Cobalt-based catalyst and preparation method and application thereof

A cobalt-based catalyst, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cost, difficulty in large-scale preparation, and high methane selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to the preparation method of a kind of cobalt-based catalyst provided by the present invention, comprises the steps:

[0027] (1) Provide nano-cobalt particles;

[0028] (2) mixing the nano-cobalt particles described in step (1) with a heat-resistant inorganic oxide precursor, a pore-forming agent, and a blasting agent in a solvent to form a slurry;

[0029] (3) The slurry obtained in step (2) is spray-dried and formed, and then roasted or not roasted;

[0030] Optionally, the operation of introducing auxiliary agents is also included in step (2) and / or after step (3);

[0031] Wherein, the nano-cobalt particles are cobalt oxide and / or cobalt hydroxide nanoparticles.

[0032] According to the present invention, the average size of the cobalt oxide and / or cobalt hydroxide nanoparticles is preferably 5-10 nm, and the nanoparticles can be prepared by any prior art, or can be commercial reagents. For example, it can be prepared by a hydrothermal or solvothermal...

Embodiment 1

[0060] (1) Preparation of Cobalt Oxide Nanoparticles

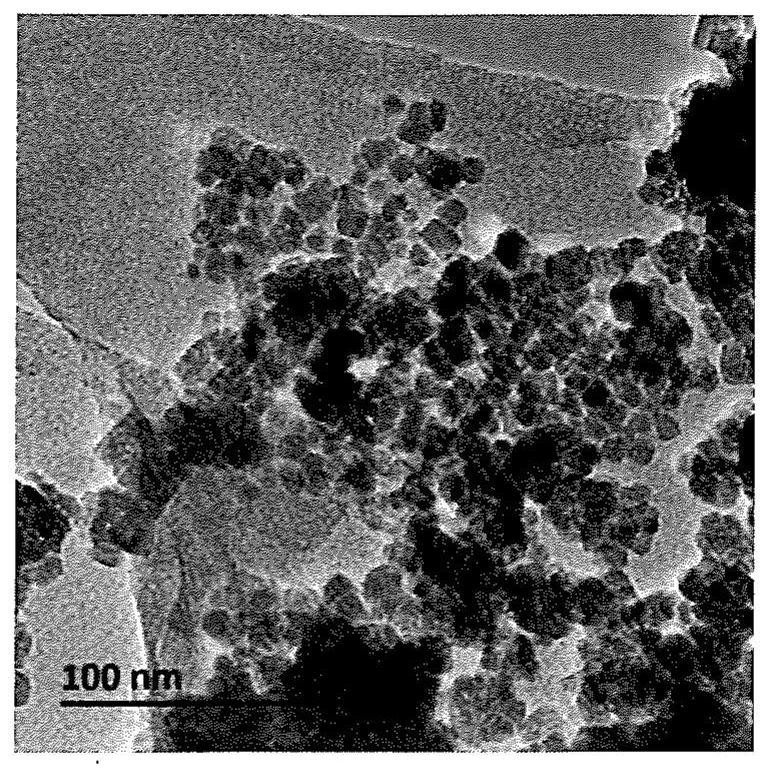

[0061] Dissolve 28.98kg of cobalt nitrate hexahydrate and 54.37kg of cetyltrimethylammonium bromide (CTAB) in 300 liters of 90% ethanol aqueous solution and stir for 30 minutes; The stainless steel reaction kettle was reacted at 160° C. for 8 hours. After the reaction, the solid nanoparticles were washed three times with 300 liters of 90% ethanol aqueous solution. The obtained nanoparticles were shown in the transmission electron microscope. figure 1 .

[0062] (2) Pulping: disperse 16.00kg pseudo-boehmite SB powder into 100L deionized water, add 0.24kg concentrated nitric acid, stir vigorously until peptized, then add the above-mentioned cobalt oxide nanoparticles, 10.0kg PEG4000 and 6.0kg Ammonium nitrate continued beating for 4h.

