A system for Fischer-Tropsch synthesis and method for preparing low-carbon olefins from synthesis gas

A technology of Fischer-Tropsch synthesis and gas-solid separator, which is applied in the chemical industry, can solve the problems of catalyst and heat exchanger collision contact, catalyst and heat exchanger are easily damaged, and increase catalyst cost, etc., and achieve easy regeneration, convenient loading and unloading, and high temperature Consistent and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

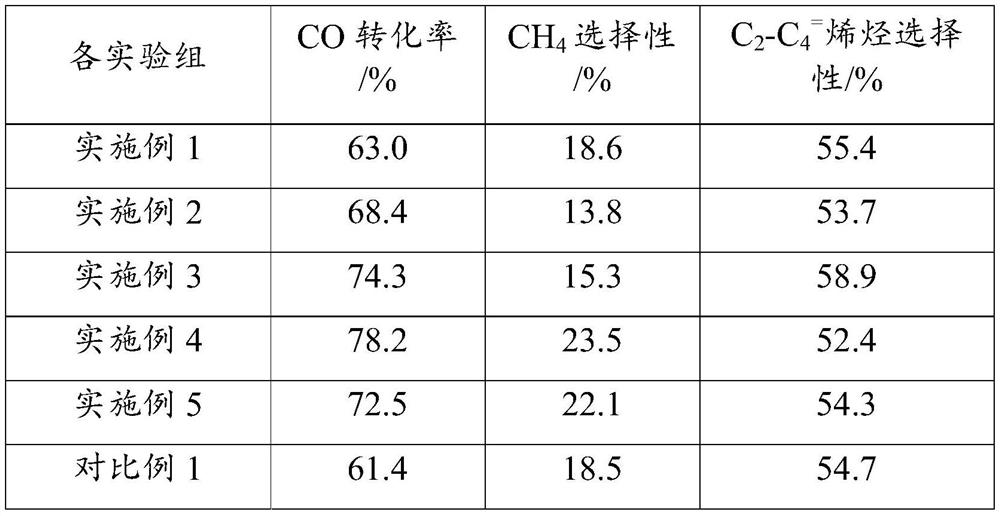

Embodiment 1

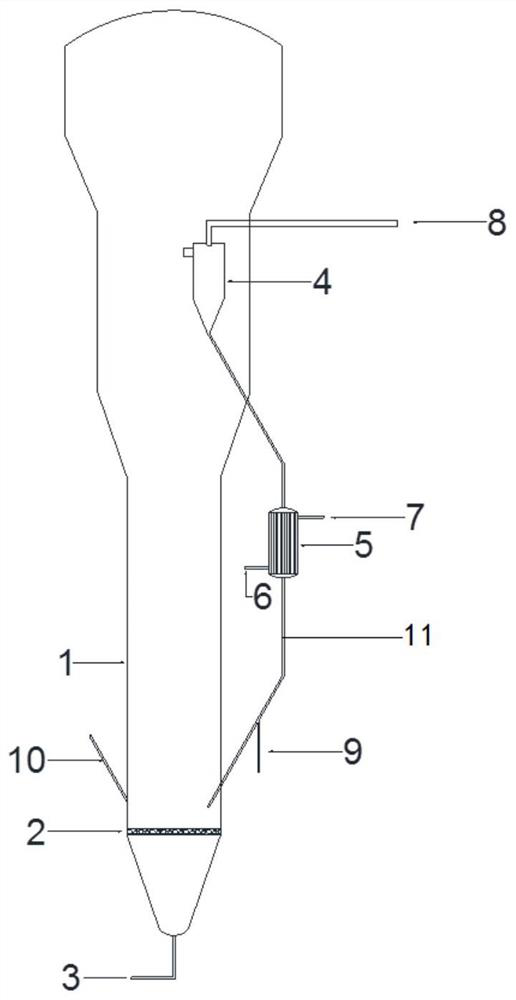

[0056] Reactors for synthesis gas to light olefins such as figure 1 shown. The main active components of the catalyst are Fe and HZSM-5, the particle size distribution range is 10-200μm, the reaction temperature is 350°C, the pressure is 1.7MPa, H 2 The molar ratio to CO is 1:1, and the total volume space velocity of raw materials is 2000h -1 .

[0057] The reaction gas enters from the bottom inlet 3 of the cylinder body 1 of the fluidized bed reactor, and enters the catalyst bed after passing through the gas distributor 2. 2 react with CO to form H under the action of a catalyst 2 O and lower olefins. The gas-solid mixture enters the built-in cyclone separator 4 for gas-solid separation, and the oil gas flows out from the outlet 8 of the reactor.

