Control method and control device for moisture content of furfural in extraction of furfural and method for preparing aromatic rubber oil

A control method and technology of water content, which are applied in the fields of refined hydrocarbon oil, hydrocarbon oil refining control/regulation, and petroleum industry, etc., can solve the problems such as not raised, and achieve the improvement of selectivity, reduction of discharge, and reduction of water injection amount of extraction solvent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] A specific implementation of the control method is:

[0033] (1) choose a temperature between 5~90 DEG C, establish the correlation model of furfural water content-furfural refractive index under this temperature;

[0034] (2) Measure the flow rate of extracting furfural, draw a side line on the extraction furfural pipeline from the furfural drying tower, make the furfural temperature in the side line be the temperature of building a model by heat exchange, then measure the refractive index of furfural;

[0035] (3) calculate the water content of furfural with the model of step (1) gained and furfural refractive index;

[0036] (4) Calculate the water flow with the furfural flow obtained in step (2), the furfural water content obtained in step (3) and the furfural water content that needs to be achieved, and inject water into the extracted furfural with the calculated flow.

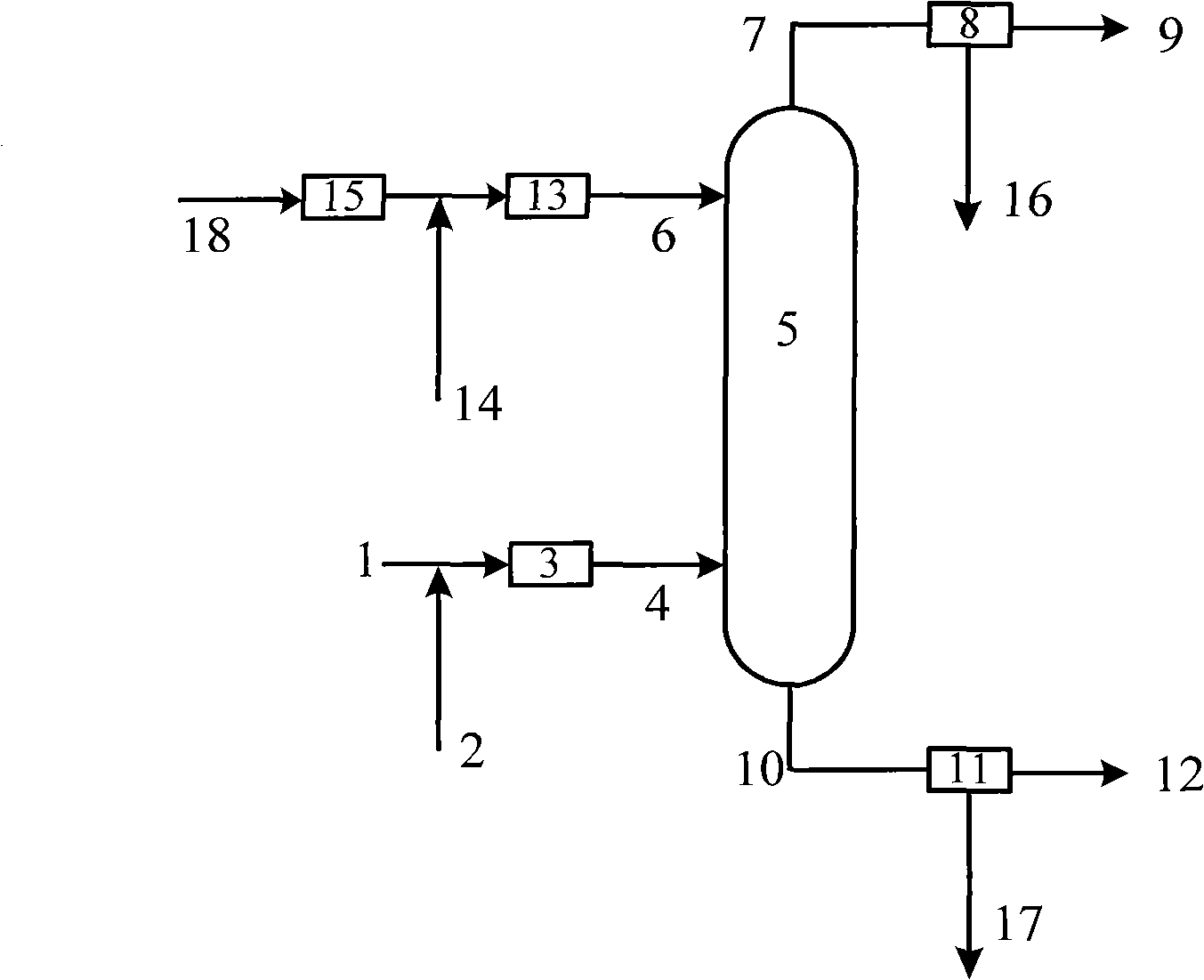

[0037] The present invention also provides a control device for realizing the above method, in...

