Patents

Literature

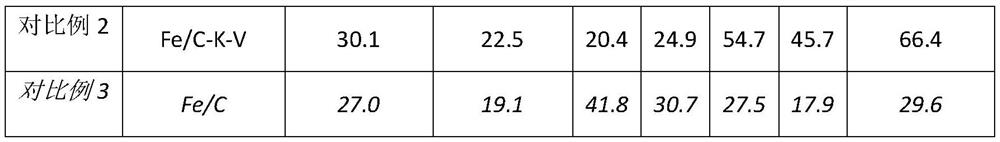

36results about How to "Regulatory selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

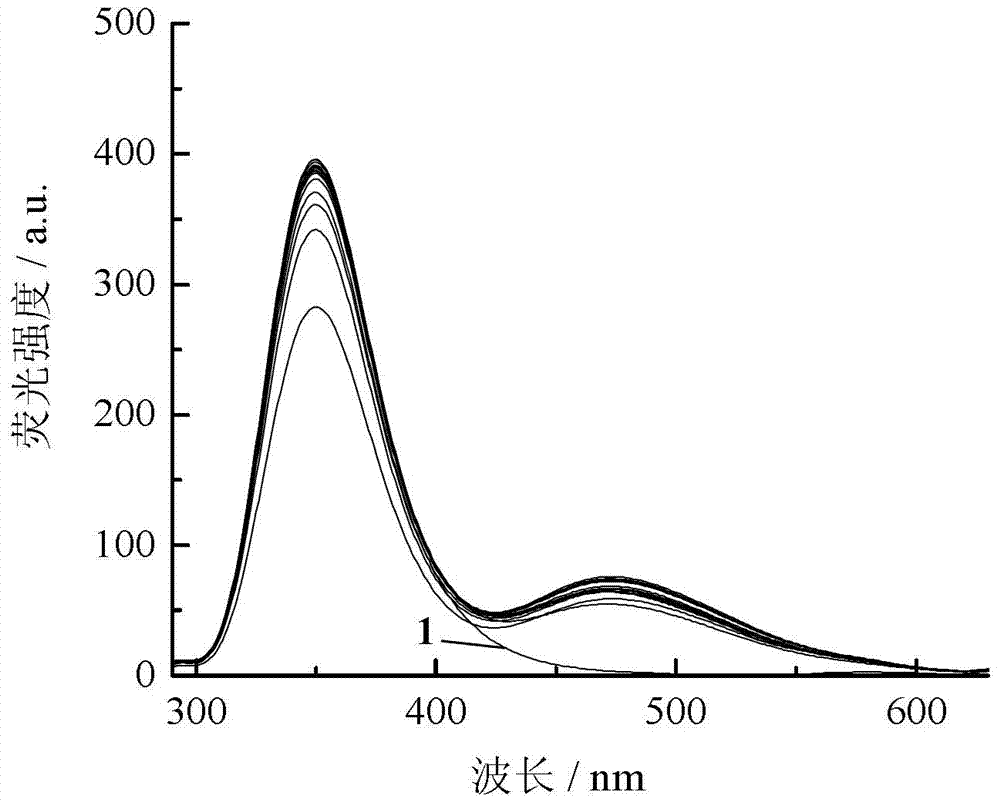

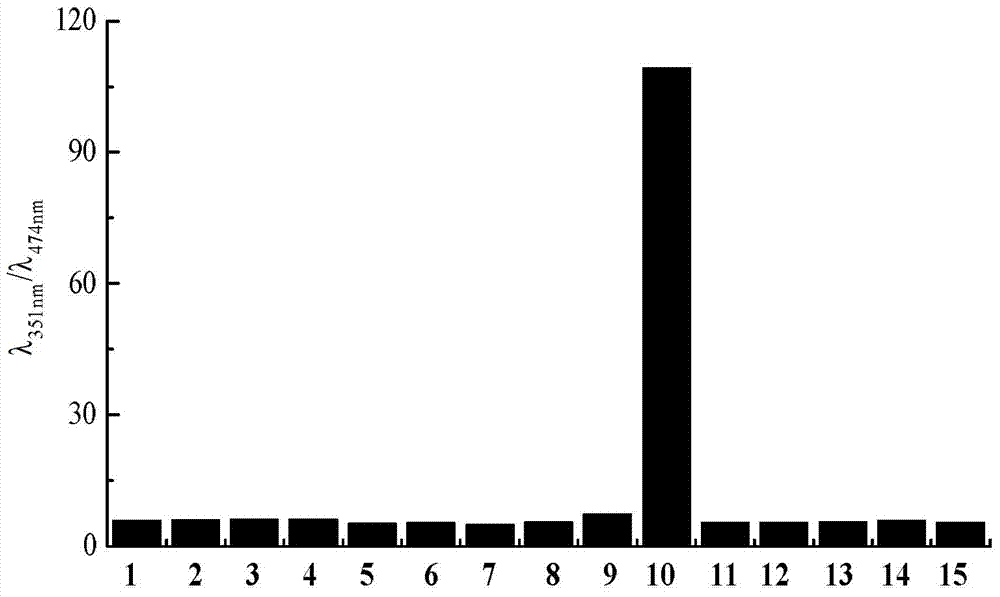

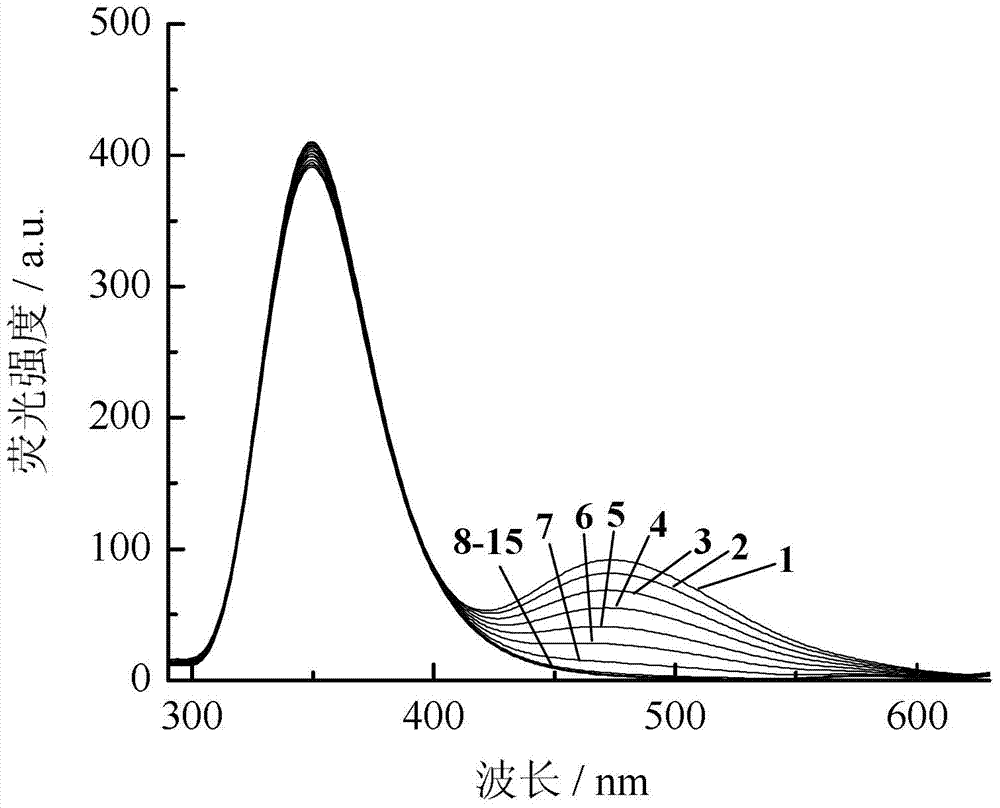

Dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer and preparation method thereof

InactiveCN103342698AHigh selectivityHigh sensitivityOrganic chemistryFluorescence/phosphorescenceImage detectionFluorophore

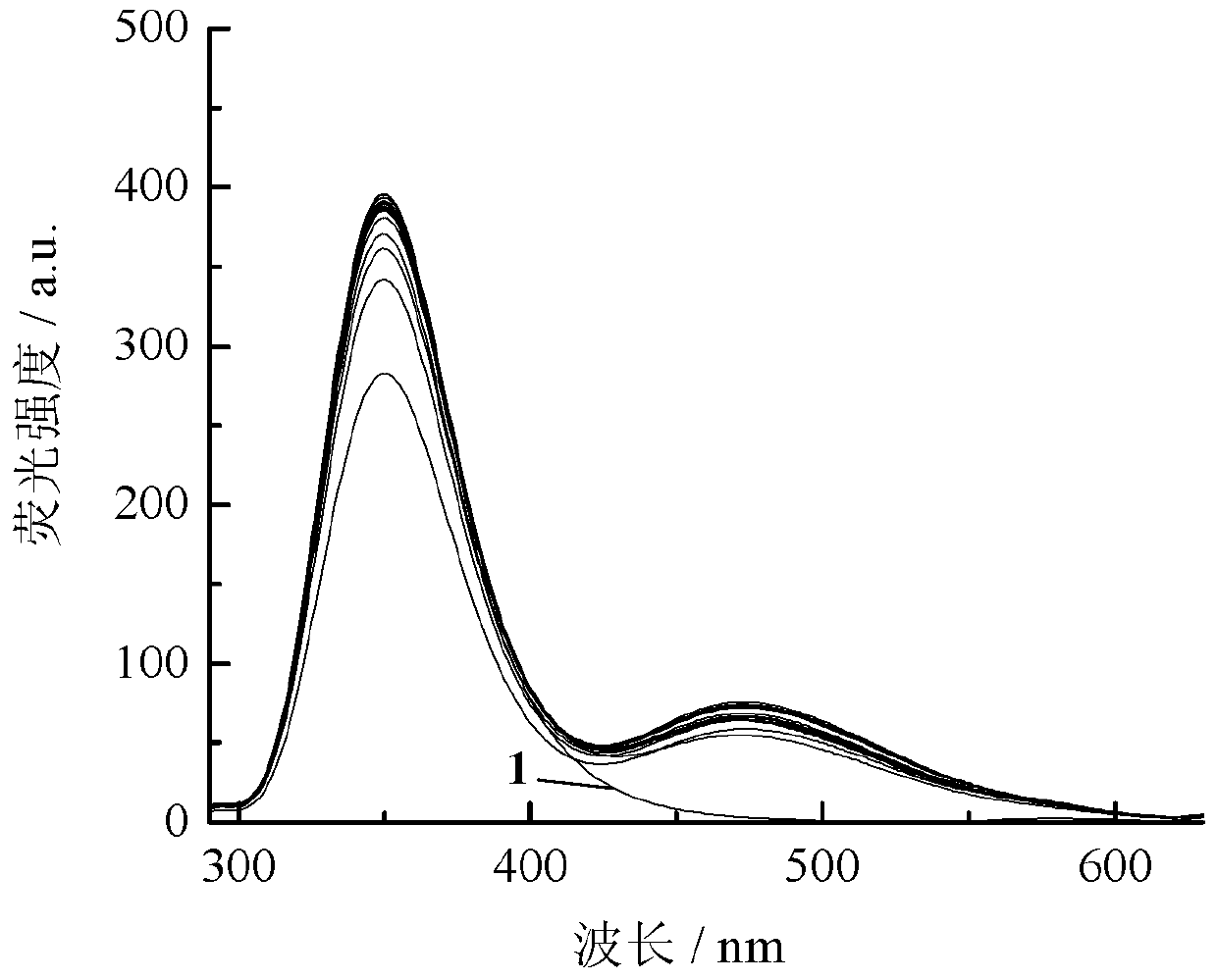

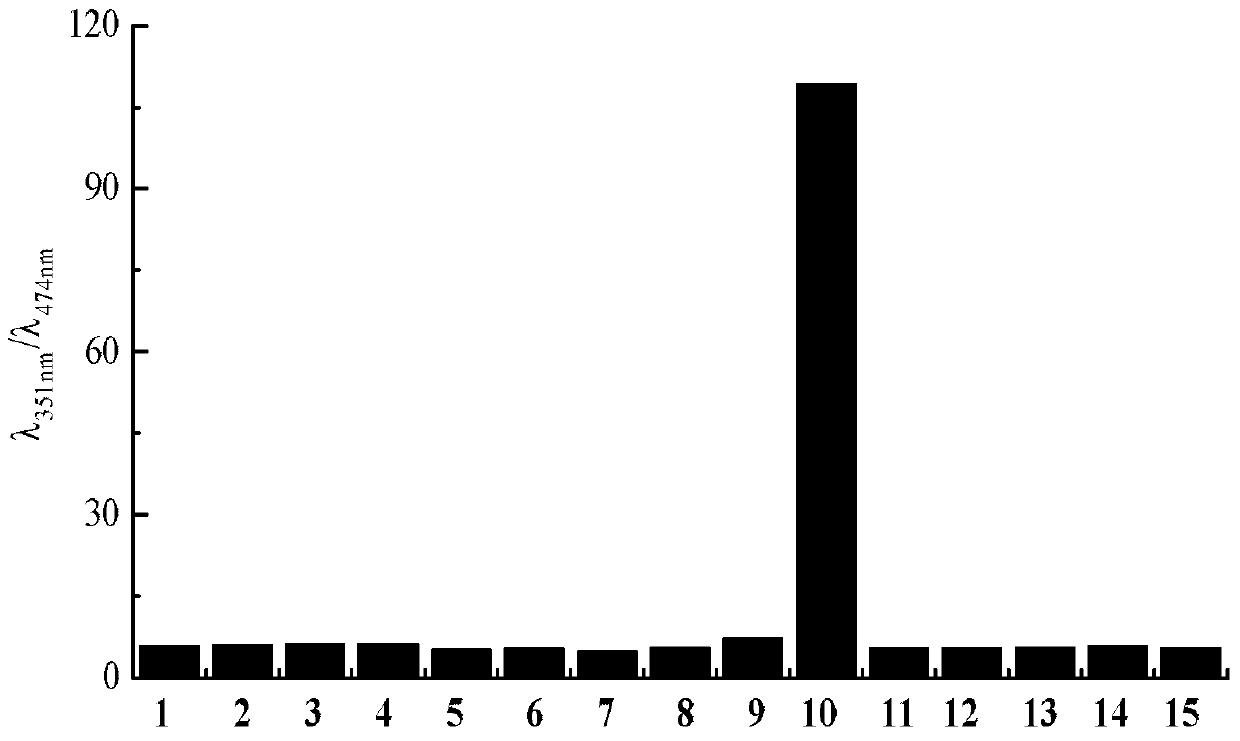

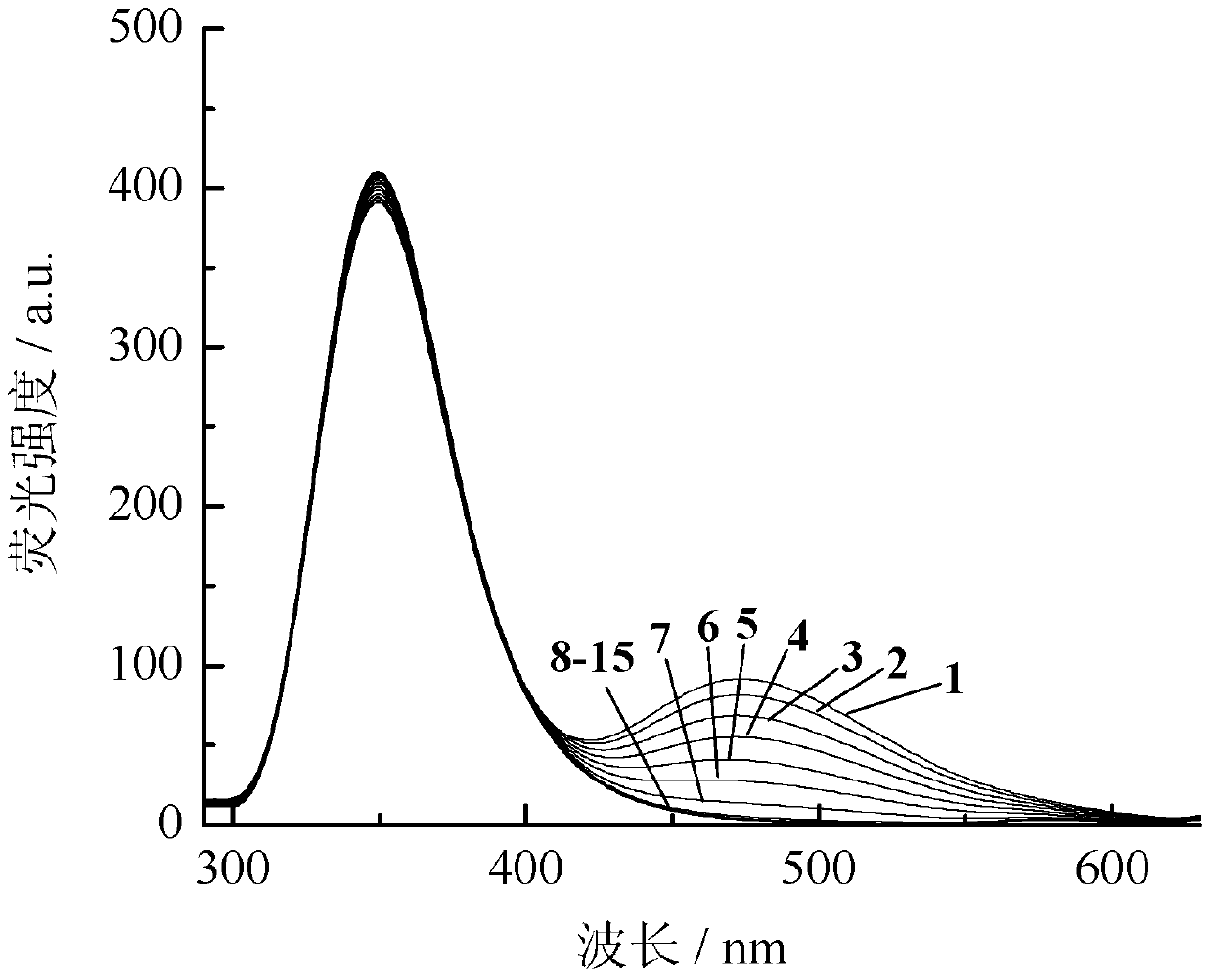

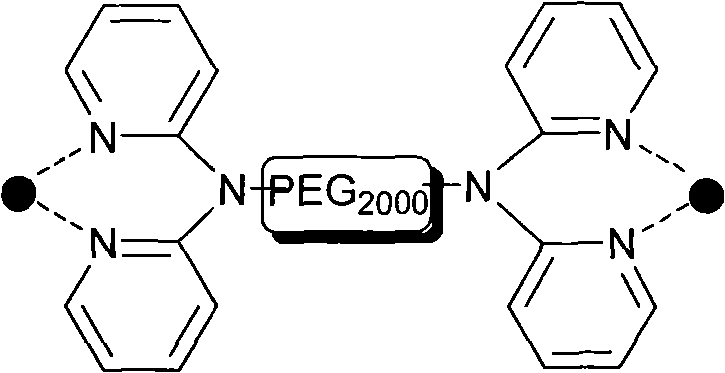

The invention discloses application of dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer, and relates to application of the dual-fluorophore ratio fluorescence molecular probe. The dual-fluorophore ratio fluorescence molecular probe disclosed by the invention is designed for solving the technical problems that due to energy loss caused by energy transfer between double fluorophores when the existing dual-fluorophore ratio fluorescence molecular probes are excited, the probes are poor in fluorescence, and not high in metal ion selectivity and sensitivity. The dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer is used for identifying fluorescence peak quenching of Cu2+, Cu2+ to the dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer at the position of 474nm, while the fluorescence peak strength at the wavelength of 351nm basically remains unchanged. The dual-fluorophore ratio fluorescence molecular probe disclosed by the invention can be applied to the fluorescence imaging detection of metal ions in biological tissue and cell microenvironments.

