral deviation micro column array chip comprises lateral deviation micro column arrays arranged intolines or arranged into rows; each subsequent line or subsequent row of lateral deviation micro column unit deviates according to a certain angle relative to the front line or the front row; one or aplurality of channels are arranged in each micro column unit; in one or a plurality of channels, the opening direction of at least one channel is different from the deviation direction of the lateraldeviation micro column array. The dimension in separation fluid is more precise; the effect of filtering small-dimension particles is achieved, so that the big-dimension particles have the enriching effects before entering the next array; the critical separation dimension of the micro column array is reduced; the separation flux is higher; the separation volume is greater.

Owner:ZIGZAG BIOTECH LTD

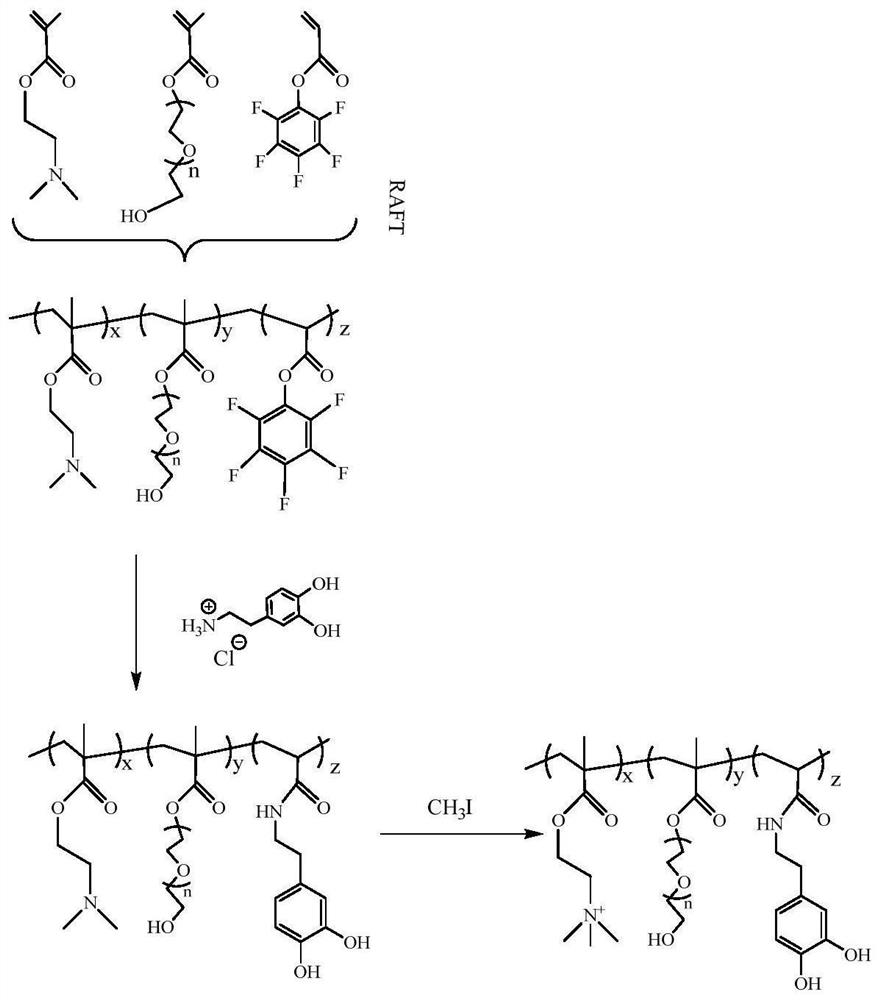

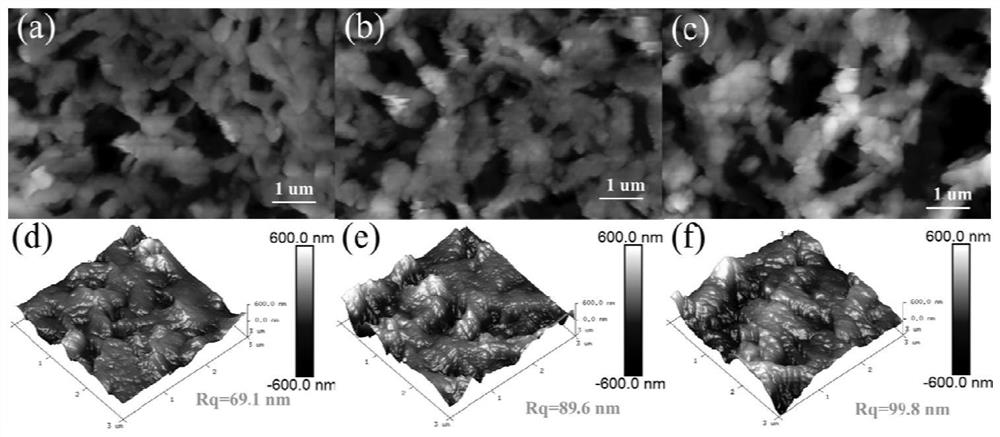

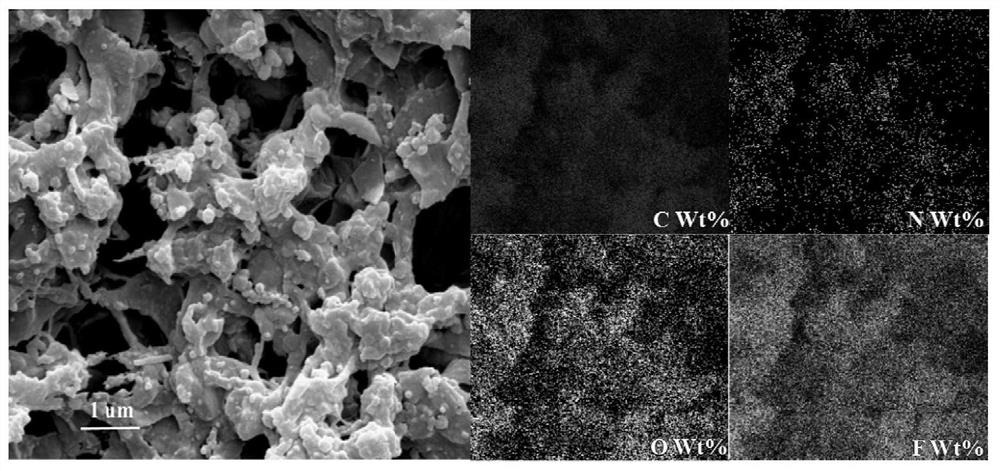

Mussel bionic functional hydrophilic polymer and hydrophilic polymer network modified super-hydrophilic net membrane, as well as preparation methods and application of mussel bionic functional hydrophilic polymer and hydrophilic polymer network modified super-hydrophilic net membrane

ActiveCN112759670AImprove performanceIncrease Separation ThroughputNon-miscible liquid separationMethacrylatePolymer science

The invention relates to the field of surface modification of high-molecular functional materials and solid materials, and discloses a mussel bionic functional hydrophilic polymer and a hydrophilic polymer network modified super-hydrophilic net membrane, as well as preparation methods and application of the mussel bionic functional hydrophilic polymer and the hydrophilic polymer network modified super-hydrophilic net membrane. The preparation method of the mussel bionic functional hydrophilic polymer comprises the steps: (1) in the presence of an initiator, enabling methacrylic acid-2-(dimethylamino)ethyl ester, polyethylene glycol methacrylate, pentafluorophenol acrylate, 4-cyano-4-(dodecylsulfanylthiocarbonyl)sulfanylpentanoic acid and 1,4-dioxane to be in contact, so as to obtain a product I; (2) contacting the product I, dichloromethane, dopamine hydrochloride and triethylamine, and performing centrifugal separation to obtain a product II; and (3) contacting the product II, dichloromethane and methyl iodide to obtain the hydrophilic polymer. The separation flux of the hydrophilic polymer network modified super-hydrophilic net membrane is as high as 5641.1 L / m<-2>*h<-1>, and the separation efficiency is as high as 99.98%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Capture chip for neuroblastoma circulating tumor cells and manufacturing method thereof

ActiveCN112391263AIncrease Separation ThroughputImprove separation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBlastomaCirculating cancer cell

The invention relates to a capture chip of neuroblastoma circulating tumor cells (CTCs) and a manufacturing method thereof. The capture chip of the neuroblastoma CTCs comprises a glass substrate layerand a polymer layer which is provided with a microcolumn array pattern, and the surface of the glass substrate layer is modified with a CD56 antibody capable of specifically capturing the CTCs. The method has the beneficial effects that 1, the separation flux is improved; 2, the separation efficiency and purity are improved; 3, CTC in-situ capture is achieved; 4, the activity of separated cells is improved; and 5, the cost is reduced, manual labor and consumable use are reduced through integrated operation, and the detection cost is remarkably reduced.

