Environment-friendly laser anti-counterfeiting printing process

A laser anti-counterfeiting and environment-friendly technology, applied in the printing process, printing, printing of special varieties of printed matter, etc., can solve the problems of cumbersome process, abnormal continuous production, easy loss of laser effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

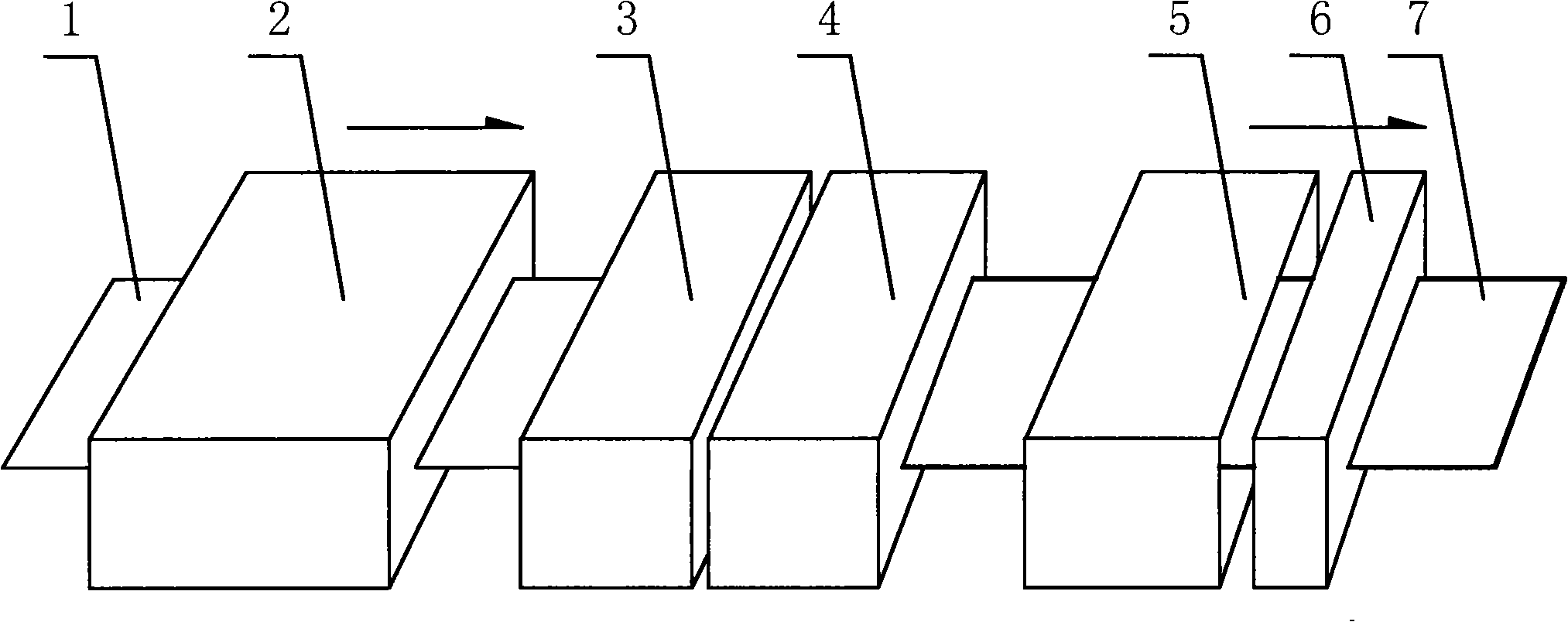

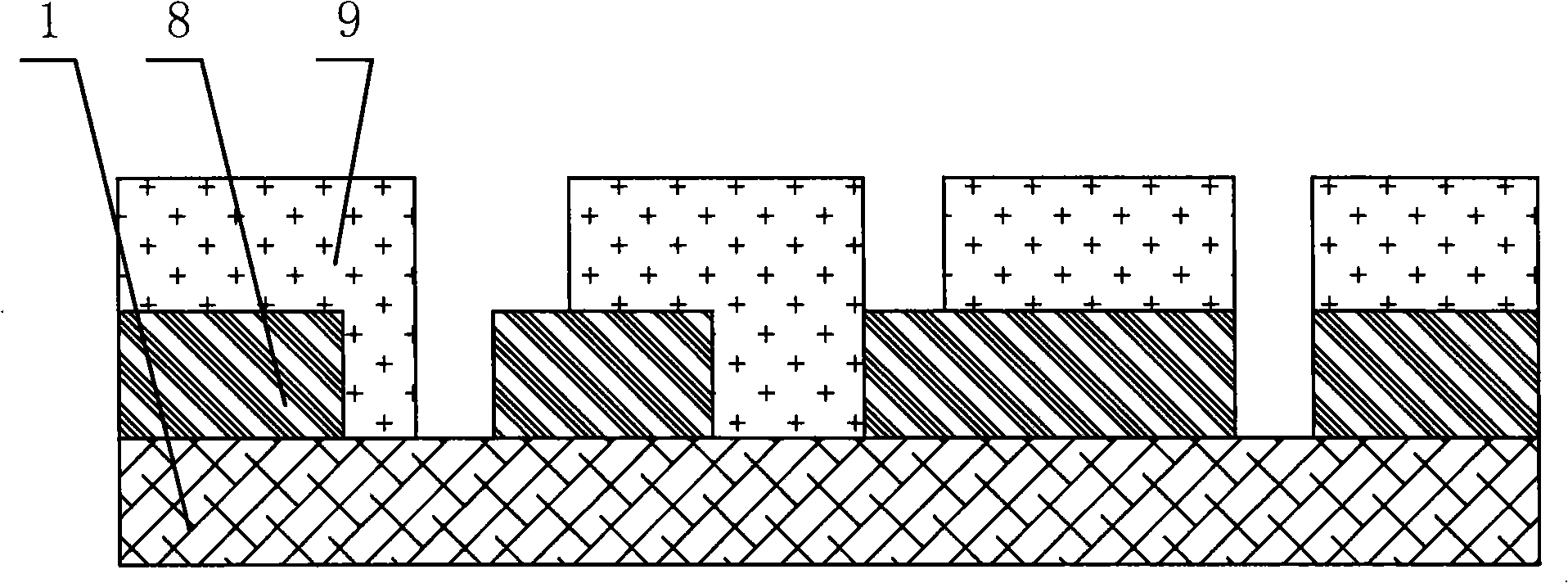

[0014] Such as figure 1 The process shown in the figure uses 80g-400g of ordinary white cardboard, gray board paper, coated paper, etc. as the substrate 1 for printing. Printing, and then print the glossy layer through the environmental protection glossy layer printing unit 3. When the glossy layer printing unit 3 is printing, the printing plate can be made with hollowed out graphic information, so that the printed graphic information can be hidden, and then through the film The pressing unit 4 loads the laser holographic anti-counterfeiting pattern on the bright layer, and then the substrate 1 passes through the drying unit 5, and the film is pressed on the bright layer of the substrate 1 and the laser holographic anti-counterfeiting pattern is cured. Finally, the peeling machine 6 immediately and continuously peels off the lamination film on the glossy layer and the laser graphic layer to obtain an environmentally friendly, anti-counterfeiting, and exquisite final product 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com