Owner:QIQIHAR UNIVERSITY

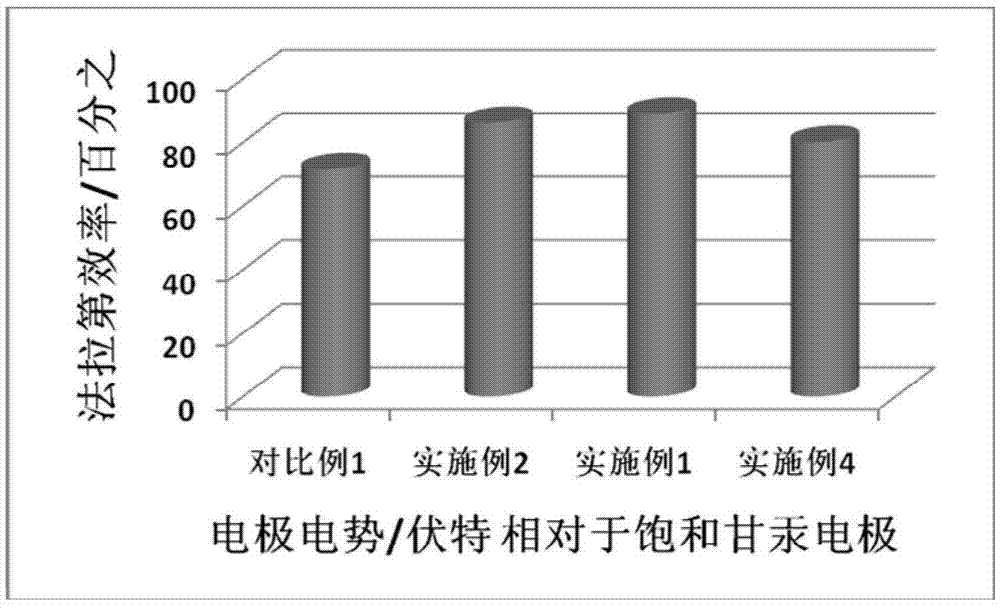

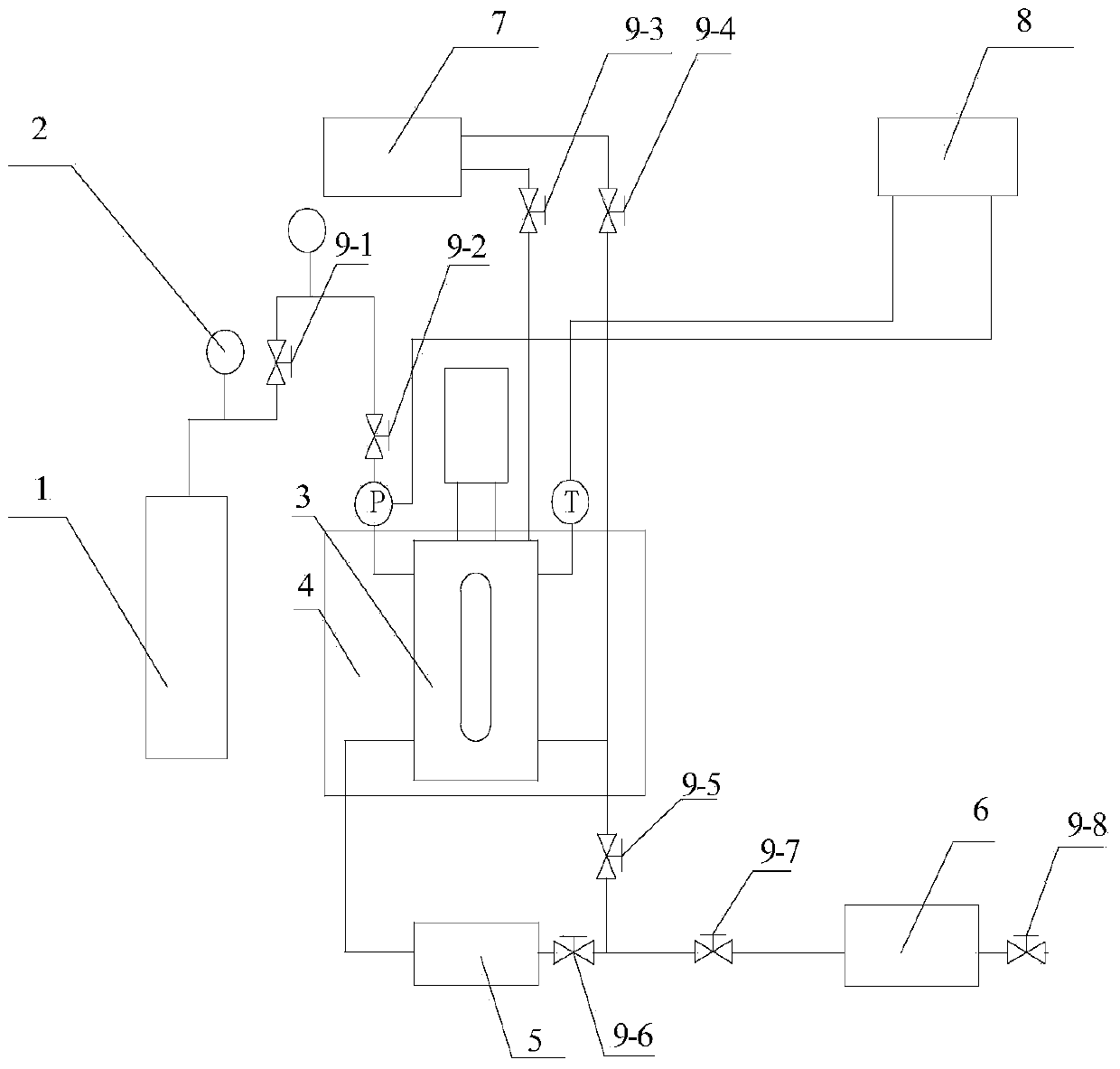

Gas diffusion electrode used for electrochemical reduction of carbon dioxide and preparation method and application of gas diffusion electrode

ActiveCN106876722AAvoid affecting performanceIncreased reaction current densityCell electrodesChemical reactionElectrochemical reduction of carbon dioxide

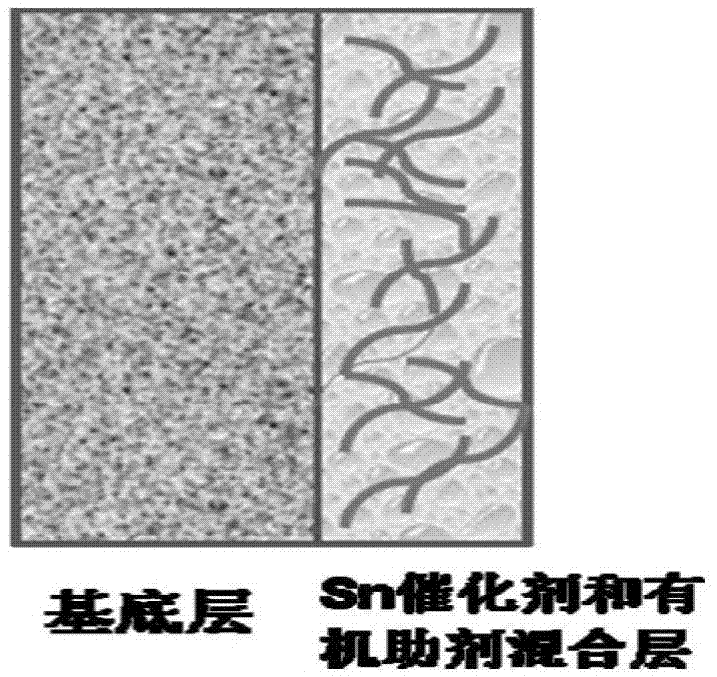

The invention relates to a gas diffusion electrode used for electrochemical reduction of carbon dioxide and a preparation method and an application of the gas diffusion electrode. The electrode comprises a base layer, and a Sn catalyst and an organic accessory ingredient mixing layer attached on the base layer; the molar ratio of the Sn catalyst to the organic accessory ingredient is 100:1 to 30:1; and the loading amount of the Sn catalyst in the electrode is 0.1-5mg / cm<-2>. In the electrochemical reduction of carbon dioxide, the base layer plays the effects of a supporting body, electric conduction, and forming liquid and gas transmission channels; the Sn catalyst catalyzes reduction of carbon dioxide while the organic accessory ingredient can stabilize an intermediate reactant CO<2>.-, so that the concentration of CO<2> is improved, overpotential in electrochemical reduction of carbon dioxide is lowered, and current density and efficiency are improved; and in addition, the accessory ingredient in the electrode also anchors the Sn catalyst on the surface of the carbon base, so that the electrode has quite high stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

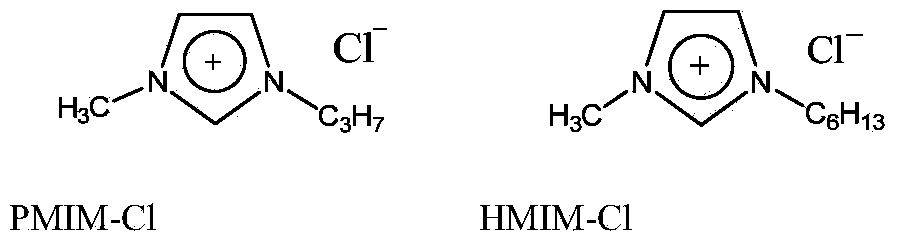

Ionic hydrate inhibitor

InactiveCN103627378AInhibition of nucleationGrowth inhibitionPipeline systemsDrilling compositionChlorideFood consumption

The invention relates to an ionic hydrate inhibitor which is prepared by dissolving an ionic liquid in a water solution, wherein the mass concentration of the ionic liquid is 0.005-0.01%; the ionic liquid is composed of imidazole cations and chloride ions; and the solvent is water. The hydrate inhibitor has the advantages of better inhibitory effect, low consumption and small influence by degree of supercooling, is easy to recycle and is more environment-friendly.

Owner:CHANGZHOU UNIV

Nickel-nitrogen co-doped porous carbon material loaded with cobalt nanoparticles, and preparation method and application thereof

ActiveCN110721724AImprove bindingImprove stabilityMaterial nanotechnologyCatalyst activation/preparationPtru catalystElectrolysis

The invention discloses a nickel-nitrogen co-doped porous carbon material loaded with cobalt nanoparticles, and a preparation method and application thereof, and relates to a preparation method of a porous carbon material. The invention aims to solve the problems that conventional methods for preparing porous carbon are tedious in operation steps, time-consuming, high in overpotential, high in equipment requirements and harmful to the environment, limit the preparation of the porous carbon material, are not suitable for large-scale production and cannot meet the new application requirements inthe fields of energy, catalysis, biology and the like. The nickel-nitrogen co-doped porous carbon material loaded with cobalt nanoparticles grows on foamed nickel in situ. The preparation method comprises the following steps: 1, pretreating the foamed nickel; 2, growing a cobalt-based zeolite imidazate framework structure material nanosheet array on the foamed nickel in situ; and 3, carrying outcalcining. The c nickel-nitrogen co-doped porous carbon material loaded with cobalt nanoparticles is used as a catalyst for hydrogen production through water electrolysis in the field of energy. The nickel-nitrogen co-doped porous carbon material loaded with cobalt nanoparticles can be obtained by using the method.

Owner:哈尔滨凯美斯科技有限公司

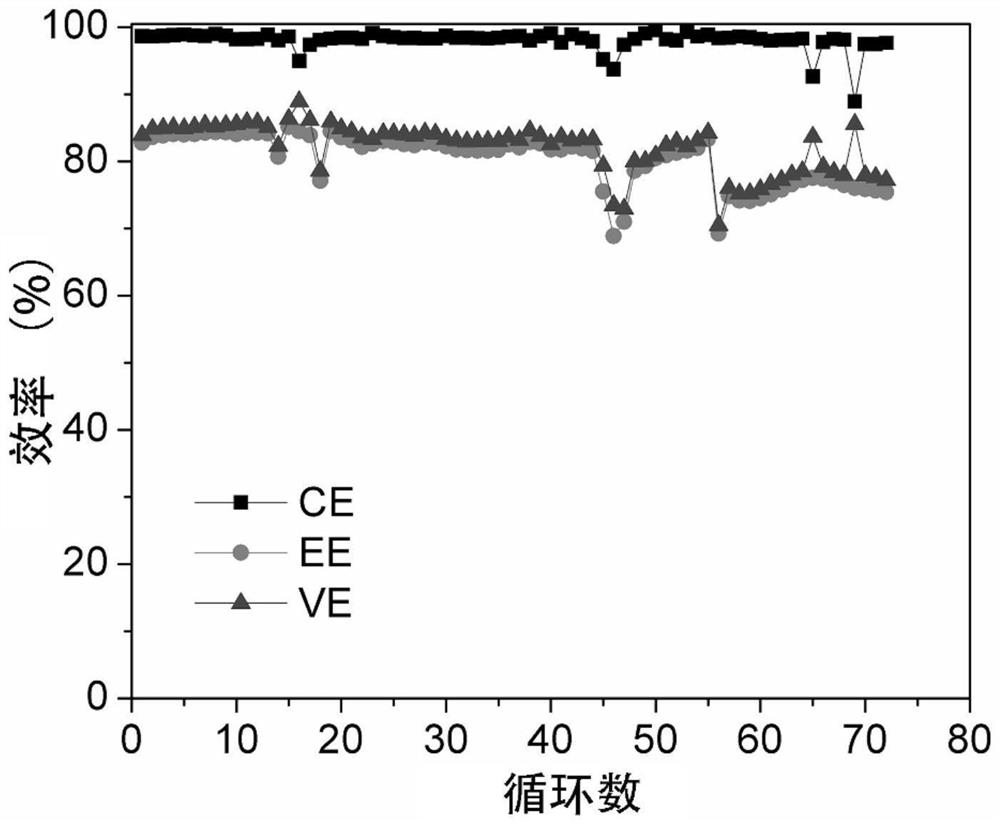

Self-assembled layers composite membrane and preparation and application thereof

ActiveCN104143613AHigh selectivityAchieving pore size distribution controlSynthetic resin layered productsCell component detailsPolymer resinPorous membrane

The invention relates to a self-assembled layers composite membrane. According to preparation of the composite membrane, a porous membrane prepared by using one or more than two of organic polymer resins or sulfonated organic polymer resins as raw materials is used as a matrix; the matrix undergoes swelling by the use of a swelling agent; and the cationic and anion polymer resins are self-assembled through electrostatic attraction on the surface of the matrix and are successively alternately arranged so as to prepare the self-assembled layers composite membrane. The number of the self-assembled layers is 1-60, and each self-assembled layer is composed of a single-layer cationic resin assembly layer or a single-layer anion resin assembly layer. In comparison with an original porous membrane, the composite membrane has advantages as follows: on the basis of maintaining ionic conductivity of the porous membrane, selectivity of hydrogen ion and vanadium ion is raised; and a battery assembled by the use of the composite membrane has higher efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