Owner:SHENZHEN CHILDRENS HOSPITAL

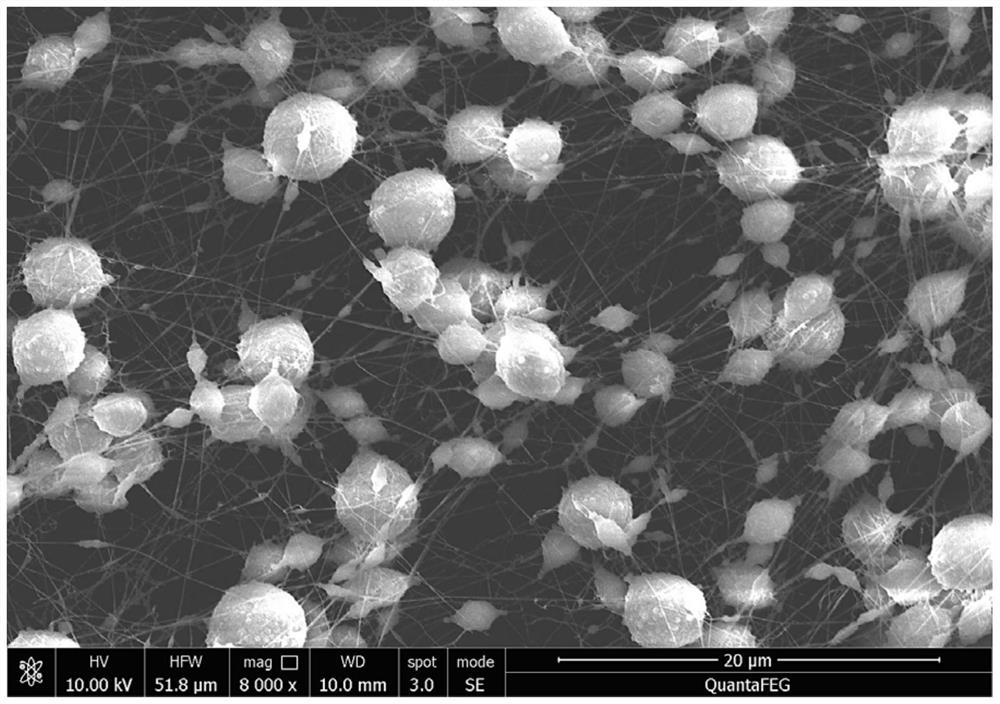

Separation membrane, preparation method, aviation kerosene dehydration and purification method and application

InactiveCN112516807AHas superhydrophobic and lipophilic propertiesReduce pollutionMembranesSemi-permeable membranesSpinningHydrophobic polymer

The invention discloses a preparation method of an oil-water separation membrane, which comprises the steps of dissolving a hydrophobic polymer film-forming material and a fluorine-containing water repellent agent in an organic solvent, and stirring at the temperature of 70-100 DEG C for 36-60 hours to form a uniform polymer solution; under the conditions that the relative air humidity is 50-100%,the spinning voltage difference is 5-50 kV, the spinning distance is 5-30 cm, the pushing speed of a spinning injector is 1.2-1.8 mL / h, and the spinning time is 0.1-100 h, spinning the polymer solution into a porous membrane through electrostatic spinning; and drying the porous membrane at the temperature of 60-80 DEG C for 1-24 hours to obtain the separation membrane. The invention also discloses a super-hydrophobic and super-oleophylic oil-water separation membrane. The separation membrane has a ball-wire connected structure and an adjustable membrane aperture. The separation membrane prepared by the invention can effectively separate aviation kerosene with high emulsification degree, the water content in the separated aviation kerosene is lower than 10ppm, and the flux reaches 20m<3> / (m<2>hbar).

