Method for preparing lubricating oil base oil with high viscosity index

A lubricating base oil, high viscosity technology, applied in the directions of lubricating compositions, chemical instruments and methods, base materials, etc., can solve the problems of difficult to accurately control the reaction, low catalyst activity, high product cost, and achieve less blocking of the reactor, The effect of high catalytic efficiency and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

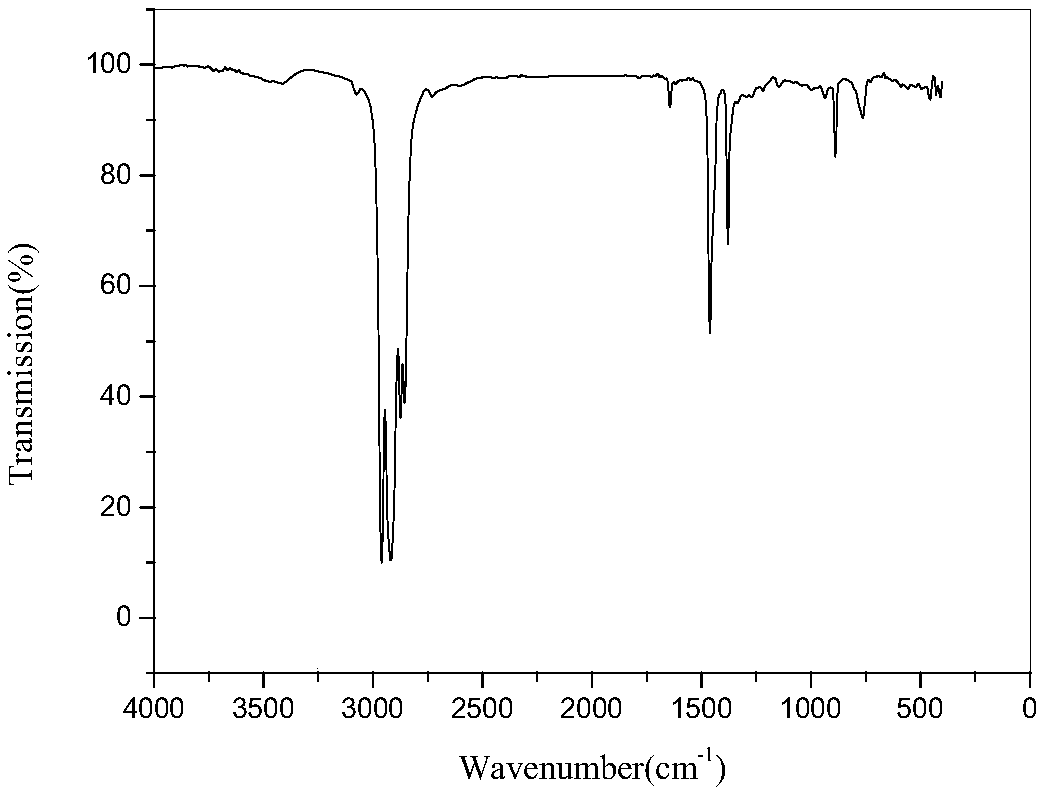

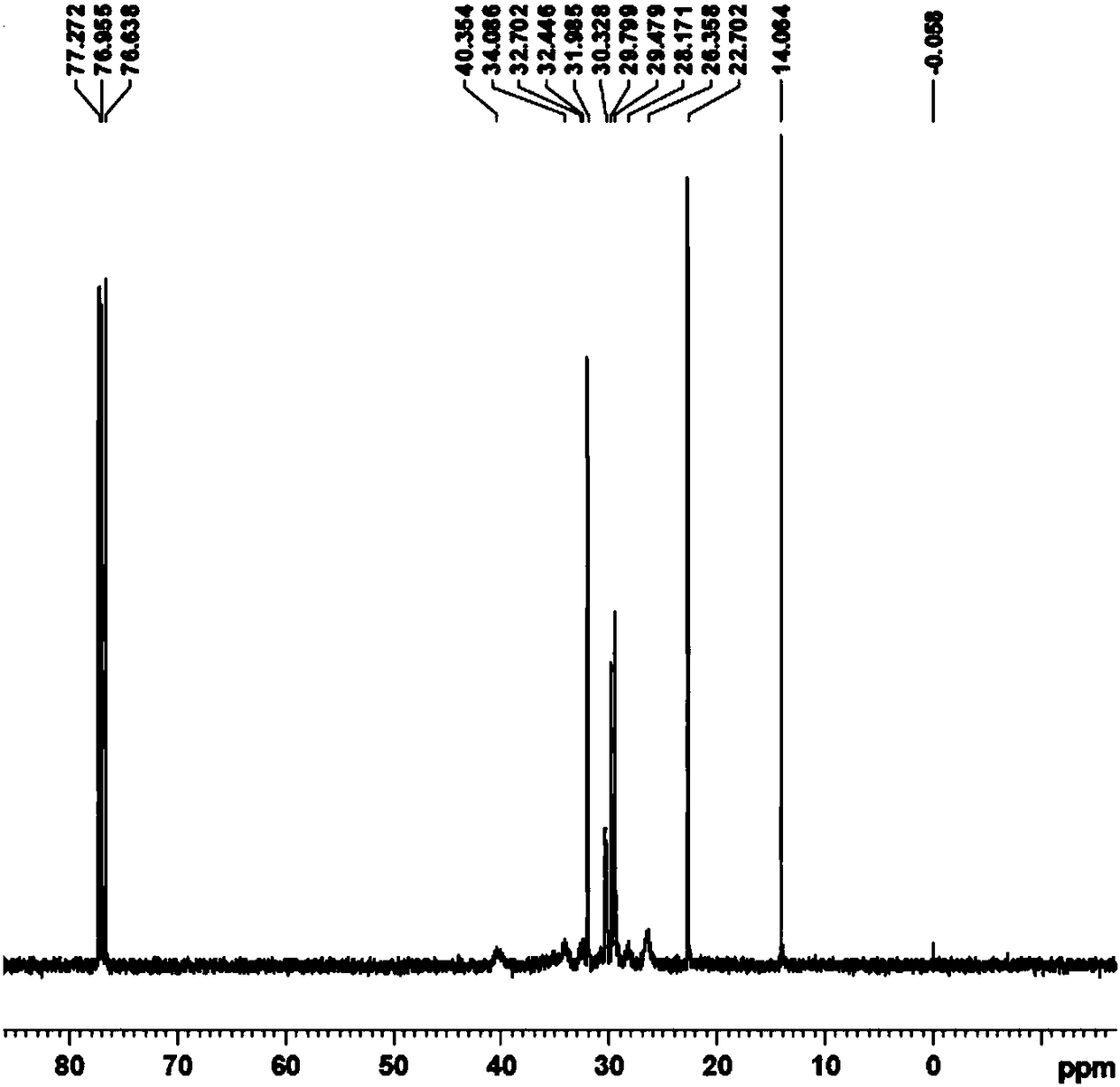

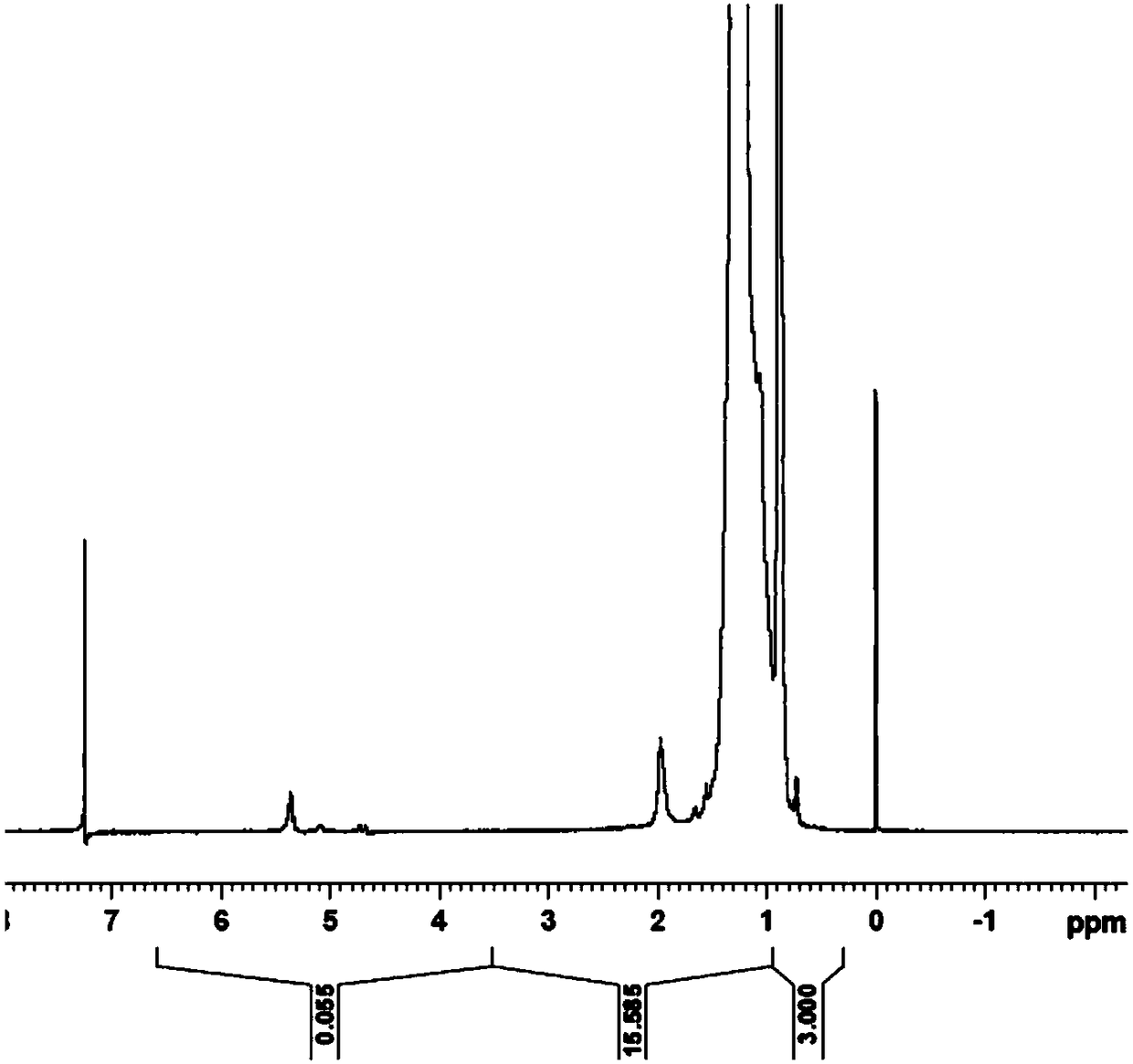

[0042] Specific embodiment one: the preparation method of polydecene-1 liquid of the present embodiment realizes according to the following steps:

