Preparation method and application of super-hydrophilic basalt fiber material

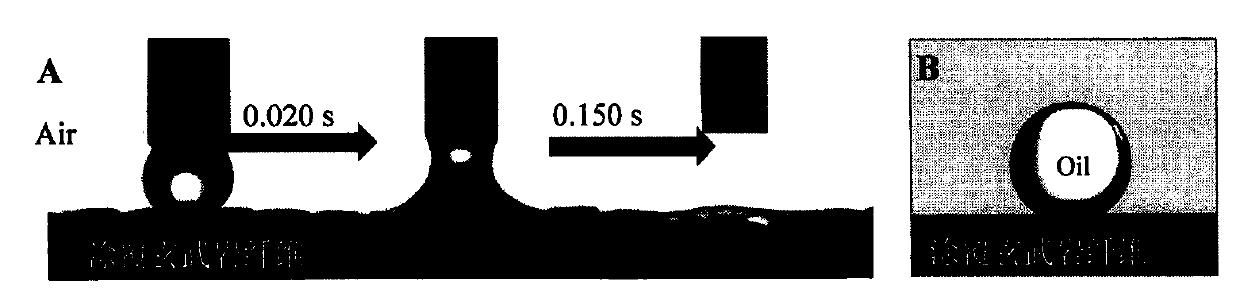

The technology of basalt fiber and basalt fiber cloth is applied in the field of preparation of super-hydrophilic basalt fiber material, which can solve the problems of oil-water separation material being easily polluted by oil, difficult to realize large-scale production, complicated post-processing, etc., and achieve high cost performance and low cost. Cost, high separation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. Dissolve 0.3 g of glucomannan powder in 100 mL of deionized water, and stir for 3 hours to obtain a homogeneous glucomannan solution;

[0024] b. Add 0.1M NaOH solution to the glucomannan solution obtained in step a to adjust the pH value to 9.5, and continue stirring for 0.5h to obtain a deacetylated glucomannan solution;

[0025] c. Soak the basalt fiber cloth with acetone and ultrasonically for 5 minutes, then soak and rinse with absolute ethanol until there is no acetone residue on the surface of the basalt fiber cloth, and place the cleaned basalt fiber in an oven at a temperature of 50°C for 0.5 h;

[0026] d. Immerse the basalt fiber cloth in step c into the solution obtained in step b, soak for 10 minutes until the basalt fiber cloth is completely wet, take it out and spread it on a Teflon board, and place it in an oven at a temperature of 90°C to dry and solidify for 2 hours to obtain super Hydrophilic basalt fiber material.

[0027] The obtained basalt fib...

Embodiment 2

[0029] a. Dissolve 0.4 g of glucomannan powder in 100 mL of deionized water and stir for 4 hours to obtain a homogeneous glucomannan solution;

[0030] b. Add 0.1M NaOH solution to the glucomannan solution obtained in step a to adjust the pH value to 9.7, and continue stirring for 0.5h to obtain a deacetylated glucomannan solution;

[0031] c. Soak the basalt fiber cloth with acetone and ultrasonically for 5 minutes, then soak and rinse with absolute ethanol until there is no acetone residue on the surface of the basalt fiber cloth, and place the cleaned basalt fiber in an oven at a temperature of 50°C for 0.5 h;

[0032] d. Immerse the basalt fiber cloth obtained in step c into the solution obtained in step b, soak for 10 minutes until the basalt fiber cloth is completely wet, take it out and spread it on a Teflon board, and place it in an oven at a temperature of 90°C to dry and solidify for 2 hours. superhydrophilic basalt fiber material.

[0033] The obtained basalt fiber...

Embodiment 3

[0035] a. Dissolve 0.5 g of glucomannan powder in 100 mL of deionized water, and stir for 5 hours to obtain a homogeneous glucomannan solution;

[0036] b. Add 0.1M NaOH solution to the glucomannan solution obtained in step a to adjust the pH value to 9.2, and continue stirring for 0.5h to obtain a deacetylated glucomannan solution;

[0037] c. Soak the basalt fiber cloth with acetone and ultrasonically for 5 minutes, then soak and rinse with absolute ethanol until there is no acetone residue on the surface of the basalt fiber cloth, and place the cleaned basalt fiber in an oven at a temperature of 50°C for 0.5 h;

[0038] d. Immerse the basalt fiber cloth obtained in step c into the solution obtained in step b, soak for 10 minutes until the basalt fiber cloth is completely wet, take it out and spread it on a Teflon board, and place it in an oven at a temperature of 90°C to dry and solidify for 2 hours. superhydrophilic basalt fiber material.

[0039] The obtained basalt fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com