Owner:CSSC SYST ENG RES INST

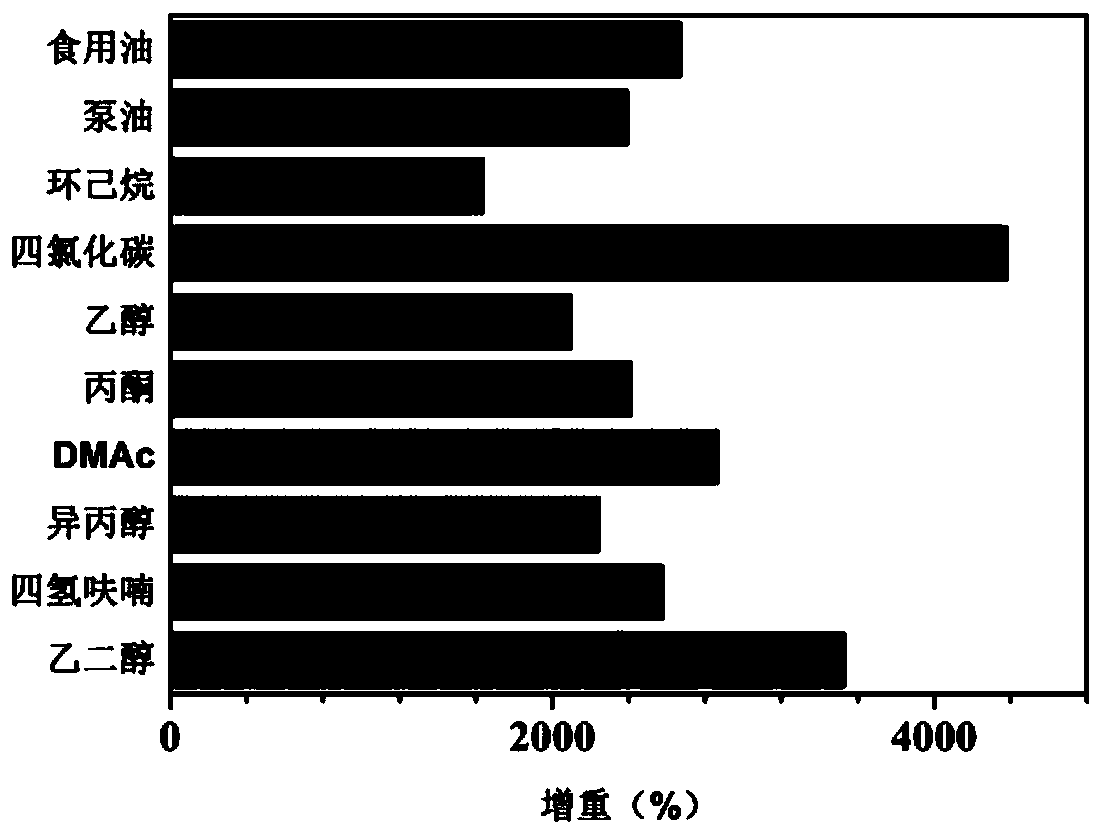

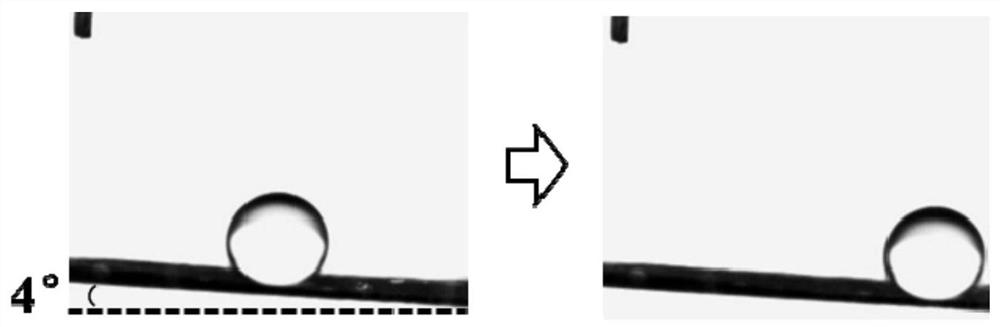

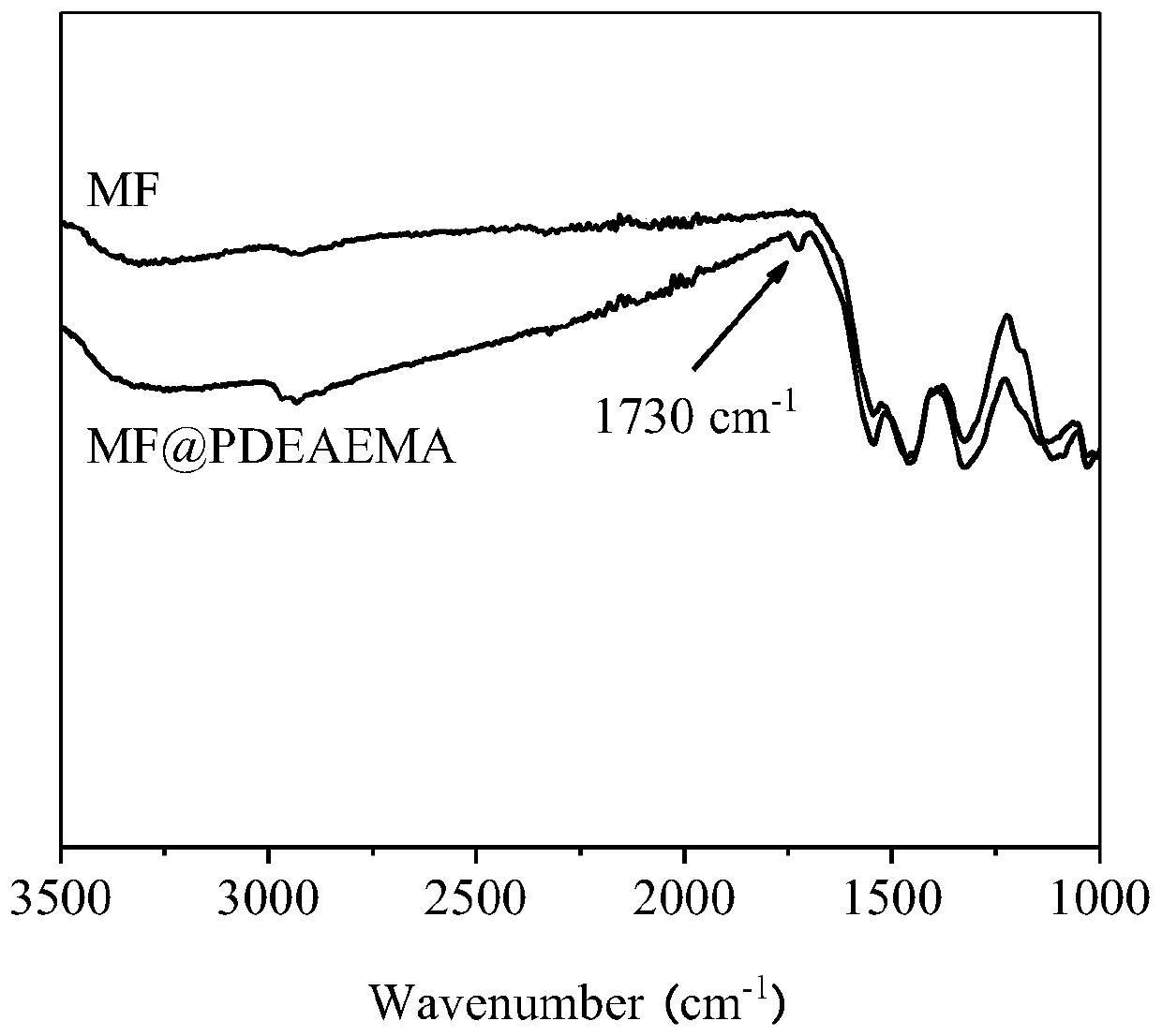

