Cation surface sizing agent emulsion

A technology of surface sizing agent and cationic etherifying agent, which is applied in the direction of water-repellent addition, can solve the problems of limited application range of secondary fibers, inability to take into account surface strength, folding resistance and solvent resistance, and eliminate disadvantages Influence, convenience of raw material acquisition, effect of improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

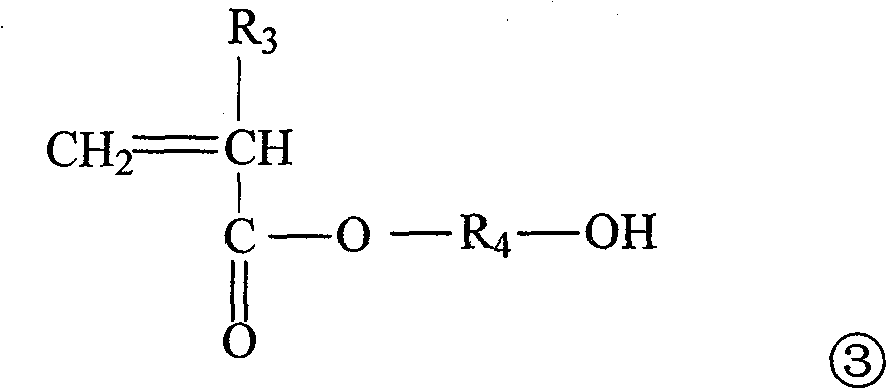

[0031] The present invention uses cross-linked film-forming component modified polyvinyl alcohol as polymer surfactant and dispersant, uses self-crosslinking monomer, vinyl monomer, and cationic monomer as comonomer, and co-polymerizes it through soap-free emulsion Polymerization to obtain a reactive cationic microemulsion-like reactive surface sizing agent.

[0032] The components of the present invention mainly contain by mass ratio:

[0033] (I) Solution E: (i) mixture A obtained by mixing 100 parts of polymer colloidal stabilizer, 100-900 parts of water and 1-100 parts of cationic etherification agent; (ii) adding to mixture A to adjust the pH value to 7 -14 alkali amount, then add the acid amount to adjust the pH value to 1-6, the obtained modified polymer colloid stabilizer B; (iii) 100 parts of modified polymer colloid stabilizer B are mixed with 80-5000 parts of water The resulting solution E.

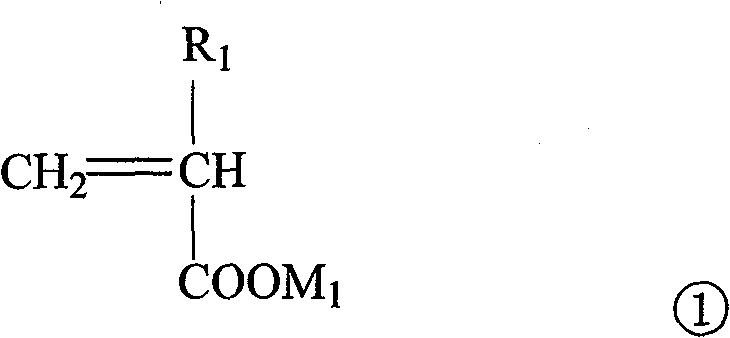

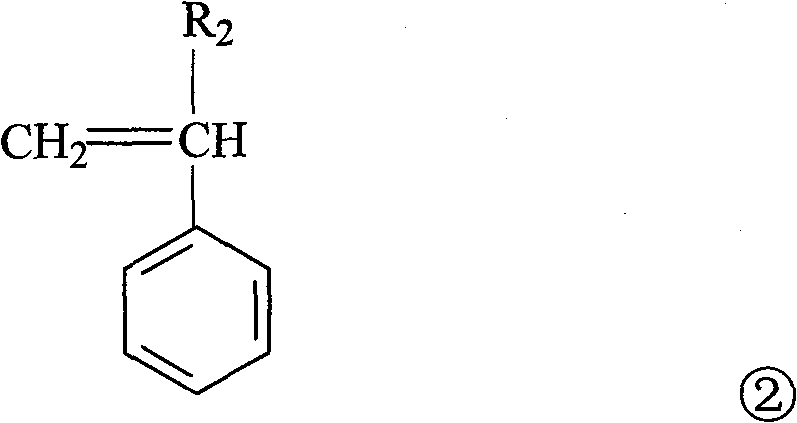

[0034] (II) Solution C: Solution C obtained by mixing 1 part of vinyl mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com