PH-responsive super-hydrophobic coating material as well as preparation method and application thereof

A super-hydrophobic coating and responsive technology, applied in coatings, separation methods, chemical instruments and methods, etc., can solve problems such as difficult separation, and achieve high separation throughput and excellent recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

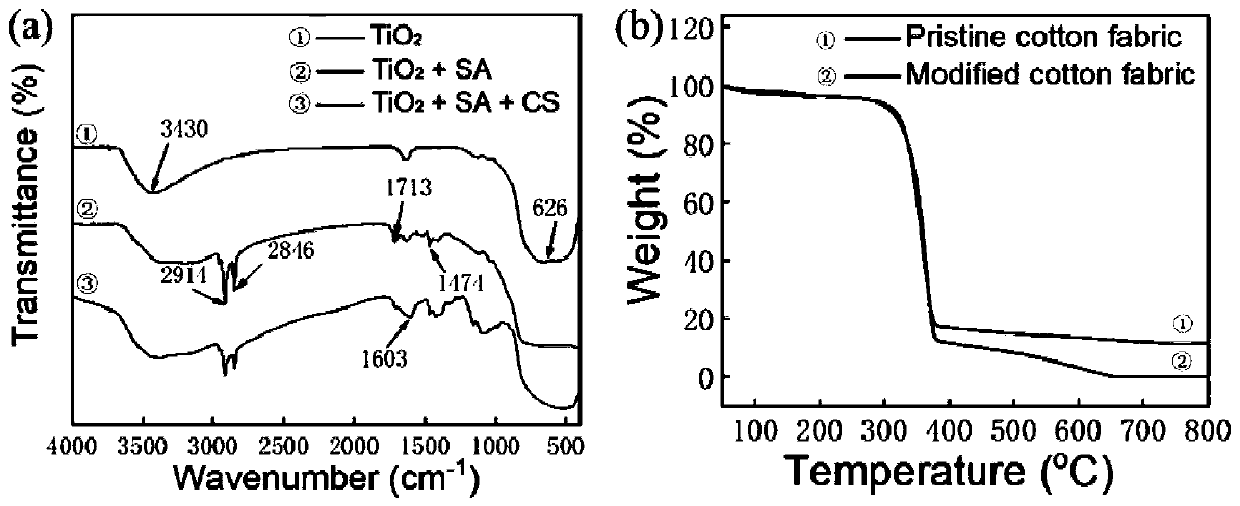

[0053] Dissolve 0.5g stearic acid in 20mL absolute ethanol, then add 0.42g TiO 2 , stirred at room temperature for 30min, then added a dispersion of 2wt% chitosan (0.06g, 3mL) in ethanol, and continued to stir for 20min at room temperature to obtain a superhydrophobic coating solution. Then put cotton cloth (Φ=4cm), filter paper (Φ=4cm), and sponge (2cm×2cm×2cm) in the prepared superhydrophobic coating solution in sequence, and the superhydrophobic material can be obtained by dip coating.