[0043] Under the protection of nitrogen, add metallocene catalyst, co-catalyst solution, hydrogen and monomer 1-decene liquid to the tank reactor in sequence, carry out oligomerization reaction at a temperature of 0-90°C for 0.5-4h, and add Boron trifluoride-isopropanol complex (47% boron trifluoride, 53% diethyl ether) 1ml, continued reaction of unreacted 1-decene monomer, to obtain poly-1-decene liquid.

[0044] The structural formula of the metallocene catalyst described therein is as follows:

[0045]

[0046] (I) R in the structural formula 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , R 8 -H, -CH 3 、-C 2 h 5 、-C 3 h 7 、-C 4 h 9 、-C 5 h 11 、-C 6 h 13 or -C 8 h 17 .

[0047] The cocatalyst is a composite catalyst MAO-Q, wherein MAO is methylaluminoxane, and Q is triethylaluminum, triisobutylaluminum, tri-n-h...

specific Embodiment approach 2

[0051] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the metallocene catalyst is bis(1-butyl-3-methylcyclopentadienyl) zirconium dichloride, bis(1-butyl Base-2-methyl-cyclopentadienyl)zirconium dichloride, bis(1-isobutyl-3-methylcyclopentadienyl)zirconium dichloride, bis(1-octyl-3- Butylcyclopentadienyl) zirconium dichloride, bis(n-butylcyclopentadienyl) zirconium dichloride, bis(methylcyclopentadienyl) zirconium dichloride, bis(tert-butylcyclopentadienyl) dichloride Zirconium chloride, bis(isobutylcyclopentadienyl)zirconium dichloride or bis(n-octylcyclopentadienyl)zirconium dichloride. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0052] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the co-catalyst is a composite catalyst MAO-Q. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com