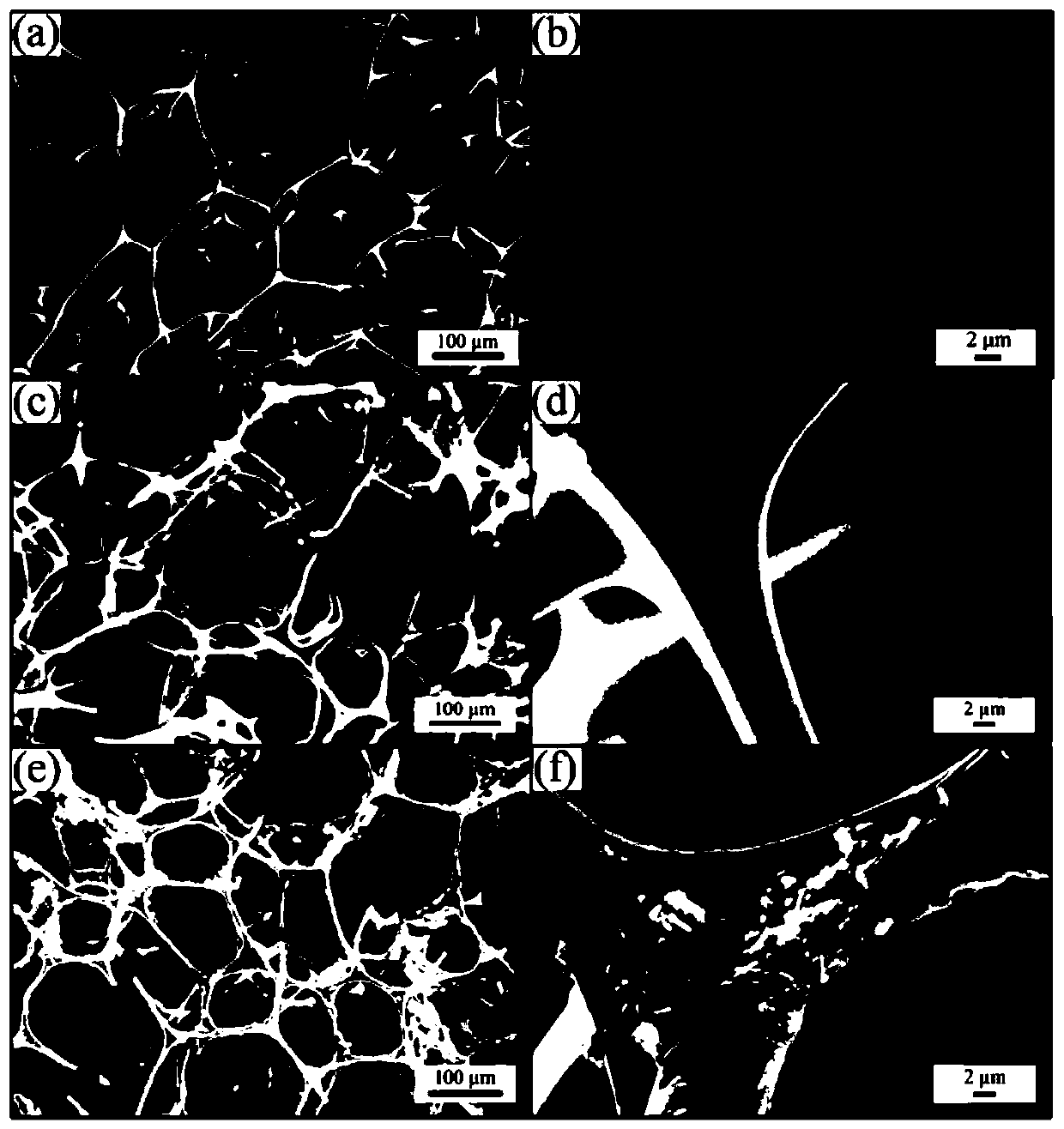

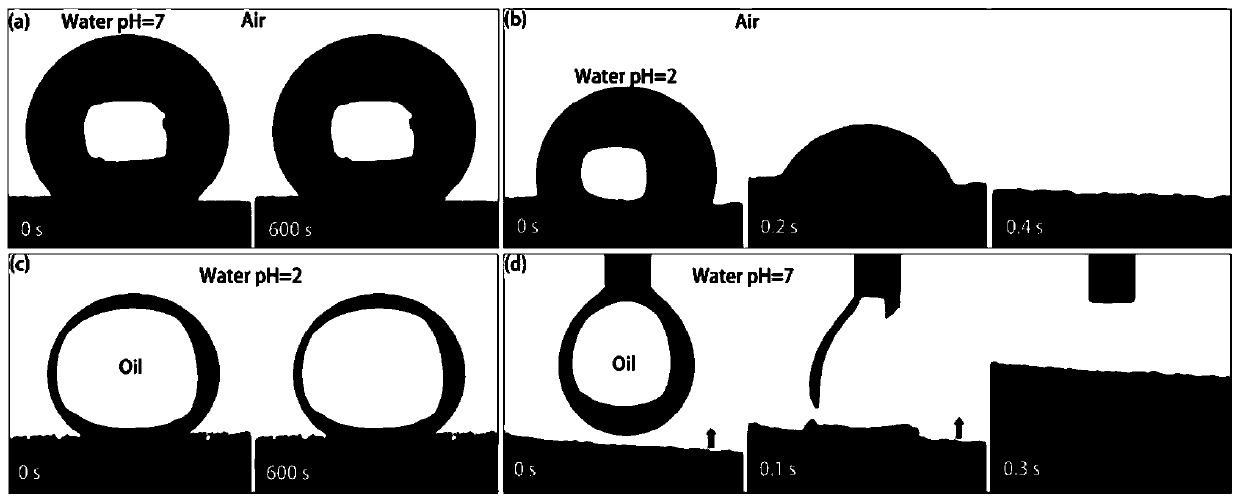

Preparation method of intelligent pH response type melamine foam oil-water separation material

