A kind of degradable water-soluble elastomer and preparation method thereof

A water-soluble, elastomer technology, applied in the field of thermoplastic elastomers, can solve the problems of inability to meet the needs of use, toxicity of elastomer products, poor water solubility, etc., to achieve good mechanical strength, high elongation at break, guaranteed mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

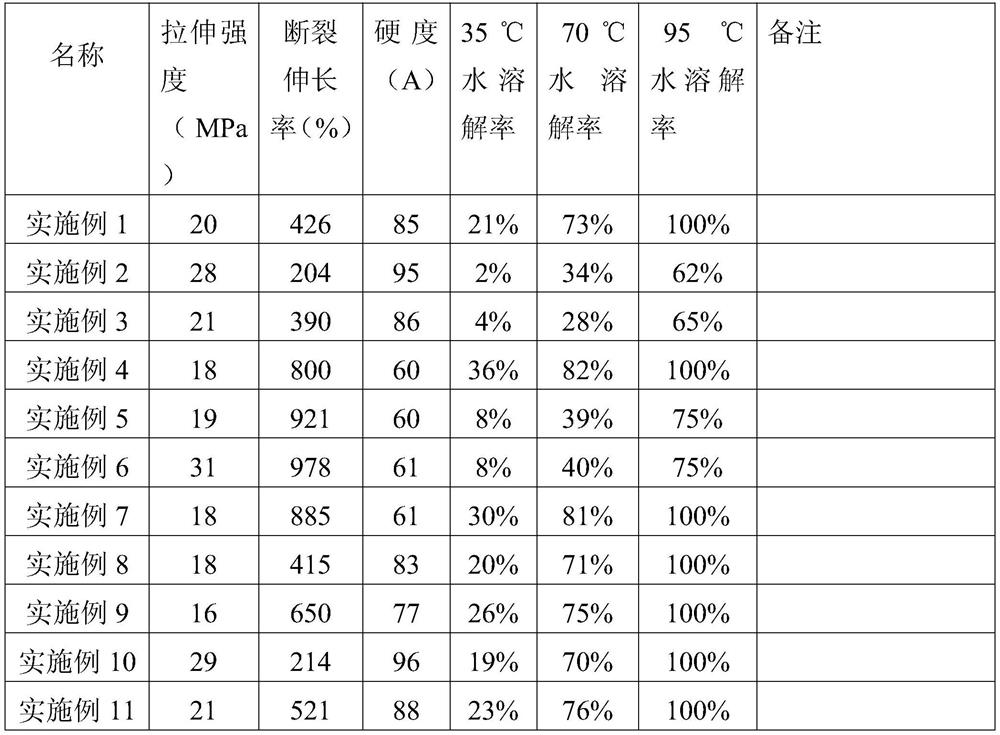

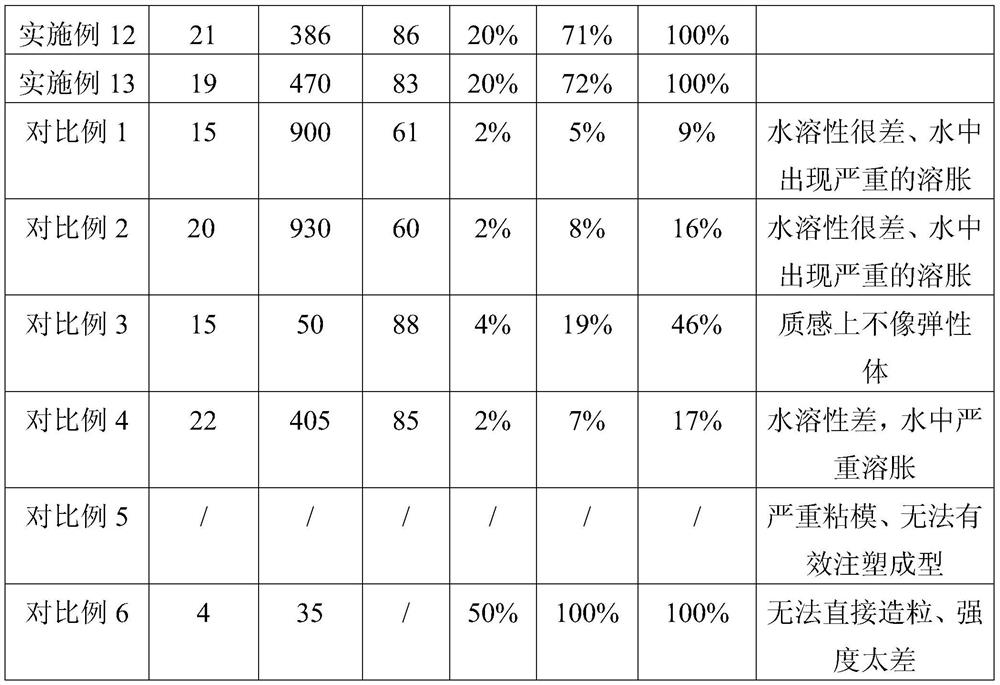

Examples

Embodiment 1

[0034] The degradable water-soluble elastomer described in this embodiment includes the following components in parts by mass:

[0035] The copolymer of polylactic acid and polyethylene glycol is used as the soft segment prepolymer, and the copolymer of 1,4-butanediol-2-sulfonate and isophorone diisocyanate is used as the hard segment prepolymer. 185 parts of segment copolymer; 30 parts of polyacrylamide; 20 parts of polyvinyl alcohol; 5 parts of hydroxyl silicone oil; 5 parts of sodium polyacrylate.

[0036] Wherein, the mass ratio of polylactic acid and polyethylene glycol in the soft segment prepolymer is 5:100; the number average molecular weight of polyethylene glycol is 1000;

[0037] The mass ratio of 1,4-butanediol-2-sodium sulfonate to isophorone diisocyanate in the hard segment prepolymer is 30:50.

[0038] The preparation method of the degradable water-soluble elastomer described in the present embodiment is as follows:

[0039] S1. Put 100 parts of polyethylene g...

Embodiment 2

[0043] The degradable water-soluble elastomer described in this embodiment includes the following components in parts by mass:

[0044] The copolymer of polylactic acid and polyethylene glycol is used as the soft segment prepolymer, and the copolymer of 1,4-butanediol-2-sulfonate and isophorone diisocyanate is used as the hard segment prepolymer. 100 parts of segment copolymer; 50 parts of guar gum; 5 parts of amino silicone oil; 50 parts of sodium polyacrylate.

[0045] Wherein, the mass ratio of polylactic acid and polyethylene glycol in the soft segment prepolymer is 1:1; the number average molecular weight of polyethylene glycol is 2000;

[0046] The mass ratio of 1,4-butanediol-2-sulfonate to isophorone diisocyanate in the hard segment prepolymer is 1:1.

[0047] The preparation method of the degradable water-soluble elastomer described in the present embodiment is as follows:

[0048] S1. Put 20 parts of polyethylene glycol 2000, 20 parts of lactide and 0.01 part of ca...

Embodiment 3

[0052] The degradable water-soluble elastomer described in this embodiment includes the following components in parts by mass:

[0053] The copolymer of polylactic acid and polyethylene glycol is used as the soft segment prepolymer, and the copolymer of 1,4-butanediol-2-sulfonate and isophorone diisocyanate is used as the hard segment prepolymer. 185 parts of segment copolymer; 3 parts of polyacrylamide, 2 parts of polyvinyl alcohol, 5 parts of hydroxyl silicone oil, and 5 parts of sodium polyacrylate.

[0054] Wherein, the mass ratio of polylactic acid and polyethylene glycol in the soft segment prepolymer is 1:20; the number average molecular weight of polyethylene glycol is 1000;

[0055] The mass ratio of 1,4-butanediol-2-sodium sulfonate to isophorone diisocyanate in the hard segment prepolymer is 3:5.

[0056] The preparation method of the degradable water-soluble elastomer described in the present embodiment is as follows:

[0057] S1. Put 100 parts of polyethylene gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com