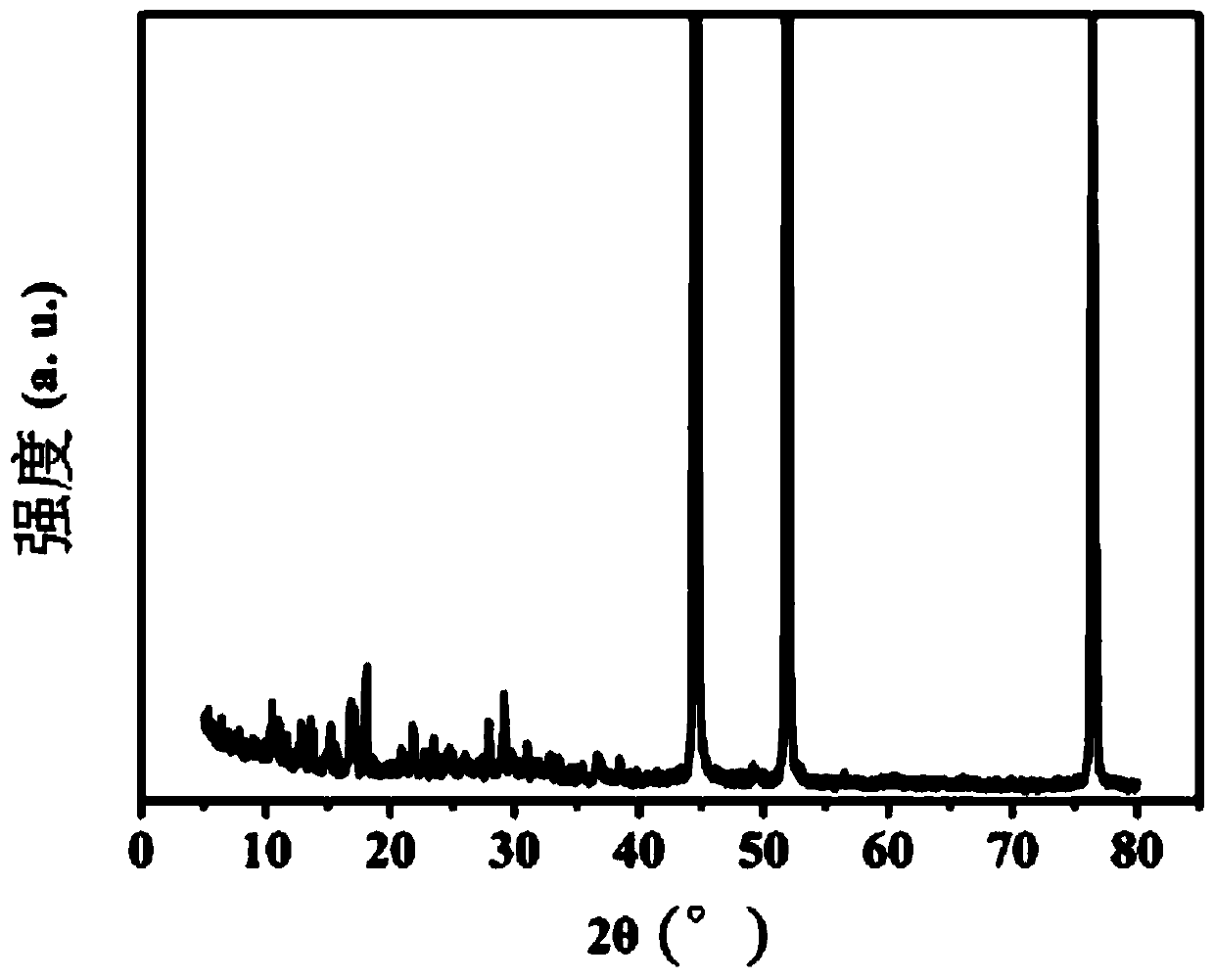

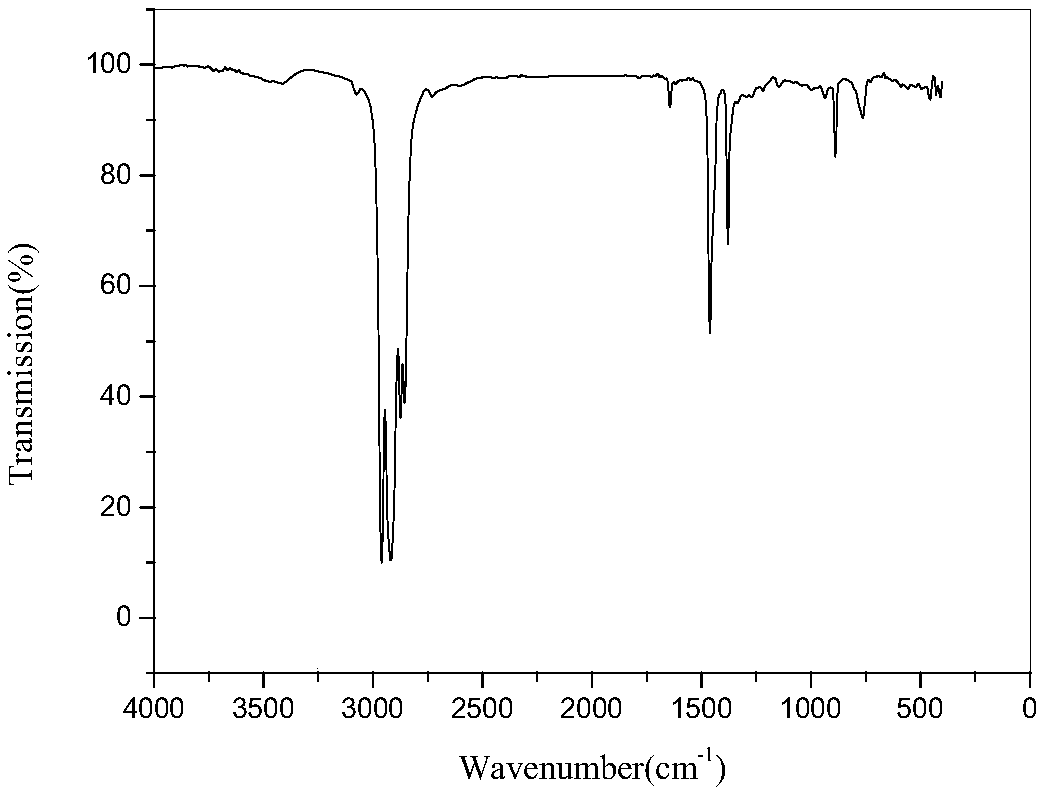

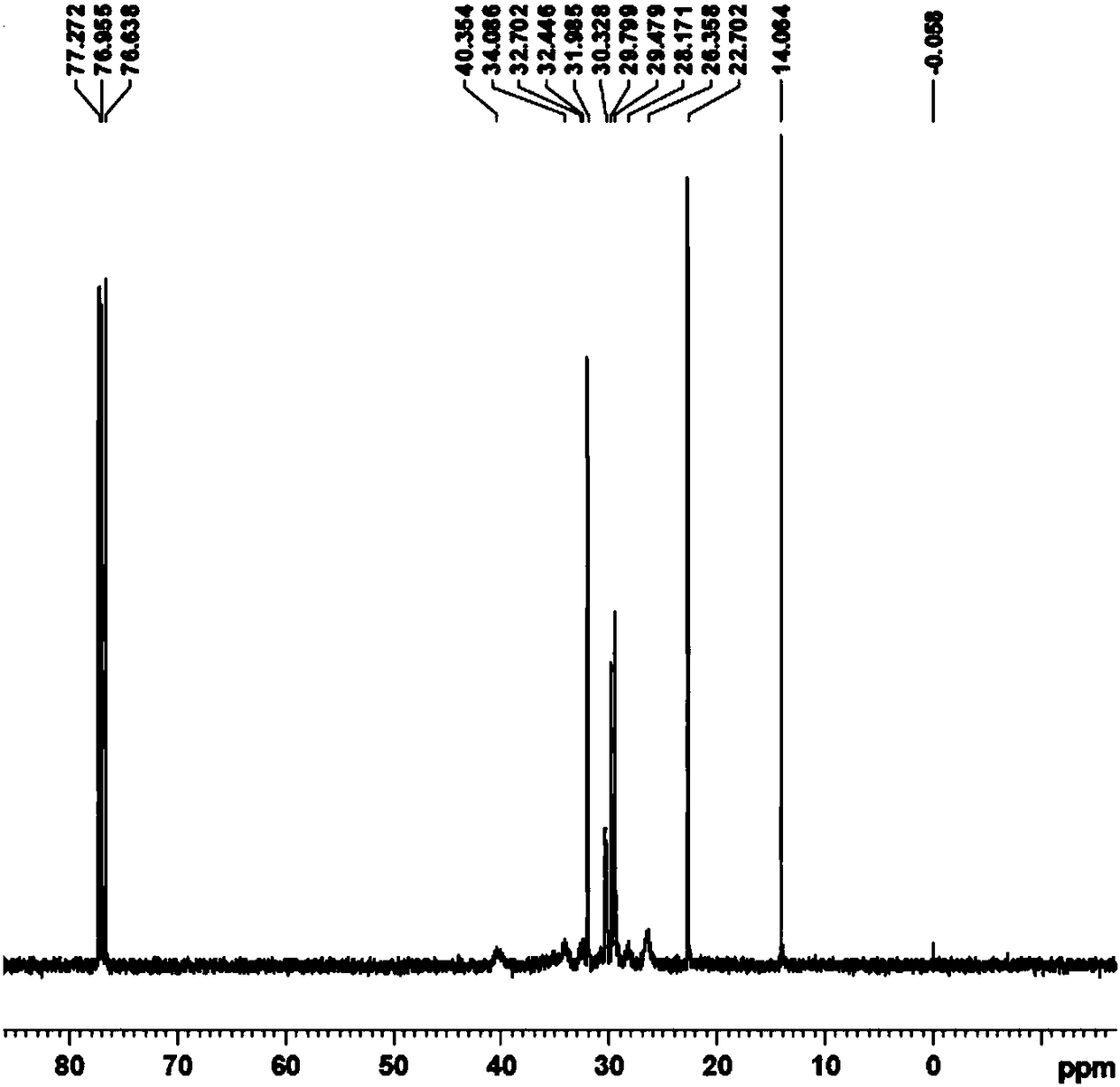

Method for preparing lubricating oil base oil with high viscosity index

InactiveCN108929186AAvoid easy cloggingHigh catalytic efficiencyCatalystsHydrocarbon preparation catalystsBoron trifluorideReaction temperature

The invention discloses a method for preparing lubricating oil base oil with a high viscosity index. The invention relates to a method for synthesizing poly alpha-olefin lubricating oil base oil fromalpha-olefin as a raw material by using a metallocene catalyst through a blending polymerization process. The method comprises the following steps: with C10 olefin as a raw material, adding the metallocene catalyst and a cocatalyst in a reactor, carrying out heating for carrying out a reaction, controlling the reaction temperature and time, adding a boron trifluoride-isopropanol complex after thereaction is finished, and continuing carrying out a reaction on the unreacted 1-decene monomer to obtain the poly alpha-olefin lubricating oil base oil. The method can be used to prepare the lubricating oil base oil with high viscosity and ultrahigh viscosity index, wherein the viscosity is 125 at a temperature of 100 DEG C, the viscosity index is 238, the viscosity-temperature property is excellent, and the low-temperature fluidity is high.

Owner:PETROCHINA CO LTD

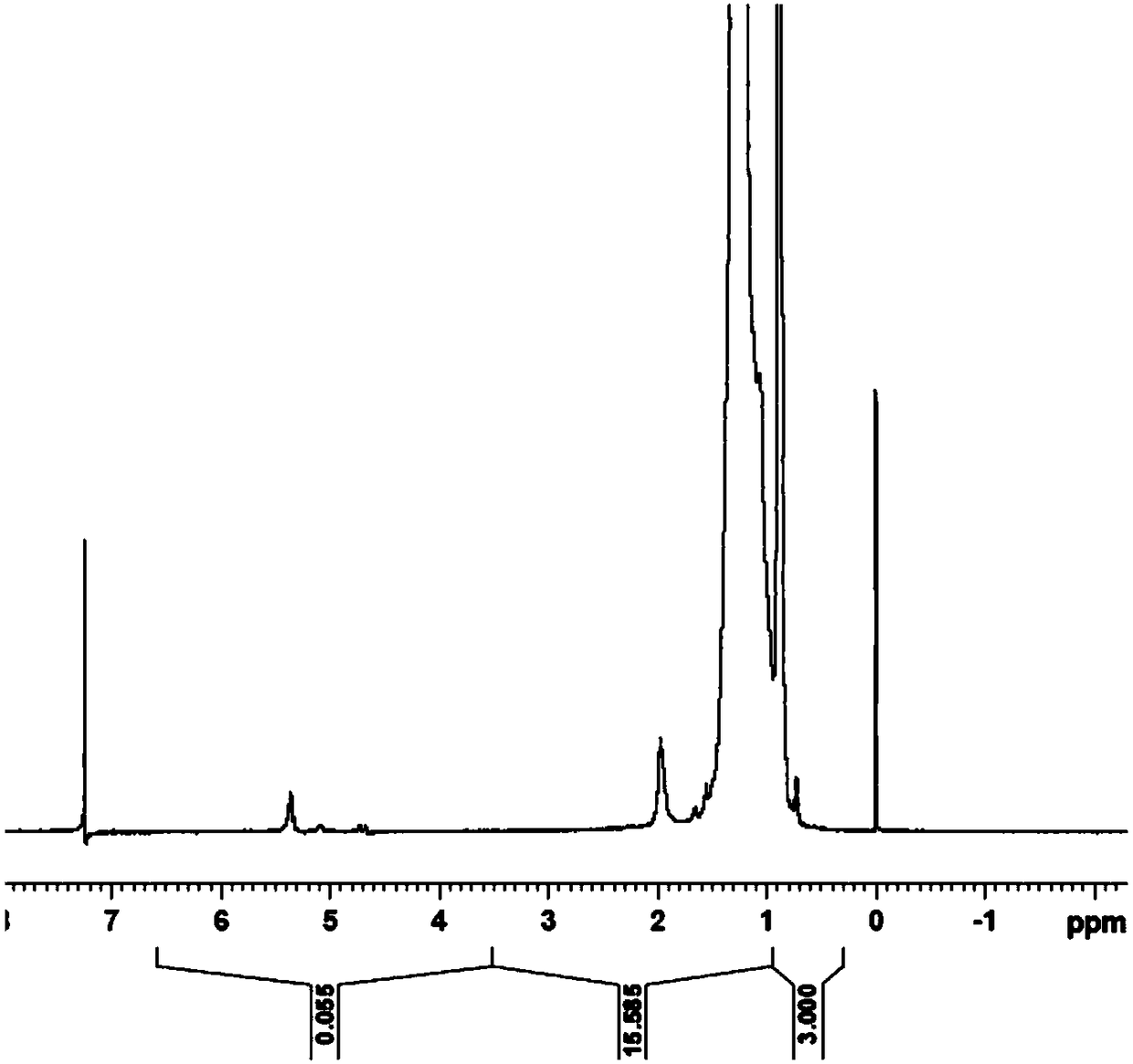

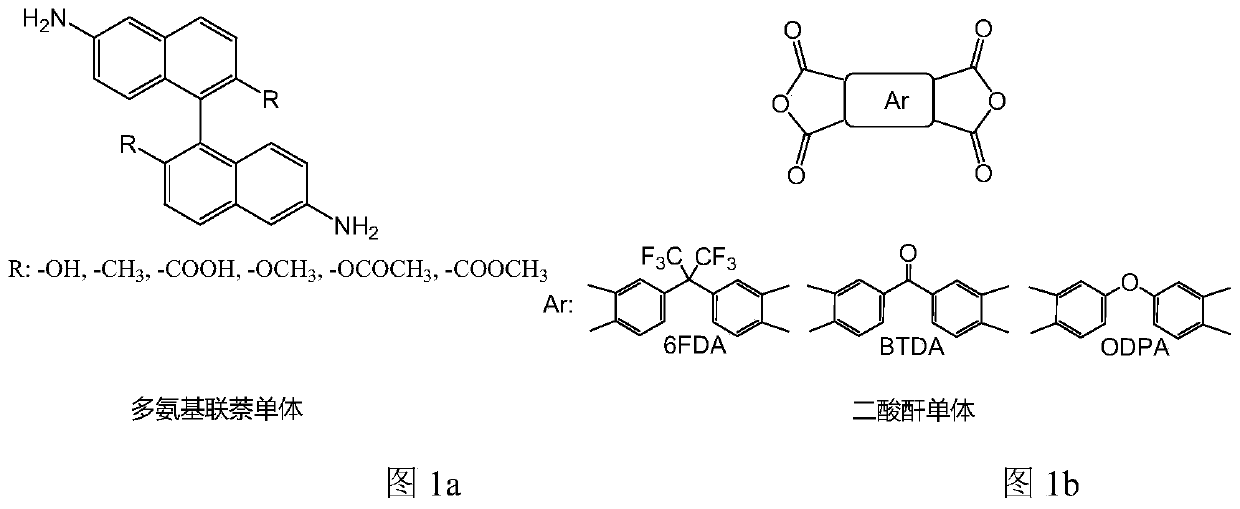

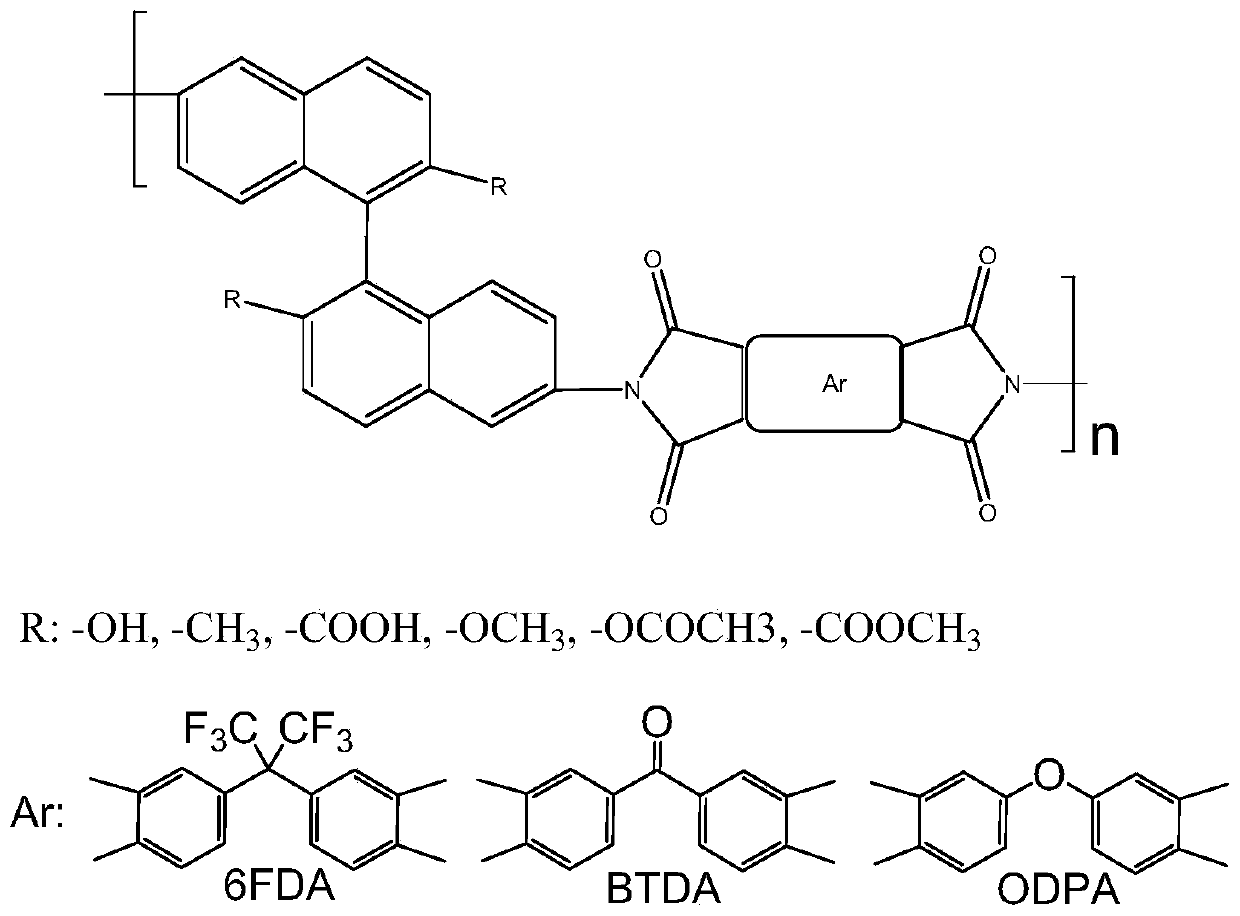

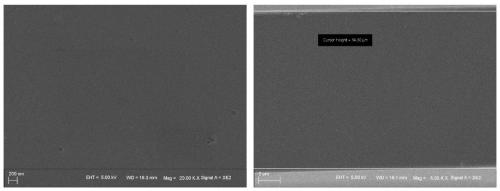

Method for preparing polyimide film with dinaphthalene structure and application

ActiveCN109821426ARegulatory selectivitySemi-permeable membranesDispersed particle filtrationHeat resistanceNitrogen

The invention discloses a method for preparing a polyimide film with a dinaphthalene structure and application. The polyimide film is used for O2 / N2 and CO2 / N2 separation, and the polyimide resin filmis synthesized by dianhydride and naphthidine monomers with different lateral functional groups. The polyimide film has advantages of high gas permeability and high selectivity; under operating pressure of 0.8MPa, O2 transmission coefficient exceeds 300barrer, and CO2 transmission coefficient exceeds 800barrer; nitrogen transmission coefficient is lower than 25barrer; O2 / N2 selectivity coefficient exceeds 13, and CO2 / N2 selectivity coefficient exceeds 68. The polyimide film is excellent in heat resistance (exceeding 50 DEG C) and mechanical performance.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

