Catalyst for preparation of linear alpha-olefins from synga as well as preparation and application of catalyst

An olefin catalyst and catalyst technology, applied in the field of iron-based catalyst preparation, achieves the effects of easy operation, simple preparation process and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

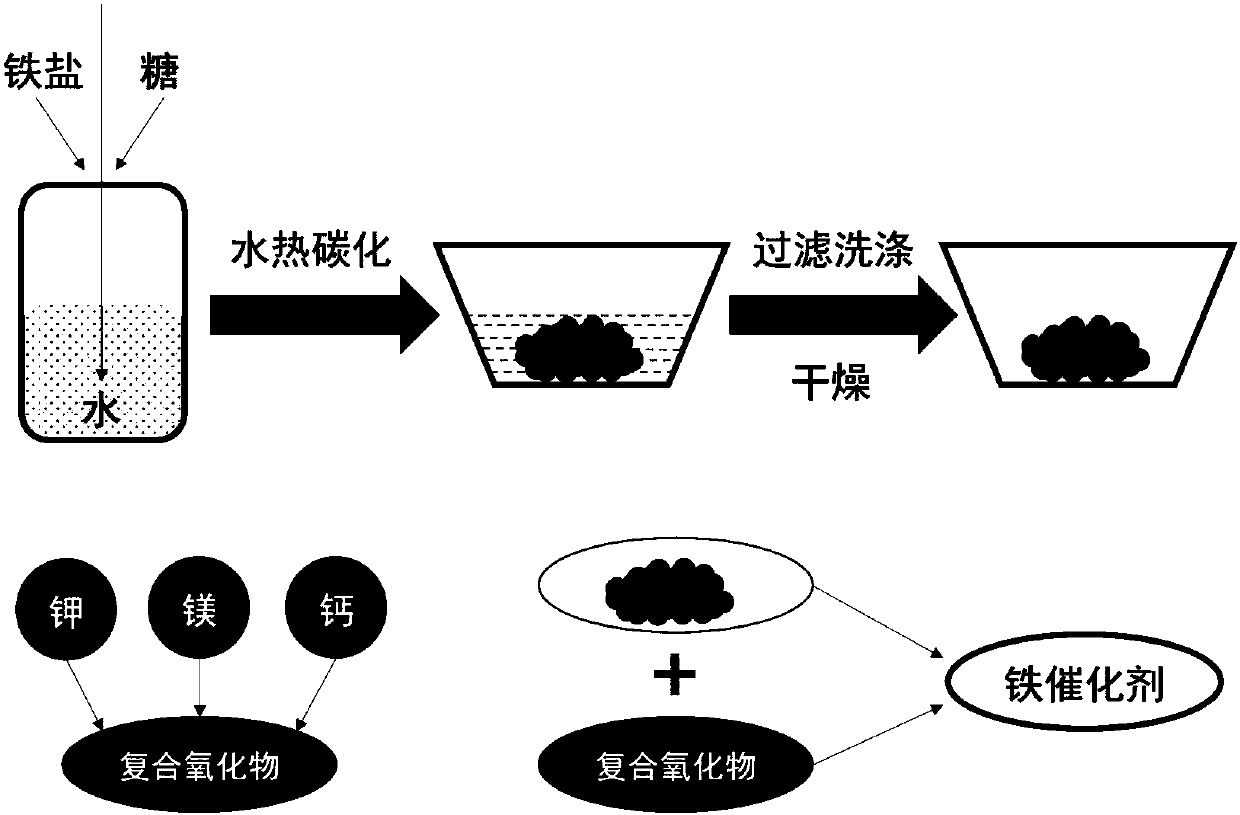

[0027] The iron catalyst preparation process is as follows:

[0028] Dissolve 2.5 g of glucose and 3.05 g of ferric nitrate nonahydrate in 30 mL of deionized water, and stir vigorously. The resulting mixed solution was transferred to a 50mL hydrothermal synthesis reactor with a polytetrafluoroethylene liner. The reaction kettle is sealed and transferred to a hydrothermal synthesis device (also called an incubator). The condition control of the hydrothermal synthesis process is 120° C. for 20 hours. The obtained product distribution was repeatedly washed several times with deionized water and absolute ethanol. Finally, the product was dried for more than 12 hours, and it was taken out, which was recorded as Fe / C. The composite powder is obtained by mechanically mixing potassium chloride, calcium carbonate and magnesium oxide according to the weight ratio of K:Ca:Mg=3:1:0.3 by means of grinding. 1.0 g of Fe / C and 0.15 g of composite powder were mechanically mixed again by me...

Embodiment 2

[0032] The iron catalyst preparation process is as follows:

[0033] Dissolve 2.5 g of glucose and 3.05 g of ferric nitrate nonahydrate in 30 mL of deionized water, and stir vigorously. The resulting mixed solution was transferred to a 50mL hydrothermal synthesis reactor with a polytetrafluoroethylene liner. The reaction kettle is sealed and transferred to a hydrothermal synthesis device (also called an incubator). The condition control of the hydrothermal synthesis process is 120° C. for 20 hours. The obtained product distribution was repeatedly washed several times with deionized water and absolute ethanol. Finally, the product was dried for more than 12 hours, and it was taken out, which was recorded as Fe / C. 1.0 g of Fe / C and 0.15 g of potassium carbonate powder were mechanically mixed again by grinding, and the prepared catalyst was recorded as Fe / C-K.

[0034]K exists in the Fe / C-K catalyst as a separate electron aid. The ratio of each component is 14% (Fe), 3.7% (K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com