Nanoscale cobalt particle Fischer-Tropsch synthetic catalyst and preparation method thereof

A Fischer-Tropsch synthesis and nano-cobalt technology, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. It is beneficial to large-scale industrial production, improve the catalytic effect, and is beneficial to cost control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

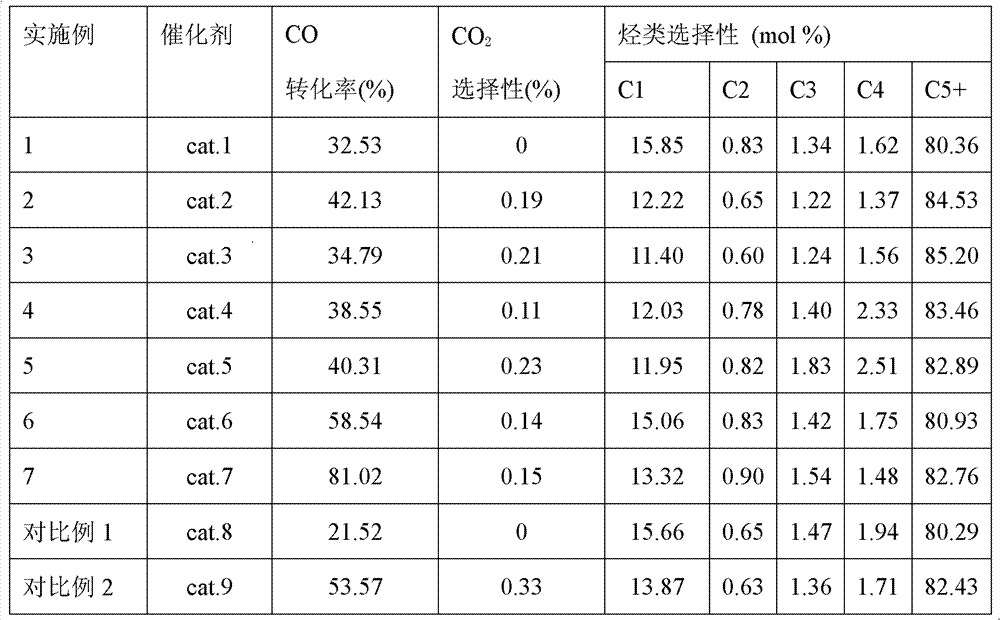

Examples

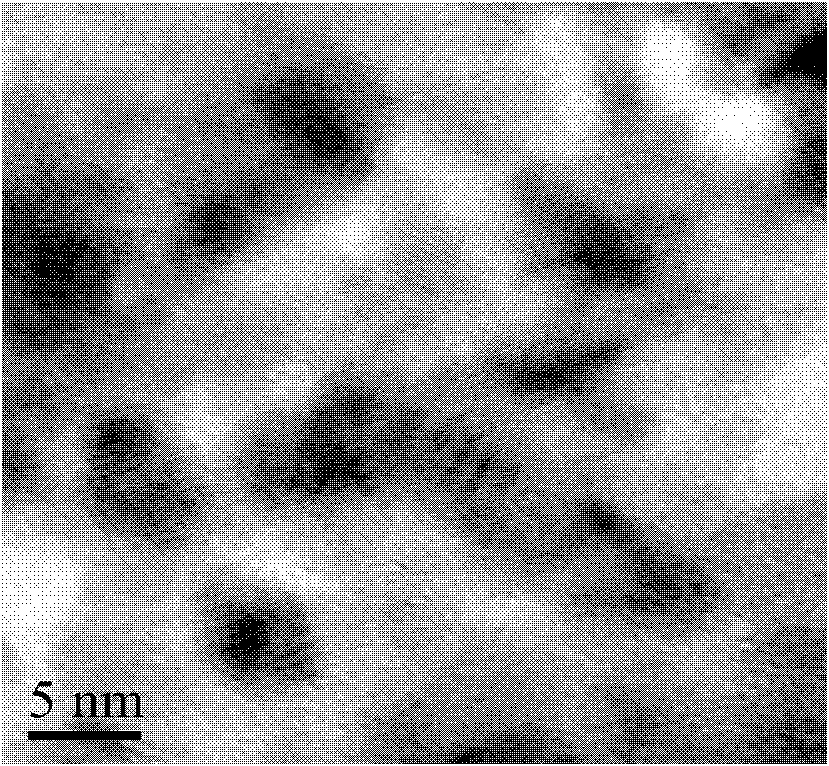

Embodiment 1

[0037] Disperse 0.6g of cobalt tetroxide nanoparticles with an average particle size of 5nm in 30ml of distilled water and put them in a round bottom flask, add 2.5g of γ-Al after ultrasonication for 10min 2 o 3 carrier, and then the carrier and particle mixture were stirred and ultrasonicated for 30 minutes to obtain a mixed slurry liquid. The mixed slurry liquid was vacuum-rotated on a rotary evaporator at 50 °C for 10 h, dried in an oven at 110 °C for 20 h, and then calcined in a muffle furnace at 350 °C for 8 h in an air atmosphere. A catalyst cat.1 containing 15 wt% of cobalt (calculated as cobalt element, the same below) was obtained, and the composition and size data of cobalt particles (cobalt tetroxide, the same below) in the catalyst cat.1 are listed in Table 1.

Embodiment 2

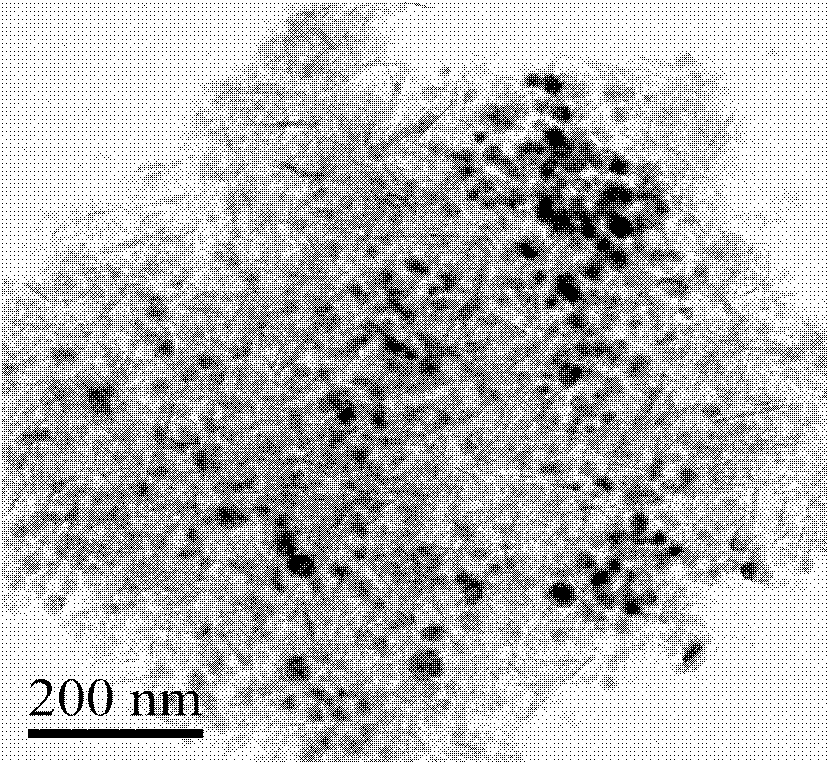