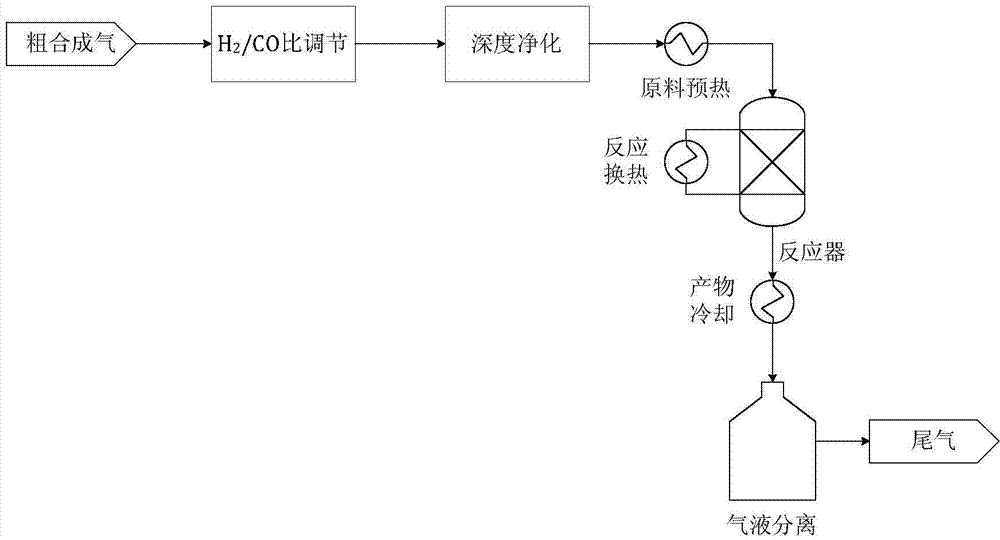

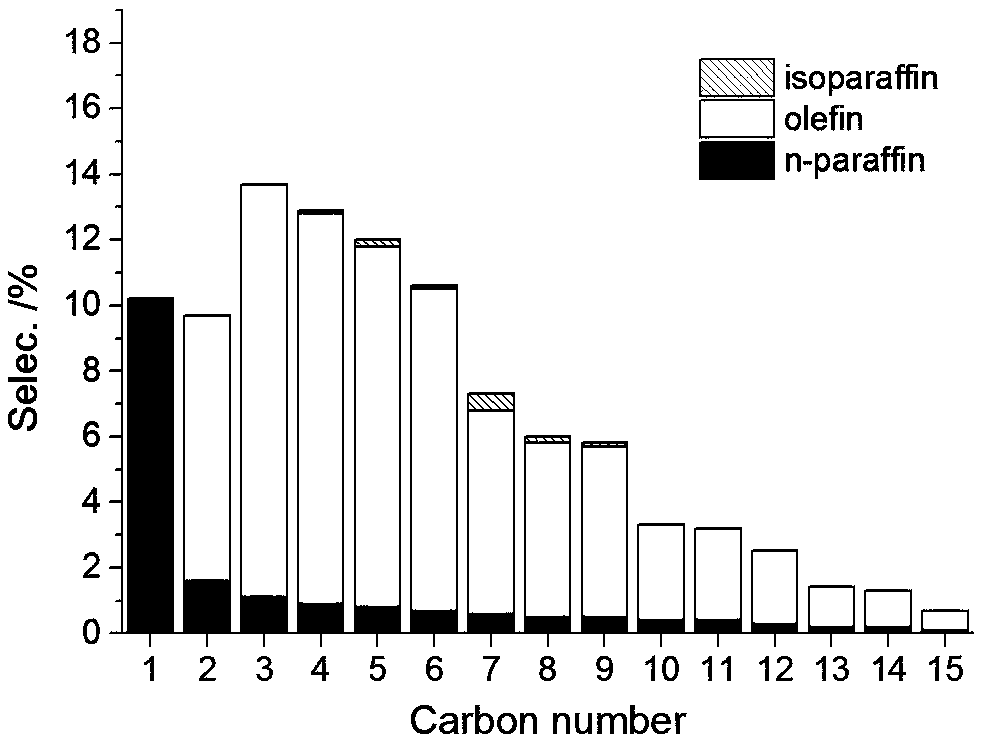

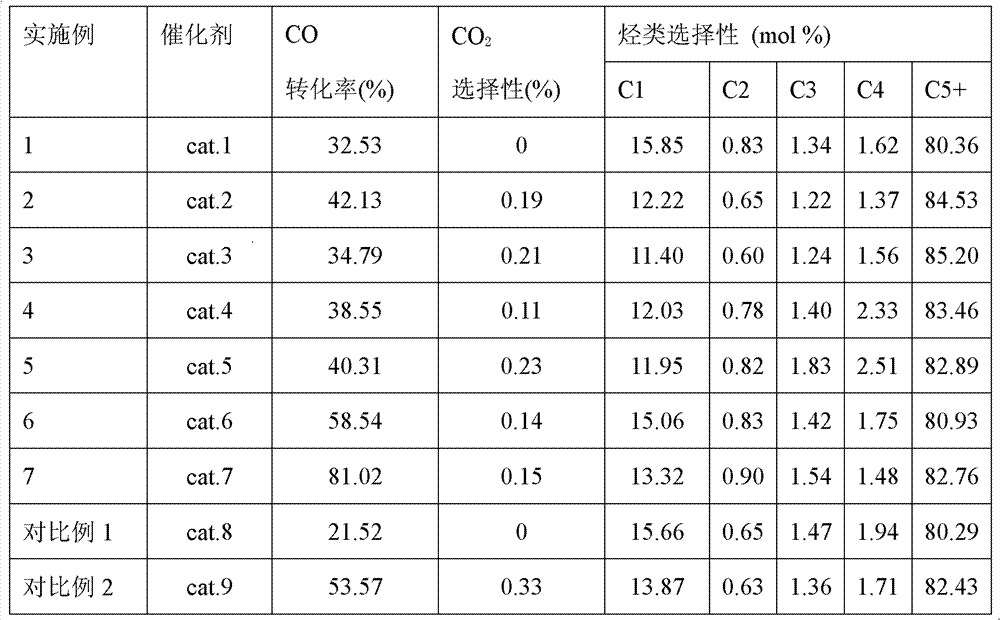

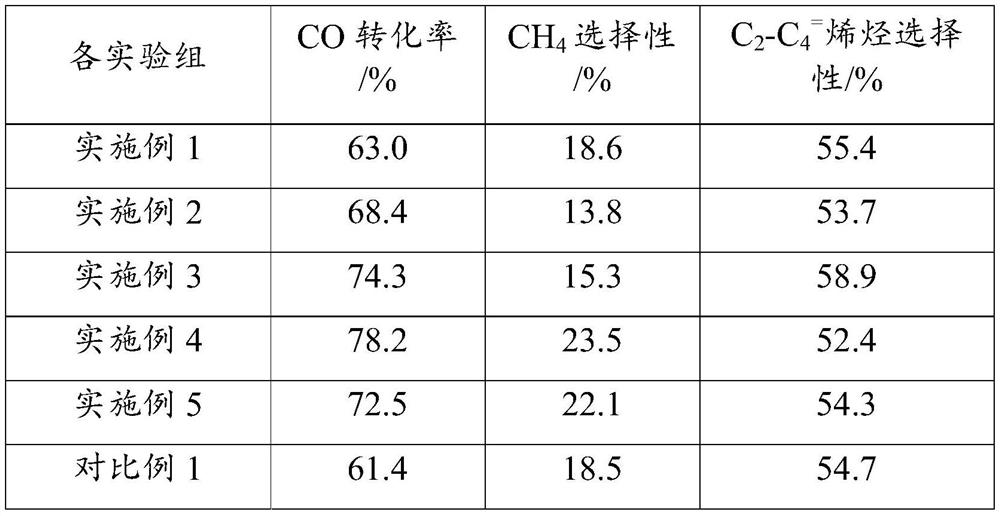

Catalyst and process for directly preparing low-carbon olefin and co-production of alpha-olefin from synthetic gas

InactiveCN104492452AWide variety of sourcesReduce dependenceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasEconomic benefits

The invention provides a catalyst and the process for directly preparing low-carbon olefin and co-production of alpha-olefin from synthetic gas. The catalyst comprises the following components in percentage by weight: 5-50% of Fe, 0.5-50% of MnO, 0.5-30% of K2O and the balance of Al2O3. The process for directly preparing low-carbon olefin and co-production of alpha-olefin from synthetic gas comprises the steps of contacting and reacting the synthetic gas containing hydrogen and carbon monoxide to prepare low-carbon olefin and jointly producing alpha-olefin. By adopting the catalyst and the process disclosed by the invention, the selectivity of methane can be well regulated and controlled, the selectivity of low-carbon olefin and alpha-olefin is increased, the utilization rationalization of synthesis gas is achieved and the economic benefits are maximized.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

