Method for preparing polyimide film with dinaphthalene structure and application

A technology of polyimide film and binaphthyl, which is applied in the field of chemical industry and O2 film enrichment, which can solve the problems of low efficiency, cumbersome process and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

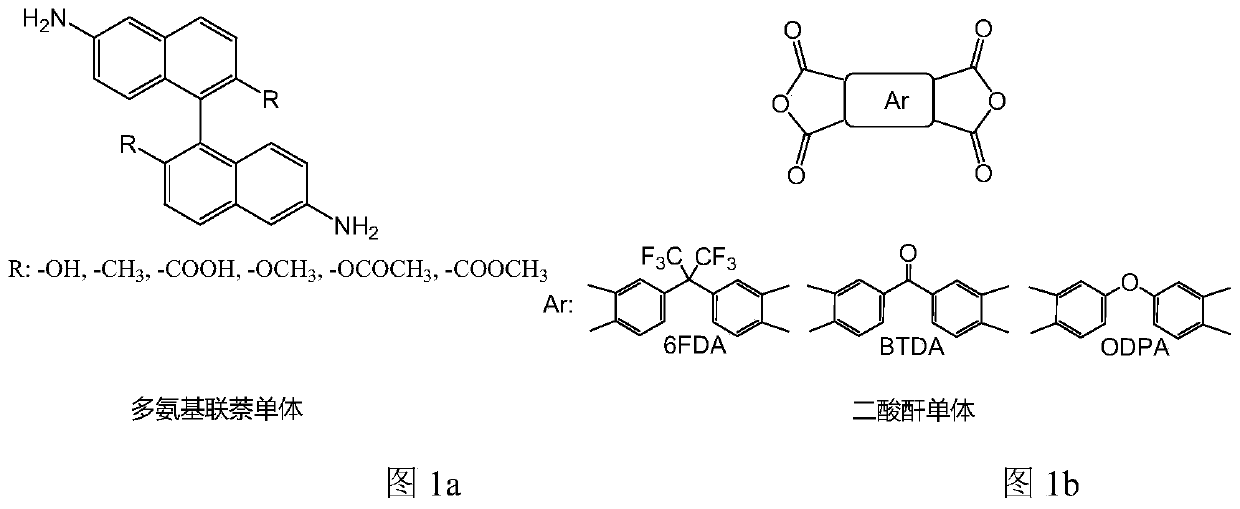

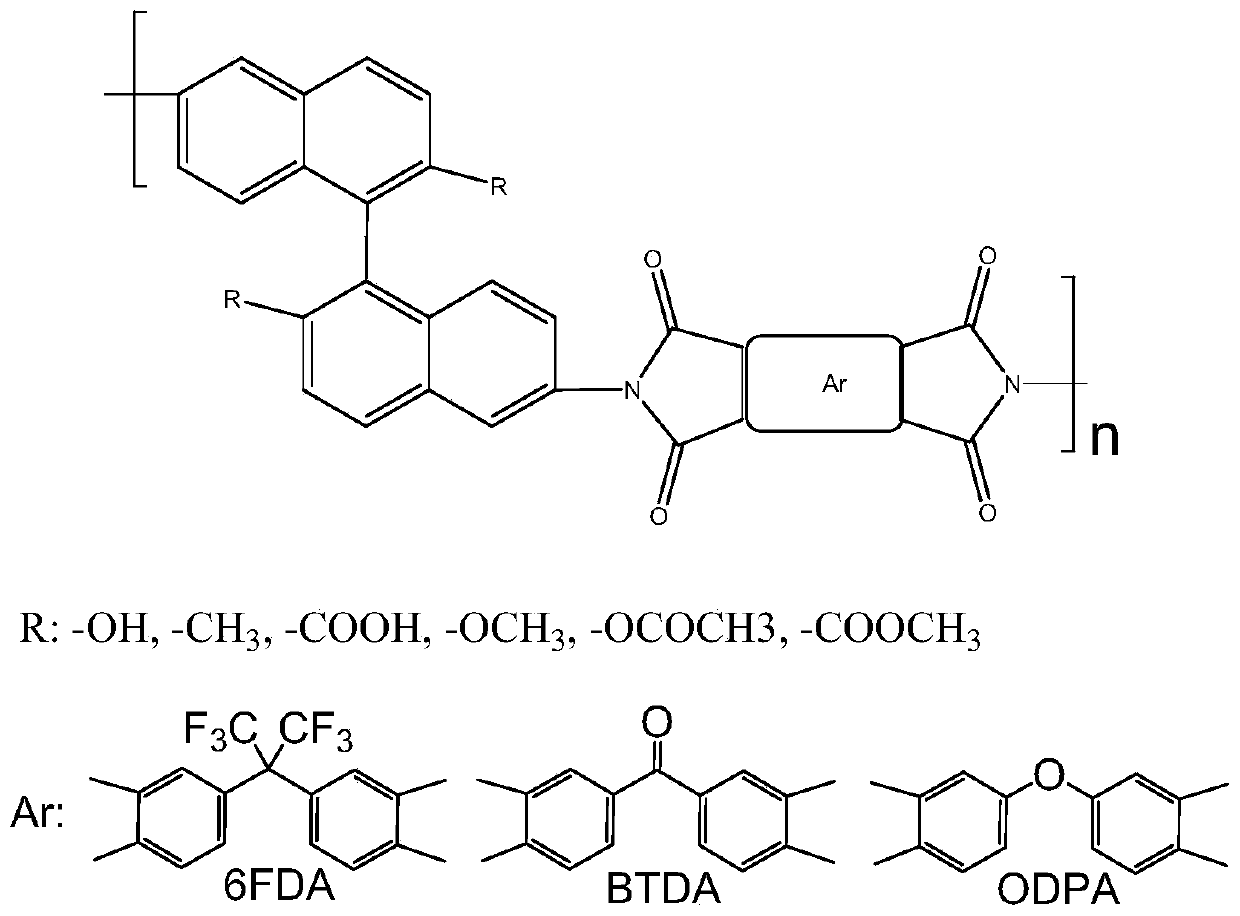

Method used

Image

Examples

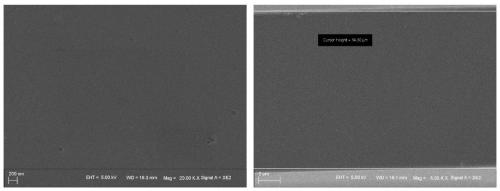

Embodiment 1

[0023] 0.62 mL of concentrated nitric acid was added dropwise into the acetic acid solution in which 1.0 g of 1,1'-bi-2-naphthol was dissolved, and stirring was continued at room temperature for 1 hour. The mixture was then poured into ice water and the solid was collected by filtration. Then the obtained solid and 10% Pd / C catalyst were added into N,N-dimethylformamide solvent, and reacted with magnetic stirring in 2 bar hydrogen atmosphere at room temperature for 24 hours. After filtering through diatomaceous earth, the filtrate was poured into deionized water for sedimentation to obtain biphenyldiamine monomer. Under an ice-water bath, put 1.26mmol of biphenyldiamine monomer, 1.28mmol of hexafluorodianhydride and 4.0mL of N,N-dimethylacetamide into a three-necked flask, and magnetically stir evenly. Continue stirring at 40° C. for 4 hours, and then add 3 mL of triethylamine and 3 mL of acid anhydride to react at room temperature for 24 hours. After the reaction, the solid...

Embodiment 2

[0025] 0.62 mL of concentrated nitric acid was added dropwise into the acetic acid solution in which 1.0 g of 1,1'-bi-2-naphthol was dissolved, and stirring was continued at room temperature for 1 hour. The mixture was then poured into ice water and the solid was collected by filtration. Then, the obtained