Embodiment 1

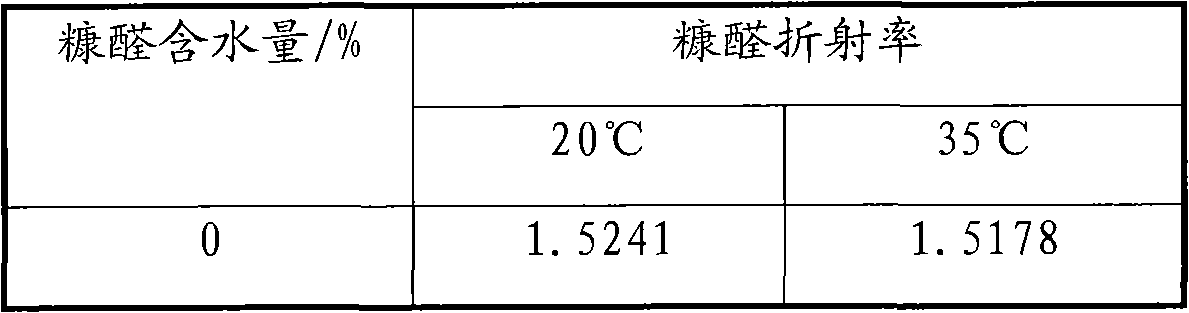

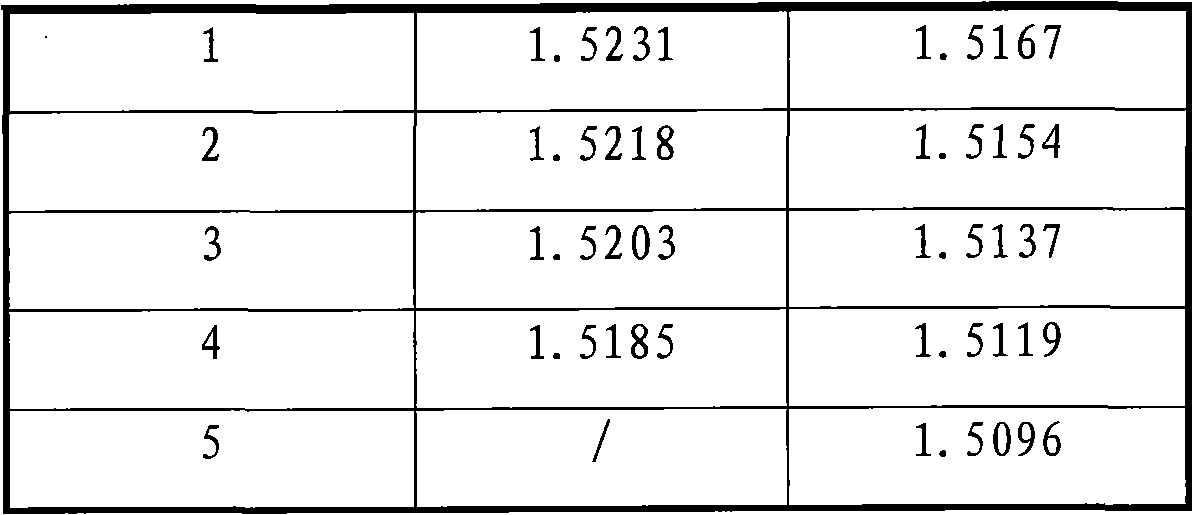

[0058] This embodiment illustrates how to set up the correlation model of furfural water content-furfural refractive index

[0059] Prepare furfural with different water contents and measure the refractive index at 20°C and 35°C, see Table 1 for specific data.

[0060] According to the obtained data, the quadratic function was fitted using origin 5.0.

[0061] The correlation models of furfural water content-furfural refractive index at 20°C and 35°C were obtained respectively.

[0062] temperature

Embodiment 2

[0064] The solvent-refined oil extracted from naphthenic crude oil minus the second-line distillate oil is used as raw material, and its properties are shown in Table 2. Extraction is carried out in a packed extraction tower (tower size Φ42mm×4000mm) with three theoretical extraction stages. The total feed flow of solvent and raw oil to the tower is 4200g / h.

[0065] Carry out solvent extraction according to accompanying drawing 1 flow process, prepare aromatic hydrocarbon rubber oil. The extraction conditions are: the temperature at the top of the extraction tower is 55°C, the temperature at the bottom of the tower is 45°C, the mass ratio of furfural and raw oil used for mixing is 0.3:1, after being mixed by the mixer 3, it enters the lower part of the extraction tower , and countercurrent contact with the furfural entering the upper part of the extraction tower, and the mass ratio of the furfural entering the upper part of the extraction tower to the raw oil is 3.0:1. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com