Supercritical carbon dioxide/polyethylene glycol stabilized palladium nano particle catalysis system

A technology of polyethylene glycol and carbon dioxide, applied in the direction of organic compound/hydride/coordination complex catalyst, oxidation to carbonyl compound, physical/chemical process catalyst, etc., can solve problems in the initial stage and achieve increased reaction Increased speed, reactivity, and avoidance of cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

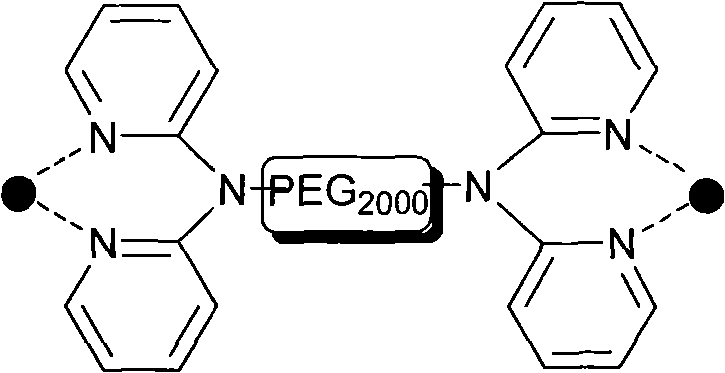

[0024] Embodiment 1: the preparation of the palladium catalyst that size is 2-5 nanometer

[0025] Acetic acid solution dissolved with 2,2′-dipyridylamine functionalized polyethylene glycol (21mg, 0.009mmol) was added to a two-necked flask, palladium acetate (4.1mg, 0.018mmol) was added, and stirred at room temperature for 4h for formulation bit. Then H was introduced at room temperature 2 , carry out reduction; after 20 minutes to obtain a brown-black solution, stop feeding hydrogen, add 8g PEG to remove acetic acid to obtain 2,2'-dipyridylamine functionalized polyethylene glycol-stabilized palladium catalyst of 2 to 5 nanometers.

Embodiment 2

[0026] Embodiment 2: The size is the preparation of the palladium catalyst of 5-10 nanometers

[0027] Acetic acid solution dissolved with 2,2′-dipyridylamine functionalized polyethylene glycol (21mg, 0.009mmol) was added to a two-necked flask, palladium acetate (4.1mg, 0.018mmol) was added, and stirred at room temperature for 4h for formulation bit. Then H was introduced at room temperature 2 , carry out reduction; 50 minutes later to obtain brown gray black solution, stop feeding hydrogen, add 8g PEG to remove acetic acid to obtain 2,2'-dipyridylamine functionalized polyethylene glycol stabilized palladium catalyst of 5 to 10 nanometers.

Embodiment 3

[0028] Example 3: In scCO 2 In the aerobic oxidation reaction of benzyl alcohol catalyzed by palladium nanoparticles in / PEG two-phase system, the example 1 adds substrate (2.4mmol) successively in the autoclave of 48ml, palladium catalyst (0.018mmol), then fills in the autoclave 19.8g of CO 2 and O 2 The mixed gas (the molar ratio of carbon dioxide and oxygen: 94:6) was heated to 80° C. with a heating mantle under electromagnetic stirring, and reacted for 6 hours. After the reaction, at a temperature of 70°C and a pressure of 17MPa, supercritical carbon dioxide was used to extract the substrate and product in situ at a certain rate, and a cold trap filled with isopropanol was used to absorb the tail gas at 0°C. According to GC analysis, the conversion rate of benzyl alcohol was 97%, and the selectivity of benzaldehyde was 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com