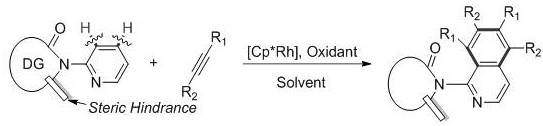

Method for synthesizing polysubstituted amino isoquinoline compound by cyclizing pyridine and alkyne under catalysis of rhodium

An aminoisoquinoline, rhodium-catalyzed pyridine technology, applied in organic chemistry and other directions, can solve the problems of high substrate, poor applicability of reactive substrate functional groups, etc., and achieves the effect of simple process, convenient industrial production, and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

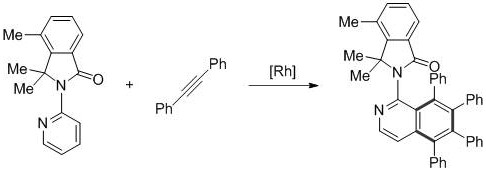

Embodiment 1

[0019] Example 1: Synthesis of 3,3-dimethyl-2-(5,6,7,8-tetraphenyl-1-isoquinolinyl)isoindole (R = phenyl):

[0020] In a 25 ml Young’s tube, add 3,3-dimethyl-2-pyridylisoindole-1-one (1 mmol), diphenylacetylene (2.4 mmol), Cp*Rh(CH 3 CN) 3 (SbF 6 ) 2 (5 mol%) and silver acetate (2.2 mmol). Finally, add 5 mL of 1,2-dichloroethane solvent to the reaction tube, and react at 100°C for 24 hours; after the reaction, the reaction solution is cooled to room temperature and reduced The organic solvent was removed by pressure to obtain the crude product, which was further separated by silica column chromatography and eluted with petroleum ether / ethyl acetate (volume ratio 10 / 1) to obtain pure product 3,3-dimethyl-2-(5, 6,7,8-Tetraphenyl-1-isoquinolinyl)isoindol-1-one, the yield was 93%. 1 H NMR (400 MHz, CDCl 3 ) δ8.29 (d, J = 5.7 Hz, 1H), 7.57 ((d, J = 7.5 Hz, 1H), 7.39 (td, J = 7.5, 1.1 Hz, 1H), 7.35-7.27 (m, 3H), 7.25-7.22 (m, 1H), 7.22-7.14 (m, 2H), 7.13-7.06 (m, 3H), 6.94 (d, J = 7...

Embodiment 2

[0021] Example 2: Synthesis of 3,3-dimethyl-2-(5,6,7,8-tetra(4-methylphenyl)-1-isoquinolinyl)isoindol-1-one ( R = 4-methylphenyl):

[0022] In a 25 ml Young’s tube, add 3,3-dimethyl-2-pyridylisoindol-1-one (1 mmol), 1,2-bis(4-methylbenzene)acetylene (2.4 mmol), Cp*Rh(CH 3 CN) 3 (SbF 6 ) 2 (5 mol%) and silver acetate (2.2 mmol). Finally, add 5 mL of 1,2-dichloroethane solvent to the reaction tube, and react at 100°C for 24 hours. After the reaction, the reaction solution is cooled to room temperature. The organic solvent was removed by pressure to obtain the crude product, which was further separated by silica column chromatography and eluted with petroleum ether / ethyl acetate (volume ratio 10 / 1) to obtain pure product 3,3-dimethyl-2-(5, 6,7,8-Tetra(4-methylphenyl)-1-isoquinolinyl)isoindol-1-one, the yield is 80%. 1 H NMR (400 MHz, CDCl 3 ) δ 8.25 (d, J = 5.7 Hz, 1H), 7.54 (d, J = 7.5 Hz, 1H), 7.38 (td, J = 7.5, 1.0 Hz, 1H), 7.30 (d, J = 5.6Hz, 1H), 7.26-7.23 (m, 1H), 7.20 (d...

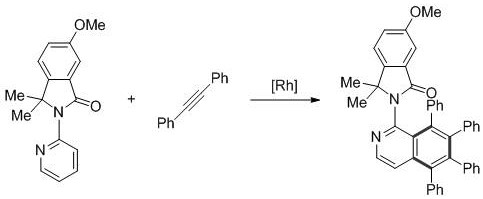

Embodiment 3

[0023] Example 3: Synthesis of 3,3-Dimethyl-2-(5,6,7,8-tetra(4-methoxyphenyl)-1-isoquinolinyl)isoindol-1-one (R = 4-methoxyphenyl):

[0024] In a 25 ml Young’s tube, add 3,3-dimethyl-2-pyridylisoindol-1-one (1 mmol), 1,2-bis(4-methoxybenzene)acetylene ( 2.4 mmol), Cp*Rh(CH 3 CN) 3 (SbF 6 ) 2 (5 mol%) and silver acetate (2.2 mmol). Finally, add 5 mL of 1,2-dichloroethane solvent to the reaction tube, and react at 100°C for 24 hours. After the reaction, the reaction solution is cooled to room temperature. The organic solvent was removed by pressure to obtain a crude product, which was further separated by silica column chromatography, and eluted with petroleum ether / ethyl acetate (volume ratio 5 / 1) to obtain pure product 3,3-dimethyl-2-(5, 6,7,8-Tetra(4-methoxyphenyl)-1-isoquinolinyl)isoindol-1-one, the yield is 76%. 1 H NMR (400 MHz, CDCl 3 ) δ8.26 (d, J = 5.6 Hz, 1H), 7.57 (d, J = 7.5 Hz, 1H), 7.41 (td, J = 7.5, 1.1 Hz, 1H), 7.33 (d, J = 5.6Hz, 1H), 7.28-7.22 (m, 2H), 7.16 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com