[0058] The solid catalyst separated by the cyclone separator 4 flows out of the reactor, enters the delivery pipe 11, and cools down through the heat exchanger 5. The heat exchange medium in the external heat exchanger 5 enter...

Embodiment 2

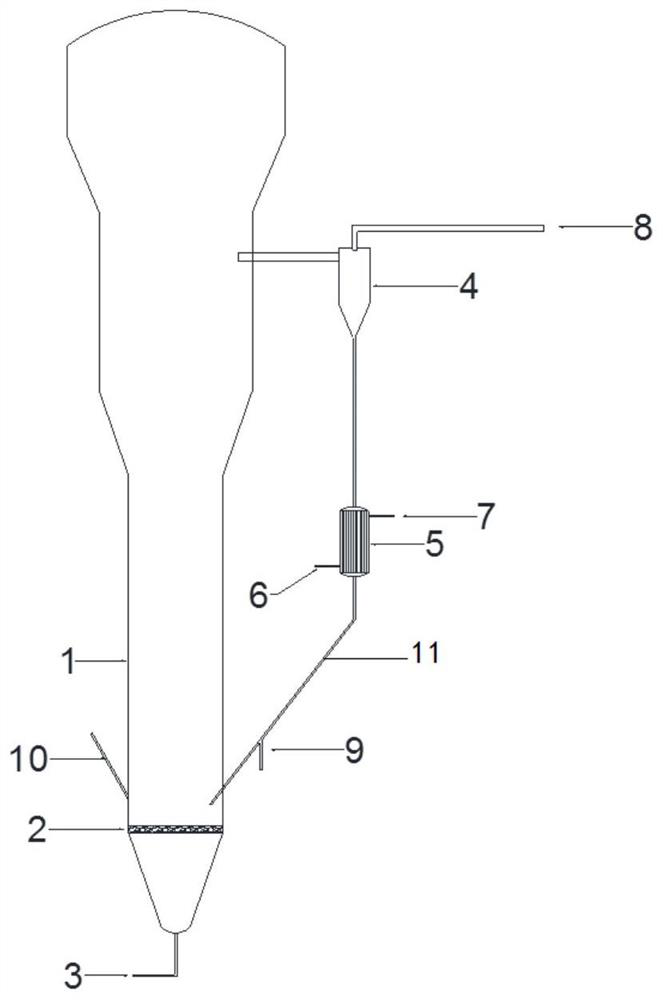

[0061] Reactors for synthesis gas to light olefins such as figure 2 shown.

[0062] The main active components of the catalyst are Co and HZSM-5, the particle size distribution range is 40-120μm, the reaction temperature is 300°C, the pressure is 0.8MPa, the H 2 The molar ratio to CO is 2:1, and the total volume space velocity of the raw material is 800h -1 .

[0063] The reaction gas enters from the bottom inlet 3 of the cylinder body 1 of the fluidized bed reactor, and enters the catalyst bed after passing through the gas distributor 2. 2 react with CO to form H under the action of a catalyst 2 O and lower olefins. The gas-solid mixture enters the external cyclone separator 4 for gas-solid separation, and the gas exits the reactor from the cyclone separator 4. The gas-liquid mixture separated by the cyclone separator 4 is discharged from the reactor outlet 8, the solid catalyst separated by the cyclone separator 4 enters the delivery pipe 11, and is cooled by the exter...

Embodiment 3

[0066] Reactors for synthesis gas to light olefins such as figure 1 shown.

[0067] The main active components of the catalyst are Fe and Y-type molecular sieves, the particle size distribution range is 40-120μm, the reaction temperature is 380°C, the pressure is 2.0MPa, H 2 The molar ratio to CO is 2:1, and the total volume space velocity of raw materials is 2000h -1 .

[0068] The reaction gas enters from the bottom inlet 3, and enters the catalyst bed after passing through the gas distributor 2. 2 react with CO to form H under the action of a catalyst 2 O and lower olefins. The gas-solid mixture enters the built-in cyclone separator 4 for gas-solid separation, and the oil gas flows out from the outlet 8 of the reactor.

[0069] The solid catalyst separated by the cyclone separator 4 flows out of the external heat exchanger 5 of the reactor to cool down, and the cooled catalyst enters the reactor barrel 1 to cool down the reaction bed.

[0070] The external heat exchan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com