Preparation method of polystyrolsulfon acid salt/polyethyleneimine crosslinking nanofiltration membrane

A technology of polystyrene sulfonate and polyethylene imine is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of good hydrophilicity, novel process, and easy control of process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

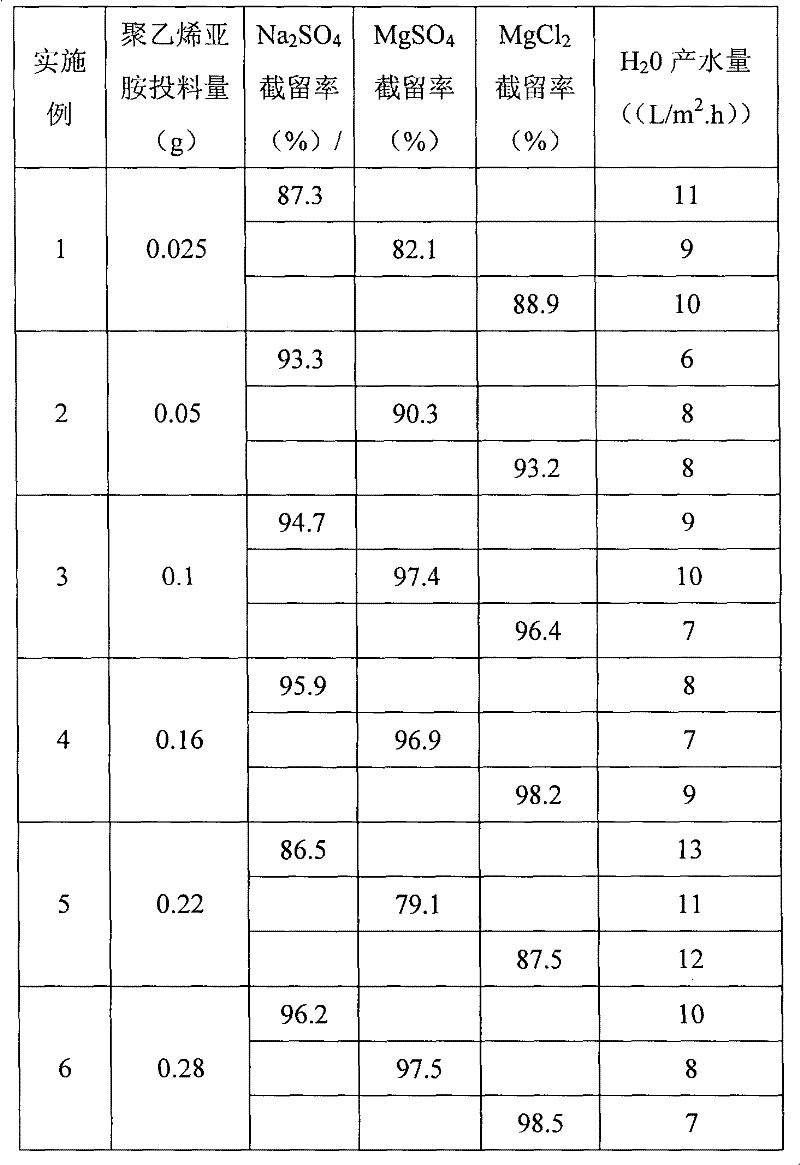

Embodiment 1-6

[0034] Dissolve 1 g of sodium polystyrene sulfonate in 99 g of water, with a mass fraction of 1%, add a certain amount of polyethyleneimine and 0.05 g of glutaraldehyde, heat to 30 ° C, and stir well; remove the casting solution with a vacuum pump After soaking for 2 hours; then pour it into a metal frame with a porous support membrane, keep it for 2 minutes, scrape it into a liquid film of a certain thickness with a scraper; remove the casting liquid remaining on the surface of the porous support membrane with a rubber roller , put the support film scraped with casting liquid into a vacuum oven and heat it to 40°C, dry it in vacuum for 20 minutes to volatilize the solvent, then take it out and place it at an inclination of 75°, spray a 7% hydrochloric acid solution onto the film with a sprayer to polymerize After the product is gelled, continue to dry in a vacuum oven for 40 minutes, and wait for the solvent to evaporate completely; transfer it to an ordinary oven for heating ...