InactiveCN111013199AIncrease Separation ThroughputWith switchable wettabilityNon-miscible liquid separationPtru catalystEthyl ester

The invention belongs to the technical field of oil absorption materials and environmental protection, and particularly relates to a preparation method of an intelligent pH response type melamine foamoil-water separation material. The preparation method comprises the following steps: firstly, carrying out silanization modification on melamine foam by adopting aminopropyltrimethoxysilane; and withcopper sulfate as a catalyst, carrying out a copper amine oxidation-reduction reaction in an aqueous solution to generate free radicals which initiate graft polymerization of diethylaminoethyl methacrylate so as to prepare the pH-responsive melamine foam oil-water separation material. According to the invention, the melamine foam with high internal porosity and large absorption capacity is selected as a matrix, and free radical graft polymerization is initiated through a simple copper-ammonium oxidation-reduction two-step method to prepare the oil-water separation foam material containing a pH response layer; the material has switchable wettability in different pH environments; and foam modification process is simple, and industrial production is easy to realize.

Owner:CHANGZHOU UNIV

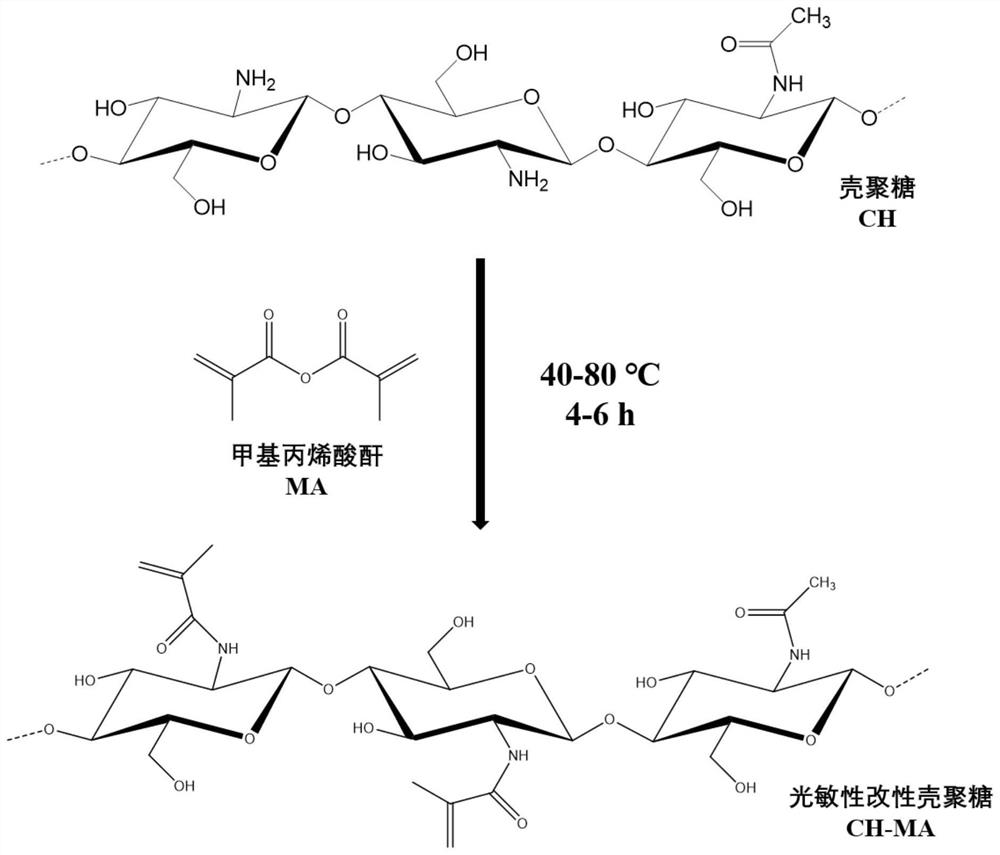

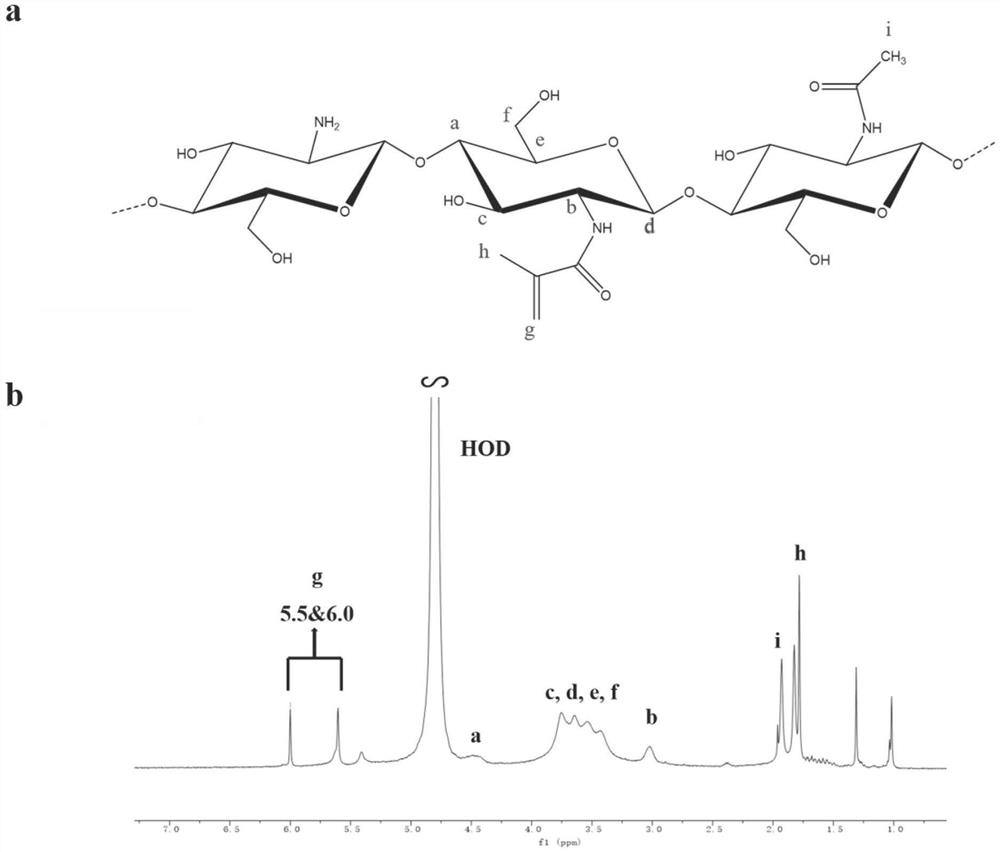

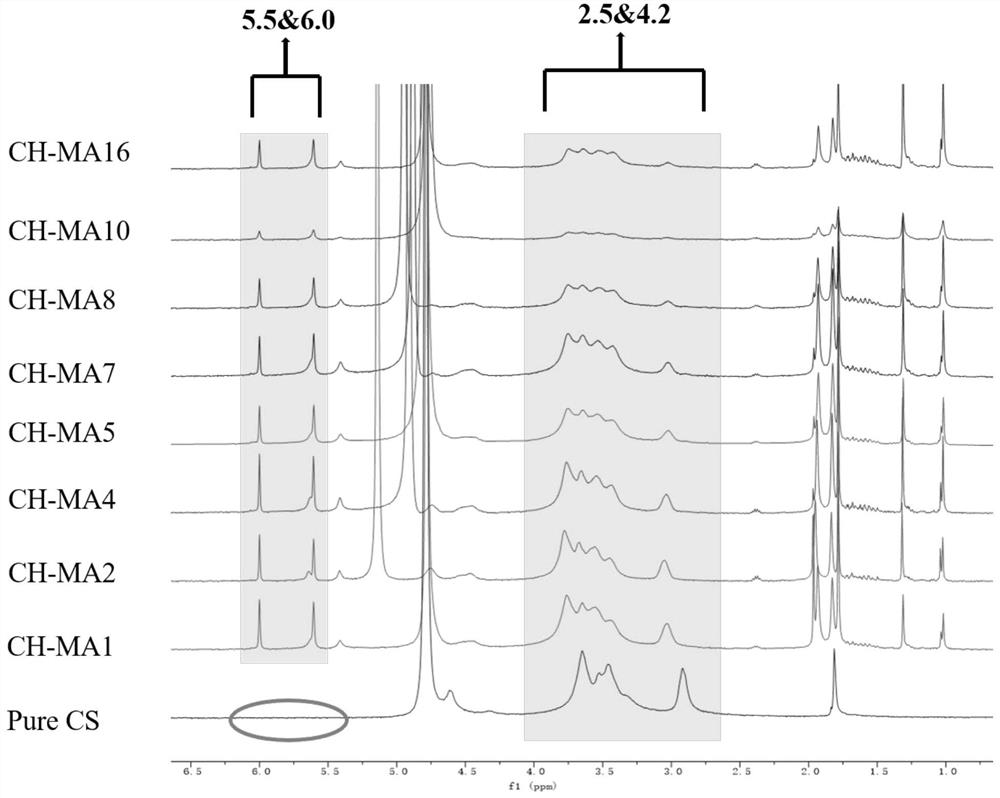

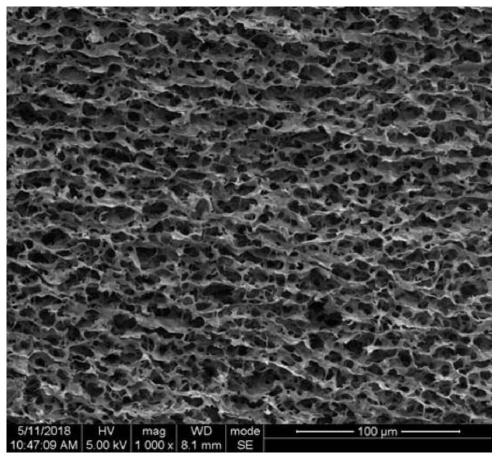

Photosensitive modified chitosan, preparation method and application thereof

ActiveCN113667037AImprove mechanical propertiesSuperhydrophilicSemi-permeable membranesAdditive manufacturing apparatusSodium bicarbonateAcetic acid

The invention provides a preparation method of photosensitive modified chitosan. The method comprises the following steps: 1) dissolving a proper amount of chitosan and acetic acid in deionized water, and uniformly mixing to obtain a mixed solution; 2) adding a proper amount of methacrylic anhydride into the mixed solution to obtain a reaction mixed solution, and carrying out heat preservation and stirring reaction at 40-80 DEG C, wherein the volume fraction of the methacrylic anhydride in the reaction mixed solution is 1-15%, preferably 6-8%; and 3) after the reaction, adjusting the pH value to 7 by using a sodium bicarbonate solution, and purifying and drying to obtain the photosensitive modified chitosan. The invention further provides the gelatin-photosensitive modified chitosan ink prepared on the basis of the method and application of the gelatin-photosensitive modified chitosan ink. The gelatin-modified chitosan membrane provided by the invention has a microporous structure, shows relatively high (more than 90%) separation efficiency in an oil-water separation experiment, and also keeps the membrane flux for pump oil with relatively high viscosity at 1000 Lm<-2>h<-1> or above.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of intrinsically hydrophobic polyimide airgel, its preparation method and application

ActiveCN109929134BHighly hydrophobicAchieve separationOther chemical processesAlkali metal oxides/hydroxidesSupercritical dryingPolymer science