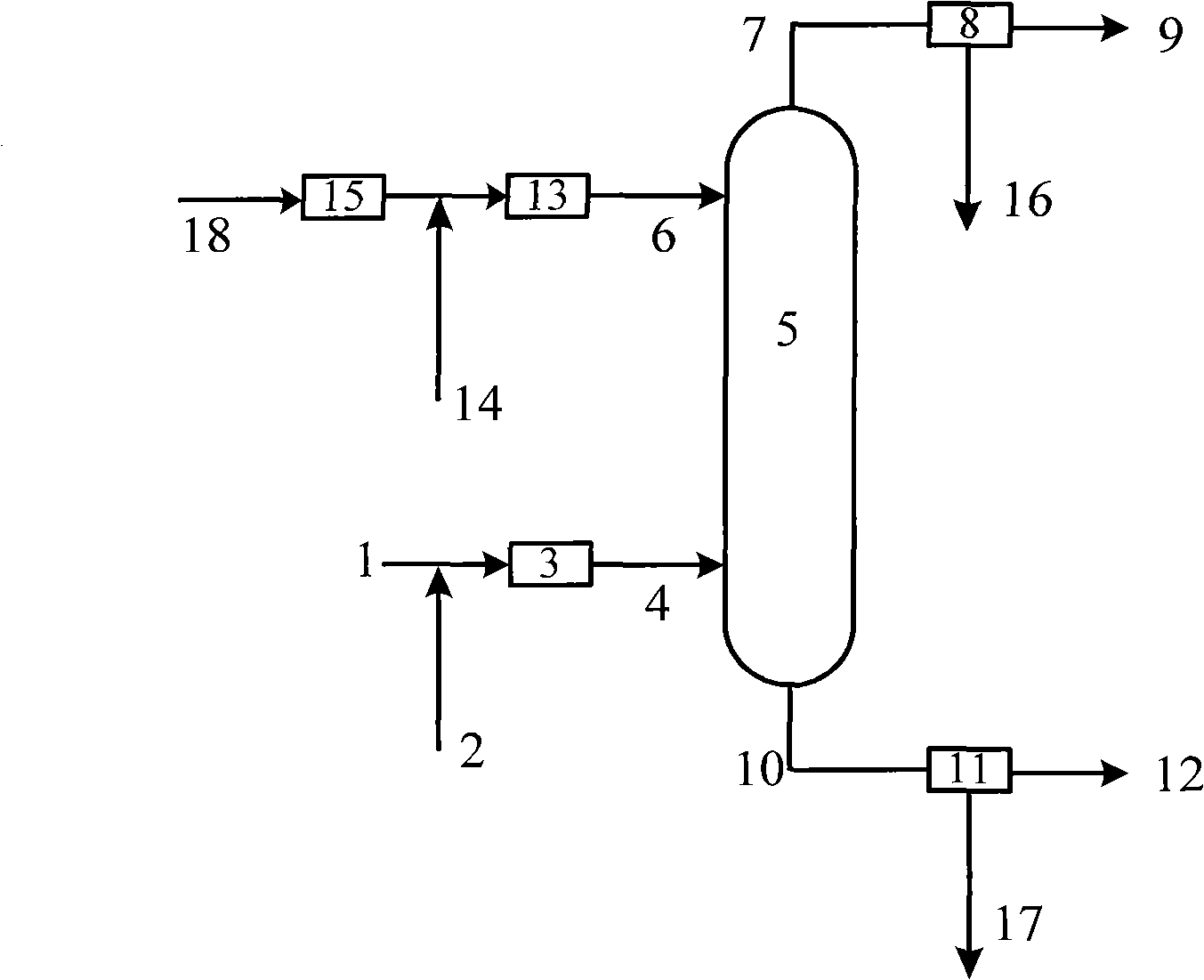

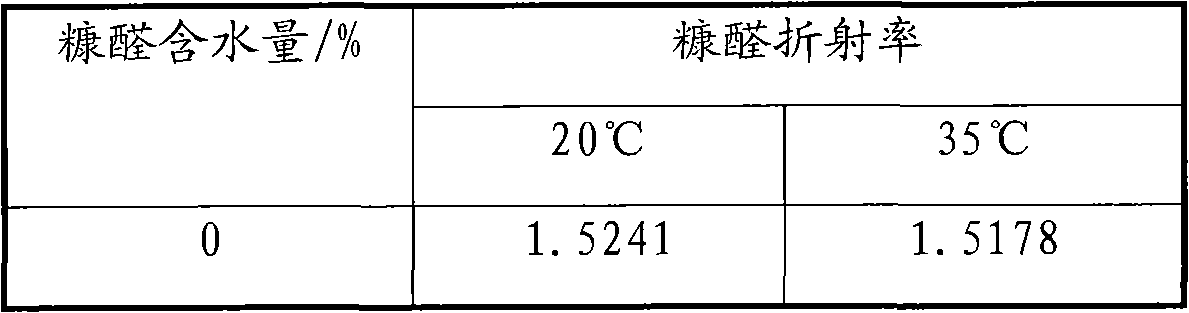

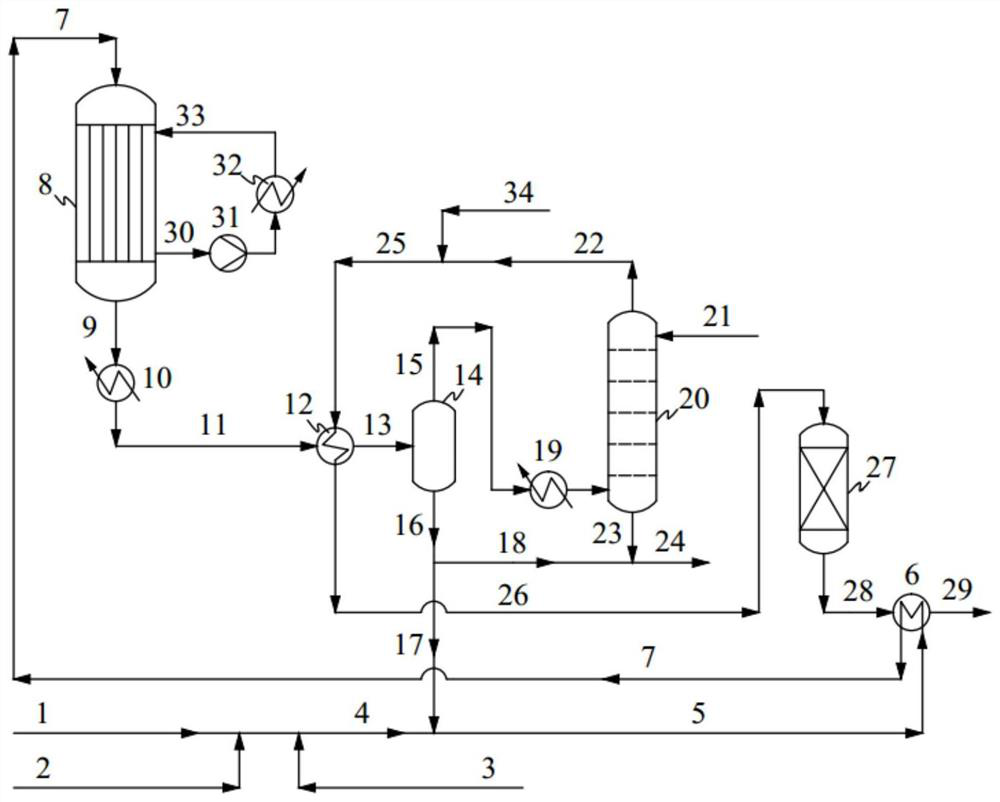

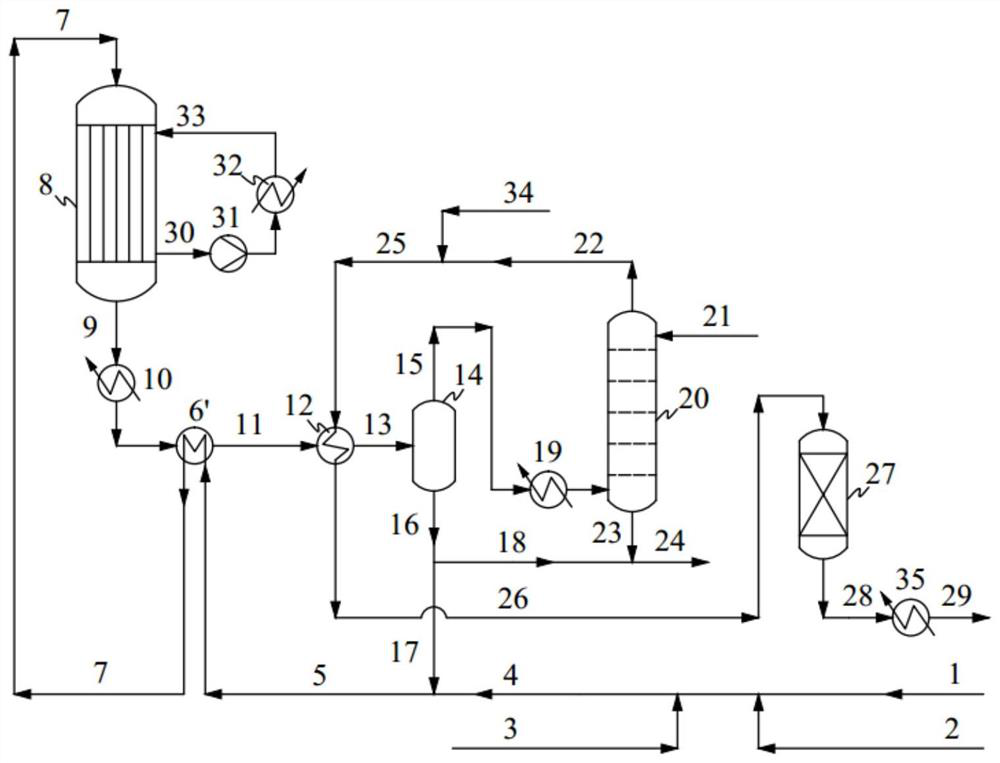

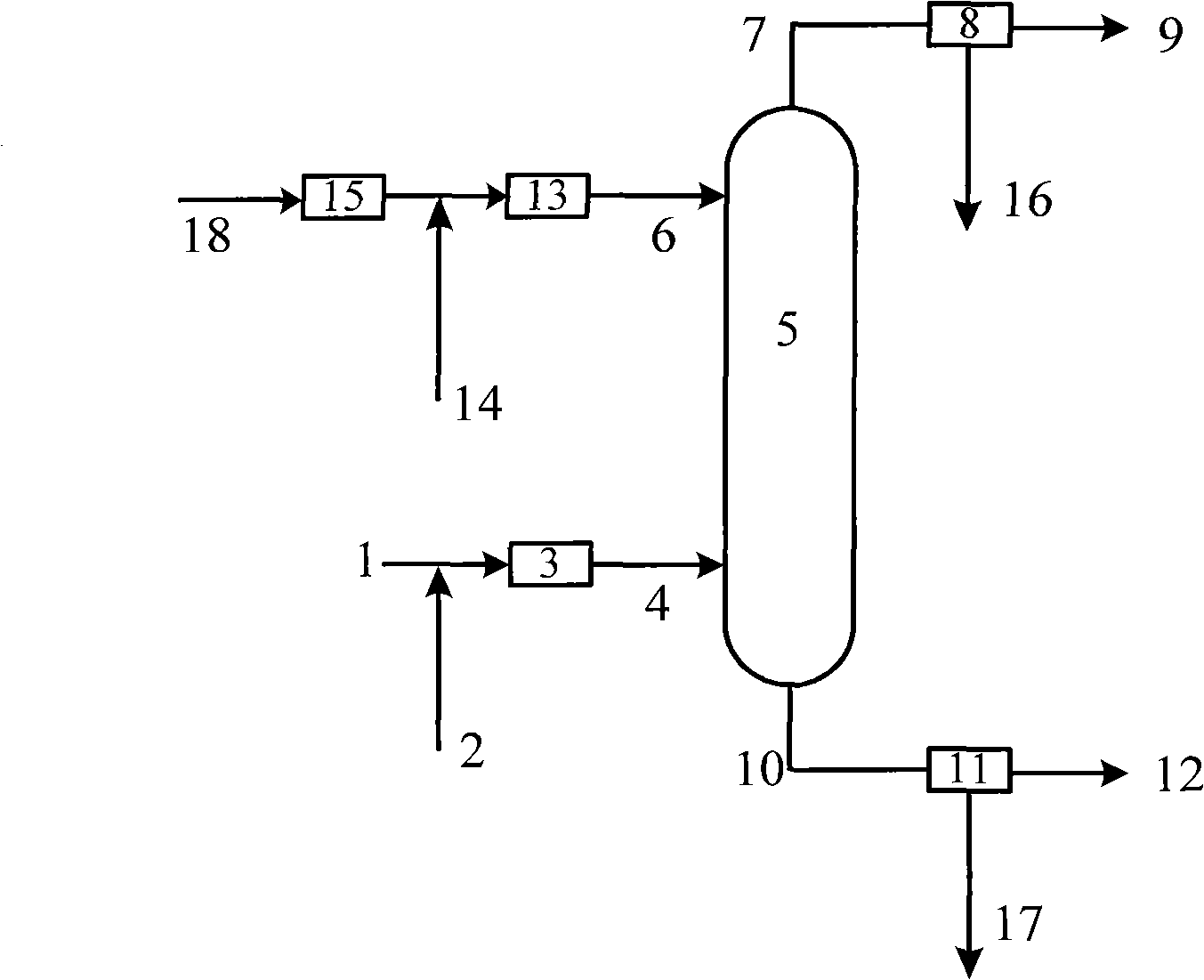

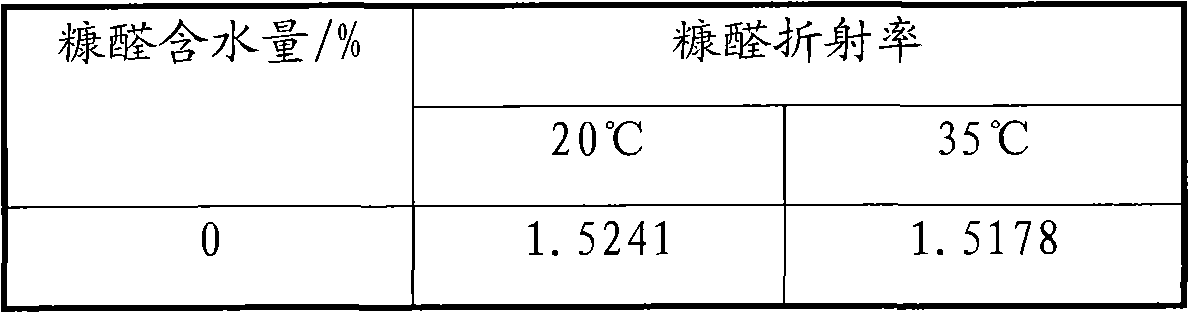

Control method and control device for moisture content of furfural in extraction of furfural and method for preparing aromatic rubber oil

ActiveCN102585886ARegulatory selectivityIncrease water contentHydrocarbon oils refining control/regulationCounter currentSolvent refining

The invention relates to a control method and a control device for the moisture content of furfural in the extraction of the furfural and a method for preparing aromatic rubber oil. The method for preparing the aromatic rubber oil comprises the following steps of: mixing a part of furfural from a furfural drying tower with raw oil and enabling the mixture to enter the lower part of an extracting tower; mixing the other part of furfural from the furfural drying tower with water and enabling the mixture to enter the upper part of the extracting tower; carrying out counter-current contact on the two parts of materials in the extracting tower; and separating raffinate from overhead raffinate. By adopting the control method provided by the invention, the moisture content of the furfural entering the upper part of the extracting tower is controlled between more than 0.5 weight percent and 10 weight percent; and the raw oil is solvent refining extract oil or dewaxed oil of the solvent refining extract oil. The aromatic rubber oil prepared by adopting the method has high yield, the prepared aromatic rubber oil satisfies the directive requirements of European Union 2005 / 69 / EC, and the mass percent of polycyclic aromatic hydrocarbon is less than 3 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

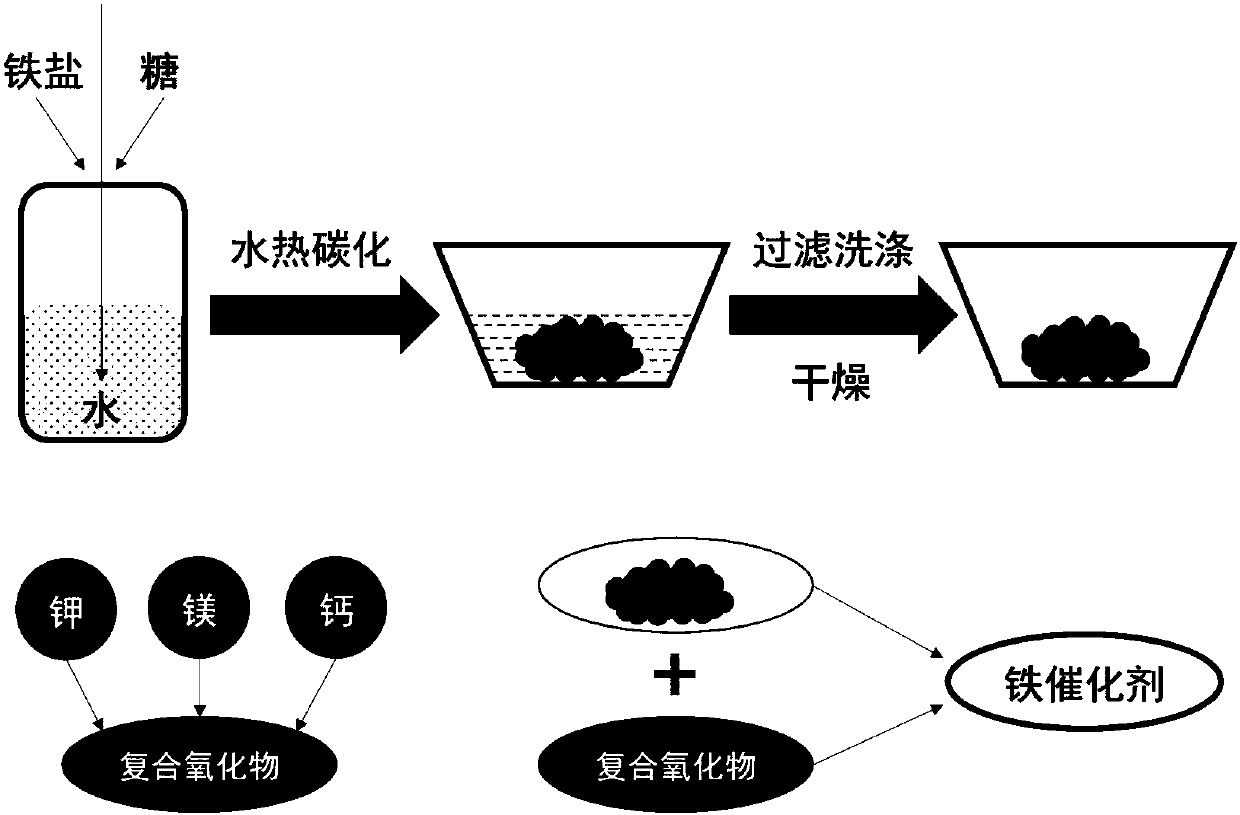

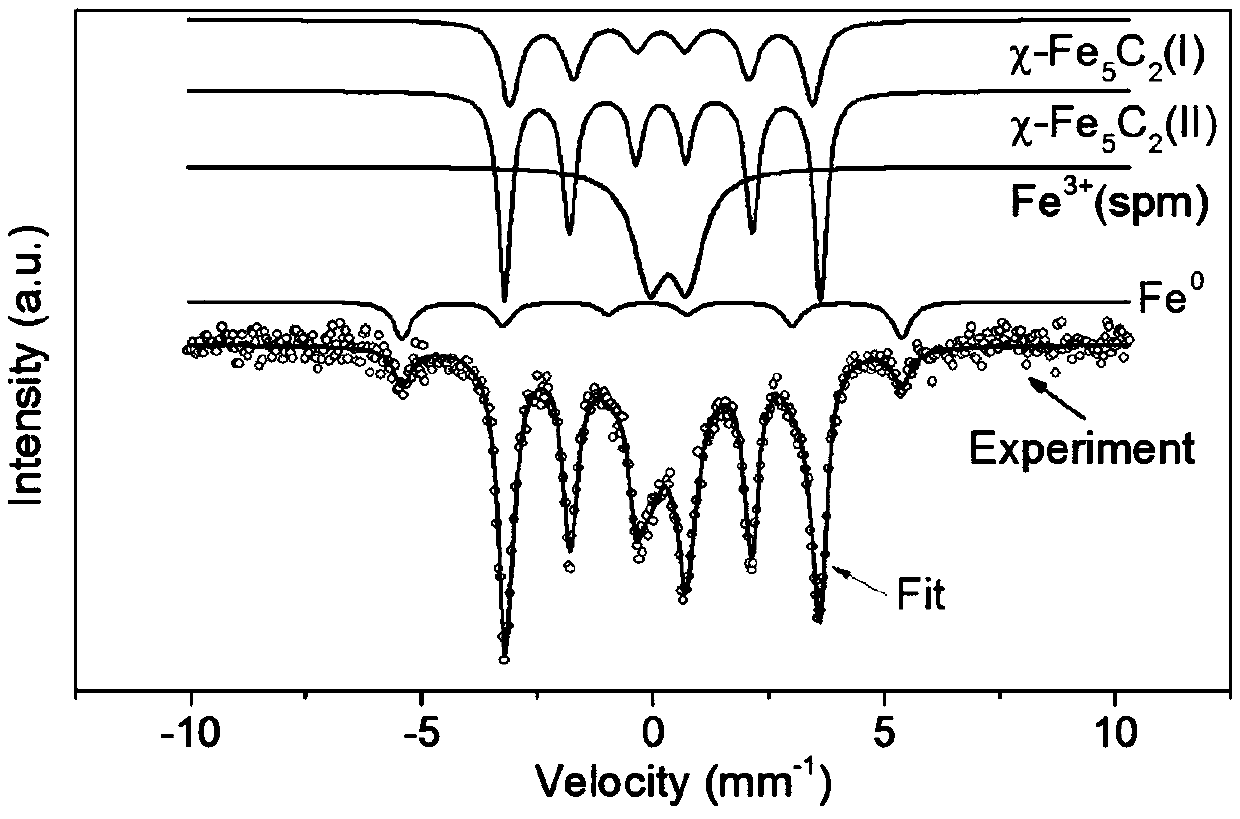

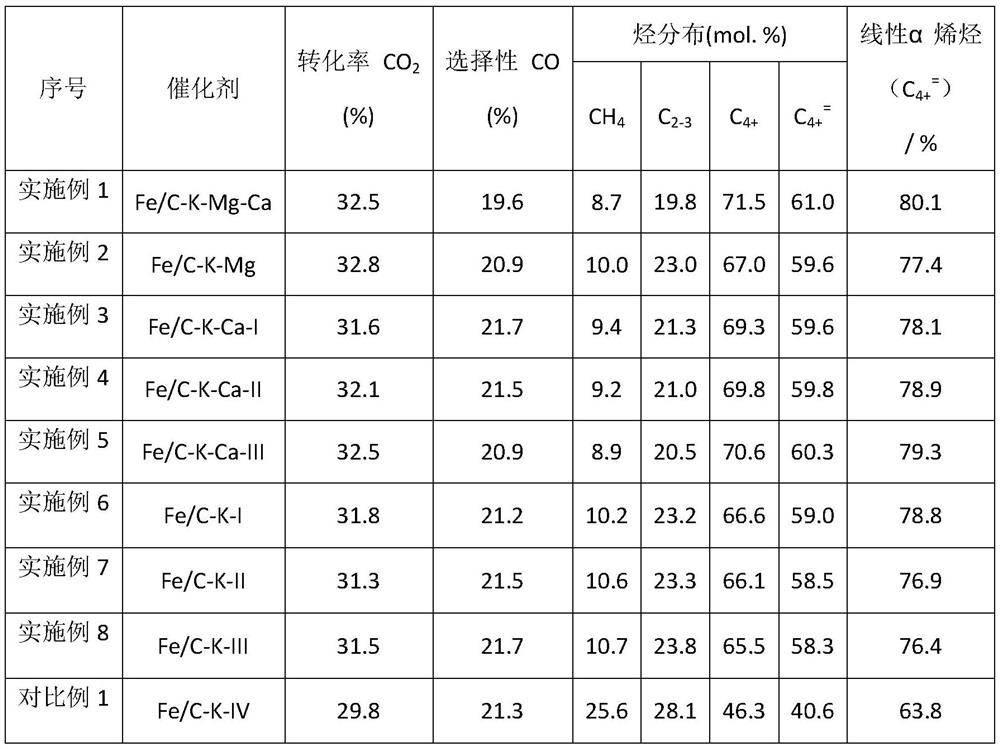

Catalyst for preparation of linear alpha-olefins from synga as well as preparation and application of catalyst

InactiveCN109865515APrepare even distributionImprove performanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasCarbon chain

The invention relates to a preparation method of a catalyst for preparation of linear alpha-olefins from a syngas, and aims to solve the problems that selectivity of alpha-olefins in a conventional syngas conversion process is low and the selectivity is difficult to control. According to the preparation method provided by the invention, one or more alkali metal elements selected from K, Mg, Ca andthe like are used as an organic auxiliary agent of the iron catalyst to prepare the high-efficiency catalyst for syngas conversion, the carbon chain growth ability is enhanced, selectivity of the linear alpha-olefin product is greatly improved, and the method is a simple and high-efficiency preparation route; and the preparation method of the catalyst provides a novel idea for effective production of the linear alpha-olefins.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

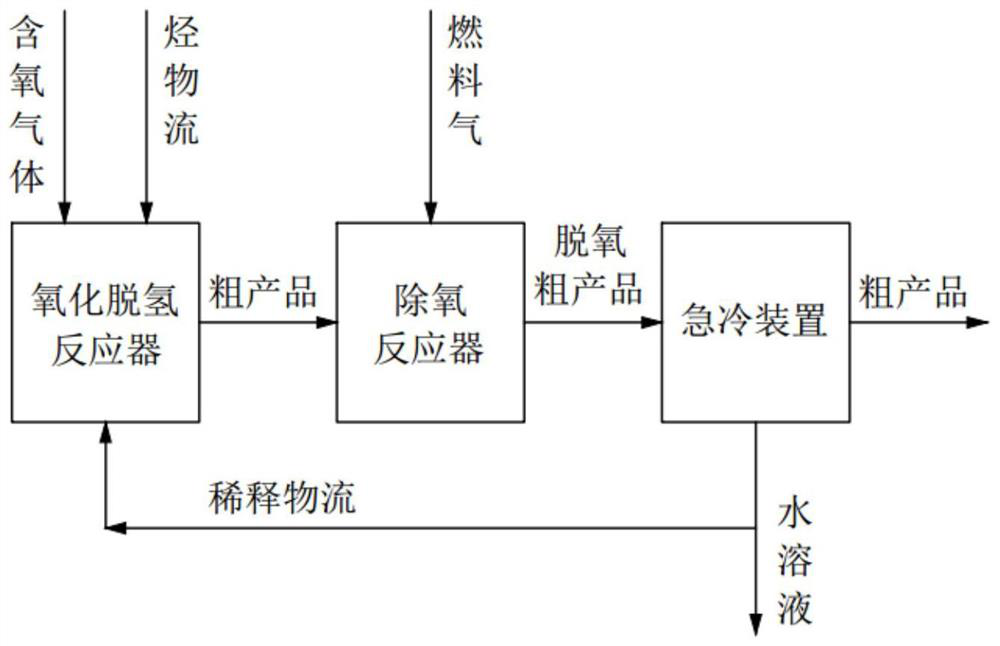

Method for removing residual oxygen in product flow of ethylene preparation by ethane catalytic oxidative dehydrogenation

PendingCN112142547AReduce processingSmall sizeChemical industryHydrocarbonsCatalytic oxidationDehydrogenation

The invention relates to a method for removing residual oxygen in a product flow of ethylene preparation by ethane catalytic oxidative dehydrogenation, wherein the method comprises the following steps: (1) feeding mixed raw material gas into an oxidative dehydrogenation reactor for reaction, carrying out waste heat recovery and cooling on the obtained crude product gas, and then feeding the crudeproduct gas into a gas-liquid separation tank for gas-liquid separation; (2) cooling a gas phase at the top in the gas-liquid separation tank, feeding the cooled gas phase into an absorption tower, and obtaining deacidified gas from the top of the absorption tower under the action of a tower top absorbent; and (3) feeding the obtained deacidified gas into a deaerator, and deoxidizing to obtain a deoxidized crude product. Compared with the prior art, the treatment capacity of the deaerator can be effectively reduced, the equipment investment is reduced, and meanwhile, the improvement of the deaeration reaction depth is facilitated. Besides, part of process condensate is injected into the mixed feed gas flow, and the reaction waste heat is gasified and recycled, so that the reaction temperature rise can be effectively controlled, and more reaction waste heat can be recycled.