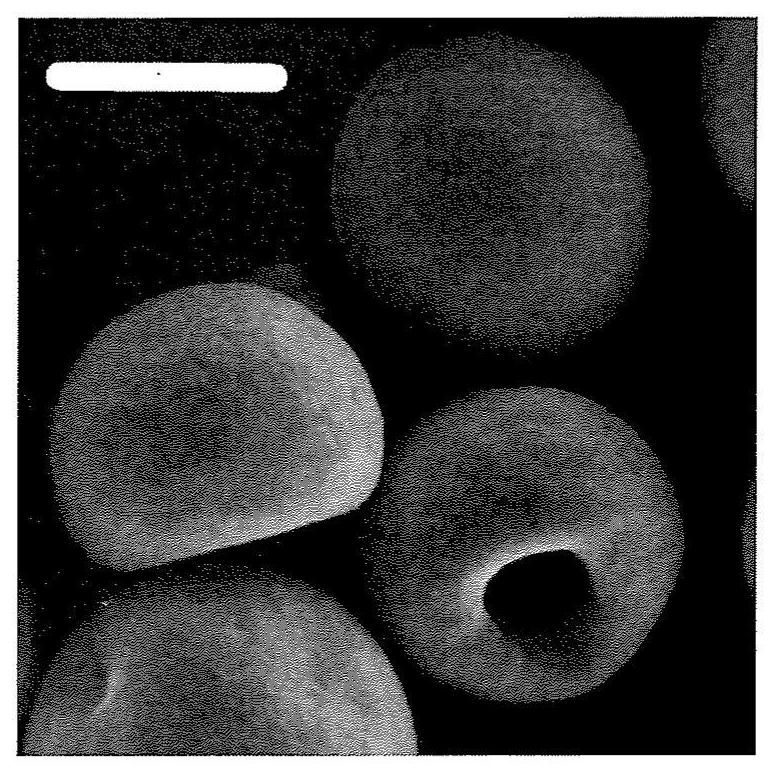

[0063] (3) spray drying molding

[0064] The above slurry was molded by a Niro Bowen Nozzle Tower spray drying device, the spray drying pressure was 6.5 to 8.0 MPa, the initial drying air ...

Embodiment 2

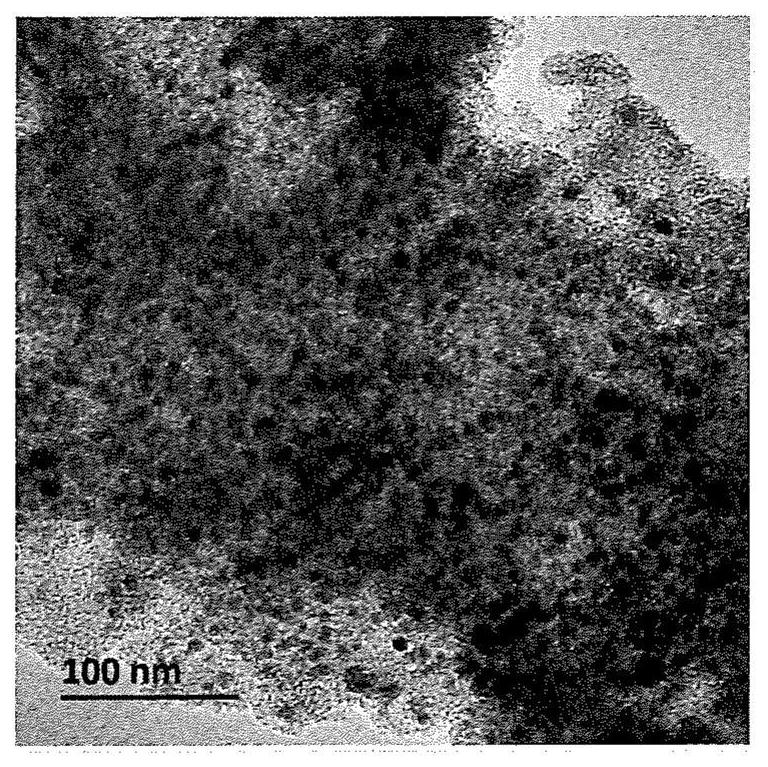

[0075] (1) Preparation of Cobalt Oxide Nanoparticles

[0076] Dissolve 21.74kg of cobalt nitrate hexahydrate and 30.11kg of tetradecyltrimethylammonium bromide (TTAB) in 300L of 90% ethanol aqueous solution and stir for 30min; by adding concentrated ammonia water until the pH of the solution is 9, transfer it to 500L of stainless steel The reaction kettle was reacted at 150° C. for 12 hours. After the reaction, the solid nanoparticles were washed three times with 300 L of 90% ethanol aqueous solution; the average particle size of the nano cobalt oxide was 6.2 nm.

[0077] (2) pulping

[0078] Disperse 18.67kg of pseudo-boehmite SB powder into 80L of deionized water, add 0.336kg of concentrated nitric acid, stir vigorously until peptized, then add the above-mentioned cobalt oxide nanoparticles, 6.0kg of PEG4000 and 3.0kg of ammonium nitrate and continue beating for 6h.

[0079] (3) spray drying molding

[0080] The above slurry is molded by a Niro Bowen Nozzle Tower spray dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com