Method for preparing nanometer CaCO3 from calcium carbide slag through ultrasonic process

A technology of nano-calcium carbonate and nano-scale calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of difficult control of particle size distribution range, long carbonization reaction time, weak functionality, etc., and achieve the preparation time Shortening shortening, high product added value, and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

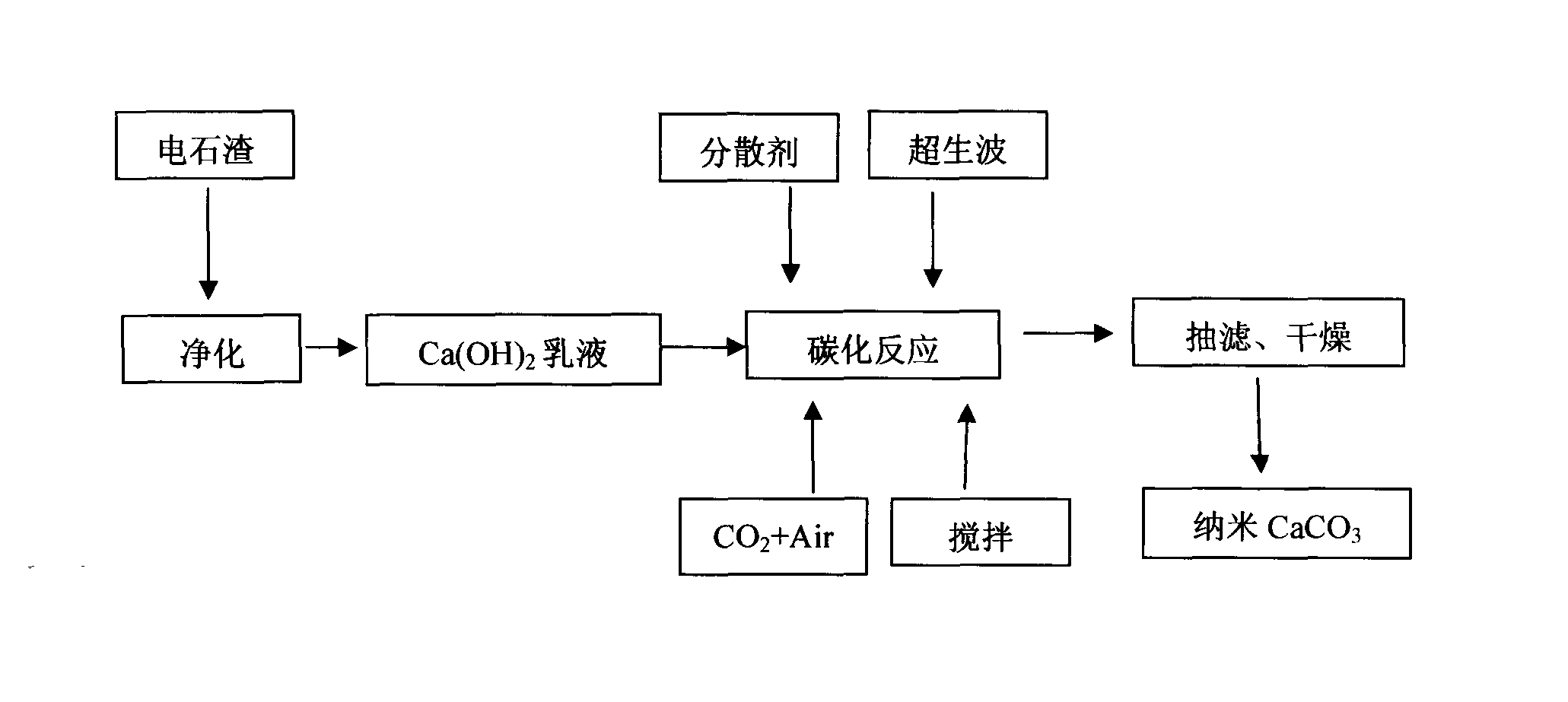

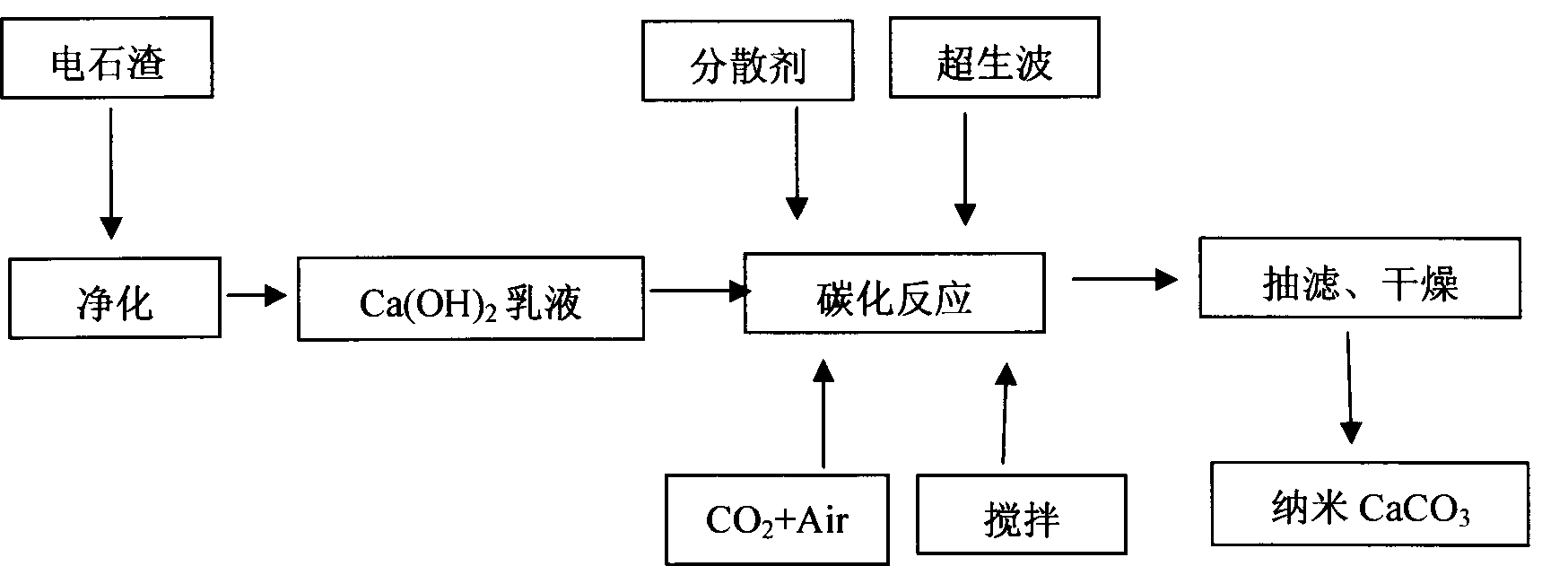

[0011] Carbide slag is purified to generate Ca(OH) 2 emulsion, then add dispersant, CO 2 And air Air, after ultrasonic irradiation, and then stir evenly, after suction filtration and drying to generate nano CaCO 3 .

[0012] The present invention will be further described below in combination with specific embodiments.

[0013] Wash the industrial waste calcium carbide slag several times with clean water until the sewage becomes clear, pass through a coarse sieve to remove some mechanical impurities, dry at 105°C for 24 hours, cool, crush, and grind the calcium carbide slag to a particle size of 106-250 μm. Calcined at 900°C for 3 hours, cooled to obtain purified carbide slag, weighed a certain amount of purified carbide slag with an electronic analytical balance, and heated the oil bath to 80°C in parts by weight of carbide slag:distilled water=1:10 Keep the temperature constant, put it into a 1000mL beaker filled with distilled water, and then put it into a magnet. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com