Owner:WISON ENG +1

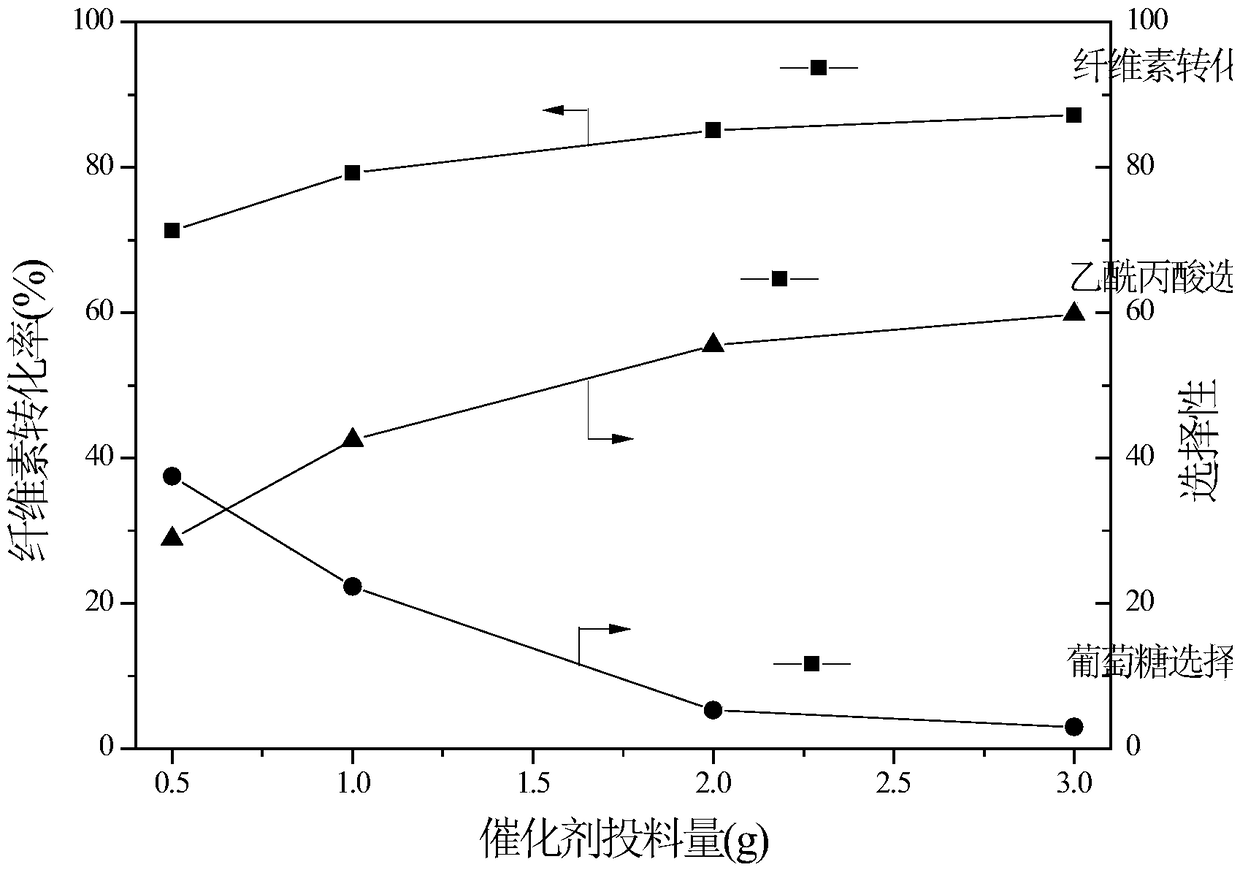

Thermo-sensitive acidic ionic liquid and preparation method and application thereof in catalyzing microcrystalline cellulose hydrolysis

InactiveCN108212212ALess corrosiveExcellent hydrolytic activitySugar derivativesOrganic compound preparationChemistryStrong acids

The invention relates to thermo-sensitive acidic ionic liquid and a preparation method and application thereof in catalyzing microcrystalline cellulose hydrolysis. The thermo-sensitive acidic ionic liquid is acidic ionic liquid which is synthesized from one quaternary ammonium salt of choline, choline chloride, betaine and dodecyl dimethyl betaine, and one fluorine-containing acidic molecule of tetrafluoroboric acid, trifluoromethanesulfonic acid and bis(trifluoromethane sulfonimide). Without sulfur acid or other strong acid groups, the ionic liquid reduces corrosion of the reaction equipment;moreover, the ionic liquid is easy to separate and recycle, thereby greatly improving the reusability of the liquid acidic catalyst.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for catalyzing selective hydrogenation of 1,3-butadiene by using CuPdPt catalyst

InactiveCN110563536AMild responseImprove catalytic activityHydrocarbon by hydrogenationCatalystsPalladiumCopper

The invention discloses a method for catalyzing selective hydrogenation of 1,3-butadiene by using a CuPdPt catalyst, and belongs to the technical field of chemistry and chemical engineering. The method comprises the following steps: putting the CuPdPt catalyst into a tubular reactor, then raising the temperature of a catalyst bed to a certain temperature, then introducing a mixed gas of 1,3-butadiene and hydrogen into the reactor, adjusting the reaction conditions to a certain pressure and a certain airspeed, and carrying out a reaction. The CuPdPt catalyst is different from traditional supported catalysts, and is characterized in that the high-activity and high-stability supported CuPdPt catalyst for selective hydrogenation of 1,3-butadiene is prepared by adjusting the contents of metallic copper, palladium and platinum in the catalyst and the content of TiO2@C. When the catalyst is used for the selective hydrogenation reaction of 1,3-butadiene, the content of 1,3-butadiene in the product is lower than 670 ppb, and the content of butane is lower than 1.5%;and the catalyst still maintains a good catalytic activity after being continuously operated for 150 h.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

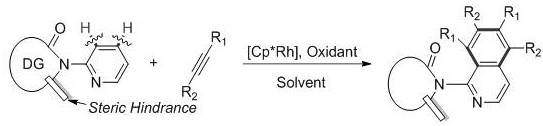

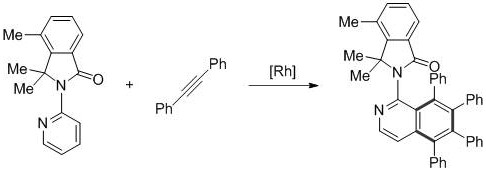

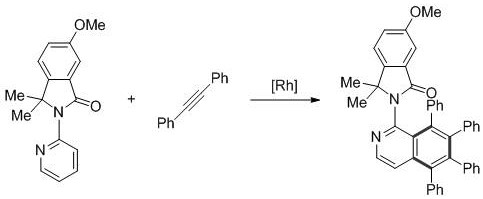

Method for synthesizing polysubstituted amino isoquinoline compound by cyclizing pyridine and alkyne under catalysis of rhodium

ActiveCN111808071AAvoid complexationRegulatory selectivityOrganic chemistryPentamethylcyclopentadienePtru catalyst

The invention discloses a method for synthesizing a polysubstituted aminoisoquinoline compound by cyclizing pyridine and alkyne under the catalysis of rhodium, which comprises the following steps: byusing a pentamethylcyclopentadienyl rhodium complex as a catalyst and a 2-aminopyridine derivative and an internal alkyne compound as raw materials, reacting in an organic solvent at 30-150 DEG C for1-24 hours, cooling the reaction solution after the reaction is finished, removing the organic solvent under reduced pressure; purifying the crude product through a silicon dioxide column, and elutingwith petroleum ether / ethyl acetate to obtain the pure polysubstituted aminoisoquinoline derivative. According to the method, a guide group (carbonyl) or a steric hindrance group (methyl) is introduced into the reaction to realize C-H bond activation and avoid the coordination effect of pyridine on the metal catalyst, and the regulation and control of the reaction activity and selectivity are efficiently realized through the regulation and control of the group with large steric hindrance. The obtained generation target products are high in selectivity, and the selectivity is 90% or above, byproducts are few, and the product separation cost is reduced, and the method is simple in synthesis process, mild in reaction condition and convenient for industrial production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

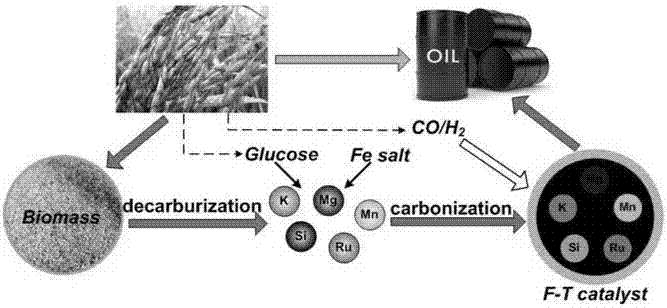

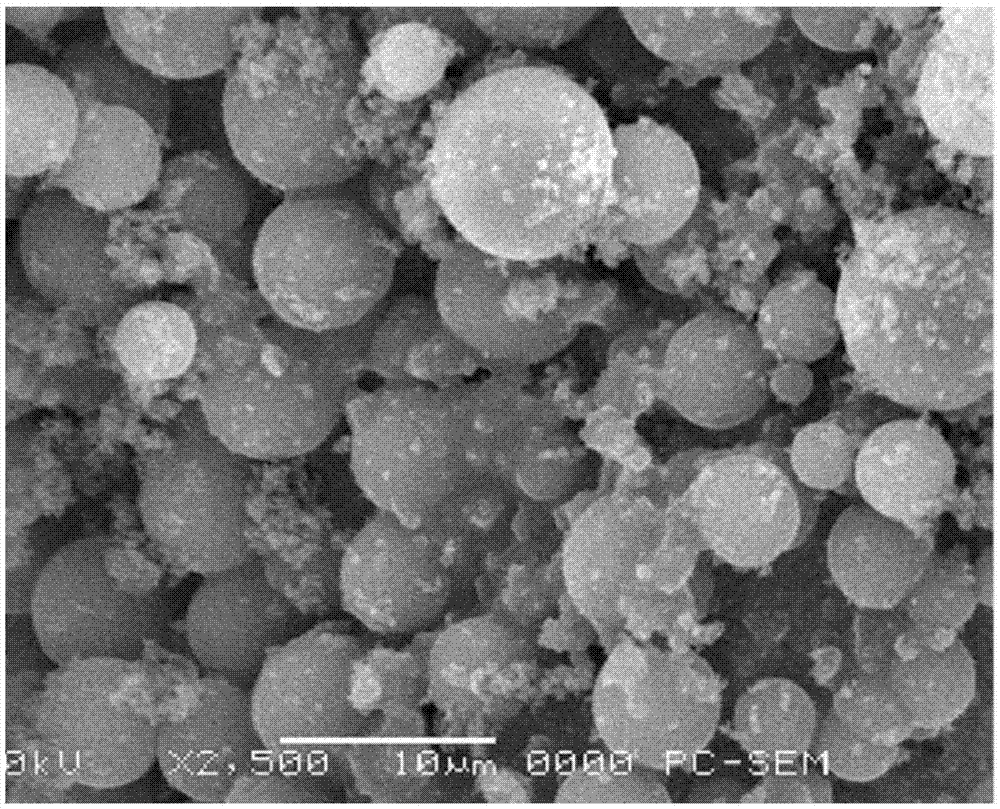

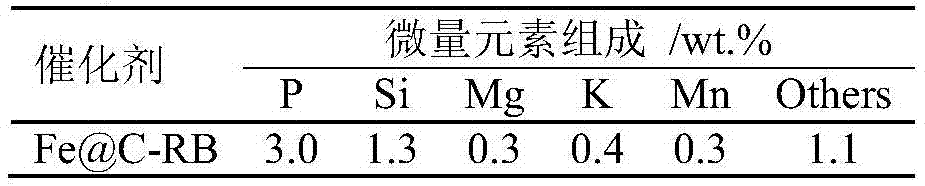

Preparation method of fischer-tropsch synthesis catalyst with biological additive effect

InactiveCN106861711ATake advantage ofPrepare even distributionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsMetalBiomass

The invention discloses a preparation method of fischer-tropsch synthesis catalyst with a biological additive effect and aims at solving the problems that traditional fischer-tropsch synthesized iron-base catalyst generally needs one or several metal additives, a preparation process is complex, and is not environmental-friendly. The preparation method disclosed by the invention is a simple and green preparation path by extracting varieties of beneficial microelements of K, Mg, Si, Mn and the like from biomass as catalyst promoters to prepare high-efficiency fischer-tropsch synthesis catalyst. By means of introducing the multi-component concomitant biological additive effect, hydrocarbon selectivity and CO conversion rate are enhanced. The preparation method can provide a full novel idea for recycling waste biomass resources and achieving green synthesis processes.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

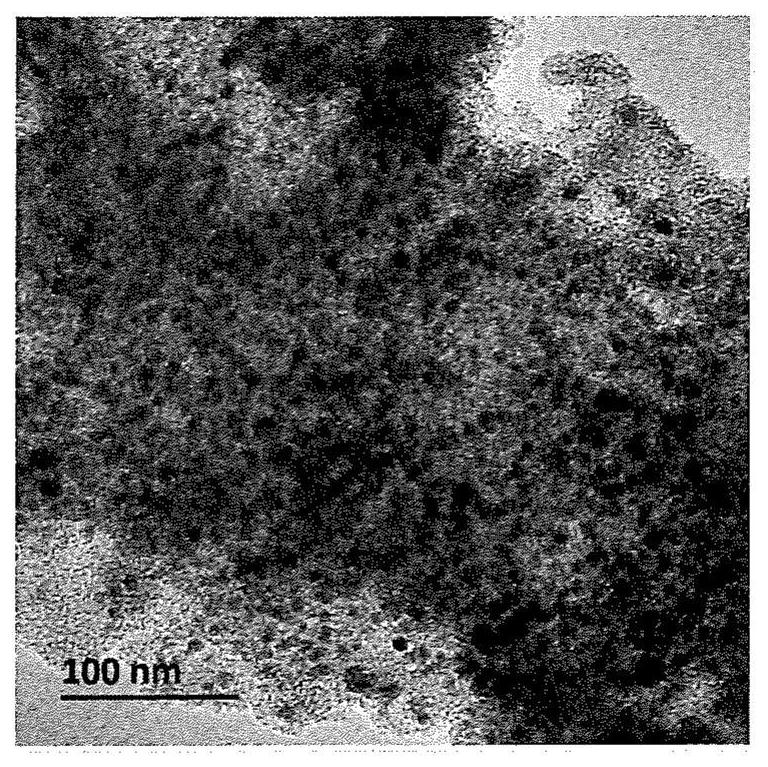

Method for preparing high-carbon linear alpha-olefin through hydrogenation of CO2 and application

InactiveCN112973698AHighly selective generationImprove the coupling effectHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCarbon chain

The invention designs a preparation method and application of a catalyst for preparing high-carbon linear alpha-olefin through hydrogenation of CO2. According to the invention, a carbon-doped Fe catalyst is prepared by adopting a hydrothermal synthesis method, a main active component is Fe, one or more of alkali metal elements selected from K, Mg, Ca and the like are jointly used as an electronic auxiliary agent of the Fe catalyst, so CO2 can be efficiently converted to produce linear alpha-olefin; the addition of the auxiliary agent enhances carbon chain growth ability, and greatly improves the selectivity of a high-carbon linear alpha-olefin product; and a new thought is provided for a high-efficiency conversion process of preparing high-added-value chemicals through selective hydrogenation of carbon dioxide, and the method has relatively good industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

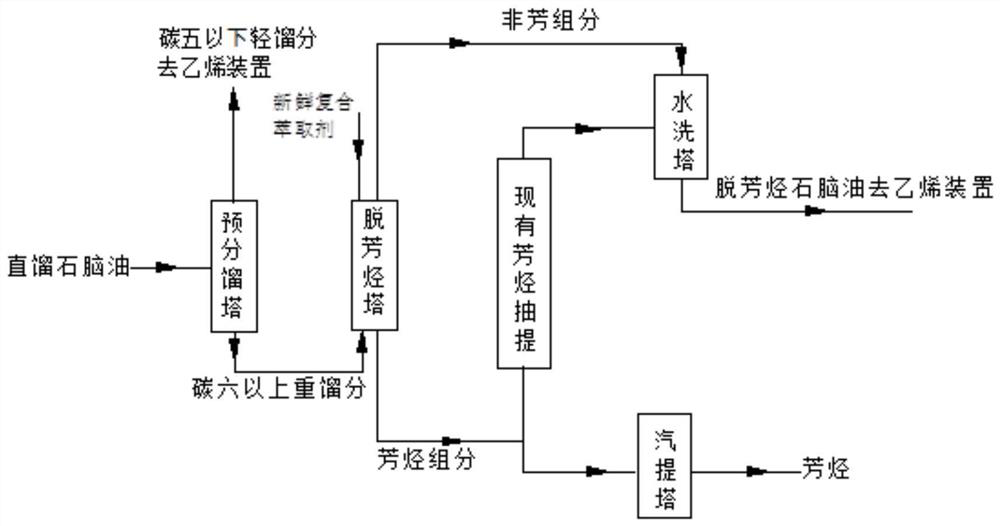

Composite extractant suitable for removing aromatic hydrocarbon in low-content aromatic hydrocarbon straight-run naphtha and application method thereof

PendingCN112552951ARegulating SolubilityRegulatory selectivityTreatment with plural serial stages onlyHydrocarbon oils refiningNaphthaPropylene carbonate

The invention provides a composite extractant suitable for removing aromatic hydrocarbon in low-content aromatic hydrocarbon straight-run naphtha and an application method of the composite extractant.The composite extractant is composed of N-N-dimethyl sulfoxide, N, N-dimethyl formamide (DMF) and propylene carbonate. According to the present invention, the naphtha with the low aromatic hydrocarbon content passes through the pre-fractionation and extraction dearomatization apparatus, and is combined with the aromatic hydrocarbon extraction water washing tower and the aromatic hydrocarbon extraction stripping tower to produce the dearomatized naphtha and the aromatic hydrocarbon product, such that the low aromatic hydrocarbon content naphtha is subjected to dearomatization under the suitable process conditions so as to obtain the high-quality ethylene cracking raw material.

Owner:NORTH HUAJIN CHEM IND CO LTD

Method for catalyzing hydrodehalogenation of heterocyclic halogen-containing organic matter by using supported metal oxide

InactiveCN111151248ARegulatory selectivityImprove adsorption capacityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHalogen

The invention relates to a hydrodehalogenation catalyst, and aims to provide a method for catalyzing hydrodehalogenation of a heterocyclic halogen-containing organic matter by using a supported metaloxide. The method comprises the following steps: uniformly mixing a solvent, a heterocyclic halogen-containing organic matter, a neutralizer and a catalyst material; introducing hydrogen into a reaction container until the pressure is 0.1 to 3.0 MPa; reacting at a controlled temperature of 25-180 DEG C for 0.1-24 h; and carrying out catalytic dehalogenation in the reaction process to finally obtain a dehalogenated heterocyclic compound. The method can effectively regulate the selectivity of the product in the dehalogenation process of the heterocyclic halogen-containing organic matter, and effectively regulate the adsorption of pyridine, thiophene and other organic molecules on the surface of the catalytic material by regulating the chemical coordination environment of the metal components, thereby efficiently preparing important compounds in the chemical and agricultural processes. In the dehalogenation process, the catalytic material is stable and can be recycled, no toxic or harmfulbyproduct is generated in the whole reaction process, and the method is green and environmentally friendly and has a high industrial application prospect.