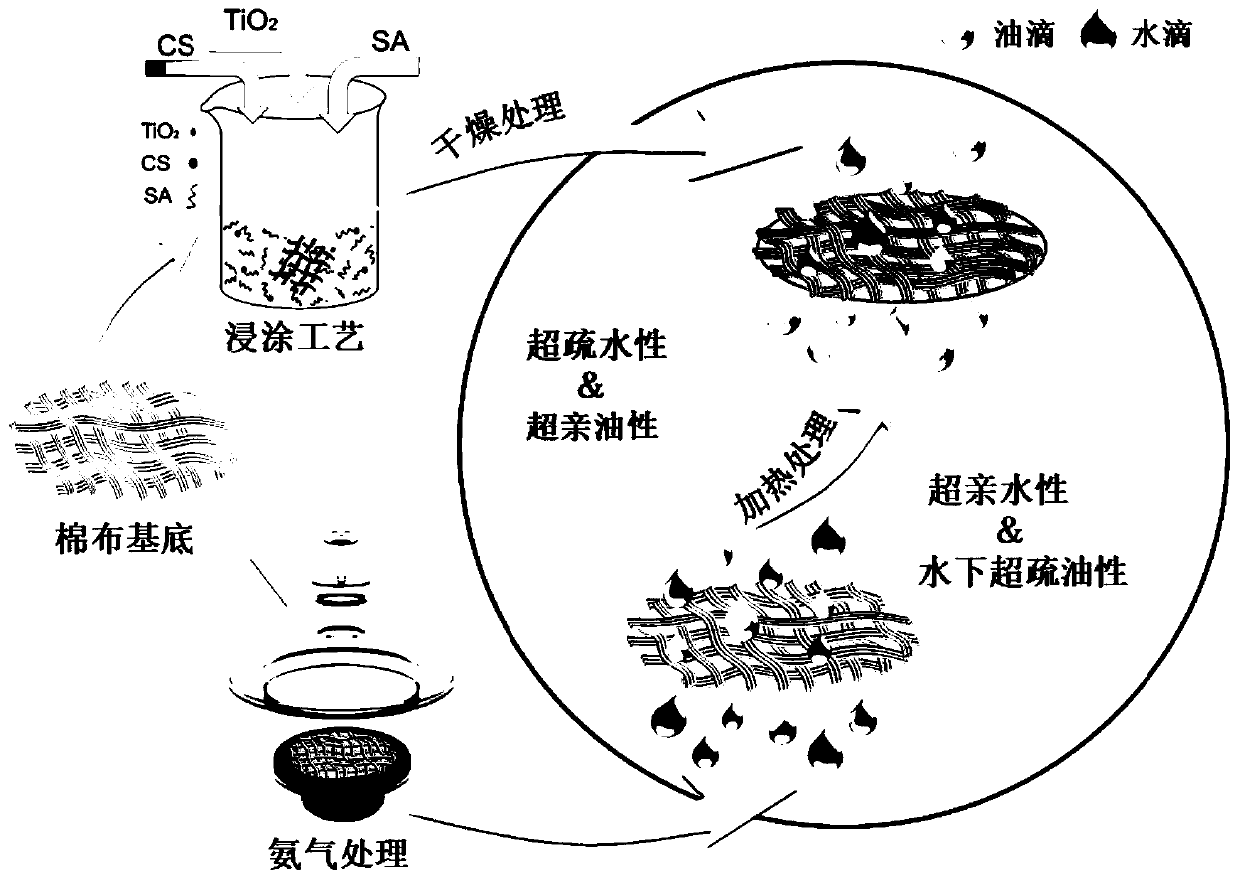

[0054] The principle of the superhydrophobic material prepared by the present disclosure is as follows: figure 1 As shown, the superhydrophobic coating is applied to the cotton cloth by the dip coating process to form a superhydrophobic material. Hydrophilic, and then after heat treatment (heating at 80°C for 15 minutes), the superhydrophobic property will be restored.

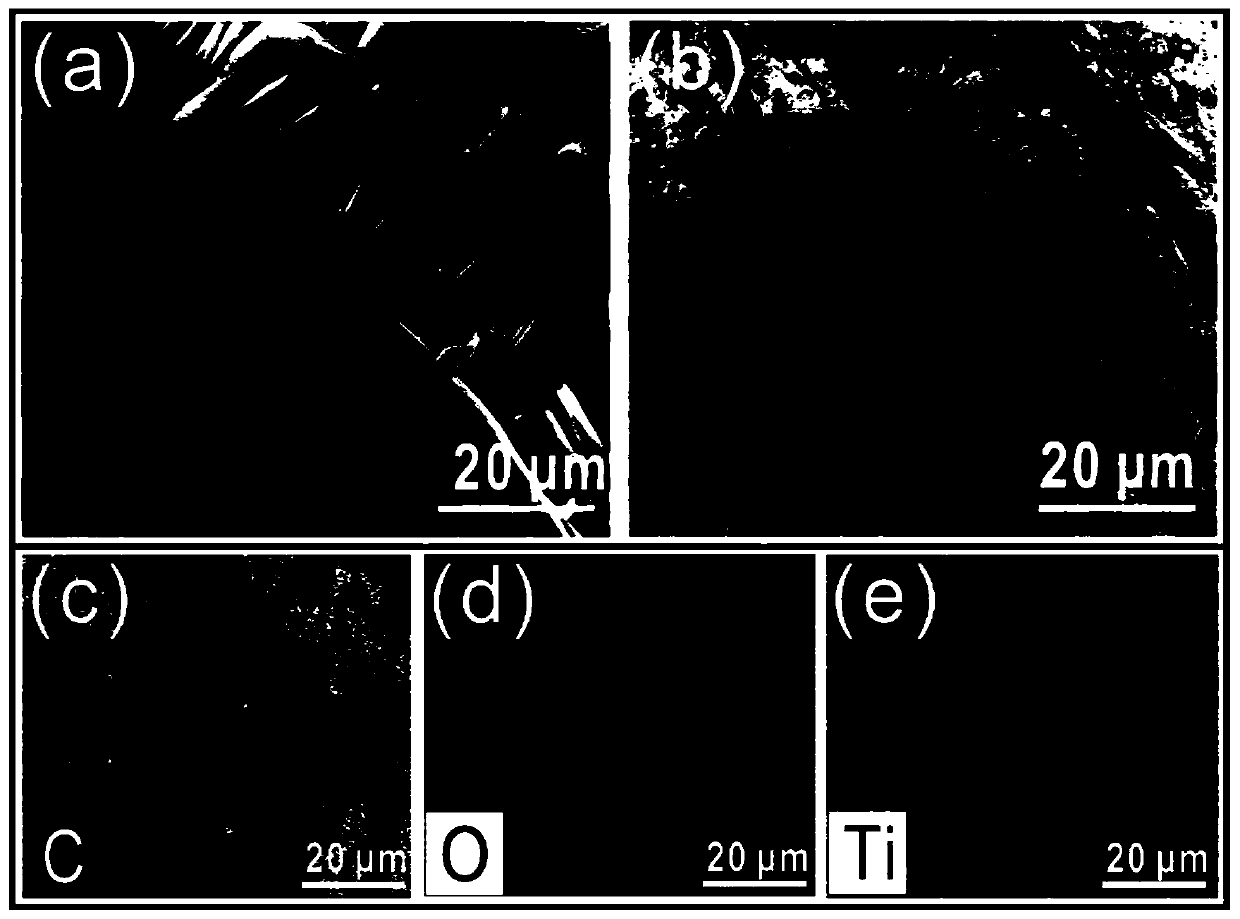

[0055] In this disclosure, chitosan (CS) with a particle size between 400-800nm and TiO with a particle size of 10-25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com