Preparation and application of underwater super-oleophobic and under-oil hydrophilic emulsion separation functional fibers

An underwater superoleophobic and emulsion separation technology, which is applied in the directions of immiscible liquid separation, liquid separation, and repelling fibers to liquids, etc. problem, to achieve the effect of stable and reusable, simple preparation method and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of an emulsion separation functional fiber with underwater superoleophobicity and oil hydrophilicity:

[0034] a. Soak 15 g skin collagen fibers in 200 mL deionized water for 24 h;

[0035] b. Add 200 mL of zirconium sulfate solution (containing 0.05 mol Zr(SO 4 ) 2 ), adjust the pH value to 1.8-2.0 at 30 o C stirred and reacted for 4.0 h;

[0036] c. Adjust the pH value to 4.0-4.5 at 40 o C stirred and reacted for 4.0 h;

[0037] d. The obtained product is filtered, washed with deionized water, washed with absolute ethanol, and dried to obtain the emulsion separation functional fiber, which is named CFs-Zr.

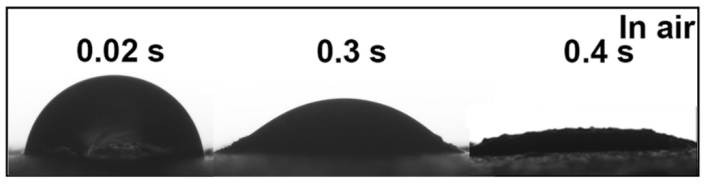

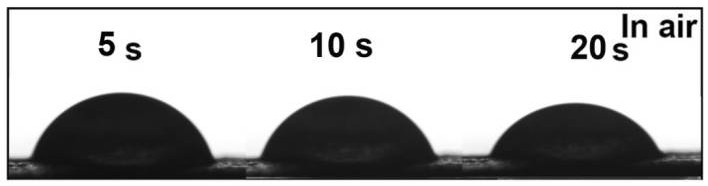

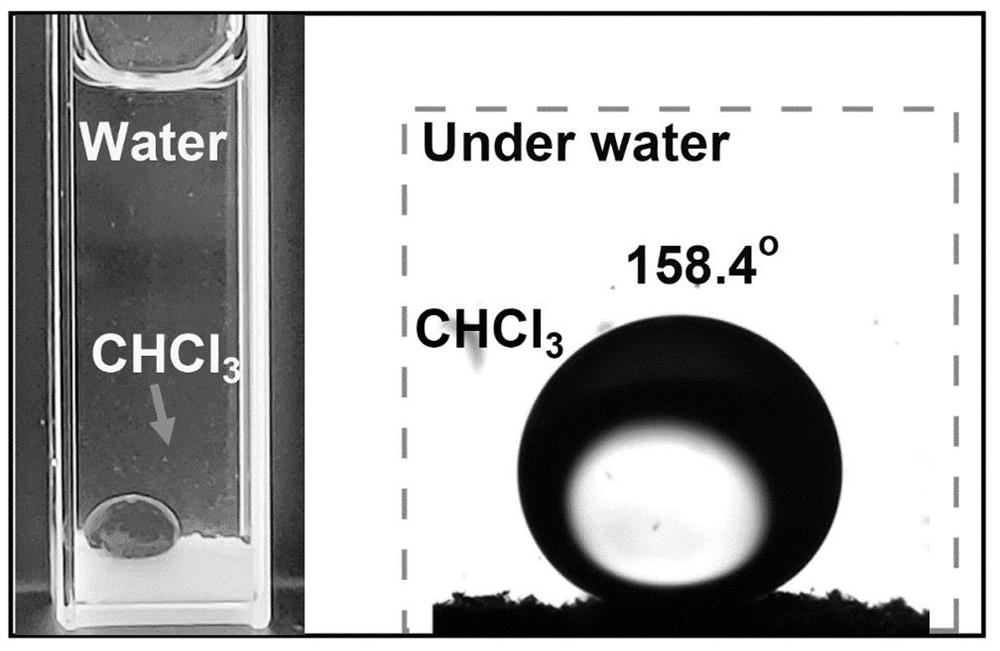

[0038] It has been determined that in the air medium, the complete infiltration time of water droplets on the surface of the emulsion separation functional fiber CFs-Zr prepared in this example is 0.4 s, and the photo of the contact angle during the infiltration process is as follows: figure 1 Shown; and the infiltration speed of water drople...

Embodiment 2

[0049] (1) Preparation of an emulsion separation functional fiber with underwater superoleophobicity and oil hydrophilicity:

[0050] a. Soak 15 g skin collagen fibers in 200 mL deionized water for 24 h;

[0051] b. Add 200 mL ferric sulfate solution (containing 0.05 mol Fe 2 (SO 4 ) 3 ), adjust the pH value to 1.8-2.0 at 30 o C stirred and reacted for 4.0 h;

[0052] c. Adjust the pH value to 4.0-4.5 at 40 o Stir at C for 4.0 h;

[0053] d. The obtained product is filtered, washed with deionized water, washed with absolute ethanol, and dried to obtain the emulsion separation functional fiber, which is named as CFs-Fe.

[0054] (2) Preparation of emulsion:

[0055] Same as emulsion composition and preparation method among the embodiment 1.

[0056] (3) Application of the emulsion separation functional fiber CFs-Fe with underwater superoleophobicity and oil hydrophilicity: 1.5 g of the emulsion separation functional fiber CFs-Fe prepared above was dry packed into a colu...

Embodiment 3

[0059] (1) Preparation of an emulsion separation functional fiber with underwater superoleophobicity and oil hydrophilicity:

[0060] a. Soak 15 g skin collagen fibers in 200 mL deionized water for 24 h;

[0061] b. Add 200 mL of titanium sulfate solution (containing 0.05 mol Ti(SO 4 ) 2 ), adjust the pH value to 1.8-2.0 at 30 o C stirred and reacted for 4.0 h;

[0062] c. Adjust the pH value to 4.0-4.5 at 40 o Stir at C for 4.0 h;

[0063] d. The obtained product is filtered, washed with deionized water, washed with absolute ethanol, and dried to obtain the emulsion separation functional fiber, which is named as CFs-Ti.

[0064] (2) Preparation of emulsion:

[0065] Same as emulsion composition and preparation method among the embodiment 1.

[0066] (3) Application of the emulsion separation functional fiber CFs-Ti with underwater superoleophobicity and oil hydrophilicity: 1.5 g of the emulsion separation functional fiber CFs-Ti prepared above was dry packed into a col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com