High-flux oil-water separation COF membrane as well as preparation method and application thereof

An oil-water separation, high-throughput technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of cumbersome synthesis process of hydrophobic COF membrane, and achieve the improvement of low mechanical strength, high separation flux, high The effect of self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

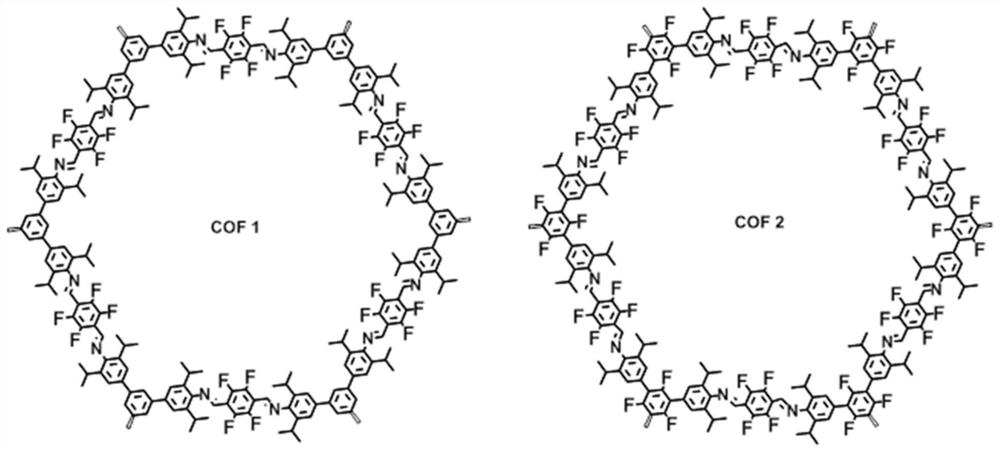

[0042] Preparation of superhydrophobic COF1 powder:

[0043] Weigh 30.2mg i Pr-TAM and 15.5 mg of TFTA were dispersed in a mixed solvent of 0.1 mL of DMA and 1.5 mL of isopropanol. After ultrasonic dispersion for 5 minutes, 0.4 mL of 3M acetic acid was added. The above suspension was then added to glass test tubes, snap frozen at 77k (liquid nitrogen bath), evacuated and sealed. After slowly returning to room temperature, it was heated at 120 °C for 3 d. After the reaction, the solid was filtered out, washed with tetrahydrofuran in a Soxhlet extractor for 24 hours to remove unreacted monomers, and finally dried under vacuum at 100 °C for 8 hours to obtain superhydrophobic COF1 solid powder.

Embodiment 2

[0045] Preparation of superhydrophobic COF2 powder:

[0046] Weigh 33.0mg F- i Pr-TAM and 15.5 mg of TFTA were dispersed in 0.3 mL of isopropanol solvent, and after ultrasonic dispersion for 5 minutes, 1.2 mL of pure acetic acid was added. The above suspension was then added to glass test tubes, snap frozen at 77k (liquid nitrogen bath), evacuated and sealed. After slowly returning to room temperature, it was heated at 120 °C for 3 d. After the reaction, the solid was filtered out, washed with tetrahydrofuran in a Soxhlet extractor for 24 hours to remove unreacted monomers, and finally dried under vacuum at 100 °C for 8 hours to obtain superhydrophobic COF2 solid powder.

Embodiment 3

[0048] Functional modification of stainless steel mesh:

[0049] Use 1.0M hydrochloric acid and 1.0M sodium hydroxide solution for 7×7cm 2 Large and small stainless steel mesh is cleaned and dried after cleaning. Then, the toluene solution of 3.0 wt.% APTES was treated at 110 °C for 2 h to modify amino groups on the surface of the stainless steel mesh.

[0050] The amino-modified stainless steel mesh was further functionalized with a dioxane solution of 0.27wt% TFTA, treated at 80°C for 2 h, and the surface of the stainless steel mesh was modified with aldehyde groups, that is, the functionalization was completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com