Composite extractant suitable for removing aromatic hydrocarbon in low-content aromatic hydrocarbon straight-run naphtha and application method thereof

A composite extractant and application method technology, applied in the field of composite extractant, can solve the problems of low reuse and high production cost, and achieve the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using N-N-dimethyl sulfoxide as the main solvent, N, N-dimethylformamide (DMF) and propylene carbonate (PC) as co-solvents, a compound extractant was prepared at a mass ratio of 70:20:10.

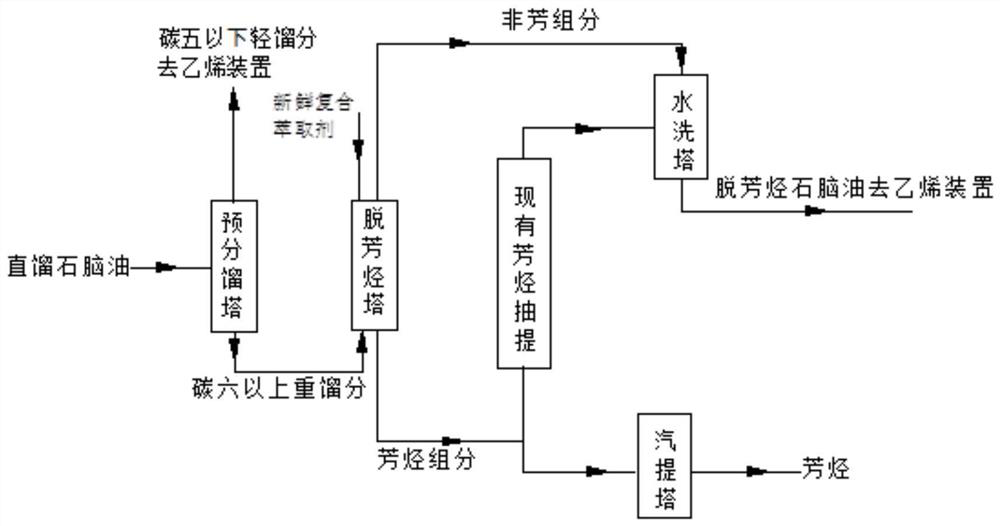

[0024] The straight-run naphtha with an aromatics content of 9wt% is passed into the pre-fractionator, the pressure is 0.5MPa, the temperature is 100°C, and the light fraction less than 60°C is distilled from the top of the tower, and the bottom product and the fresh composite extractant are in mass ratio 2:1 Extraction and dearomatization are carried out in the dearomatization tower, the extraction pressure is 0.5MPa, and the extraction temperature is 50°C. The non-aromatic components distilled from the top of the dearomatization tower are connected to the water washing tower of the existing aromatics extraction device to form dearomatized naphtha after the solvent is removed, and the aromatic-rich components distilled from the bottom of the tower are connected to the existing aromat...

Embodiment 2

[0026] Using N-N-dimethyl sulfoxide as the main solvent, N, N-dimethylformamide (DMF) and propylene carbonate (PC) as co-solvents, a compound extractant was prepared at a mass ratio of 80:10:10.

[0027] The straight-run naphtha with an aromatics content of 9wt% is passed into the pre-fractionator, the pressure is 0.5MPa, the temperature is 100°C, and the light fraction less than 60°C is distilled from the top of the tower, and the bottom product and the fresh composite extractant are in mass ratio 2:1 Extraction and dearomatization are carried out in the dearomatization tower, the extraction pressure is 0.5MPa, and the extraction temperature is 50°C. The non-aromatic components distilled from the top of the dearomatization tower are connected to the water washing tower of the existing aromatics extraction device to form dearomatized naphtha after the solvent is removed, and the aromatic-rich components distilled from the bottom of the tower are connected to the existing aromat...

Embodiment 3

[0029] Using N-N-dimethylsulfoxide as the main solvent, N,N-dimethylformamide (DMF) and propylene carbonate (PC) as co-solvents, a compound extractant was prepared at a mass ratio of 65:20:15.

[0030] The straight-run naphtha with an aromatics content of 9wt% is passed into the pre-fractionator, the pressure is 0.5MPa, the temperature is 100°C, and the light fraction less than 60°C is distilled from the top of the tower, and the bottom product and the fresh composite extractant are in mass ratio 2:1 Extraction and dearomatization are carried out in the dearomatization tower, the extraction pressure is 0.5MPa, and the extraction temperature is 50°C. The non-aromatic components distilled from the top of the dearomatization tower are connected to the water washing tower of the existing aromatics extraction device to form dearomatized naphtha after the solvent is removed, and the aromatic-rich components distilled from the bottom of the tower are connected to the existing aromatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com