[0039] Disperse 0.6g of cobalt tetroxide nanoparticles with an average particle size of 7nm in 30ml of distilled water and put it in a round bottom flask, add 2.5g of γ-Al after ultrasonication for 10min 2 o 3 carrier, and then the carrier and particle mixture were stirred and ultrasonicated for 30 minutes to obtain a mixed slurry liquid. The mixed slurry liquid was dried by vacuum rotary evaporation on a rotary evaporator at 50°C for 10b, then dried in an oven at 110°C for 20h, and then calcined in a muffle furnace at 350°C for 8h in an air atmosphere. The catalyst cat.2 containing 15 wt% cobalt was obtained, and the composition and cobalt particle size data in the catalyst cat.2 are listed in Table 1.

Embodiment 3

[0041] Disperse 0.6g of cobalt tetroxide nanoparticles with an average particle size of 15nm in 30ml of distilled water and put it in a round bottom flask, add 2.5g of γ-Al after ultrasonication for 10min 2 o 3 carrier, and then the carrier and particle mixture were stirred and ultrasonicated for 30 minutes to obtain a mixed slurry liquid. The mixed slurry liquid was dried by vacuum rotary evaporation on a rotary evaporator at 50°C for 10b, then dried in an oven at 110°C for 20h, and then calcined in a muffle furnace at 350°C for 8h in an air atmosphere. The catalyst cat.3 containing 15 wt% cobalt was obtained, and the composition and cobalt particle size data in the catalyst cat.3 are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com