A zno/sio2-γ-al2o3 catalyzed hydrolysis of methyl bromide to prepare methanol and dimethyl ether

A technology of methyl bromide and catalyst is applied in the field of preparing ZnO/SiO2-γ-Al2O3 catalyst by sol-gel method, which can solve the problems of low conversion rate of methanol or dimethyl ether, poor selectivity and the like, and achieves low reaction temperature, high conversion rate, The effect of the synthesis process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] γ-Al 2 o 3 Preparation: Weigh 22.5034g of aluminum nitrate nonahydrate and dissolve it in 100ml of water to form a solution in a 250ml beaker. Take 25ml of concentrated ammonia water to dilute 3 times and slowly drop into the solution for making aluminum nitrate. Stir while dripping until the pH of the solution is 8-9, after the precipitation is completed, the slurry is stirred at room temperature for 1 h. Suction filtration was performed and washed until the pH was 7, and the filter cake was dried at 120° C. for 12 hours to obtain a γ-AlOOH precursor. Afterwards, it was calcined in a muffle furnace at 600°C for 4 hours to obtain γ-Al 2 o 3 , grind 180 mesh and sieve for later use.

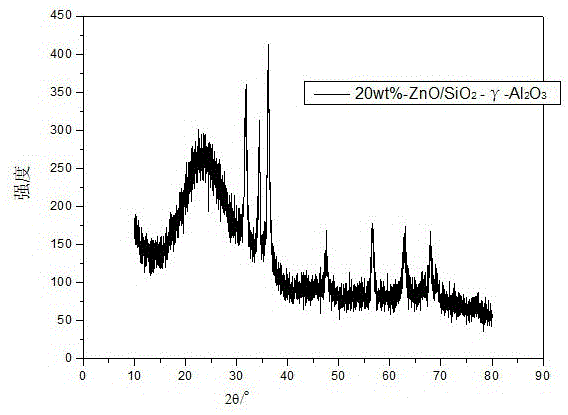

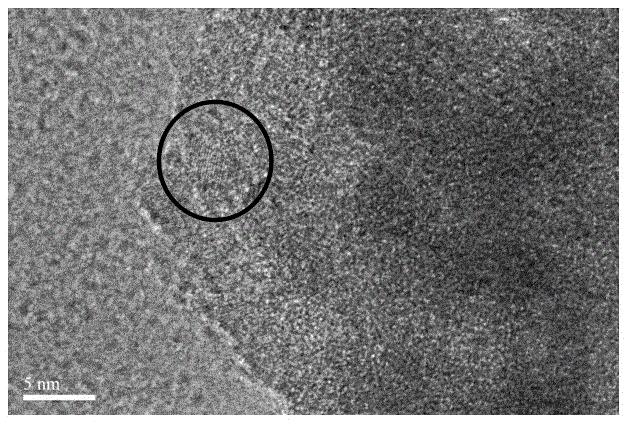

[0028] 20wt%-ZnO / SiO 2 -γ-Al 2 o 3 Catalyst preparation

[0029]Weigh 3.1680g of oxalic acid solid and dissolve it in 70ml of deionized water to fully dissolve, then add 52.7014g of tetraethyl orthosilicate and seal and stir to form solution A. Weigh 14.6205g of zinc nitrate hexahy...

Embodiment 2

[0034] 10wt%-ZnO / SiO 2 -γ-Al 2 o 3 Catalyst preparation

[0035] Weigh 3.5640g of oxalic acid solid and dissolve it in 70ml of deionized water to fully dissolve, then add 59.2891g of tetraethyl orthosilicate and seal and stir to form solution A. Weigh 7.3103g of zinc nitrate hexahydrate and dissolve it in 10ml of deionized water to obtain solution B. After stirring solution A for 2 hours, add solution B to solution A and add 0.9g of synthesized γ-Al 2 o 3 , continue to stir for 2 hours, then put it in an 80°C water bath and stir until it becomes a solid sol, take it out and pour it into a glass petri dish and place it in a 120°C oven for 6 hours, then take out the dried solid and place it in a muffle furnace at 2°C / min The heating rate is to heat up to 350°C, maintain the temperature for 5 hours and then lower the temperature. After the temperature drops to room temperature, take out the catalyst and sieve out 30-60 mesh for later use. Final 10%-ZnO / SiO 2 -γ-Al 2 o 3 ...

Embodiment 3

[0040] 20wt%-ZnO / SiO 2 -γ-Al 2 o 3 Catalyst preparation

[0041] Weigh 3.1680g of oxalic acid solid and dissolve it in 70ml of deionized water to fully dissolve, then add 52.7014g of tetraethyl orthosilicate and seal and stir to form solution A. Weigh 14.6205g of zinc nitrate hexahydrate and dissolve it in 20ml of deionized water to obtain solution B. After stirring solution A for 2 hours, add solution B to solution A and add 0.8g of synthesized γ-Al 2 o 3 , continue to stir for 2 hours, then put it in an 80°C water bath and stir until it becomes a solid sol, take it out and pour it into a glass petri dish and place it in a 120°C oven for 6 hours, then take out the dried solid and place it in a muffle furnace at 2°C / min The heating rate is to heat up to 350°C, maintain the temperature for 5 hours and then lower the temperature. After the temperature drops to room temperature, take out the catalyst and sieve out 30-60 mesh for later use. Finally get 20%-ZnO / SiO 2 -γ-Al ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com