Owner:SICHUAN UNIV

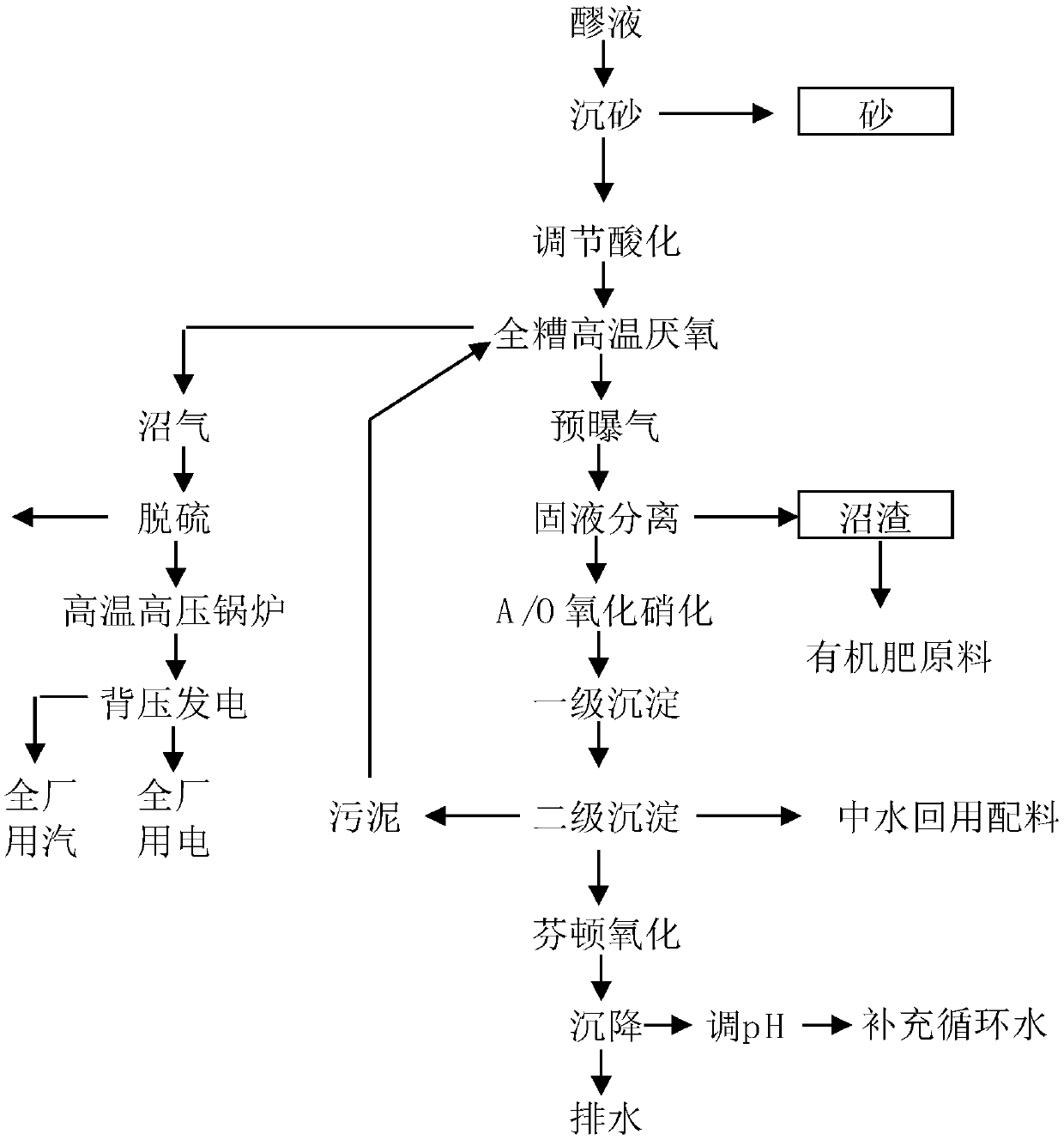

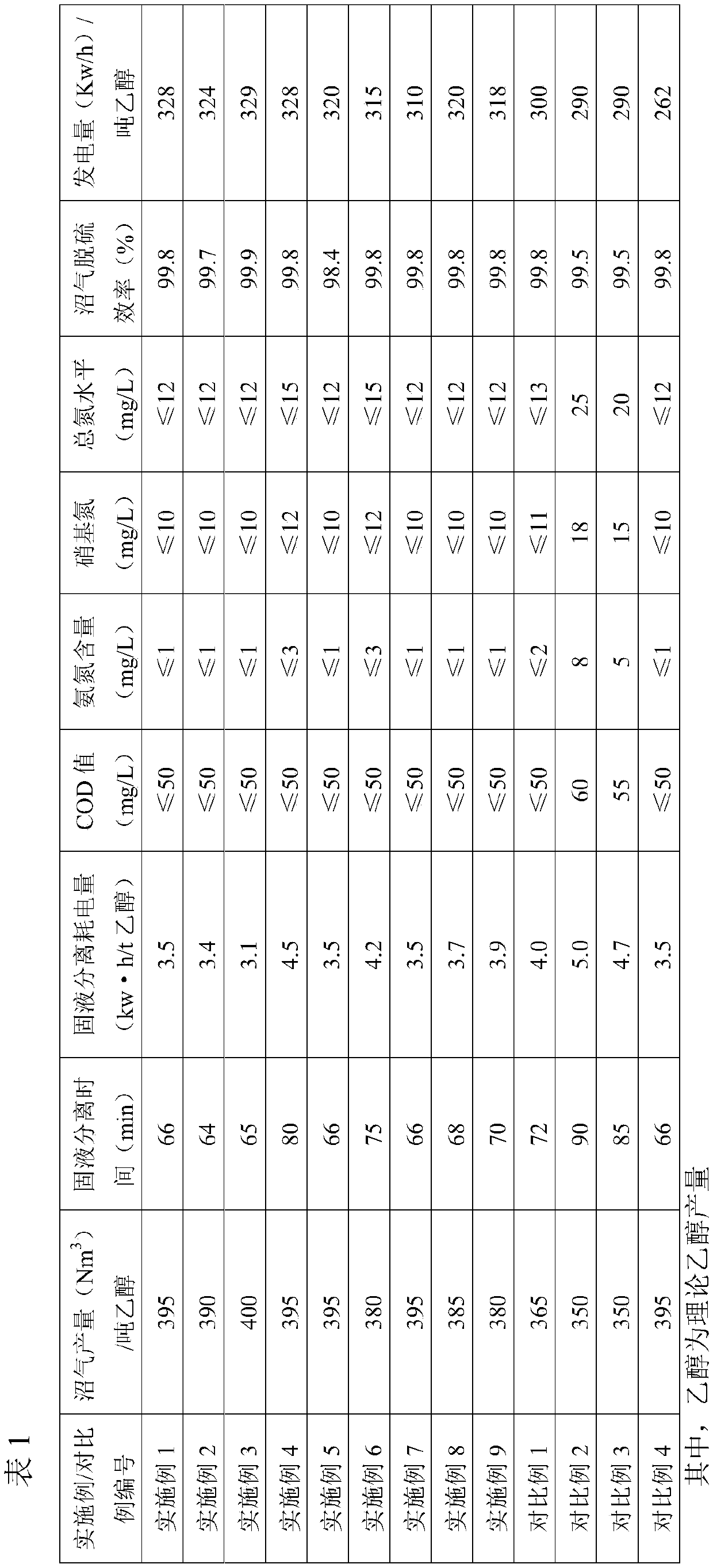

Method for coproducing alcohol and marsh gas by virtue of cassava and method for generating electricity by virtue of marsh gas

The invention relates to the marsh gas fermentation field, and discloses a method for coproducing alcohol and marsh gas by virtue of cassava and a method for generating electricity by virtue of the marsh gas. The method for coproducing alcohol and marsh gas comprises the following steps: sequentially carrying out crushing, pulp mixing, liquidation, saccharification and fermentation on the cassava,so as to obtain fermented mash; distilling the fermented mash, so as to obtain alcohol and waste mash liquid; cooling the waste mash liquid, inoculating a fermentation strain, and carrying out anaerobic fermentation at 50-70 DEG C for 18-25 days, so as to generate the marsh gas, wherein the anaerobic fermentation is carried out in at least one group of anaerobic fermentation systems, each group of the anaerobic fermentation systems comprises a plurality of anaerobic fermentation units which are connected in series, and multiple groups of the anaerobic fermentation systems are connected in parallel. The method for generating the electricity by virtue of the marsh gas comprises the steps of: preparing desulfurated marsh gas, and burning the desulfurated marsh gas in a high-temperature and high-pressure gas boiler so as to generate steam, wherein the generated steam is used for generating the electricity by virtue of a high-temperature and high-pressure turbine, the high temperature is at least 540 DEG C, and the high pressure is at least 9.8MPa. According to the two methods, the yield of the marsh gas can be remarkably increased, the generating capacity can be increased, and the energy consumption of a whole system can be reduced.

Owner:GUOTOU BIO TECH INVESTMENT CO LTD

Polyimide microporous film and preparation method thereof, and application of polyimide microporous film in oil-water separation

ActiveCN111363178AIncrease Separation ThroughputImprove separation efficiencyLiquid separationImidePolymer science

The invention relates to a polyimide microporous film and a preparation method thereof, and application of the polyimide microporous film in oil-water separation. The preparation method comprises thefollowing steps: (1) providing a polyamide acid solution; (2) adding a hydrophobic modifier into the polyamide acid solution; (3) molding a mixed solution obtained in the step (2) into a film material, and solidifying the obtained film material by adopting a coagulating bath to obtain a polyamide acid microporous film; (4) carrying out solvent replacement on the polyamide acid microporous film byadopting a low-surface-tension solvent; and (5) imidizing the polyamide acid microporous film treated in the step (4) to obtain the polyimide microporous film. The polyimide microporous film providedby the invention has good mechanical flexibility and structural designability, shows high separation efficiency on different types of oil-water mixtures, and has the advantages of low cost, high flux,high precision and high applicability; and the preparation method is simple in preparation process, easy to realize, rich in raw material sources and low in cost.

Owner:BEIJING JIAOTONG UNIV +1

High-flux emulsion separation composite material and preparation method and application thereof

ActiveCN111068523AIncrease Separation ThroughputImprove separation purposeMembranesSemi-permeable membranesPolymer scienceTortuosity

The invention belongs to the technical field of oil-water separation, and particularly relates to a high-flux emulsion separation composite material and a preparation method and application thereof. The emulsion separation material provided by the invention is composed of a porous layer with high tortuosity and a membrane layer with a large-aperture structure, a porous layer / membrane layer composite material with good mechanical stability is formed after compounding, and the oil-water selectivity is improved through hydrophobic modification. The preparation method provided by the invention hasrelatively low requirements on fiber types, expands fiber sources, and has relatively high flexibility; and the high-flux emulsion separation composite material is simple in composition, convenient to prepare and controllable in structure, has relatively high emulsion separation flux, and has a wide application prospect in the field of high-flux emulsion separation.

