Preparation method of purple sweet potato pigment

A purple sweet potato pigment and pigment technology, which is applied in the field of natural plant pigment preparation, can solve the problems of large amount of organic solvent, easy structure degradation, low yield, etc., and achieve the effect of bright color, fine texture and high purity of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] ① Cleaning and cutting into strips: Soak the purple sweet potato, wash away the attached soil, pathogenic bacteria and residual pesticides with running tap water, dry until there are no visible water droplets on the surface, and cut into thin strips of about 1cm×1cm×3cm.

[0035] ②Crude extraction: add 2% glacial acetic acid to the water to prepare the extractant, the extraction temperature is 40°C, the ratio of solid to liquid is 1:4 (g / mL), and the extraction time is 1h. And collect the pigment crude extract.

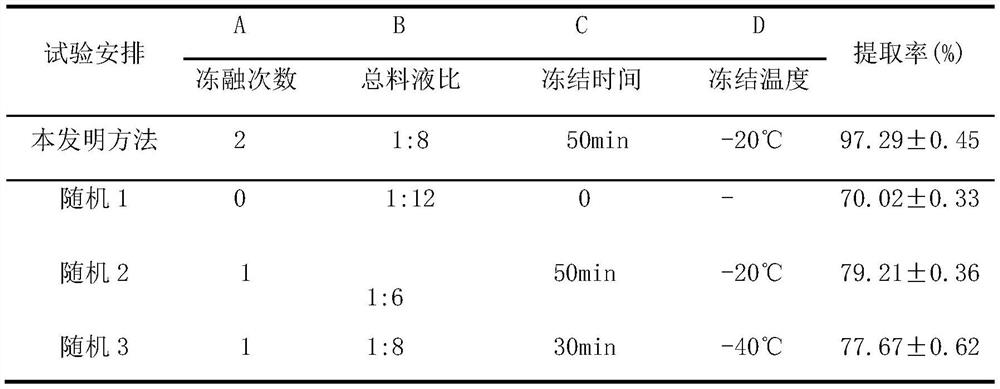

[0036] ③ Freezing and thawing: put the roughly extracted purple potato strips into a plastic bag and place them in a -20°C freezer for 1 hour, then take them out and thaw them at room temperature, and then add an extractant with a solid-to-liquid ratio of 1:2 (g / mL) ( The extractant prepared in step ②), repeated freeze-thaw extraction twice, combined step ② and the pigment crude extract obtained after the two freeze-thaws.

[0037] ④ Filtration and concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com