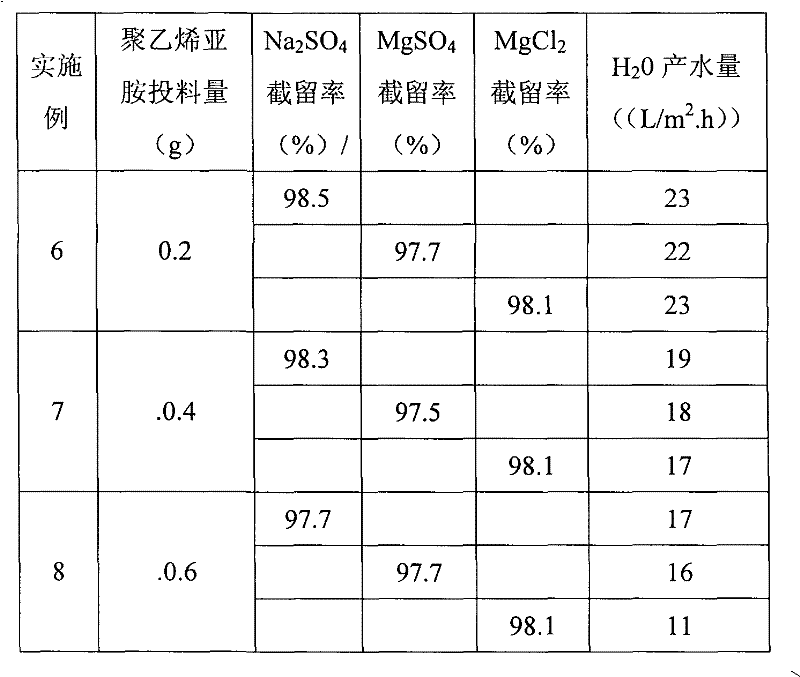

Embodiment 6-8

[0037]With other conditions unchanged, after adding an appropriate amount of polyethyleneimine, a small amount of acid solution was added dropwise under stirring to adjust the pH value to 3.

[0038]

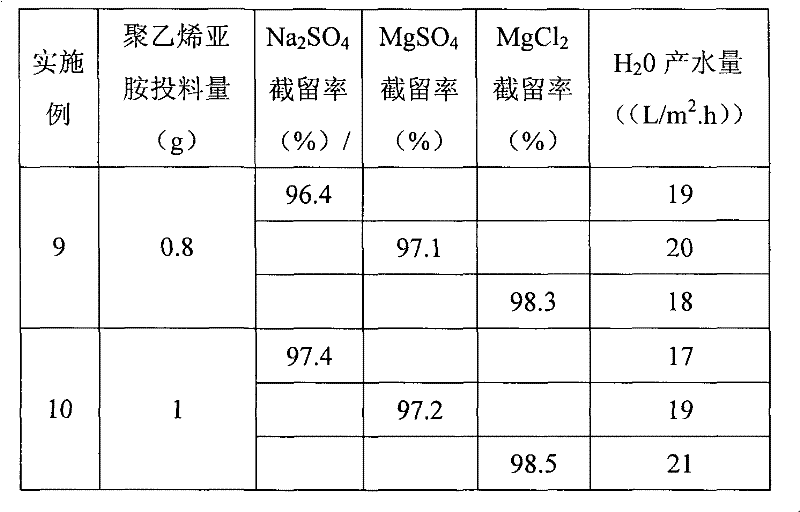

Embodiment 9

[0039] Example 9, 10

[0040] Other conditions remain the same, as in Example 4-6, increase the amount of PEI and adjust the pH. When the pH value increases to 3, a large amount of viscous jelly is precipitated, and the solution appears turbid. After filtering the turbid solution, take the clear solution to form a membrane, and the method is the same as above.

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com