Owner:ZHEJIANG UNIV

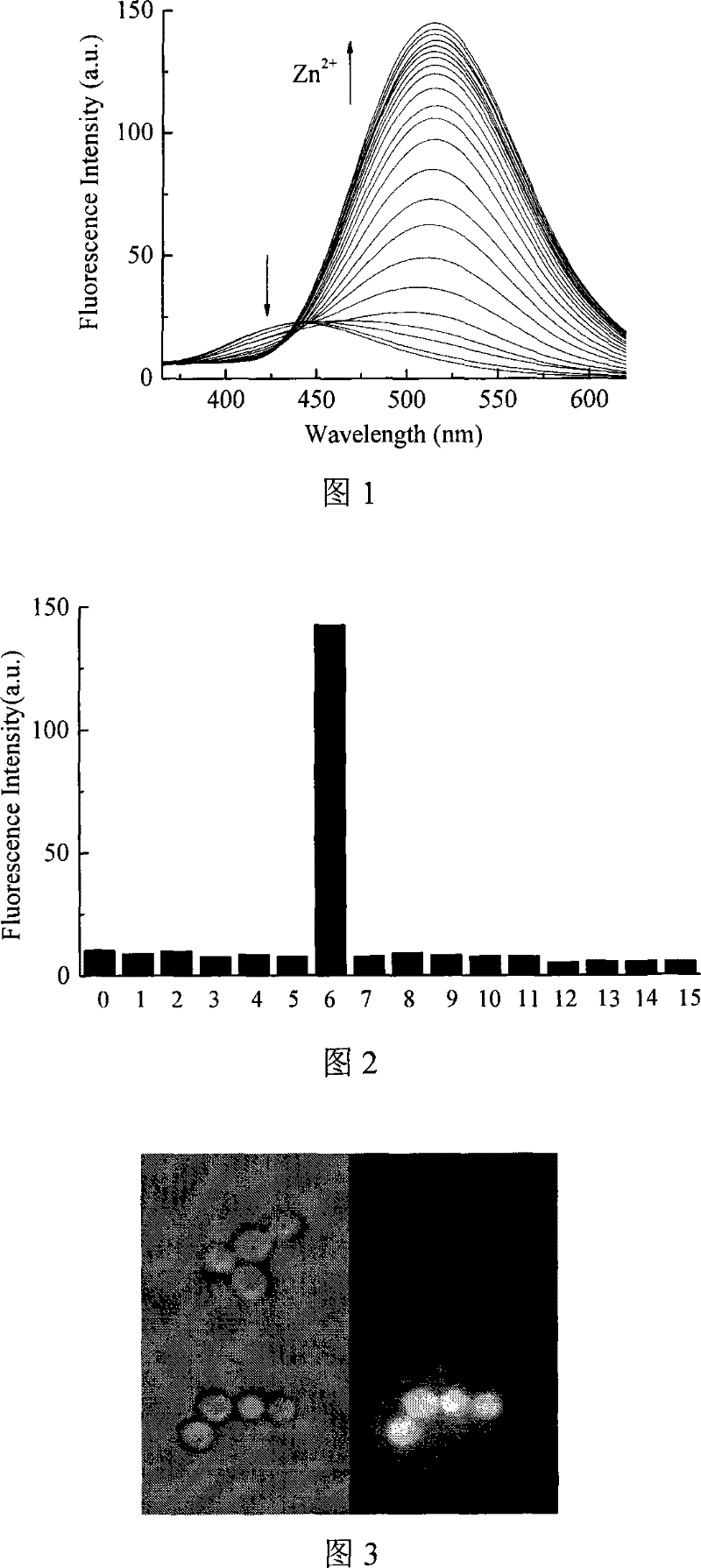

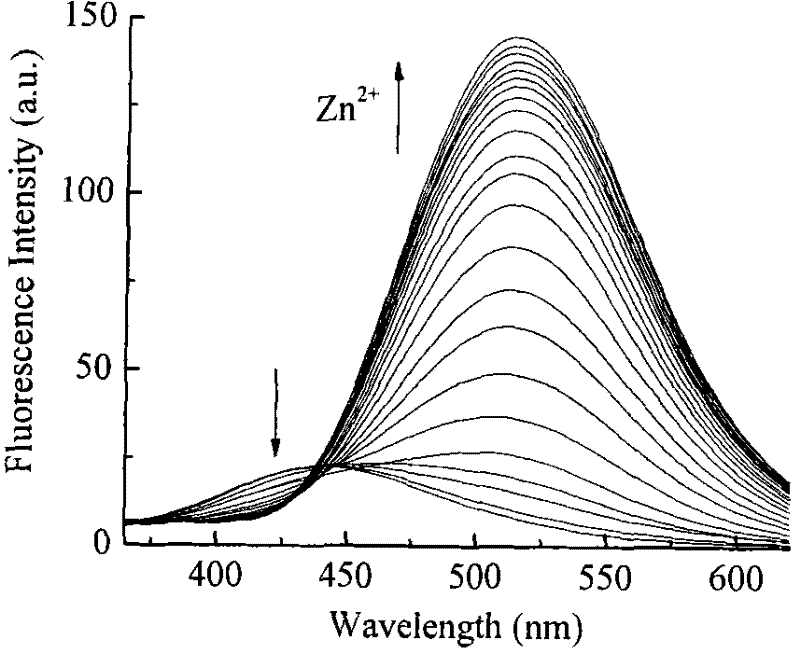

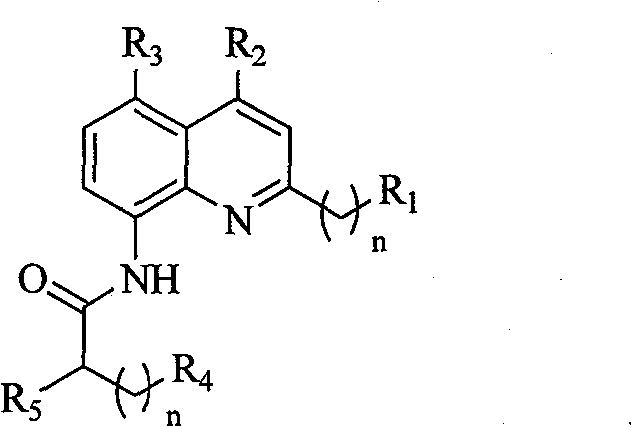

Synthesis of N-acyl-8-amino quinoline derivatives and use thereof as fluorescent molecular probe

InactiveCN101440062BEasy to synthesizeRaw materials are easy to getOrganic chemistryBiological testingFluorescenceImage detection

The invention relates to the synthesis of N-acyl-8-aminoquinoline derivatives and application thereof as fluorescent molecular probes. The invention takes 8-aminoquinoline as a matrix, can introduce substitutional groups at position 2, 4 and 5 of the quinoline matrix, and can acylate on an amino group to synthesize a series of novel acylaminoquinoline derivatives. The compounds with relatively simple structures and easy synthesis can be used for fluorescence detection of transition and heavy metal ions in solutions, show high sensitivity and selectivity, and are successfully applied to the fluorescence imaging detection of zinc ions in living cells. The compounds are expected to be widely applied in the fields such as analytical inspection of transition metal and heavy metal ions and the catalysis of metal complexes in biological tissues, cells, environment, medicine, and industrial and agricultural production and so on.

Owner:QIQIHAR UNIVERSITY

Method for catalyzing selective hydrogenation of 1, 3-butadiene by using NiPdRu catalyst

InactiveCN110560132AChange charge distributionEnhanced strong interactionHydrocarbon purification/separationCatalyst activation/preparationHydrogenation reactionRuthenium

The invention discloses a method for catalyzing selective hydrogenation of 1, 3-butadiene by using a NiPdRu catalyst, and belongs to the technical field of chemistry and chemical engineering. The method comprises the following steps: putting the NiPdRu catalyst into a tubular reactor, heating a catalyst bed to a certain temperature, introducing a mixed gas of the 1, 3-butadiene and hydrogen into the reactor, and carrying out a reaction at a certain pressure and airspeed. Different from the traditional supported catalyst, the high-activity and high-stability supported NiPdRu catalyst for selective hydrogenation of the 1, 3-butadiene can be prepared by adjusting the contents of metal nickel, palladium and ruthenium and the content of TiO2@C in the catalyst according to the invention. When the catalyst is used for selective hydrogenation reaction of the 1, 3-butadiene, the content of the 1, 3-butadiene in the product is lower than 595ppb, the content of butane is lower than 1.2%, and thecatalyst still keeps good catalytic activity after continuous operation for 150h.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Application of dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer

InactiveCN103342698BHigh selectivityHigh sensitivityOrganic chemistryFluorescence/phosphorescenceImage detectionFluorophore

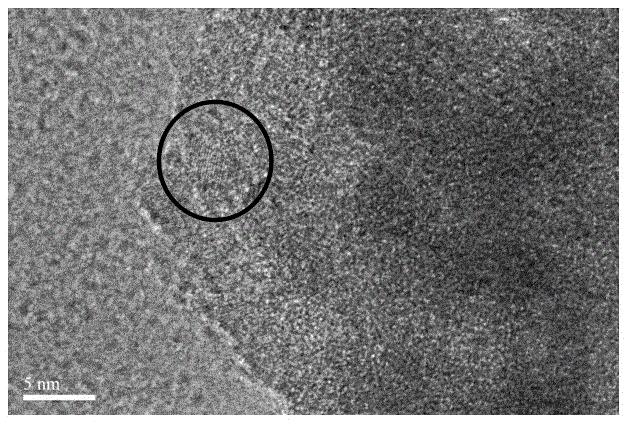

The invention discloses a dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer and a preparation method thereof, which relates to a dual-fluorophore ratio fluorescence molecular probe and a preparation method thereof. The dual-fluorophore ratio fluorescence molecular probe and the preparation method thereof disclosed by the invention are designed for solving the technical problems that due to energy loss caused by energy transfer between double fluorophores when the existing dual-fluorophore ratio fluorescence molecular probes are excited, the probes are poor in fluorescence, and not high in metal ion selectivity and sensitivity. The structure formula of the dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer is shown in the specification. The preparation method of the dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer comprises the steps of 1, preparing an intermediate; and 2, preparing the dual-fluorophore ratio fluorescence molecular probe for non-fluorescence resonance energy transfer. The dual-fluorophore ratio fluorescence molecular probe disclosed by the invention can be applied to the fluorescence imaging detection of metal ions in biological tissue and cell microenvironments.

Owner:QIQIHAR UNIVERSITY

Control method and control device for moisture content of furfural in extraction of furfural and method for preparing aromatic rubber oil

ActiveCN102585886BRegulatory selectivityIncrease water contentHydrocarbon oils refining control/regulationPolycyclic aromatic hydrocarbonPolymer science

Owner:CHINA PETROLEUM & CHEM CORP +1

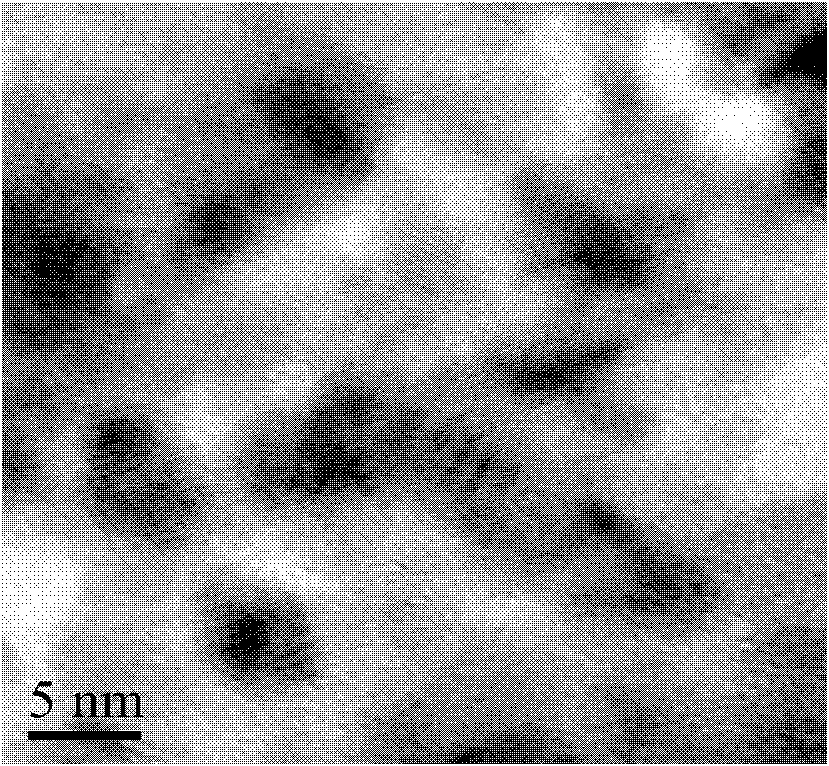

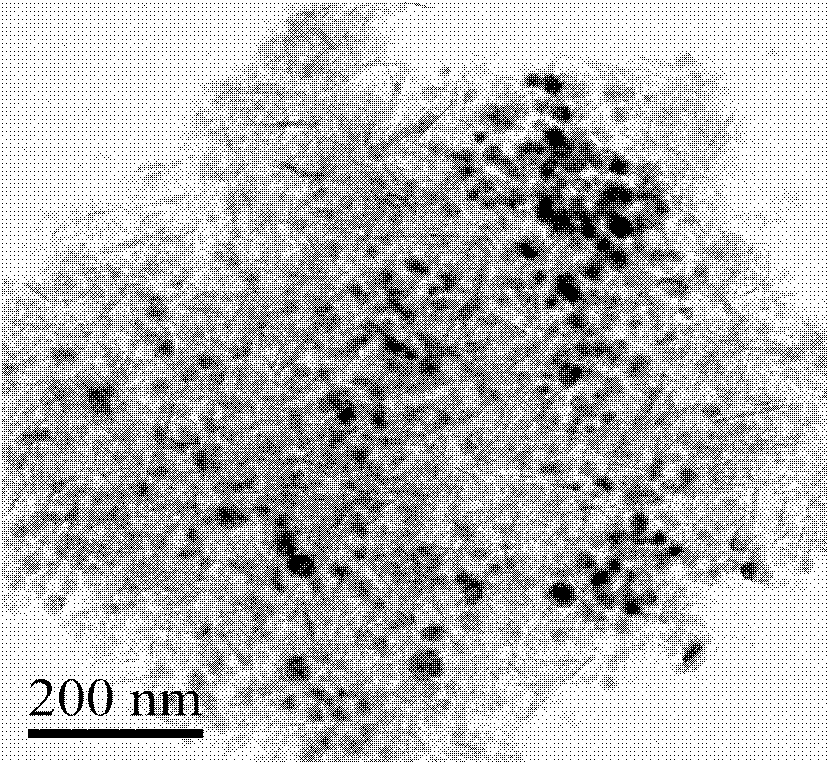

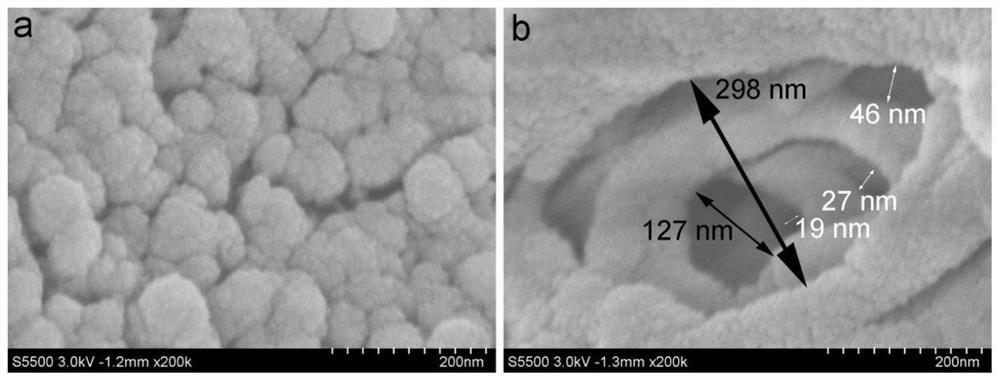

Nanoscale cobalt particle Fischer-Tropsch synthetic catalyst and preparation method thereof

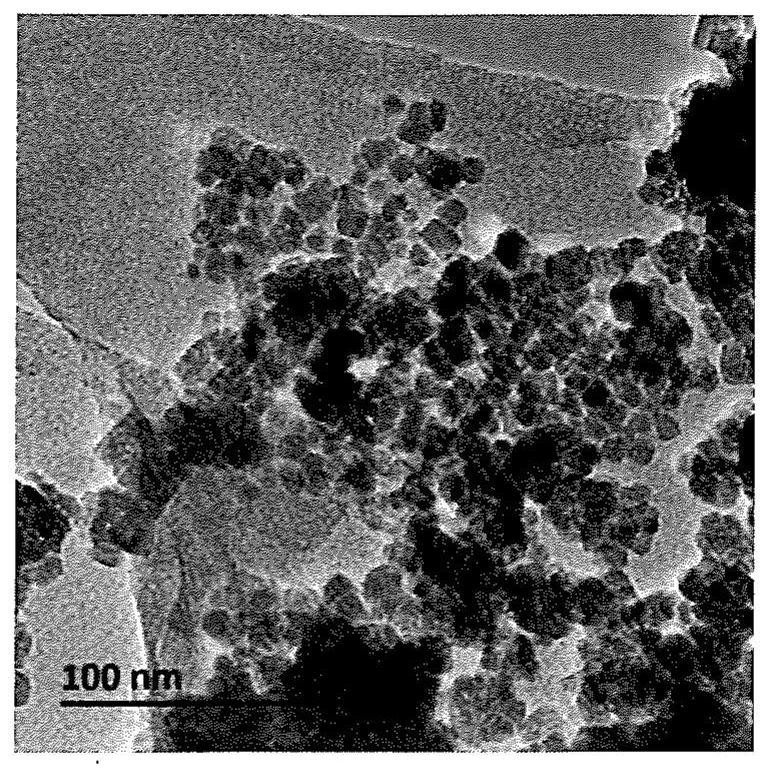

ActiveCN102274726BFlexible size adjustmentHigh activityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsDispersityMetal particle

