Nickel-nitrogen co-doped porous carbon material loaded with cobalt nanoparticles, and preparation method and application thereof

A technology of porous carbon materials and co-doping, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high equipment requirements, high overpotential, harmful environment, etc., and achieve strong proton transport ability, diffusion The effect of low resistance and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

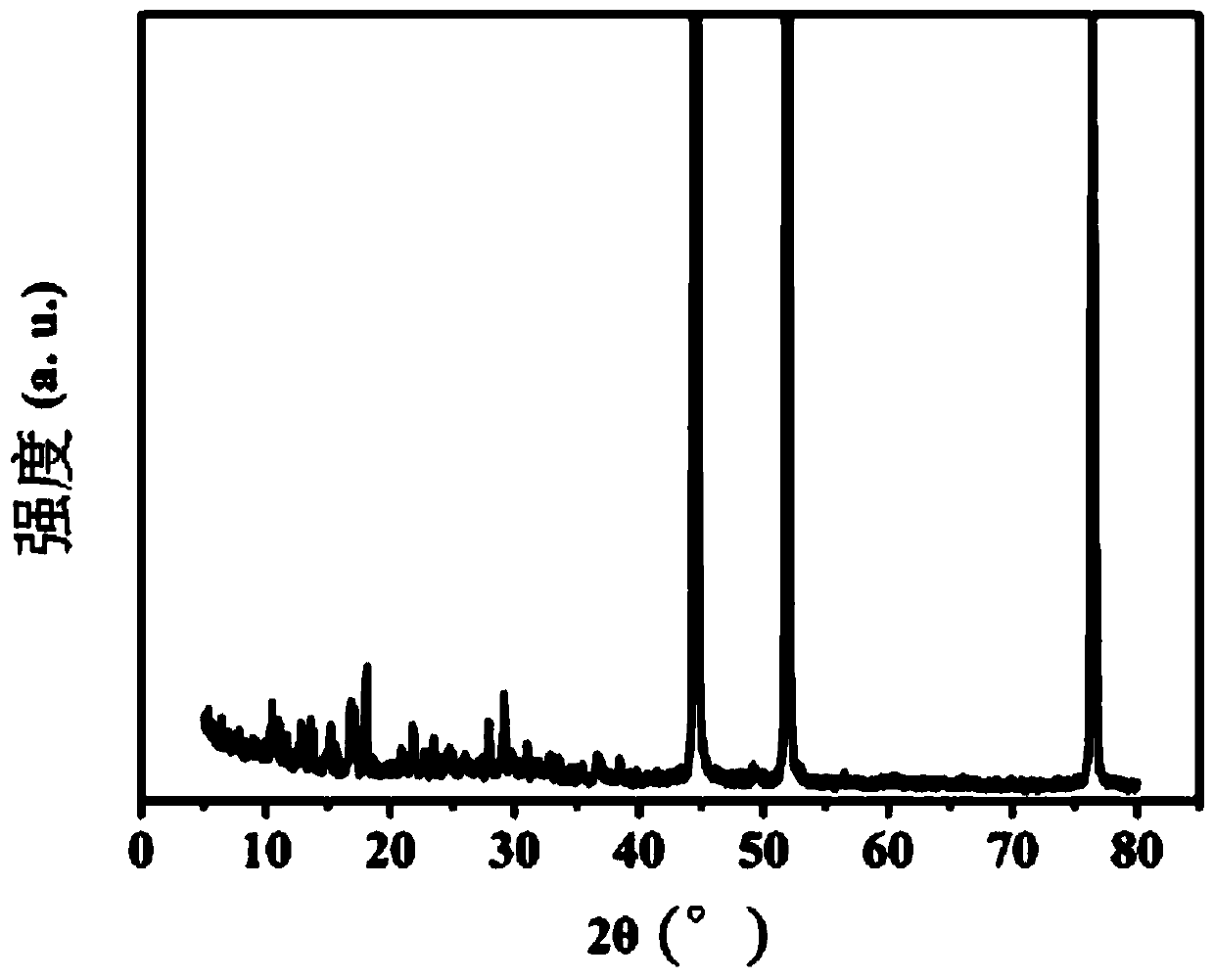

[0051] Embodiment 1: In this embodiment, a nickel-nitrogen co-doped porous carbon material loaded with cobalt nanoparticles is grown in situ on nickel foam, and the cobalt particles are embedded on the nitrogen-nickel co-doped porous carbon material. The content of cobalt is 5-30%, the content of nickel is 0.1%-5%, and the content of nitrogen is 3%-8%. The cobalt particles are ellipsoidal crystals with a size of 5nm-30nm.

specific Embodiment approach 2

[0052] Specific embodiment two: This embodiment is a method for preparing a nickel-nitrogen co-doped porous carbon material loaded with cobalt nanoparticles, which is completed according to the following steps:

[0053] 1. Pretreatment of nickel foam:

[0054] Sequentially use dilute hydrochloric acid, deionized water and absolute ethanol as cleaning agents to ultrasonically clean the foamed nickel, and then vacuum-dry to obtain pretreated foamed nickel;

[0055] 2. In situ growth of cobalt-based zeolite imidazolate framework material nanosheet array on nickel foam:

[0056] 1. Dissolving cobalt nitrate hexahydrate into deionized water to obtain an aqueous solution of cobalt nitrate hexahydrate;

[0057] The concentration of the cobalt nitrate hexahydrate aqueous solution described in step 1. is 0.05mol / L~0.15mol / L;

[0058] ②, dissolving dimethylimidazole in deionized water to obtain an aqueous solution of dimethylimidazole;

[0059] The concentration of the dimethylimidaz...

specific Embodiment approach 3

[0078] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass fraction of dilute hydrochloric acid described in step one is 1% to 20%, the power of ultrasonic cleaning is 100W to 180W, and the ultrasonic cleaning The drying time is 10min-30min; the vacuum drying temperature in step 1 is 50°C-90°C, and the vacuum drying time is 4h-10h. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com