Owner:宁夏惟远新能源有限公司

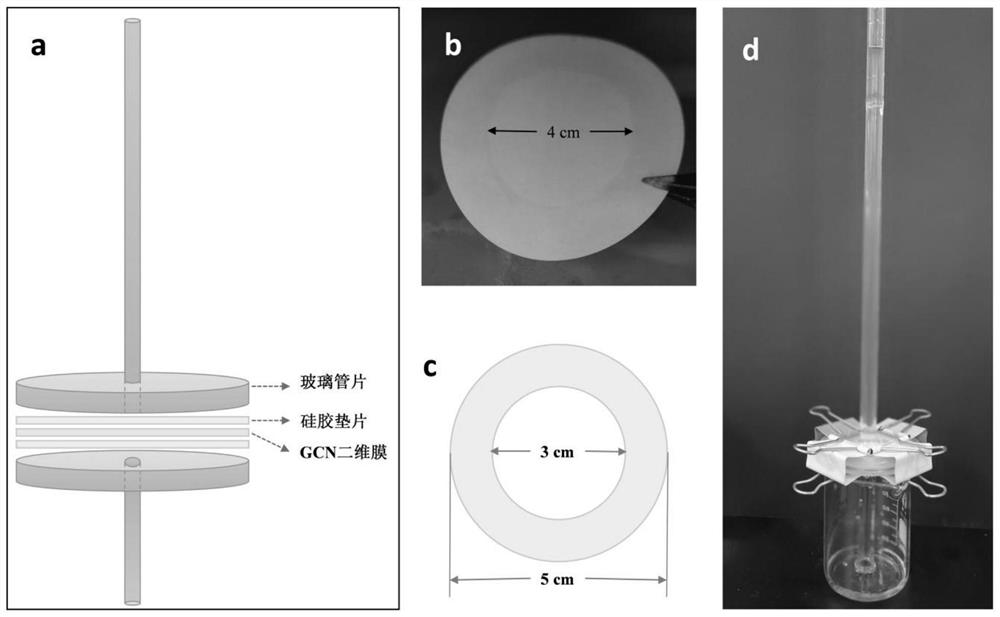

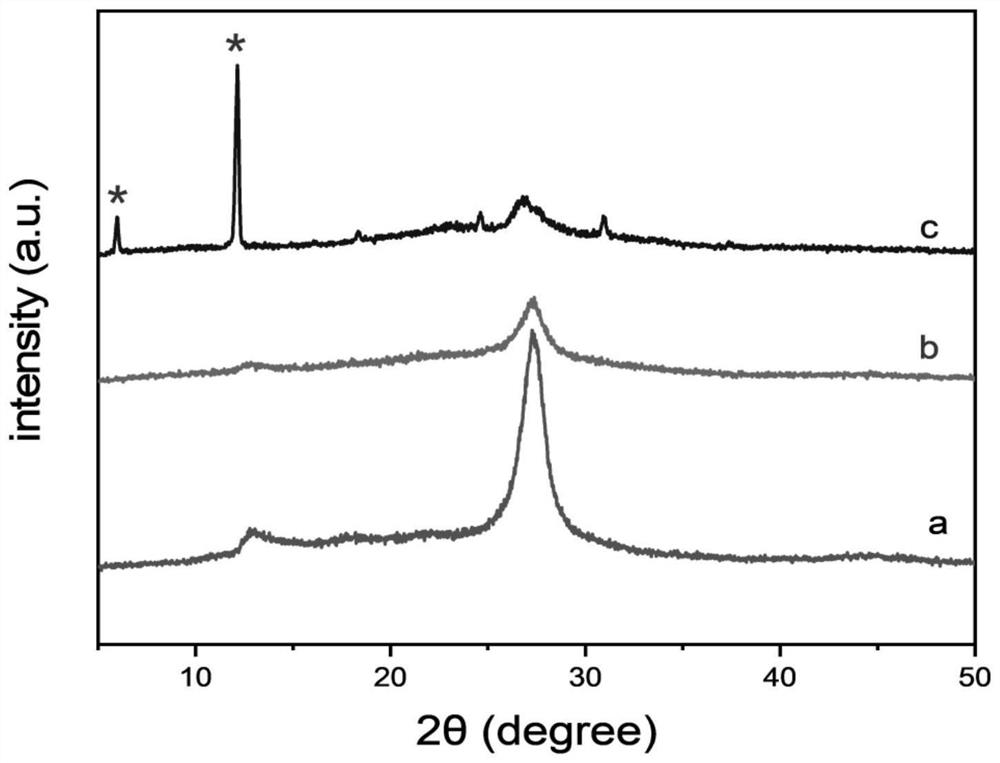

Graphite-phase C3N4 nanosheet two-dimensional film for oil-water separation and preparation method thereof

InactiveCN113289496AGood dispersionGood thermal stabilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSulfate radicalsThin membrane

The invention discloses a graphite-phase C3N4 nanosheet two-dimensional film for oil-water separation and a preparation method thereof. The method comprises the steps: (1) preparing graphite phase C3N4 powder; (2) preparing a graphite phase C3N4-sulfuric acid composite material suspension; and (3) preparing graphite phase C3N4 and graphite phase C3N4-sulfuric acid composite material films. The graphite-phase C3N4 nanosheet is better in dispersity, a colloidal aqueous solution of the graphite-phase C3N4 nanosheet can be kept stable for at least 6 months without agglomeration, the uniformity of the membrane prepared by a vacuum filtration method can be controlled, and the two-dimensional membrane has better thermal stability and chemical stability in a water-phase system; and the interlayer spacing regulated by embedded sulfate anions is stable and not easy to collapse, so that the smoothness of a molecular channel and a relatively large separation flux are ensured.