The invention relates to the technical field of Fischer-Tropsch synthetic catalyst preparation, and specially provides a nanoscale cobalt particle Fischer-Tropsch synthetic catalyst allowing flexible adjustment on a catalyst load capacity, nanoscale cobalt particle sizes and carrier types, and a preparation method thereof. The preparation method comprises preparing nanoscale cobalt particles intoa colloidal solution with appropriate concentration, immersing carriers into the colloidal solution, and mixing uniformly the nanoscale cobalt particles and the carriers in nanoscale by effects of ultrasound to realize interaction between the nanoscale cobalt particles and the carriers. The nanoscale cobalt particle Fischer-Tropsch synthetic catalyst prepared by the preparation method can load selectively with active metal particles having different sizes through different carriers, and thus selective adjustment on products is realized. Through adjustment produced by interaction between active metal and carriers, dispersity and reductibility of the nanoscale cobalt particle Fischer-Tropsch synthetic catalyst are improved simultaneously. Therefore, selective adjustment and high activity and stability of the nanoscale cobalt particle Fischer-Tropsch synthetic catalyst are realized simultaneously.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

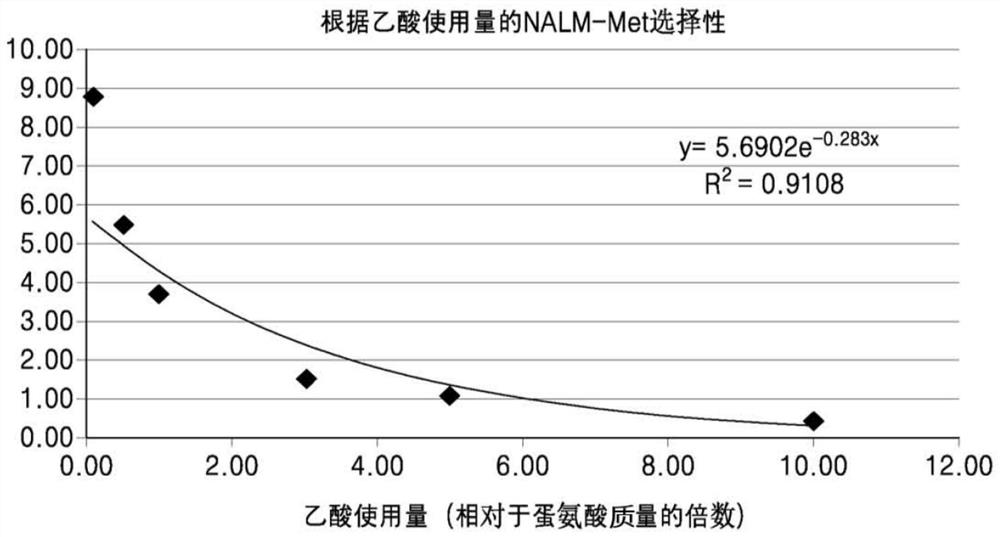

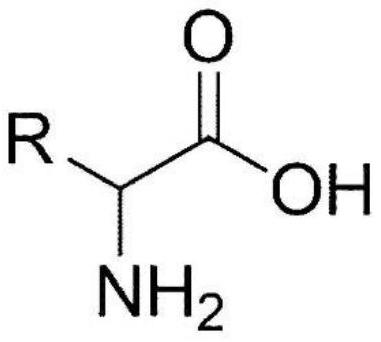

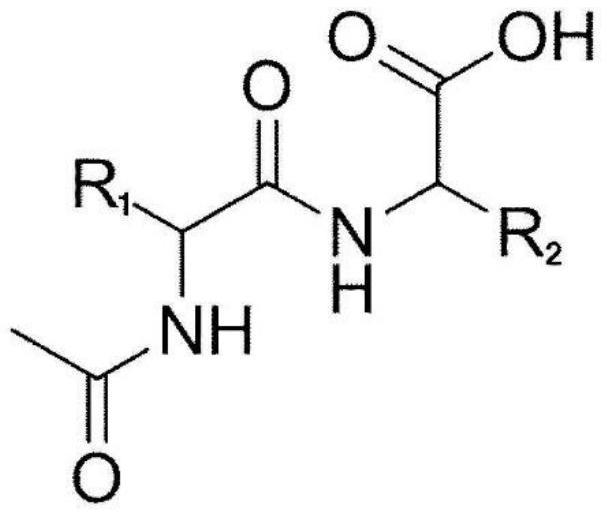

Method for producing n-acetyl dipeptide and n-acetyl amino acid

PendingCN112888702ACheap manufacturingRegulatory selectivityThiol preparationOrganic compound preparationAcetic anhydrideAcetyl chloride

The present invention provides a method for producing an N-acetyl dipeptide and an N-acetyl amino acid, comprising the step of reacting an amino acid with acetic anhydride or acetyl chloride to form an N-acetyl dipeptide and an N-acetyl amino acid.

Owner:CJ CHEILJEDANG CORP

Porous ion conduction membrane with gradient distribution of pore diameters, and preparation method and application thereof

ActiveCN112652797AHigh selectivityImprove ionic conductivityRegenerative fuel cellsOrganic polymerMaterials science

The invention discloses an application of a porous ion conduction membrane with gradient distribution of pore diameters in an alkaline zinc-iron flow battery. The membrane is prepared by blending organic polymer resin and inorganic particles capable of reacting with acid to generate gas and then carrying out phase inversion in an acid solution. In the membrane forming process, a membrane casting solution solvent exchanges with a non-solvent to form a pore structure, and meanwhile, protonic acid in the non-solvent reacts with inorganic particles in the membrane casting solution to generate gas after entering the membrane casting solution, so that a porous ion conduction membrane with pore diameters in gradient distribution is generated in the membrane forming process. The porous ion conduction membrane with gradient distribution of pore diameters is simple in process, environment-friendly in process and controllable in pore diameter and porosity, and batch production is easy to realize. Compared with an original porous membrane, the porous ion conduction membrane with gradient distribution of pore diameters can control the pore structure by controlling the content of inorganic particles and the concentration of acid in a non-solvent, so that the flow battery assembled by the porous ion conduction membrane has good battery performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

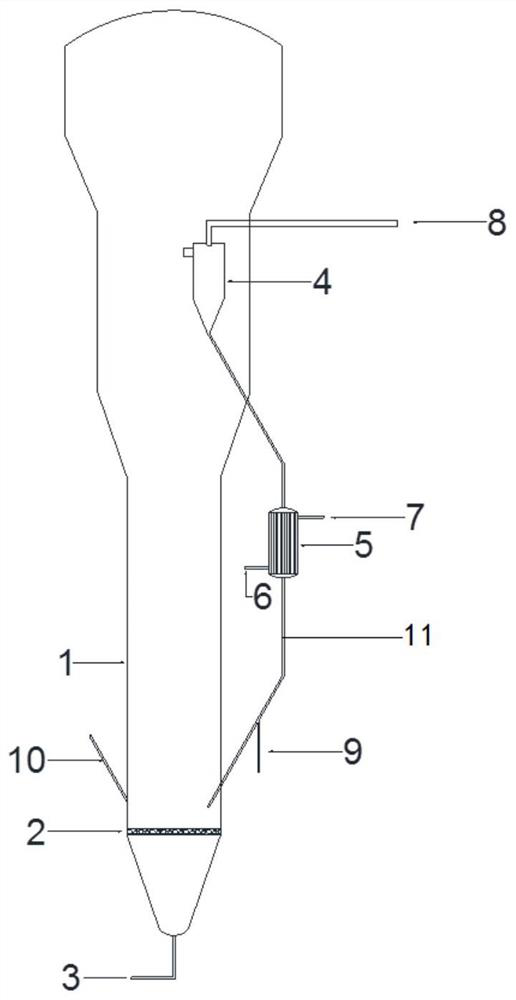

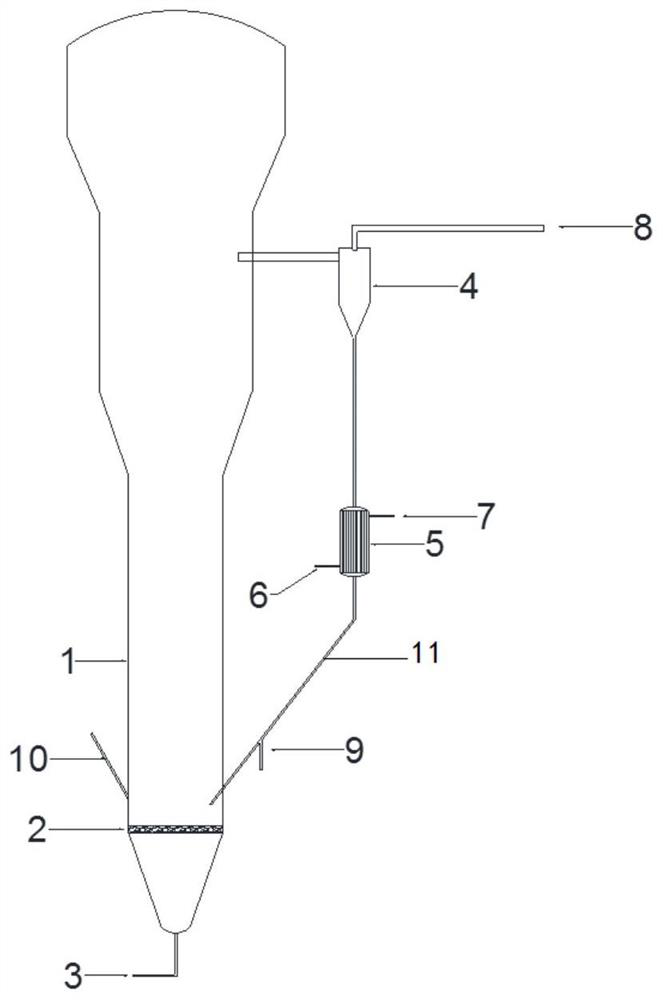

A system for Fischer-Tropsch synthesis and method for preparing low-carbon olefins from synthesis gas

ActiveCN107899519BImprove overall lifespanImprove conversion rateLiquid hydrocarbon mixture productionChemical/physical processesPtru catalystFluidized bed

The invention provides a system for Fischer-Tropsch synthesis, and a method for preparing low-carbon olefins from synthetic gas. The system for Fischer-Tropsch synthesis includes a fluidized bed reactor cylindrical shell, a gas-solid separator, a heat exchanger and a catalyst delivery tube; a product outlet is arranged at the top of the fluidized bed reactor cylindrical shell, and the product outlet is connected with the gas-solid separator; the gas-solid separator is provided with a solid product outlet, the solid product outlet is connected with one end of the catalyst delivery tube, and theother end of the catalyst delivery tube is connected with the bottom of the fluidized bed reactor cylindrical shell; and the heat exchanger is used to exchange heat with the delivery tube, and the heat exchanger and the delivery tube are arranged outside the fluidized bed reactor cylindrical shell. The system timely removes the reaction heat of a reactor, avoids the problems of abrasion of a catalyst and easy destruction of devices during heat removal, and recycles the removed heat.

Owner:SINOPEC ENG GRP CO LTD

Method for Catalyzing Dehalogenation of Aromatic Halogen-Containing Organic Compounds Using Supported Metal Oxide

ActiveCN111153758BEfficient manufacturingRegulatory selectivityPreparation by dehalogenationCarboxylic acid nitrile preparationSimple Organic CompoundsOrganic solvent

The invention relates to a catalyst for hydrogenation dehalogenation, and aims to provide a method for selective dehalogenation of aromatic halogen-containing organic substances catalyzed by supported metal oxides. Including: adding organic solvents, aromatic halogen-containing organic substances, neutralizers and catalyst materials into a sealable reaction vessel, and mixing them uniformly; filling hydrogen until the pressure is 0.1-3.0MPa, controlling the reaction temperature from 25°C to 180°C, The reaction time is 0.1 to 24 hours; during the reaction process, the catalytic dehalogenation is realized by the catalyst, and finally the dehalogenated organic matter is obtained. The invention can effectively control the selectivity of products in the dehalogenation process of aromatic halogen-containing organic substances, and can still efficiently dehalogenate even when the halogen-containing organic substances contain two or more functional groups that can be reduced, thereby efficiently preparing chemical and Important compounds in agricultural processes. In the dehalogenation process, the catalytic material is stable and can be recycled, and no toxic and harmful by-products are produced in the whole reaction process, which is green and environmentally friendly, and has industrial application prospects.

Owner:ZHEJIANG UNIV

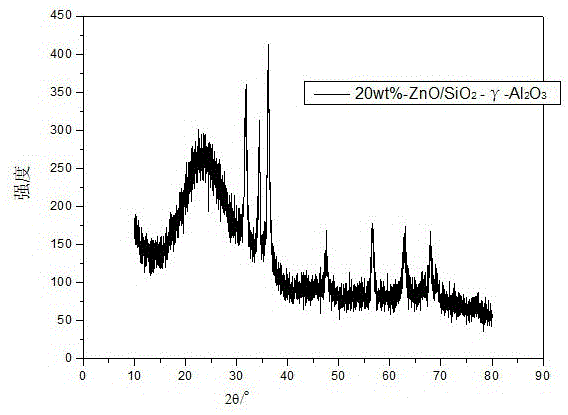

A zno/sio2-γ-al2o3 catalyzed hydrolysis of methyl bromide to prepare methanol and dimethyl ether

InactiveCN104492411BEasy to makeEasy to synthesizeOrganic compound preparationHydroxy compound preparationReaction temperatureDimethyl ether

Owner:EAST CHINA NORMAL UNIV

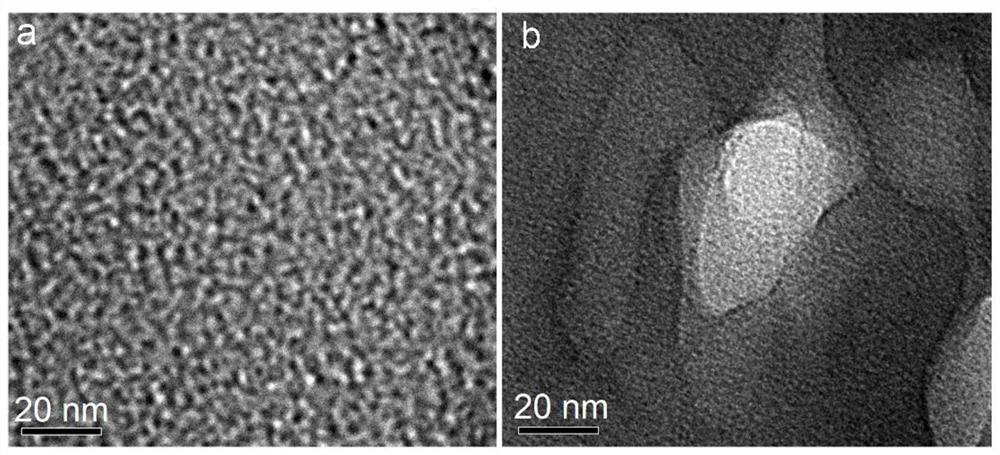

Cobalt-based catalyst and preparation method and application thereof

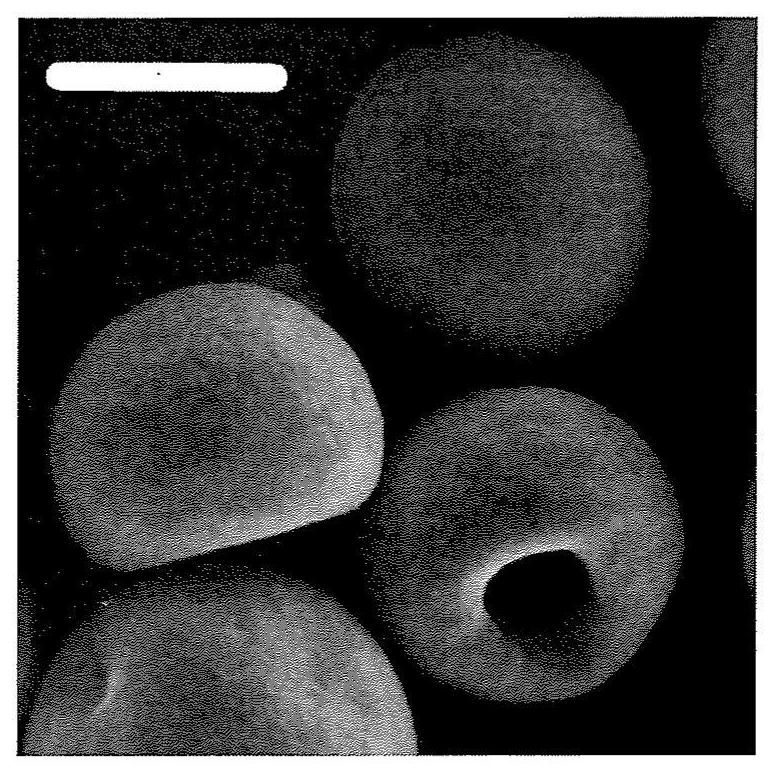

PendingCN113617356ARegulatory selectivityHigh activityCatalyst activation/preparationLiquid hydrocarbon mixture productionSpray driedNanoparticle

The invention discloses a cobalt-based catalyst, a preparation method and application. The catalyst contains an active component cobalt and a heat-resistant inorganic oxide. By taking the weight of the catalyst as a reference, the content of cobalt in terms of Co3O4 is 30-70 wt%, and the content of the heat-resistant inorganic oxide is 30-70 wt%. The morphology of the catalyst is a hollow microsphere with a macropore on the surface and a cavity structure inside, and the active component cobalt is dispersed in the microsphere in the form of nanoparticles. The preparation method comprises the following steps of: (1) providing nano cobalt particles; (2) mixing the nano cobalt particles obtained in the step (1) with a heat-resistant inorganic oxide precursor, a pore forming agent and a blasting agent in a solvent to form slurry; and (3) spray-drying and molding the slurry obtained in the step (2), and then roasting or not roasting to obtain the catalyst. When the cobalt-based catalyst is applied to Fischer-Tropsch synthesis, the activity and selectivity of the catalyst are obviously superior to those of a catalyst in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supercritical carbon dioxide/polyethylene glycol stabilized palladium nano particle catalysis system

InactiveCN101596467AAvoid cross contaminationAchieving Green RestorationOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by oxidationPolyethylene glycolPalladium catalyst

The invention provides a supercritical carbon dioxide / polyethylene glycol stabilized palladium nano particle catalysis system, belonging to the technical field of catalyst application, mainly comprising the following steps: (1) using 2,2'-dipyridylamine modified polyethylene glycol as a carrier, after coordinating with palladium acetate, based on the reducer of hydrogen, reducing Pd(II) as Pd(0), obtaining Pd nano particle catalyst; (2) sequentially adding the substrate, palladium catalyst, polyethylene glycol to a high pressure kettle, and then sequentially quantitatively filling CO2, O2 in the high pressure kettle, preferably 10 g to 20 g of mixed gases of CO2 and O2, heating to the appointed temperature with the heating sleeve in the electromagnetic stirring. After the reaction is finished, in situ extracting the substrate and the product with the supercritical carbon dioxide at the temperature of 70 DEG C and preferable pressure of 16 MPa to 20 MPa, and absorbing the tail gas with the cold trap filled with isopropanol.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com