Catalyst and process for directly preparing low-carbon olefin and co-production of alpha-olefin from synthetic gas

A low-carbon olefin and synthesis gas technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, and hydrocarbon production from carbon oxides, can solve the problem of not paying attention to high value-added α-olefins , complex, expensive preparation of catalysts, etc., to achieve the effect of improving flexibility and anti-risk ability, good selectivity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example provides a catalyst for direct synthesis of low-carbon olefins and co-production of α-olefins from syngas, the weight percentage of each component is: Fe 15%, MnO 10%, K 2 O 3%, Al 2 o 3 72%.

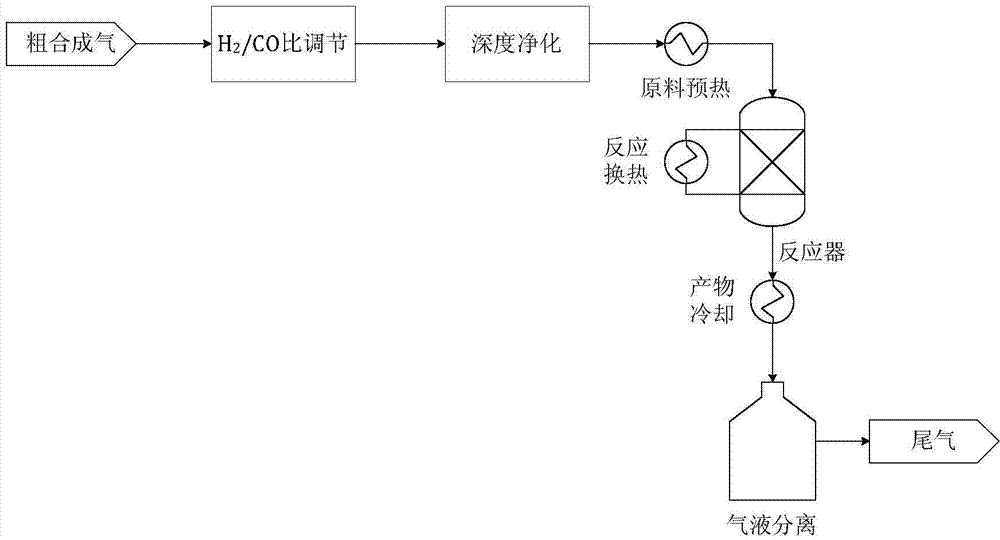

[0025] This embodiment also provides a process for direct synthesis of low-carbon olefins and co-production of α-olefins from syngas, the process of which is as follows figure 1 As shown, the process includes the following steps:

[0026] H 2 The / CO volume ratio is adjusted to 2:1, and then the sulfur content of the gas is lower than 0.1ppm through deep purification, and the effective synthesis gas is obtained as the raw material gas;

[0027] Before the reaction, pass through hydrogen to activate the catalyst for 4 hours at 450°C;

[0028] After activation, the raw material gas (which can be preheated to 450°C through a heat exchanger) is passed into the synthesizer to react with the catalyst. The reaction temperature is 320°C, the pressure is 1.0MPa, and the ...

Embodiment 2

[0031] This example provides a catalyst for direct synthesis of low-carbon olefins and co-production of α-olefins from syngas, the weight percentage of each component is: Fe 20%, MnO 10%, K 2 O 10%, Al 2 o 3 60%.

[0032] This embodiment also provides a process for direct synthesis of low-carbon olefins and co-production of α-olefins from syngas, the process of which is as follows figure 1 As shown, the process includes the following steps:

[0033] H 2 The / CO volume ratio is adjusted to 2:1, and then the sulfur content of the gas is lower than 0.1ppm through deep purification, and the effective synthesis gas is obtained as the raw material gas;

[0034] Before the reaction, pass through hydrogen to activate the catalyst for 4 hours at 450°C;

[0035] After activation, the raw material gas (which can be preheated to 450°C through a heat exchanger) is passed into the synthesizer to react with the catalyst. The reaction temperature is 320°C, the pressure is 4.0MPa, and the r...

Embodiment 3

[0038] This example provides a catalyst for direct synthesis of low-carbon olefins and co-production of α-olefins from syngas, the weight percentage of each component is: Fe 20%, MnO 20%, K 2 O 5%, Al 2 o 3 55%.

[0039] This embodiment also provides a process for direct synthesis of low-carbon olefins and co-production of α-olefins from syngas, the process of which is as follows figure 1 As shown, the process includes the following steps:

[0040] H 2 The / CO volume ratio is adjusted to 2:1, and then the sulfur content of the gas is lower than 0.1ppm through deep purification to obtain effective synthesis gas as the raw material gas, and then the raw material gas is preheated to 450°C through the heat exchanger and sent to the reactor;

[0041] Before the reaction, pass through hydrogen to activate the catalyst for 4 hours at 450°C;

[0042] After activation, feed the raw material gas (which can be preheated to 450°C through a heat exchanger) into the synthesizer to reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com