Owner:UNIV OF SCI & TECH OF CHINA

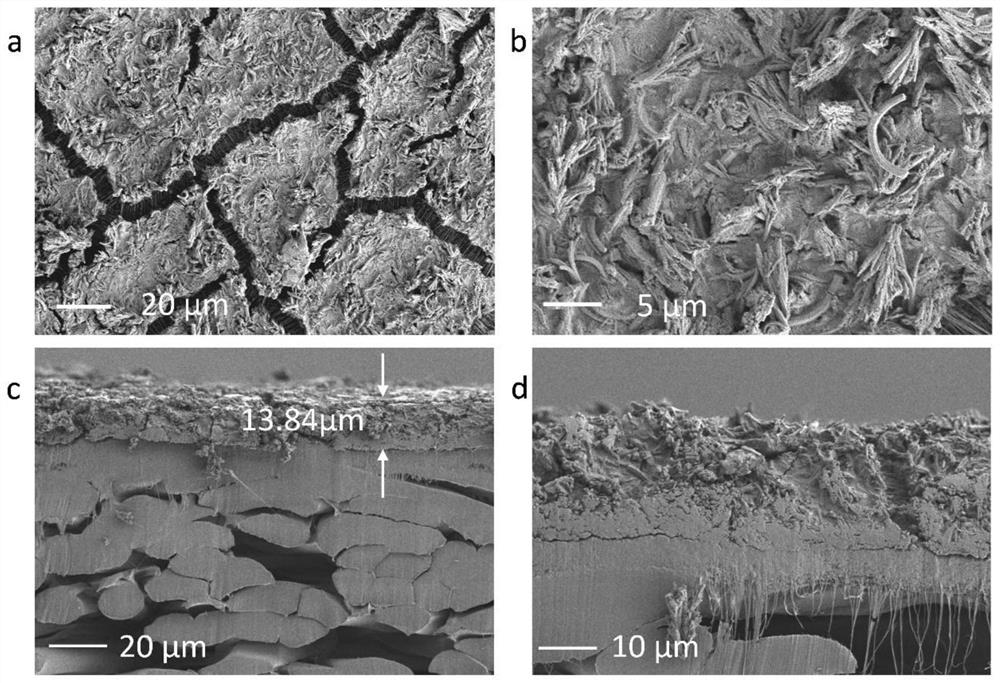

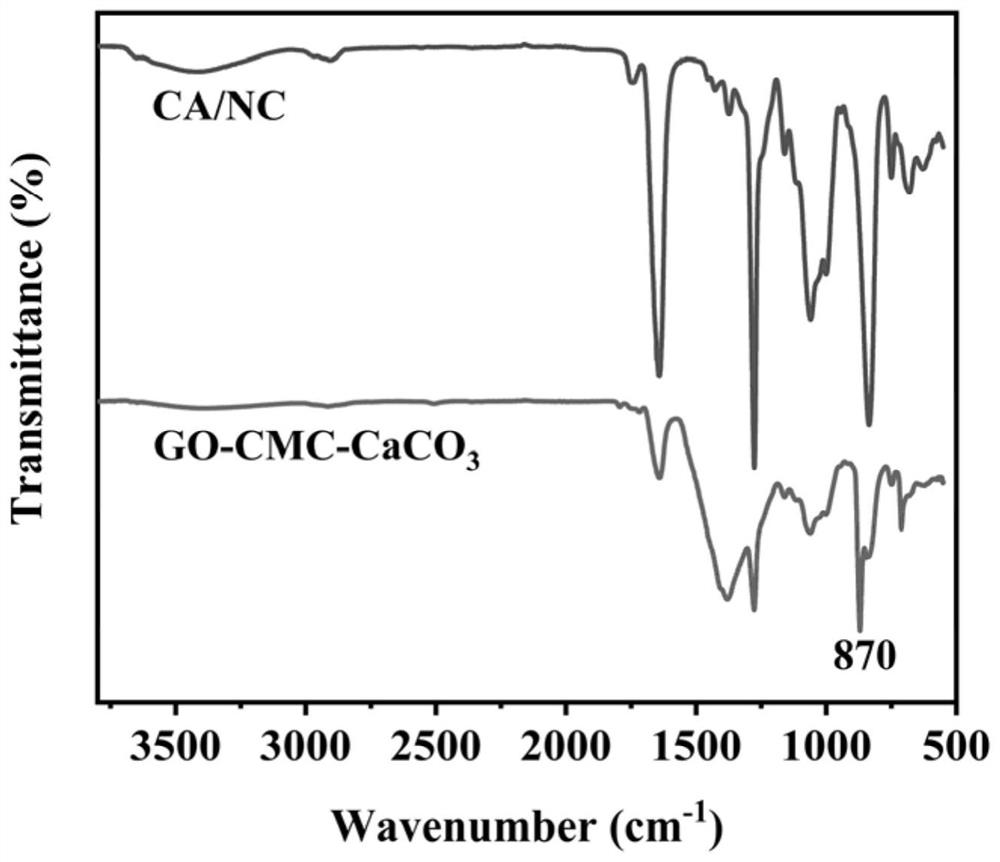

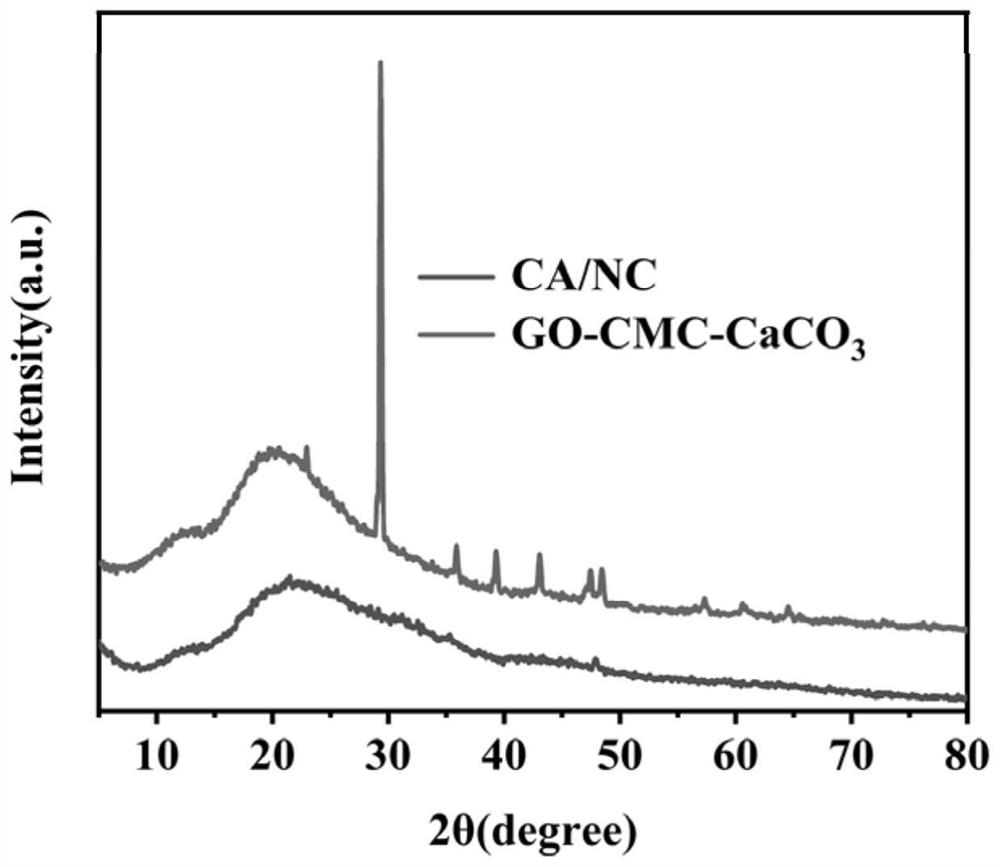

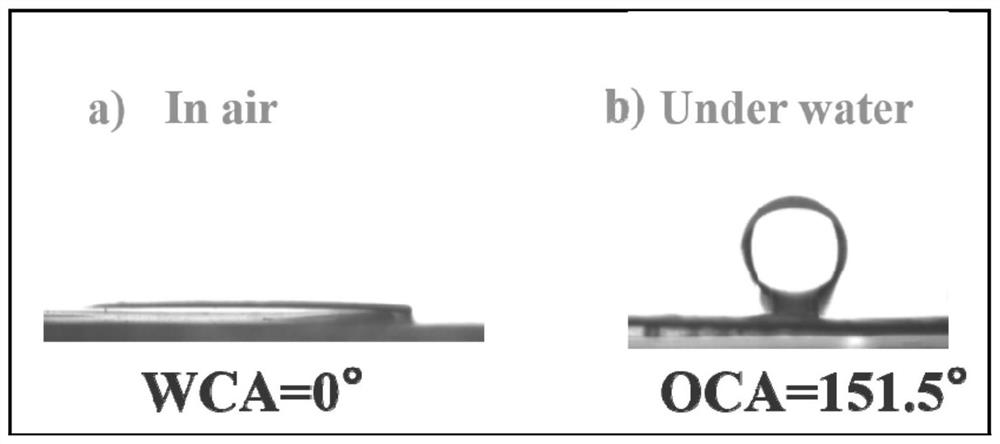

Anti-pollution calcium carbonate-based cellulose composite membrane as well as preparation method and application thereof

ActiveCN112023720AStrong anti-pollutionExcellent antigen oil adhesion performanceMembranesSemi-permeable membranesCelluloseFiber

The invention provides a preparation method of an anti-pollution calcium carbonate-based cellulose composite membrane, which comprises the following steps: S1, preparing a GO / CMC / CaCl2 mixed solution,respectively preparing a CaCl2 solution, a CMC solution and a GO dispersion solution, and mixing the CaCl2 solution, the CMC solution and the GO dispersion solution to obtain a GO / CMC / CaCl2 mixed solution; and S2, preparing a Na2CO3 solution, mixing the Na2CO3 solution with the GO / CMC / CaCl2 mixed solution obtained in the step S1, performing stirring to obtain a suspension, and performing suctionfiltration on the suspension onto a fiber membrane to obtain the GO-CMC-CaCO3 composite membrane. The anti-pollution calcium carbonate-based cellulose composite membrane provided by the invention hasthe advantage that the water flux, the anti-pollution property, the self-cleaning property and the like of the oil-water separation membrane are obviously improved.

Owner:XIHUA UNIV +1

Miniature capillary array device for isoelectric focusing electrophoresis

ActiveCN102120754AImprove throughputHigh precisionPeptide preparation methodsElectrophoresisBiochemical engineering

The invention relates to a miniature capillary array device for isoelectric focusing electrophoresis (IEF) in the technical field of biochemical engineering. The device consists of an array type electrophoresis tank and miniature capillaries, wherein the array type electrophoresis tank has two symmetrical parts; a groove array is carved on the array type electrophoresis tank; and the miniature capillaries are arranged in the groove array. One pair or multiple pairs of the array devices of the invention are selected to perform IEF simultaneously according to need and the separation flux of theprotein sample can be from dozens of tubes to hundreds of tubes. The diameter and length of the miniature capillaries in the device are shorter, thus the IEF time and cost can be effectively reduced.

Owner:SHANGHAI JIAODA INTELLECTUAL PORPERTY MANAGEMENT CO LTD +1

Preparation and application of high-flux emulsion separation material

InactiveCN110747642ASignificant capillary effectOvercoming Transport Kinetics ShortcomingsSemi-permeable membranesAnimal fibresFiberActive agent

The invention discloses preparation and application of a high-flux emulsion separation material. The preparation comprises: firstly, coordinating metal ions, having a specific concentration, with skincollagen fibers under the action of high-speed stirring; secondly, growing a metal organic framework compound sieving layer on the surface of the skin collagen fibers by controlling the molar concentration ratio of the metal ions to organic ligands and controlling the reaction time; and thirdly, subjecting the obtained metal organic framework compound-modified skin collagen fibers to surface hydrophobic treatment through a low surface energy substance so as to prepare a high-flux emulsion separation material. The emulsion separation material disclosed by the invention can provide high-throughput separation for various surfactant-stabilized microemulsions and nanoemulsions owing to capillary action of the skin collagen fibers.

Owner:SICHUAN UNIV

Preparation method of palladium-wood film capable of synchronously carrying out oil-water separation and dye degradation

PendingCN112125375AImprove performanceRich reservesFatty/oily/floating substances removal devicesWater contaminantsHydrophilic membraneOrganic chemistry

The invention discloses a preparation method of a palladium wood film capable of synchronously carrying out oil-water separation and dye degradation, and relates to a preparation method of a palladium-wood film. According to the invention, the problems that the membrane flux is reduced due to the fact that hydrophilic membrane pores are easily blocked by greasy dirt, and an oil-water separation membrane and an oil absorption material can only physically adsorb limited dyes and cannot degrade the dyes are solved. The preparation method comprises the following steps: 1, preparing pretreated rawmaterials; 2, loading palladium particles; and 3, drying. The preparation method is used for preparing the palladium-wood film capable of synchronously carrying out oil-water separation and dye degradation.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com