solid and 10% Pd / C catalyst were added into N,N dimethylformamide solvent, and the reaction was carried out under magnetic stirring in 2 bar hydrogen atmosphere at room temperature for 24 hours. After filtering through diatomaceous earth, the filtrate was poured into deionized water for sedimentation to obtain biphenyldiamine monomer. Under an ice-water bath, put 1.26mnol of biphenyldiamine monomer, 1.28mmol of 3,3',4,4'-benzophenone tetra-acid dianhydride and 4.0mL of N,N-dimethylacetamide into a three-necked flask , magnetic stirring evenly. Continue stirring at 40° C. for 4 hours, and then add 3 mL of triethylamine and 3 mL of acid anhydride to react at room temperature...

Embodiment 3

[0027]0.62 mL of concentrated nitric acid was added dropwise into the acetic acid solution in which 1.0 g of 1,1'-bi-2-naphthol was dissolved, and stirring was continued at room temperature for 1 hour. The mixture was then poured into ice water and the solid was collected by filtration. Then, the obtained solid and 10% Pd / C catalyst were added into N,N dimethylformamide solvent, and the reaction was carried out under magnetic stirring in 2 bar hydrogen atmosphere at room temperature for 24 hours. After filtering through diatomaceous earth, the filtrate was poured into deionized water for sedimentation to obtain biphenyldiamine monomer. Under an ice-water bath, put 1.26mnol of biphenyldiamine monomer, 1.28mmol of 4,4'-biphenyl ether dianhydride and 4.0mL of dimethylacetamide into a three-necked flask, and magnetically stir evenly. Continue stirring at 40° C. for 4 hours, and then add 3 mL of triethylamine and 3 mL of acid anhydride to react at room temperature for 24 hours. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal properties | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com